In the realm of small engines, comprehending the arrangement of various elements is crucial for effective maintenance and repair. A well-structured visual representation serves as a valuable resource, guiding users through the intricacies of assembly and functionality. This knowledge not only enhances the understanding of individual components but also promotes efficient troubleshooting.

Thorough insights into the configuration of engine elements can significantly improve the overall performance and longevity of the equipment. By familiarizing oneself with how each part interacts within the system, users can make informed decisions regarding repairs and upgrades. This section aims to shed light on these crucial aspects, providing a clear overview that empowers users to navigate their equipment with confidence.

Whether for personal use or professional maintenance, having access to a detailed overview of these components can transform the approach to engine care. Gaining proficiency in identifying and understanding the role of each segment paves the way for successful interventions and enhancements.

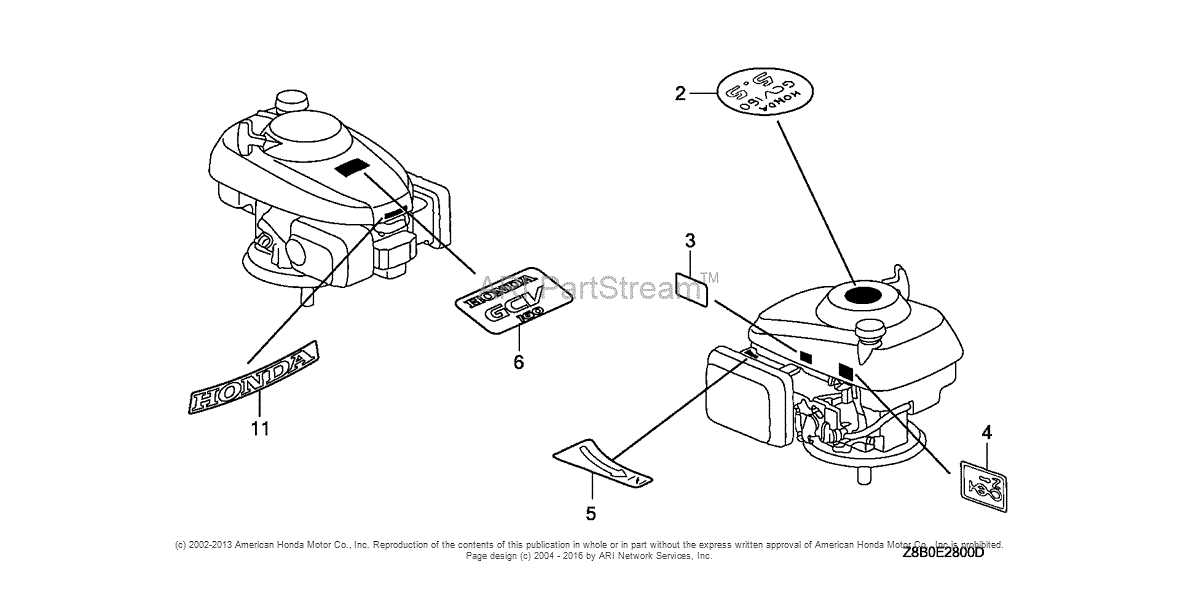

GCV160 Overview and Specifications

This section provides a detailed examination of a popular small engine model known for its reliability and efficiency. Designed for various applications, this engine is widely utilized in outdoor power equipment, making it a preferred choice among users.

The following are key specifications that characterize this engine:

- Engine Type: Four-stroke, single-cylinder

- Displacement: Approximately 160 cc

- Power Output: Around 4.0 hp

- Fuel Type: Unleaded gasoline

- Oil Capacity: About 0.5 quarts

Additionally, the design incorporates several features aimed at enhancing performance and user convenience:

