The intricate design of lifting devices plays a crucial role in various applications, from automotive repair to construction. A comprehensive grasp of these mechanisms enhances efficiency and safety in their operation. By breaking down each element, users can gain insights into functionality and maintenance.

When examining the individual elements, one can appreciate how each piece contributes to the overall performance of the equipment. Recognizing the interplay between these components not only aids in troubleshooting but also ensures optimal use. This exploration invites enthusiasts and professionals alike to delve deeper into the assembly.

Understanding these structures is essential for anyone involved in their use or repair. Whether you’re a seasoned expert or a novice, familiarizing yourself with the intricacies can lead to improved outcomes and longevity of your tools. Let’s embark on this journey to uncover the ultimate knowledge about these vital systems.

Understanding Fulton F2 Jack Components

In the world of mechanical devices, various elements come together to create a reliable and functional unit. Each component plays a crucial role in ensuring optimal performance and safety during operation. This section delves into the intricate pieces that form a complete assembly, highlighting their functions and interrelationships.

Key elements of this system include:

- Support Structure: Provides the necessary stability and strength.

- Adjustable Mechanism: Allows for precise height adjustments, accommodating different needs.

- Release Handle: Facilitates easy operation and secure locking.

- Connector Points: Ensure compatibility with various accessories and equipment.

- Safety Features: Designed to prevent accidents and enhance user protection.

Each of these components is engineered to work in harmony, contributing to the overall efficacy of the system. Understanding their individual roles aids users in proper maintenance and troubleshooting.

To further appreciate the functionality, consider the following:

- Regular inspection of the support structure for signs of wear.

- Ensuring the adjustable mechanism operates smoothly without obstruction.

- Verifying the effectiveness of safety features during routine checks.

By familiarizing oneself with these crucial elements, users can enhance their experience and ensure longevity and reliability in operation.

Importance of F2 Jack in Applications

The significance of this lifting mechanism in various fields cannot be overstated. It plays a crucial role in enhancing efficiency and safety, making it indispensable in numerous operations. Understanding its functionality helps in recognizing its value across different industries.

Efficiency in Heavy Lifting

This device is engineered to facilitate the lifting of substantial loads with minimal effort. Its design allows for smooth operation, enabling workers to complete tasks more swiftly and effectively. In construction, automotive repair, and logistics, the ability to manage heavy items effortlessly contributes to overall productivity.

Safety Considerations

In addition to efficiency, the reliability of this apparatus ensures the safety of personnel involved in lifting tasks. By employing robust materials and innovative engineering, it minimizes the risks associated with heavy lifting. Regular maintenance and proper usage further enhance its reliability, safeguarding both operators and the loads being handled.

Common Issues with Fulton F2 Jacks

Various challenges can arise with the operation of specific lifting mechanisms, impacting their efficiency and safety. Identifying and addressing these problems promptly is crucial for maintaining functionality and ensuring user safety.

Mechanical Failures

One of the most prevalent issues is mechanical breakdowns. Components may wear out over time, leading to decreased performance or complete failure. Regular inspections can help detect signs of wear, such as unusual noises or reduced lifting capability, allowing for timely maintenance or replacements.

Hydraulic Leaks

Another common concern involves hydraulic fluid leaks. These leaks can severely impact the lifting power and create unsafe conditions. Users should regularly check for signs of fluid loss, such as puddles or drops, and address any leaks immediately to ensure optimal operation and safety.

Essential Tools for Repairing F2 Jack

To effectively restore and maintain specific mechanical components, having the right set of tools is crucial. This ensures that the process is efficient, precise, and yields long-lasting results. Below is a compilation of indispensable instruments that can significantly aid in the repair process.

| Tool | Purpose |

|---|---|

| Precision Screwdriver Set | Used for loosening and tightening small screws in confined spaces. |

| Multimeter | Essential for testing electrical continuity and diagnosing issues. |

| Wire Strippers | Necessary for preparing electrical connections by removing insulation from wires. |

| Soldering Iron | Used to make strong electrical connections between components. |

| Heat Shrink Tubing | Provides insulation and protection for soldered connections. |

| Pliers | Handy for gripping, bending, and cutting wires or small components. |

Equipping yourself with these essential tools not only streamlines the repair process but also enhances the overall quality of your work, ensuring optimal functionality of the device in question.

