The assembly of a utility vehicle is a complex network of various elements working in harmony to ensure optimal performance. Grasping the intricacies of these components can greatly enhance maintenance and repair tasks. By delving into the essential aspects, one can achieve a more profound understanding of the vehicle’s functionality.

Each section of the vehicle plays a vital role, contributing to overall efficiency and reliability. Recognizing how these components interconnect will assist users in troubleshooting issues and making informed decisions regarding upgrades or replacements. With a clear perspective on the individual elements, the process of ensuring the vehicle’s longevity becomes significantly more manageable.

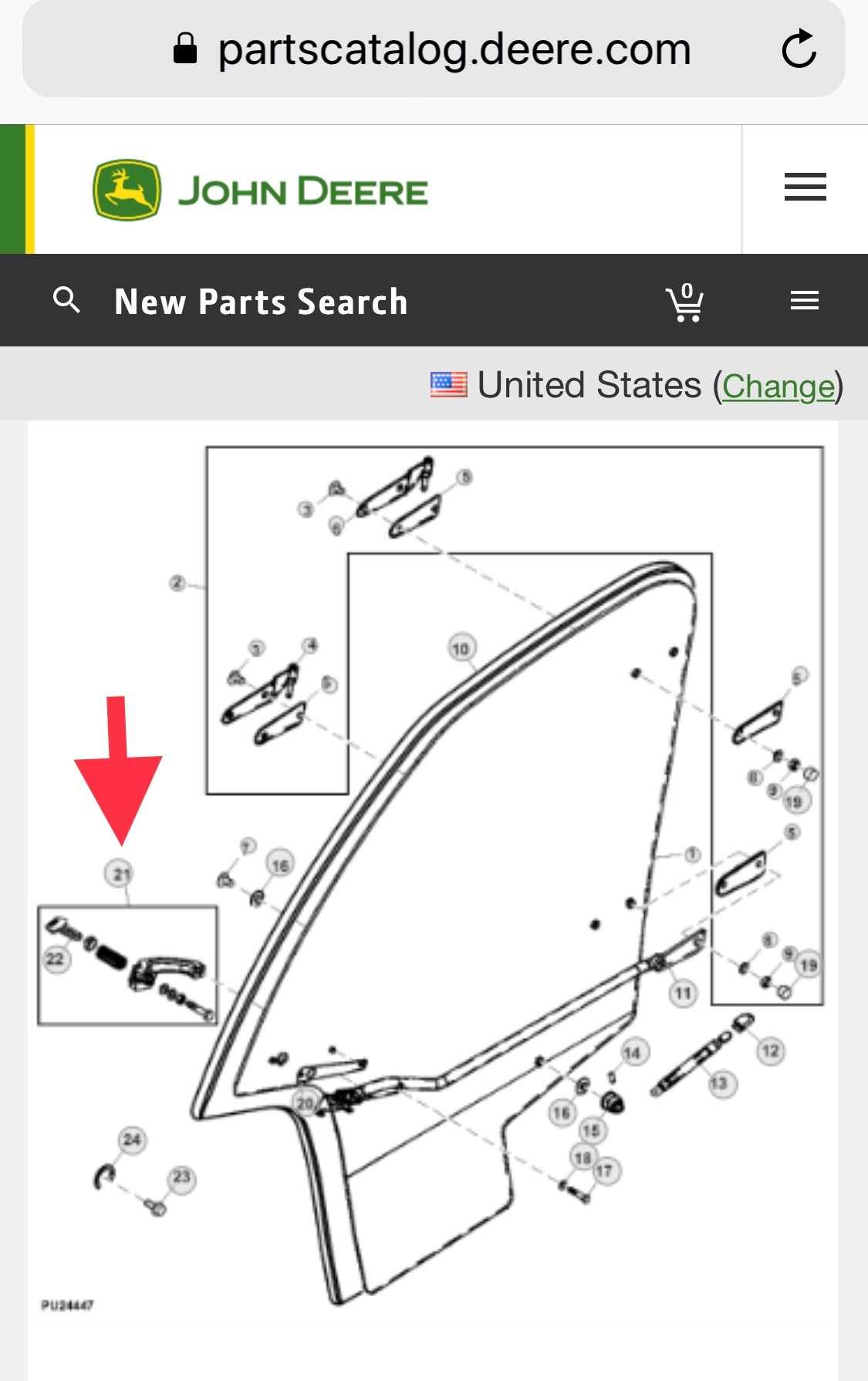

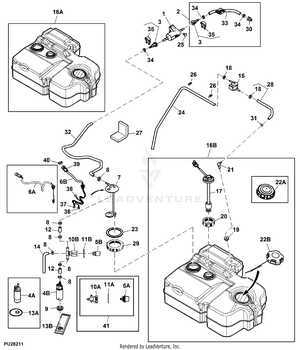

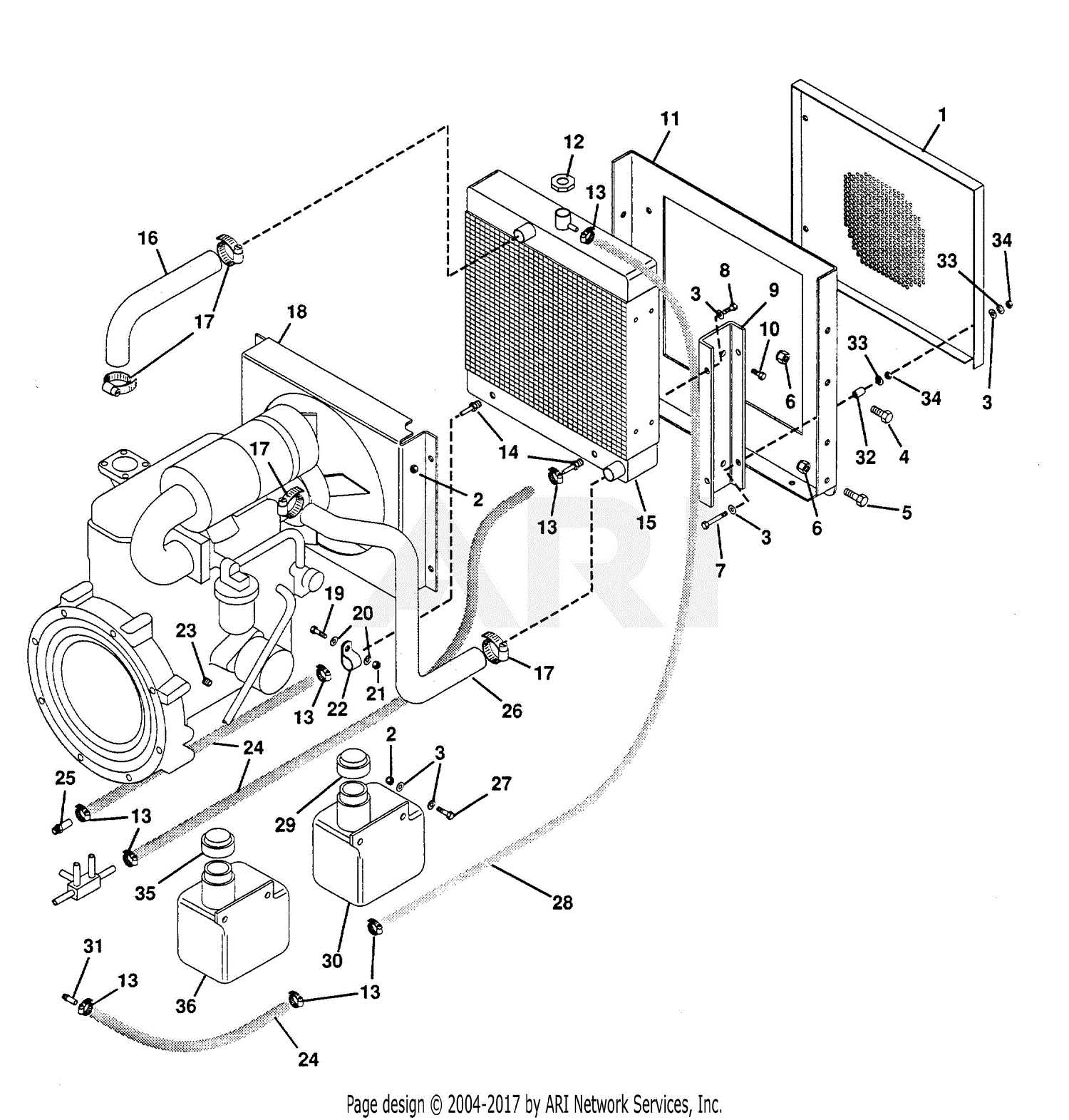

Utilizing visual aids, such as comprehensive schematics, can provide valuable insights into the arrangement and function of these elements. Such resources serve as effective tools for both novice and experienced users, offering clarity and direction when addressing maintenance challenges.

Understanding Gator 825i Parts