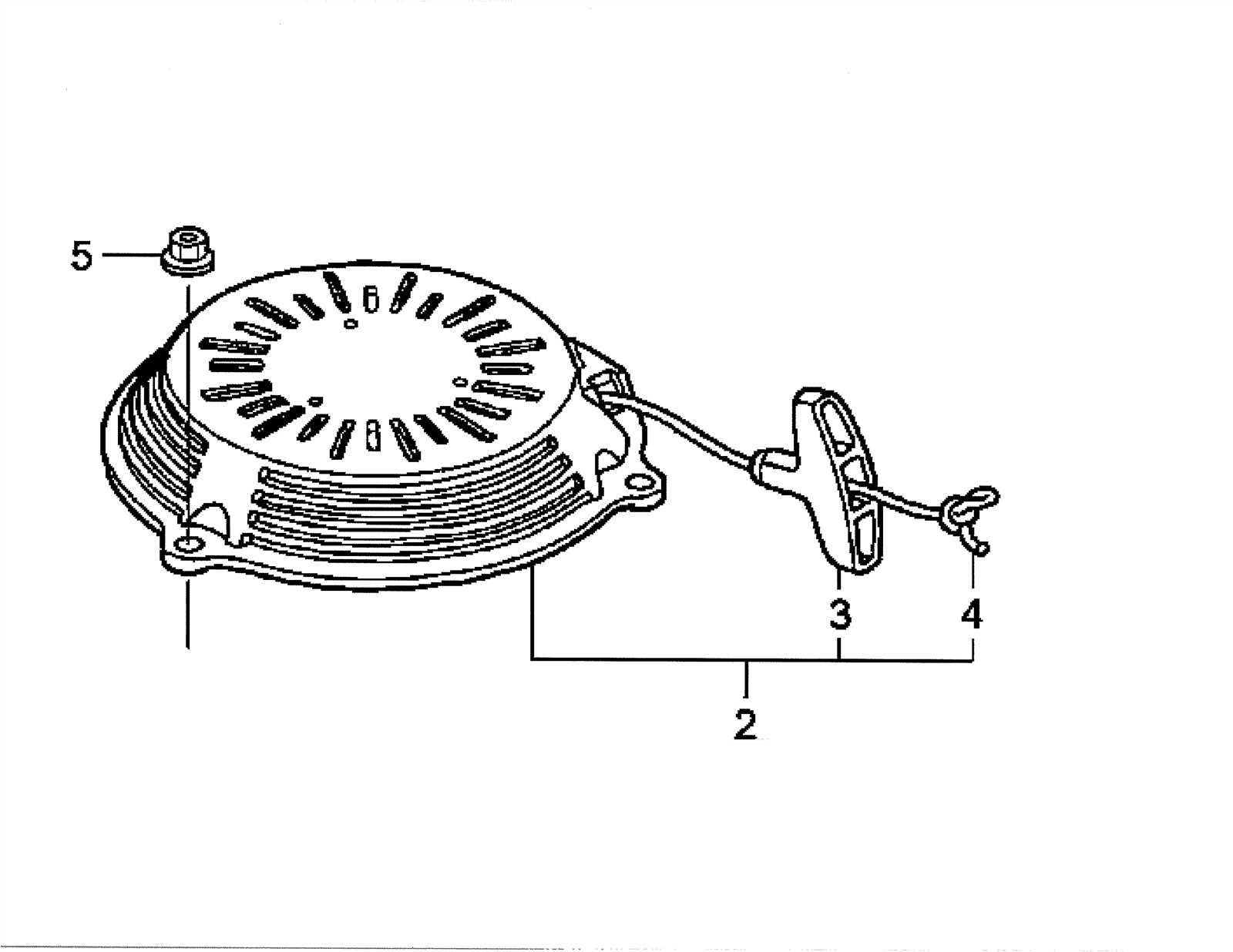

- Easy starting mechanism with a recoil starter

- Compact size for improved maneuverability

- Low emissions technology to meet environmental standards

- Durable construction for extended service life

In conclusion, this engine model stands out for its balance of power and efficiency, making it suitable for a variety of tasks in residential and commercial settings.

