In the world of automotive engineering, a critical aspect lies in the functionality of the braking mechanisms that ensure safety and control. Among these intricate systems, a specific assembly plays a vital role in amplifying brake force, allowing for a more responsive driving experience. By examining the essential elements involved, one can appreciate the sophisticated design and engineering that contribute to optimal vehicle performance.

This section aims to explore the various components and their interactions, shedding light on the mechanics behind effective braking. A thorough understanding of these elements not only enhances maintenance practices but also equips vehicle owners with the knowledge needed for troubleshooting potential issues.

To truly grasp the nuances of this assembly, it is important to delve into the layout and functions of each component. From hydraulic mechanisms to supportive structures, each part contributes significantly to the overall system, ensuring that drivers can rely on their vehicles under various conditions.

Understanding GM Hydroboost Systems

This section explores the intricacies of a hydraulic-assisted braking system utilized in various General Motors vehicles. These systems enhance stopping power by leveraging hydraulic fluid from the power steering setup, offering a more responsive brake feel while reducing the load on the engine.

| Component | Function |

|---|---|

| Master Cylinder | Converts mechanical force into hydraulic pressure. |

| Hydraulic Unit | Amplifies pressure using power steering fluid. |

| Brake Lines | Transport hydraulic fluid to brake calipers. |

| Calipers | Apply force to the brake pads, slowing the vehicle. |

Understanding the role and operation of each component is crucial for maintaining efficiency and performance in these braking systems, ultimately ensuring safety on the road.