This section provides insights into the various components that make up a utility vehicle, highlighting their significance and functionality. Familiarity with these elements is essential for effective maintenance and optimal performance.

Key Components Overview

Every vehicle consists of numerous essential elements, each serving a unique purpose. Understanding these components allows for better troubleshooting and enhancement of the machine’s overall efficiency.

Component Categories

To facilitate comprehension, the parts can be categorized into several groups, such as mechanical, electrical, and structural elements. Each category plays a critical role in the vehicle’s operation.

| Component Type | Description |

|---|---|

| Mechanical | Parts that facilitate movement and functionality, including the engine and transmission. |

| Electrical | Elements responsible for power distribution and lighting systems. |

| Structural | Framework and body components that provide support and protection. |

Key Components of Gator 825i

The efficiency and functionality of utility vehicles rely heavily on their essential elements, each playing a crucial role in overall performance. Understanding these vital parts can enhance the user experience and ensure optimal operation.

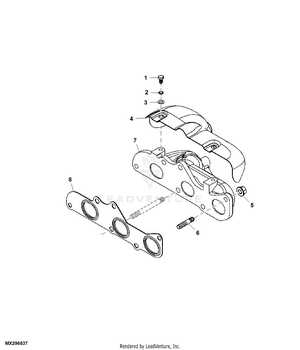

Engine: The powerhouse of the vehicle, providing the necessary energy for movement and operation.

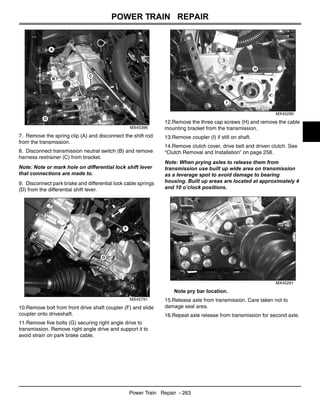

Transmission: This component is responsible for transferring power from the engine to the wheels, ensuring smooth acceleration and deceleration.

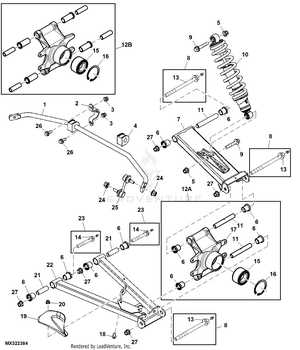

Suspension System: Essential for stability, it absorbs shocks from uneven terrain, contributing to a comfortable ride.

Braking Mechanism: A critical safety feature, enabling effective stopping power in various conditions.

Chassis: The framework that supports the vehicle, housing all other components while providing structural integrity.

Wheels and Tires: These elements ensure traction and maneuverability, playing a significant role in the vehicle’s handling and performance.

Electrical System: Vital for powering lights, ignition, and other electronic features, contributing to overall functionality.

Maintenance Tips for Longevity

Proper upkeep is essential for extending the lifespan of your machinery. Regular attention to maintenance can prevent issues and ensure smooth operation over time.

- Regular Inspections: Routinely check all components for wear and tear.