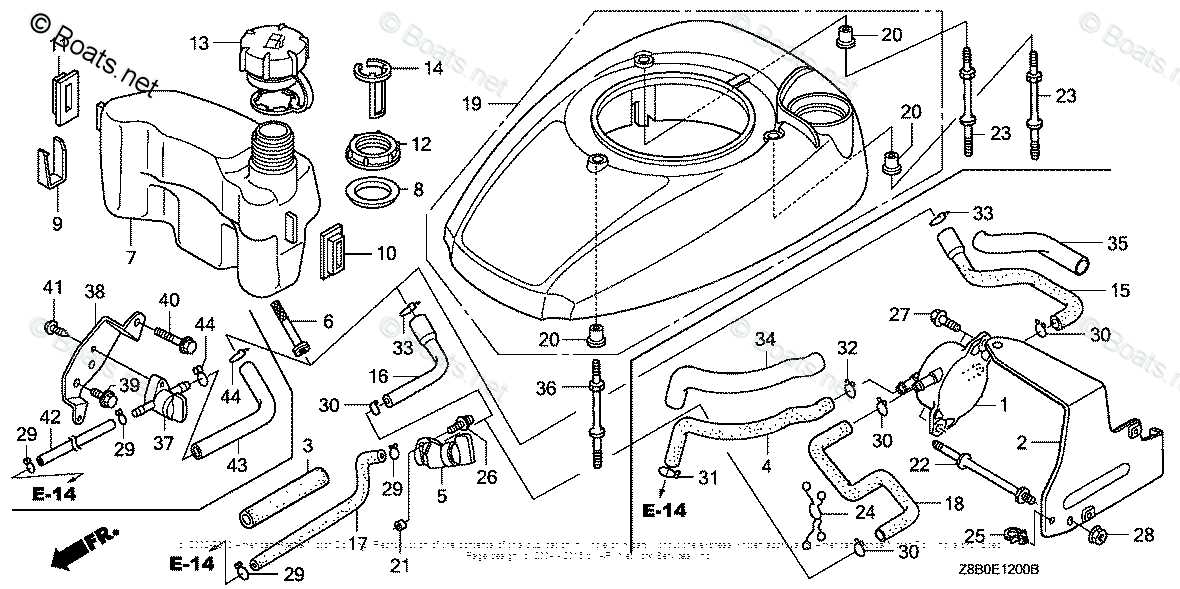

Importance of Parts Diagrams

Understanding the components of a machine is essential for effective maintenance and repair. Visual representations serve as valuable resources, offering clarity on the relationships between various elements. They assist users in identifying specific sections, facilitating more straightforward troubleshooting and replacements.

Benefits of Visual Representations

- Enhances comprehension of complex systems.

- Provides quick reference for component locations.

- Aids in accurate ordering of replacements.

Role in Maintenance and Repair

- Streamlines the diagnostic process by highlighting potential issues.

- Increases efficiency in repairs, saving time and effort.

- Fosters a deeper understanding of equipment functionality.

