This section delves into the essential elements of a culinary instrument designed for efficient food processing. By examining the various components, one can gain insight into the overall functionality and efficiency of the device.

Each element plays a crucial role in the operation, contributing to the seamless performance required in kitchen environments. Familiarizing oneself with these individual pieces not only enhances usability but also aids in maintenance and troubleshooting.

Through a detailed exploration of these components, users will develop a better understanding of how to optimize their experience and ensure longevity in their kitchen endeavors. This knowledge empowers individuals to make informed decisions regarding care and replacement of the various segments involved.

Comprehensive Guide to Globe Slicers

This guide offers a thorough overview of a specific type of food preparation equipment, designed for slicing various items with precision. Understanding its components and their functions can enhance the efficiency of culinary tasks, making it an essential tool in both commercial and home kitchens.

Key Features of Food Preparation Equipment

The main attributes of this culinary device include its adjustable thickness settings, which allow for uniform cuts tailored to specific needs. Additionally, the construction materials often ensure durability, while the ergonomic design contributes to user comfort during operation.

Maintenance and Care Tips

Regular maintenance is vital for optimal performance. Cleaning the surfaces after each use, checking for wear and tear, and ensuring that all moving parts are properly lubricated will prolong the lifespan of the equipment. Following the manufacturer’s recommendations for upkeep can help prevent operational issues and ensure safety during use.

Understanding Globe Slicer Functionality

This section explores the operational aspects of a particular food preparation device designed for precise cutting. The mechanism allows users to achieve consistent thickness in various food items, enhancing both presentation and preparation efficiency.

Core Mechanisms

The device relies on a rotating blade that interacts with the food product, providing uniform slices. This functionality is crucial for chefs and culinary enthusiasts seeking to optimize their workflow while maintaining quality.

Benefits of Efficient Design

A well-engineered apparatus minimizes effort and maximizes output. By integrating safety features and easy maintenance, users can focus on creativity rather than complications, ensuring an enjoyable cooking experience.

Key Components of Globe Slicers

The essential elements of these cutting machines play a crucial role in their functionality and efficiency. Understanding the main components helps users maintain and operate them effectively. Each part contributes to the overall performance, ensuring precision in slicing various products.

Blade: The sharp, rotating circular element is vital for achieving clean and uniform cuts. Its design and material significantly affect the quality of the slices produced.

Carriage: This movable platform supports the item being sliced. Its stability and ease of adjustment are important for accommodating different sizes and shapes of food items.

Base: The sturdy foundation holds all components together. A robust base enhances stability during operation, minimizing vibrations and ensuring safety.

Control Mechanism: This feature allows users to adjust the thickness of slices. Its accessibility and reliability are essential for achieving consistent results.

Safety Guard: This protective element ensures user safety by covering the blade when not in use. A well-designed safety guard is crucial for preventing accidents during operation.

By familiarizing oneself with these fundamental components, users can optimize the performance and longevity of their cutting machines.

Maintenance Tips for Longevity

Proper care is essential for ensuring the durability and optimal performance of your equipment. Regular maintenance routines can significantly extend its lifespan and enhance its functionality. By following a few simple guidelines, you can keep your machine running smoothly for years to come.

Regular Cleaning: Ensure that all components are cleaned frequently to prevent buildup that could affect performance. Use gentle cleaning agents to avoid damaging any surfaces.

Periodic Inspections: Conduct thorough inspections at regular intervals to identify any wear or potential issues early on. This proactive approach can save you from costly repairs in the future.

Lubrication: Apply appropriate lubricants to moving parts as recommended. This helps reduce friction and wear, ensuring smooth operation.

Proper Storage: Store the equipment in a dry, protected environment when not in use. This prevents damage from moisture or dust, preserving its integrity.

Use as Intended: Follow the manufacturer’s guidelines for operation to avoid unnecessary strain on the machine. Operating outside of intended parameters can lead to premature failure.

Identifying Common Issues in Slicers

Understanding frequent problems that arise in food preparation tools is essential for maintaining optimal performance. These challenges can affect efficiency and quality, leading to subpar results. Recognizing the signs of malfunction can save time and resources while ensuring consistent output.