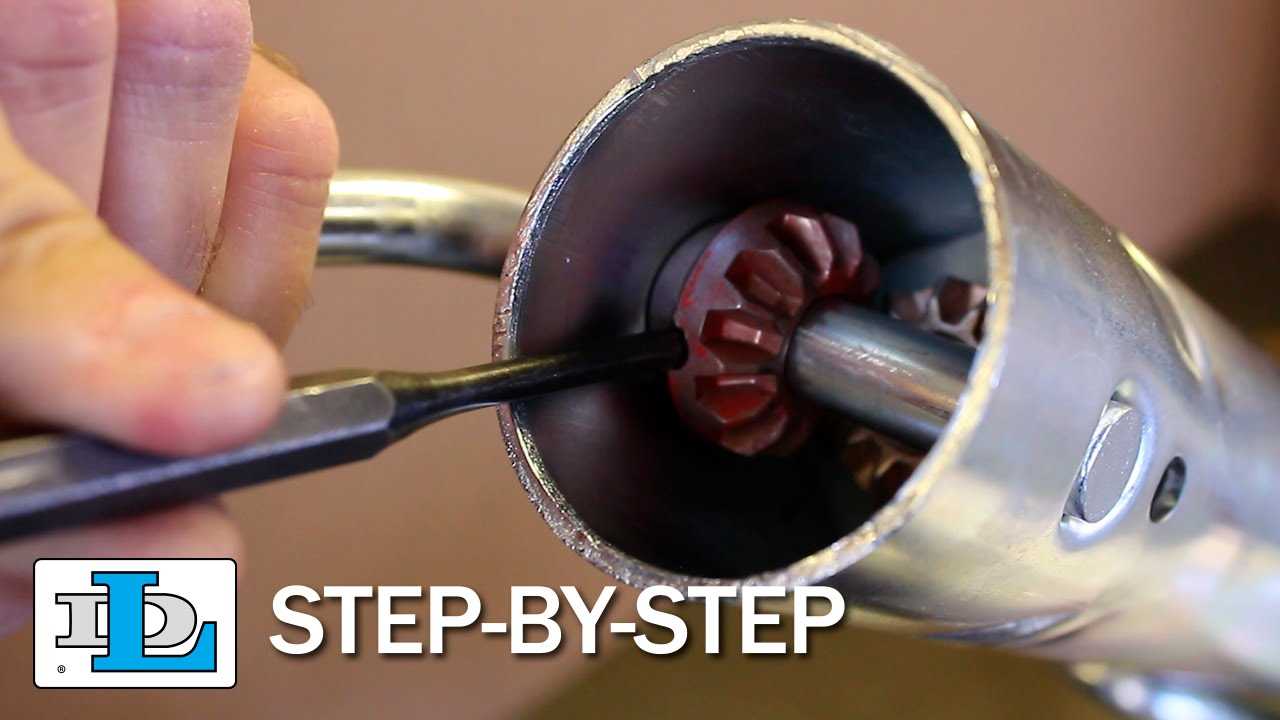

Step-by-Step Assembly Guide for F2 Jack

This guide provides a comprehensive approach to assembling the essential lifting device, ensuring a smooth and effective process. By following these steps, you will achieve a robust assembly, ready for reliable use.

Required Tools and Materials

- Socket wrench set

- Screwdriver

- Lubricating oil

- Safety gloves

Assembly Steps

- Gather all components in a clean, organized workspace.

- Begin by connecting the base with the main support column using the provided screws.

- Attach the lifting mechanism to the upper section of the support.

- Ensure all connections are tightened securely to avoid any instability.

- Apply lubricating oil to moving parts for optimal performance.

- Perform a final inspection to verify that all components are assembled correctly.

How to Identify F2 Jack Parts

Understanding the components of a lifting device is essential for maintenance and effective usage. Recognizing the individual elements allows for better troubleshooting and replacement when necessary. This section will guide you through identifying these crucial elements.

| Component | Description |

|---|---|

| Base | The sturdy foundation that supports the entire mechanism. |

| Piston | The cylinder that moves to elevate the load. |

| Release Valve | Controls the flow of hydraulic fluid to lower the load. |

| Handle | Used to operate the lifting mechanism. |

| Wheel Assembly | Allows for mobility and positioning of the device. |

Maintenance Tips for Optimal Performance

Ensuring the longevity and efficiency of your equipment requires regular upkeep and attention to detail. A consistent maintenance routine not only enhances functionality but also prevents potential failures that could disrupt operations. By implementing a few key practices, users can maximize the reliability and performance of their machinery.