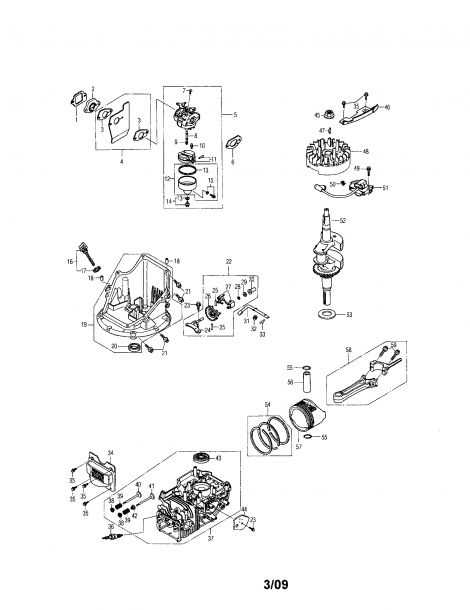

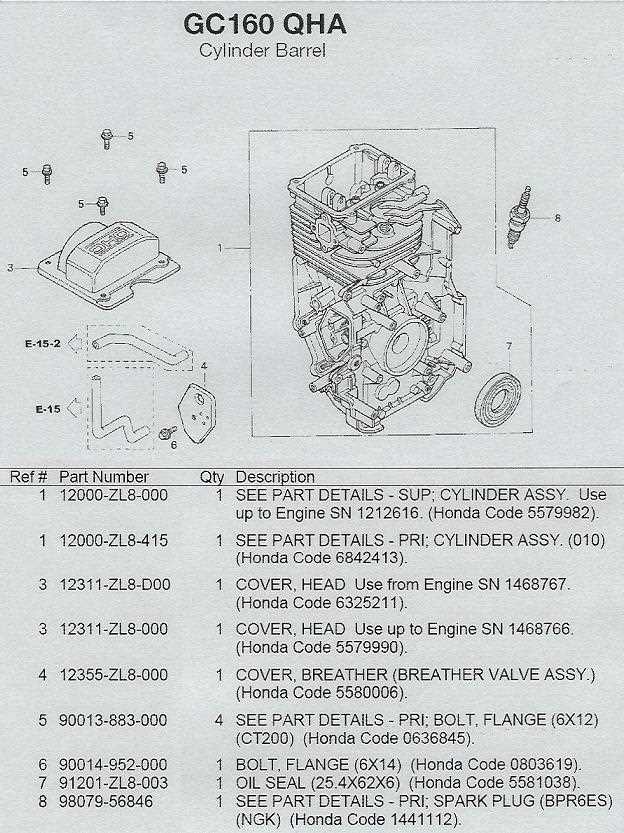

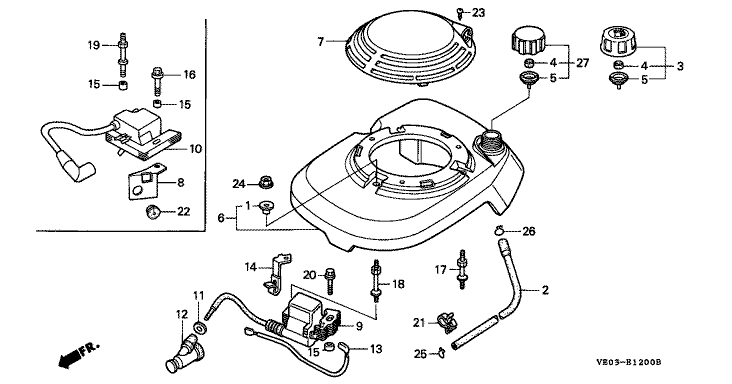

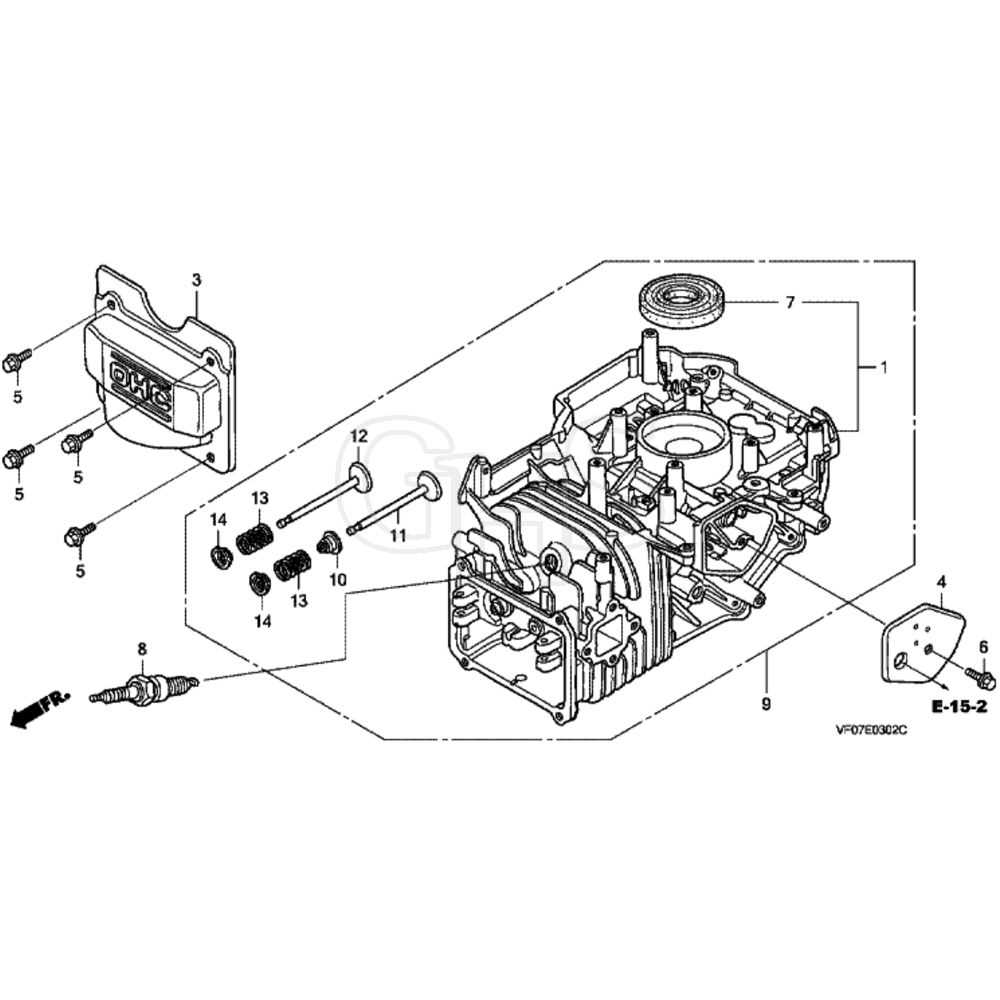

Identifying Key Components

Understanding the essential elements of a small engine is crucial for effective maintenance and troubleshooting. Each component plays a specific role in the overall functionality, contributing to the machine’s performance and reliability. By familiarizing oneself with these vital parts, one can enhance the repair process and ensure optimal operation.

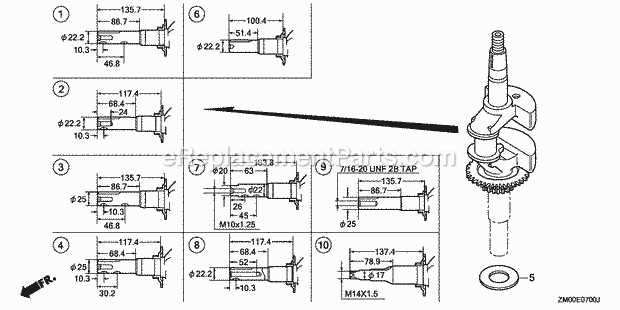

Major Elements Overview

Key components of a small engine include the cylinder, crankshaft, and ignition system. The cylinder houses the combustion process, while the crankshaft transforms linear motion into rotational power. The ignition system is responsible for initiating the combustion, ensuring the engine starts efficiently. Recognizing these parts is fundamental for anyone involved in engine care.

Importance of Each Component

Each element plays a significant role in the engine’s operation. The cylinder’s design affects the power output, while the crankshaft’s integrity ensures smooth operation. Additionally, a well-functioning ignition system prevents misfires and enhances fuel efficiency. Understanding these factors contributes to better maintenance practices and extends the engine’s lifespan.

Common Issues and Solutions

This section addresses frequent challenges encountered during the operation of small engines, providing practical solutions for each issue. Understanding these common malfunctions can significantly enhance performance and extend the lifespan of the equipment.

Engine Won’t Start

A non-starting engine is one of the most common problems users face. This can be due to various factors such as fuel issues, ignition failure, or a clogged air filter. Below are potential causes and remedies:

| Cause | Solution |

|---|---|

| Empty fuel tank | Refill with fresh fuel |

| Dirty spark plug | Clean or replace the spark plug |

| Clogged air filter | Inspect and clean the air filter |

Overheating

Overheating is another issue that can lead to engine failure. This often results from insufficient lubrication or blockages in the cooling system. The following are common causes and their respective fixes:

| Cause | Solution |

|---|---|

| Low oil levels | Add the appropriate engine oil |

| Debris in cooling fins | Clean the cooling fins and check for blockages |

| Faulty cooling system | Inspect and repair the cooling system components |

Maintenance Tips for GCV160

Regular upkeep of your small engine is crucial for optimal performance and longevity. Following a few essential maintenance steps can help ensure that your machine operates efficiently and reliably for years to come. This guide provides practical advice for maintaining your equipment, focusing on critical aspects that contribute to its overall health.