Mechanical Failures

One prevalent concern involves mechanical components that may wear out over time. This can manifest as irregular cutting or unusual noises during operation. Regular inspection of these elements can help detect issues before they escalate.

Maintenance Neglect

Another significant factor is the lack of proper upkeep. Residue buildup and inadequate cleaning can hinder functionality and even pose safety risks. Adopting a regular maintenance schedule ensures longevity and reliable performance.

How to Clean Your Globe Slicer

Maintaining the efficiency of your food preparation device is essential for optimal performance and hygiene. Regular cleaning ensures that the equipment remains in top condition, preventing the buildup of food particles and bacteria. Here’s a simple guide to help you keep your device spotless and functioning smoothly.

Necessary Supplies

Before starting the cleaning process, gather the following items:

| Item | Purpose |

|---|---|

| Soft cloth | For wiping surfaces |

| Warm water | To moisten the cloth |

| Gentle detergent | For breaking down grease |

| Brush | To reach crevices |

| Sanitizing solution | To disinfect |

Cleaning Steps

Follow these steps for effective cleaning:

- Unplug the device and ensure it has cooled down.

- Remove any detachable components for separate cleaning.

- Wipe down the surfaces with a damp cloth and detergent to remove residues.

- Use a brush to clean hard-to-reach areas, ensuring no debris is left behind.

- Rinse all components thoroughly with warm water and allow them to dry.

- Once dry, reassemble the parts and apply a sanitizing solution to the surfaces.

By following these simple steps, you can maintain your equipment’s hygiene and functionality, ensuring it serves you well for years to come.

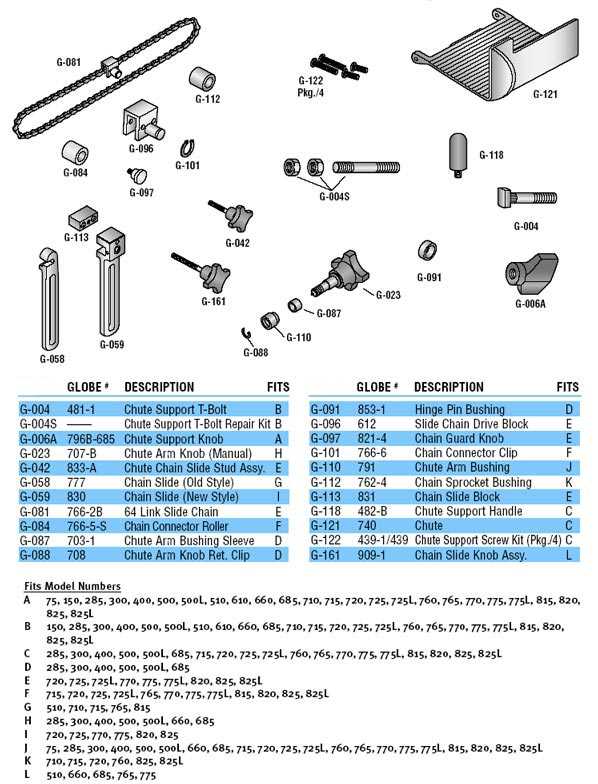

Replacement Parts Availability and Sources

Finding the right components for your machine is crucial for maintaining its functionality and efficiency. Various options exist for sourcing these necessary items, ensuring that users can keep their equipment in optimal condition without significant downtime.

Potential Sources for Components

- Authorized Dealers: These retailers offer genuine items, ensuring quality and compatibility with your device.

- Online Marketplaces: Websites specializing in equipment parts can provide a wide selection, often at competitive prices.

- Local Repair Shops: Many local services may stock essential items or can order them for you, providing personalized support.

- Manufacturer’s Website: Directly purchasing from the official site guarantees authenticity and often provides detailed information on each item.

Considerations When Purchasing

- Quality: Always prioritize high-quality items to ensure longevity and performance.

- Compatibility: Verify that the component fits your specific model to avoid installation issues.

- Warranty: Check if the item comes with a warranty to protect your investment.

- Reviews: Look for feedback from other users to gauge the reliability of the source.

Safety Features of Globe Slicers

The design of commercial cutting devices prioritizes user protection and operational safety. Various features are implemented to minimize risks associated with their usage, ensuring a secure environment for operators and bystanders alike.