- Fluid Checks: Ensure that oil, coolant, and other fluids are at the appropriate levels.

- Cleanliness: Keep the machine clean to prevent dirt and debris from causing damage.

- Tire Maintenance: Monitor tire pressure and tread to maintain optimal performance.

- Battery Care: Inspect the battery for corrosion and ensure connections are secure.

- Lubrication: Apply lubricant to moving parts to minimize friction.

By following these guidelines, you can enhance the reliability and durability of your equipment.

Identifying Common Replacement Parts

When maintaining machinery, understanding the typical components that may require replacement is essential. These elements are crucial for ensuring optimal performance and longevity of the equipment. Familiarizing oneself with these common items can help streamline repairs and enhance efficiency.

Key Components to Monitor

Several parts often need attention due to wear and tear. Regular inspection of these elements can prevent potential breakdowns and costly repairs.

| Component | Function | Signs of Wear |

|---|---|---|

| Belts | Transfer power between moving parts | Cracking, fraying, or slippage |

| Filters | Remove contaminants from fluids | Clogging, discoloration, or reduced flow |

| Seals | Prevent leakage of fluids | Visible cracks or fluid leaks |

Replacement Recommendations

When replacing these components, it is advisable to source high-quality alternatives. This approach ensures reliability and performance consistency. Additionally, consulting the equipment manual can provide specific guidance on compatible parts and maintenance schedules.

Exploring Gator 825i Accessories

When it comes to enhancing the functionality and comfort of utility vehicles, a wide array of supplementary items is available. These enhancements not only improve performance but also offer a more enjoyable experience for users.

Types of Accessories

- Storage Solutions: Organizers and boxes that maximize cargo space.

- Protective Gear: Covers and shields that safeguard against harsh weather conditions.

- Lighting Enhancements: Upgraded lights for better visibility during night rides.

- Seating Options: Cushioned seats or covers for added comfort.

Choosing the Right Additions

Selecting the appropriate accessories depends on individual needs and the intended use of the vehicle. Consider factors such as terrain, climate, and personal preferences to make the best choices.

Assembly Instructions for Key Parts

This section provides essential guidelines for the proper assembly of significant components within the machinery. Understanding the connection and interaction of these elements is crucial for ensuring optimal functionality and durability.

Begin by organizing all necessary components in a clean workspace. Refer to the accompanying schematic to identify each piece clearly. Ensure you have the appropriate tools on hand to facilitate the assembly process.

Start with the primary structure, ensuring that all attachment points align correctly. Utilize fasteners as indicated, tightening them to the manufacturer’s specifications. After securing the main frame, proceed to attach secondary elements, paying close attention to any specific orientation or alignment requirements.

Finally, conduct a thorough inspection to confirm that all connections are secure and that no components are misaligned. This careful approach will promote a reliable and efficient operation of the equipment.

Where to Find Genuine Parts

Locating authentic components for your vehicle is essential for optimal performance and longevity. Reliable sources ensure quality, fit, and durability, helping you maintain your machine effectively.

- Authorized Dealers: Visit local authorized dealerships, as they offer original items directly from the manufacturer.

- Official Websites: Check the manufacturer’s website for online purchasing options, where you can browse an extensive selection of genuine merchandise.

- Reputable Retailers: Seek well-established retailers known for their integrity and quality assurance.

- Online Marketplaces: Utilize trusted online platforms that specialize in original components, but verify the seller’s credibility.

Maintaining awareness of these sources allows you to secure the best quality items for your equipment.

Comparing Aftermarket vs. OEM Parts

When considering components for machinery, the choice often comes down to two main categories: standard and alternative options. Each type presents unique advantages and disadvantages, influencing overall performance and longevity.

Standard components are produced by the original manufacturer and tend to maintain the quality and specifications set during the initial production. They are known for:

- Consistency in performance

- Guaranteed compatibility

- Comprehensive warranty coverage

On the other hand, alternative components offer a variety of options often at a lower price point. These alternatives can provide:

- Cost savings

- Potential for enhanced features

- A wider selection of choices

Ultimately, the decision hinges on individual needs, budget constraints, and performance expectations. Evaluating both options carefully ensures a well-informed choice.