One of the most important tasks is to routinely check and change the oil. Fresh oil reduces friction and wear, thereby prolonging engine life. Additionally, keeping the air filter clean prevents debris from entering the engine, improving air circulation and performance.

Fuel quality also plays a significant role in the maintenance of your machine. Using fresh, high-quality fuel helps to avoid issues related to combustion and engine performance. Always ensure that the fuel is stored properly to prevent degradation.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Oil Change | Every 50 hours of operation | Use the recommended oil type |

| Air Filter Inspection | Every 25 hours of operation | Clean or replace as needed |

| Fuel Check | Before each use | Use fresh fuel and check for water contamination |

| Spark Plug Replacement | Every 100 hours of operation | Inspect and clean regularly |

Following these maintenance tips can greatly enhance the performance and durability of your engine, ensuring that it runs smoothly when you need it most. Regular attention to these tasks will lead to fewer repairs and a more enjoyable experience with your equipment.

Replacement Parts and Compatibility

When maintaining small engines, ensuring the availability of suitable components is essential for optimal performance. Understanding the compatibility of different elements can significantly influence the functionality and longevity of the equipment.

Identifying Suitable Components is crucial for effective repairs. Various manufacturers offer a range of compatible items designed to fit specific models. It is advisable to consult manufacturer guidelines to determine which replacements are appropriate.

Quality Considerations should also be taken into account. Utilizing high-quality replacements can prevent potential issues that arise from inferior alternatives. Investing in reliable components can lead to enhanced durability and efficiency.

Compatibility with Other Models may offer additional options when sourcing replacements. Many components are interchangeable across different engine models, allowing users to explore various avenues for acquiring necessary items.

In summary, understanding the compatibility of various components is vital for maintaining the effectiveness of small engines. Proper research and quality consideration can lead to successful repairs and extended equipment lifespan.

Step-by-Step Assembly Guide

This section provides a comprehensive approach to assembling your engine components efficiently. By following a structured method, you can ensure that each part fits together seamlessly, enhancing overall performance and longevity. Proper assembly is crucial for the optimal functioning of your machine.

Preparation and Tools Needed

Before starting the assembly process, gather all necessary components and tools. This may include wrenches, screwdrivers, and lubricants. Organizing your workspace will help streamline the procedure and prevent any misplaced parts.

Assembly Process

Begin by laying out the main elements in the order of assembly. Ensure that all connection points are clean and free from debris. Start with the base unit, attaching the crucial components securely. Proceed methodically, checking that each piece aligns correctly as you move along. Regularly refer to your reference materials to confirm the arrangement and avoid any potential mistakes.

Using the Parts Diagram Effectively

Understanding the layout of a mechanical assembly is crucial for proper maintenance and repair. A visual representation of components allows users to identify individual elements quickly, ensuring that each piece is accounted for during inspection or replacement. This approach enhances the efficiency of troubleshooting and simplifies the overall process.

Identifying Components

When navigating a visual reference, take note of each component’s unique identifier. This can significantly expedite the ordering process and ensure compatibility with your specific model. Familiarizing yourself with the various elements also aids in understanding their functions within the system.

Planning Maintenance

Utilizing a visual reference effectively involves strategic planning. Before starting any maintenance task, review the layout thoroughly to determine which components may require attention. This proactive approach not only saves time but also minimizes the risk of overlooking essential repairs.

Tools Needed for Repairs

When undertaking maintenance or fixing machinery, having the right tools is crucial for ensuring efficiency and effectiveness. A well-equipped workspace can significantly simplify the repair process, allowing you to address issues promptly and accurately.

Essential Hand Tools

Basic hand tools form the backbone of any repair job. These include items such as wrenches, screwdrivers, and pliers. Each tool serves a specific function, making it easier to tackle various components without causing damage. Additionally, a reliable set of socket wrenches can greatly enhance accessibility in tight spaces.

Power Tools and Accessories

In many instances, power tools are necessary for more intensive repairs. Items like drills and impact wrenches can expedite tasks, especially when dealing with stubborn fasteners. It’s also important to have the right accessories, such as drill bits and blades, to match the specific requirements of the job.