Regularly inspect all components for signs of wear and tear. Lubrication of moving parts is essential to reduce friction and prevent overheating. Additionally, keeping the equipment clean and free of debris helps avoid unnecessary strain. Always refer to the manufacturer’s guidelines for specific maintenance schedules and procedures to ensure compliance and optimal operation.

Consider implementing a tracking system for maintenance activities. Documenting inspections, repairs, and replacements allows for better planning and helps identify patterns that could indicate underlying issues. This proactive approach can save time and costs in the long run.

Lastly, training personnel on proper usage and maintenance techniques is crucial. Educated operators are more likely to notice irregularities and perform routine checks, leading to enhanced safety and performance. Ultimately, a well-maintained system not only operates smoothly but also contributes to the overall productivity of your operations.

Comparing Fulton F2 with Other Jacks

This section explores the distinctions and similarities among various lifting mechanisms, focusing on performance, durability, and user convenience. Understanding these differences can help consumers make informed decisions when selecting the right tool for their needs.

| Feature | F2 Model | Competitor A | Competitor B |

|---|---|---|---|

| Weight Capacity | 2,000 lbs | 1,800 lbs | 2,500 lbs |

| Material | Steel | Aluminum | Composite |

| Height Adjustment | Quick Release | Manual | Electric |

| Warranty | 3 Years | 2 Years | 5 Years |

Ultimately, evaluating these features reveals how different models cater to diverse preferences and usage scenarios, ensuring users find the most suitable option for their specific requirements.

Upgrades Available for Fulton F2 Jack

Enhancing the functionality and efficiency of your lifting equipment can significantly improve performance and ease of use. Various modifications and accessories can elevate the standard features, ensuring that your setup meets specific demands and preferences.

Here are some popular upgrades to consider:

- Heavy-Duty Wheels: Upgrade to robust wheels for improved mobility and stability on uneven surfaces.

- Extended Handle: A longer handle can provide better leverage, making lifting easier and reducing effort.

- Custom Mounting Brackets: Tailor-made brackets can enhance compatibility with different trailers and equipment.

- Locking Mechanisms: Install advanced locking systems for increased safety and security during use.

- Weather-Resistant Coating: Apply protective finishes to guard against rust and corrosion, extending the lifespan of your equipment.

Each upgrade offers distinct advantages that can adapt your setup to specific tasks, ensuring optimal performance and longevity. Consider your needs carefully to select the best enhancements for your equipment.

Safety Precautions When Using Jacks

When utilizing lifting equipment, ensuring safety is paramount to prevent accidents and injuries. Proper handling and awareness of potential hazards can significantly enhance the safety of the operation. It is essential to adhere to guidelines and use the equipment as intended to maintain a secure working environment.

Inspect Equipment Before Use

Always conduct a thorough inspection of the lifting apparatus before each use. Check for any visible damage, wear, or malfunction. Pay attention to the hydraulic system, connections, and support components. If any issues are detected, refrain from using the equipment until it is repaired or replaced.

Stabilization and Support

Ensure the load is placed on a level surface and that the equipment is properly stabilized. Utilize supports or chocks to prevent any movement during operation. Never exceed the recommended weight limit, as overloading can lead to failure and potential harm. Always use personal protective equipment such as gloves and safety shoes to enhance your protection while handling loads.

Where to Buy F2 Jack Parts

Finding components for your lifting equipment can be straightforward with the right resources. Various retailers and online platforms offer a range of items that cater to specific needs, ensuring functionality and durability.

Recommended Retailers

Several well-known suppliers specialize in lifting equipment components. Here are some options:

| Supplier | Location | Website |

|---|---|---|

| Tool Supply Co. | USA | toolsupply.com |

| Lift Tech Solutions | Europe | lifttech.com |

| Parts Online Store | Global | partsonline.com |

Online Marketplaces

In addition to specialized retailers, several online marketplaces offer a variety of components. These platforms often provide competitive pricing and user reviews to aid in decision-making.

Real-World Applications of F2 Jacks

The versatile components in mechanical systems play a crucial role across various industries. Their ability to elevate and support heavy loads makes them indispensable in numerous applications.

- Automotive Repair: Essential for lifting vehicles during maintenance, enabling easy access to undercarriages.

- Construction: Utilized in scaffolding and equipment support, ensuring stability on job sites.

- Manufacturing: Integral in assembly lines for positioning heavy machinery, enhancing efficiency.

- Home Improvement: Helpful in DIY projects, allowing homeowners to safely lift and move appliances.

Overall, these components provide the ultimate support in various scenarios, showcasing their importance in everyday tasks and professional environments.