Tools Required for Repairs

When undertaking maintenance or fixing tasks on utility vehicles, having the right instruments is essential for efficiency and safety. The proper tools not only facilitate smoother operations but also contribute to achieving optimal results.

Commonly needed instruments include wrenches, sockets, and screwdrivers, each playing a crucial role in various repair procedures. Additionally, specialized equipment such as torque wrenches can ensure that components are tightened to manufacturer specifications, preventing potential issues down the line.

Safety gear, including gloves and goggles, should not be overlooked. These items protect the user from injuries and ensure that repairs are carried out in a secure environment. By assembling the correct tools and safety equipment beforehand, the repair process can be executed with confidence and precision.

Safety Precautions During Maintenance

Ensuring safety during upkeep activities is crucial for both personnel and equipment longevity. Proper precautions help mitigate risks associated with mechanical failures and potential injuries.

Wear Appropriate Personal Protective Equipment

Personal protective equipment (PPE) is essential when performing maintenance tasks. Items such as gloves, goggles, and helmets protect against hazardous materials and falling objects. Always ensure that PPE is in good condition and suitable for the specific task at hand.

Secure the Work Area

Maintaining a clean and organized work environment is vital for safety. Remove unnecessary tools and debris to prevent tripping hazards. Additionally, ensure that the area is well-lit and that emergency exits are accessible at all times.

Understanding Warranty and Coverage

Warranty and coverage are essential aspects of any product ownership, ensuring that consumers have protection against defects and malfunctions. This section explores the key components of warranties, emphasizing their importance in safeguarding your investment.

Types of Warranties: There are typically two main categories of warranties: express and implied. An express warranty is clearly stated by the manufacturer, while an implied warranty is automatically applied, guaranteeing the product meets certain standards.

Duration and Scope: Understanding the duration of your warranty is crucial. Warranties may vary in length and the specific conditions they cover. Familiarizing yourself with these details can help you make informed decisions during ownership.

Exclusions and Limitations: It’s important to be aware of any exclusions that may apply. Certain damages or uses might void your warranty, so understanding these limitations is vital for proper care and maintenance.

In summary, being knowledgeable about warranties and their coverage can enhance your experience and provide peace of mind when using your purchased item.

Troubleshooting Common Issues

Addressing frequent problems can enhance the performance of your vehicle. Identifying symptoms accurately is crucial for effective resolution, ensuring a smoother operation and longevity.

One common challenge is the engine not starting. This may stem from a drained battery, faulty ignition system, or fuel supply issues. Checking these components systematically can often reveal the root cause.

Another issue is unusual noises during operation. Such sounds might indicate worn-out belts or loose parts. Conducting a thorough inspection will help pinpoint the exact source and facilitate timely repairs.

Finally, if performance is sluggish, consider examining the air and fuel filters. Clogged filters can significantly hinder efficiency. Regular maintenance of these elements is essential for optimal functionality.

Upgrading Your Gator 825i

Enhancing your utility vehicle can significantly improve its performance and functionality. Whether you’re seeking to boost power, increase efficiency, or enhance comfort, various modifications can make a substantial difference. Exploring options for upgrading different components allows you to tailor the vehicle to meet your specific needs.

Performance Enhancements: Consider upgrading the engine or exhaust system for better power output and efficiency. Installing a high-performance air filter can also help in optimizing airflow, leading to improved throttle response.

Suspension Upgrades: Upgrading the suspension system can enhance ride quality and handling. Stiffer springs or adjustable shock absorbers allow for a smoother experience on various terrains, ensuring comfort during longer trips.

Accessory Additions: Adding accessories such as upgraded lighting, storage solutions, or sound systems can enhance the overall functionality and enjoyment of your vehicle. These additions not only provide practical benefits but can also improve the aesthetic appeal.

Investing in these upgrades can elevate your driving experience, making it more enjoyable and suited to your personal preferences.