Proper organization and maintenance of your tools are essential to ensure they remain in good working condition. Regular checks and cleaning can extend their lifespan and improve performance.

Safety Precautions During Repairs

When undertaking maintenance or fixing machinery, adhering to safety guidelines is paramount. These measures are designed to protect both the technician and the equipment, ensuring a safe working environment. Prioritizing safety reduces the risk of accidents and enhances the overall efficiency of the repair process.

Before commencing any repair work, it is crucial to equip oneself with appropriate personal protective equipment (PPE). This includes items such as gloves, goggles, and sturdy footwear. Furthermore, maintaining a tidy workspace can help minimize hazards.

| Safety Equipment | Purpose |

|---|---|

| Gloves | Protect hands from sharp objects and chemicals. |

| Goggles | Shield eyes from debris and harmful substances. |

| Safety Footwear | Prevent foot injuries from heavy equipment. |

| Ear Protection | Reduce noise exposure in loud environments. |

Always disconnect the power supply before initiating repairs to prevent electrical shock. If working with heavy machinery, ensure that it is properly supported and stabilized to avoid unintended movement. Additionally, familiarize yourself with the tools and equipment being used to prevent misuse and potential accidents.

Where to Find GCV160 Parts

Locating the necessary components for your engine can greatly enhance its performance and longevity. Whether you are in need of replacement elements or enhancements, understanding where to source these items is essential. Various options exist for acquiring the needed supplies, catering to different preferences and requirements.

Online Retailers

One of the most convenient methods to procure items is through online platforms. Numerous websites specialize in engine components and offer extensive catalogs, allowing you to compare prices and features effortlessly. This approach provides access to customer reviews, which can assist in making informed decisions.

Local Repair Shops

Another effective avenue is visiting local repair shops or authorized dealers. These establishments often maintain a stock of essential items and can provide personalized advice based on your specific needs. Building a relationship with local suppliers may also lead to potential discounts and faster service.

| Source | Description |

|---|---|

| Online Marketplaces | Wide selection, customer reviews, and price comparisons available. |

| Local Dealers | Personalized service, immediate access, and expert recommendations. |

| Specialized Stores | Focus on specific types of components, often with knowledgeable staff. |

Customer Reviews on GCV160 Parts

This section highlights feedback from users regarding components related to the engine model. Insights from consumers can provide valuable information on reliability, performance, and overall satisfaction with various elements associated with this engine.

Many users have shared their experiences, focusing on different aspects:

- Quality: Customers often emphasize the durability and craftsmanship of the components, noting how these features contribute to the engine’s longevity.

- Performance: Several reviews highlight improvements in efficiency and functionality after replacing certain elements, indicating a positive impact on overall operation.

- Ease of Installation: Feedback suggests that many users found it straightforward to install the new components, which is an essential factor for DIY enthusiasts.

- Customer Support: Many reviews mention the helpfulness of customer service when addressing questions or concerns about the components, enhancing the overall purchasing experience.

In summary, reviews indicate a generally favorable perception of the engine-related components, with users appreciating quality, performance, and customer service. These insights can assist prospective buyers in making informed decisions.

Frequently Asked Questions

This section aims to address common inquiries regarding maintenance and component identification for small engines. Understanding these aspects can enhance the overall performance and longevity of your equipment.

What are the most common issues faced with small engines?

Some typical problems include difficulty starting, poor fuel efficiency, and unusual noises during operation. Regular inspections can help identify these issues early.

How can I ensure proper maintenance?

Regular maintenance includes checking and replacing filters, changing oil, and inspecting belts and hoses. Keeping a maintenance schedule is beneficial.

Where can I find replacement components?

Replacement components can often be sourced from authorized dealers, online retailers, or local hardware stores. Ensure compatibility with your specific engine model when purchasing.

What tools do I need for basic repairs?

Basic repairs typically require common hand tools such as wrenches, screwdrivers, and pliers. More extensive repairs may necessitate specialized equipment.

How often should I perform routine checks?

It is advisable to conduct routine checks before each use and perform more thorough maintenance at least once a season or every 50 hours of operation, whichever comes first.