Key Safety Mechanisms

These devices incorporate several critical elements to enhance safety:

| Feature | Description |

|---|---|

| Blade Guard | A protective barrier that shields the blade when not in use, reducing accidental contact. |

| Automatic Shut-off | This mechanism halts operation if the equipment is tilted or improperly positioned, preventing injuries. |

| Non-slip Base | Ensures stability during operation, minimizing the risk of movement and accidents. |

User Training and Guidelines

Proper training and adherence to operational guidelines are essential for maintaining safety standards. Users should be familiar with all safety features to maximize protection while ensuring efficient performance.

Assembly Instructions for New Parts

This section provides essential guidance for the successful integration of new components into your device. Understanding the process ensures that each element is correctly positioned and functions optimally, enhancing overall performance.

Preparation Steps

Before beginning the assembly, ensure all necessary tools are available and that the workspace is clean. Carefully review the provided components to confirm they are undamaged and ready for installation. Familiarizing yourself with each piece will streamline the process.

Installation Process

Start by securing the primary unit on a stable surface. Gently align the new components with the designated areas, applying even pressure to fit them securely. If applicable, use fasteners to hold the pieces in place. Finally, conduct a thorough inspection to verify that everything is assembled correctly and functions as intended.

Upgrading Globe Slicer Components

Enhancing the functionality of slicing machines can significantly improve efficiency and performance in various settings. Upgrading specific elements can lead to better results, increased safety, and prolonged lifespan of the equipment. It is essential to assess the existing components and identify opportunities for enhancement.

- Blade Replacement: Regularly updating the cutting element ensures precision and effectiveness.

- Motor Upgrade: A more powerful motor can enhance speed and reduce operational strain.

- Hopper Enhancements: Modifying the feeding mechanism can improve material handling and reduce waste.

- Safety Features: Integrating advanced safety systems can protect operators and reduce the risk of accidents.

By focusing on these areas, operators can create a more efficient and reliable machine tailored to their specific needs. Prioritizing quality components and innovative designs will contribute to overall performance improvements.

Comparing Different Globe Slicer Models

When assessing various models of food preparation equipment, it is essential to consider their unique features and capabilities. Each variant brings a distinct set of attributes that cater to specific needs, influencing both performance and usability.

Design Variations: Different configurations can impact the ease of operation and maintenance. Some models prioritize compactness, while others focus on robustness and durability.

Performance Factors: Speed and precision are crucial. Certain versions offer enhanced slicing efficiency, making them ideal for high-volume environments, while others provide greater control for intricate tasks.

User Experience: Ergonomics and accessibility play significant roles in the overall satisfaction of the user. Features like intuitive controls and safety mechanisms vary, affecting daily operations.

Warranty Information and Coverage

This section outlines the protections and guarantees associated with your appliance. Understanding these details is crucial for ensuring that you receive the necessary support throughout the product’s lifespan.

The coverage typically includes various aspects such as:

- Duration: The length of time the warranty remains valid.

- Repairs: Types of repairs covered under the warranty agreement.

- Parts Replacement: Conditions under which components may be replaced without charge.

- Exclusions: Specific situations or damages that are not included in the warranty.

To make the most of your warranty, it is advisable to:

- Keep the original purchase receipt as proof of purchase.

- Read the warranty terms thoroughly to understand your rights.

- Contact customer service promptly if issues arise within the coverage period.

By being informed about your warranty, you can ensure effective maintenance and support for your device.

Customer Reviews and Feedback Analysis

Analyzing customer opinions and evaluations provides invaluable insights into product performance and user satisfaction. This section delves into the various aspects of user feedback, highlighting trends, common praises, and notable concerns.

- Positive Aspects:

- Durability and reliability are frequently commended.

- Users appreciate the efficiency of operation.

- Design and ease of use often receive favorable remarks.

- Common Issues:

- Some users report challenges with maintenance and cleaning.

- Occasional complaints about noise levels during use.

- Inconsistent performance noted in specific models.

- Suggestions for Improvement:

- Many customers recommend enhancements in user manuals.

- Feedback includes requests for additional features.

- Some users desire better customer support options.

Overall, user feedback serves as a critical resource for understanding strengths and areas needing attention, guiding future enhancements.