Components of Hydroboost Assemblies

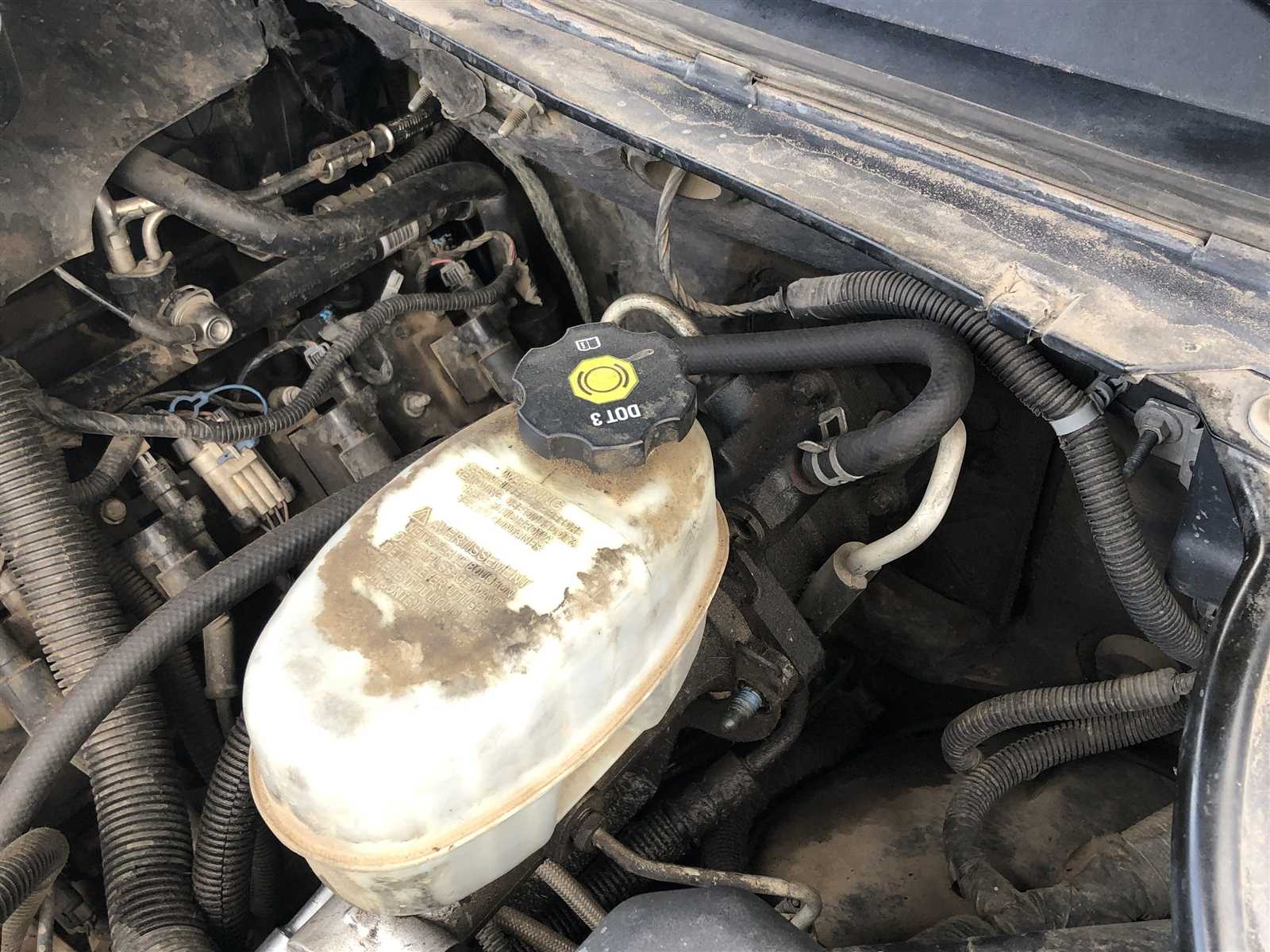

Understanding the various elements of a hydraulic brake assist system is essential for effective maintenance and repair. Each component plays a crucial role in ensuring optimal performance and responsiveness during operation.

Main Elements

- Power Steering Pump

- Hydraulic Actuator

- Pressure Accumulator

- Mounting Bracket

- Control Valve

Supporting Components

- Fluid Reservoir

- Hoses and Fittings

- Seals and Gaskets

- Return Lines

- Electrical Connections

Each of these elements contributes to the overall efficiency and effectiveness of the system, making it vital to recognize their importance during inspections and repairs.

How Hydroboost Works in Vehicles

The braking system in modern vehicles often utilizes an innovative mechanism that enhances the efficiency and responsiveness of braking efforts. This technology relies on fluid pressure to amplify the driver’s input, ensuring a quicker and more effective stopping power.

At its core, this system functions by channeling hydraulic fluid from the power steering system. When the brake pedal is pressed, fluid is directed through a series of valves, creating a significant boost in braking force. This allows for less physical effort from the driver while maintaining control over the vehicle.

Moreover, the integration of this system is particularly beneficial in larger vehicles, where the demands on braking are higher. It not only improves performance but also enhances safety by reducing stopping distances, ultimately leading to a more confident driving experience.

Common Issues with Hydroboost Systems

Vehicles equipped with this type of assist mechanism often experience several recurring problems that can affect performance and safety. Understanding these common issues can help in early diagnosis and maintenance, ensuring that the system operates efficiently.

Fluid Leaks

One of the most frequent complications is fluid leakage. When seals or hoses deteriorate, hydraulic fluid can escape, leading to a drop in pressure. This can result in a noticeable decrease in braking performance. Regular inspection of all connections and components is essential to identify and rectify leaks promptly.

Performance Degradation

Another prevalent issue is the gradual loss of effectiveness in the assist mechanism. Over time, internal components may wear out or become contaminated, which can cause a reduction in response time and overall efficiency. Drivers may notice increased effort needed to engage the brakes, signaling that the system requires attention.

Routine maintenance and checks are crucial to prevent these issues, ensuring reliable operation and enhancing the vehicle’s safety features.

Benefits of Using Hydroboost Technology

In modern automotive engineering, the integration of hydraulic assistance has revolutionized the efficiency of braking systems. This technology provides a significant enhancement in performance and responsiveness, ultimately ensuring a safer driving experience.

One major advantage is the ability to achieve quicker response times, allowing drivers to react swiftly in critical situations. This heightened sensitivity contributes to improved control over the vehicle, particularly in emergency scenarios.

Additionally, this system minimizes the effort required from the driver, making it especially beneficial for larger vehicles that may otherwise demand considerable force to operate the brakes. The reduction in physical strain enhances overall comfort during extended drives.

Moreover, this technology often results in lighter components, promoting better fuel efficiency and performance. By utilizing hydraulic pressure instead of a traditional vacuum system, vehicles can achieve a more compact design without compromising power.

Overall, the implementation of this innovative system not only boosts safety and comfort but also enhances the driving experience by delivering superior control and efficiency.

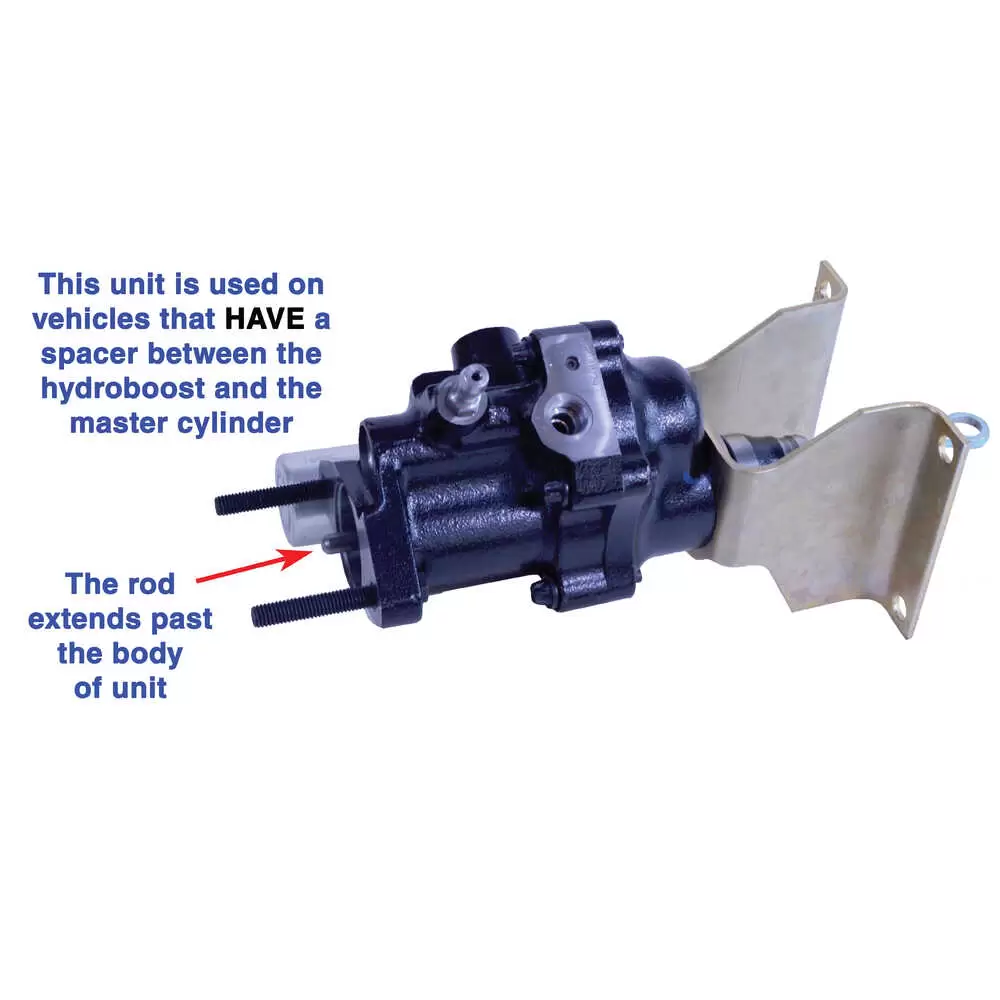

Identifying Hydroboost Parts on Diagrams

Understanding the various components of a hydraulic assist system is essential for effective maintenance and troubleshooting. Visual representations can simplify the identification process, making it easier to locate and recognize each element’s role within the overall assembly.

Key Components Overview

To effectively navigate through visual aids, familiarize yourself with the primary elements, such as the booster unit, connecting hoses, and the control mechanisms. Each component plays a critical role in enhancing vehicle performance and safety.

Tips for Recognition

Pay attention to the shapes and connections illustrated in the visuals. Identifying the orientation and position of each item will help you understand how they interact. Using color coding or labeling in these representations can also assist in quickly pinpointing specific elements for reference.

Differences Between Hydroboost and Vacuum Boosters

When considering braking systems, two popular types emerge, each with unique mechanisms and advantages. One system utilizes hydraulic pressure from the power steering, while the other relies on engine vacuum to amplify braking force. Understanding these distinctions is crucial for optimal performance and compatibility with various vehicle designs.

The hydraulic system generally offers quicker response times and better performance under high-stress conditions, such as towing or heavy loads. In contrast, the vacuum-operated variant tends to be simpler and more common in standard vehicles, making it easier to service and maintain.

Additionally, the installation requirements differ; the hydraulic option may necessitate more complex plumbing and integration with other systems, while the vacuum type is often more straightforward to install in traditional setups. These differences ultimately affect the driving experience, reliability, and maintenance needs of each braking system.

Maintenance Tips for Hydroboost Systems

Proper upkeep of the hydraulic assist system is crucial for optimal vehicle performance and safety. Regular checks can prevent issues that may arise from wear and tear or fluid contamination.

- Regularly inspect hydraulic fluid levels and top off as needed.

- Check for any leaks around connections and seals.

- Replace fluid according to the manufacturer’s recommended schedule to avoid degradation.

- Examine hoses and fittings for signs of wear or damage.

- Ensure that all connections are secure to prevent air intrusion.

By following these tips, you can help ensure that the system operates efficiently and reliably for years to come.

Hydroboost Installation Process Explained

This section outlines the process of installing a specific hydraulic assistance system, essential for enhancing braking efficiency in vehicles. Proper installation is crucial for optimal performance and safety, requiring attention to detail and adherence to guidelines.

Preparation Steps

Begin by gathering necessary tools and components. Ensure the vehicle is securely lifted and positioned to allow easy access to the assembly area. Disconnect the battery and drain the hydraulic fluid to prevent spills during the installation.

Installation Procedure

Next, remove the existing system, taking care to note the arrangement of components. Install the new assembly by following the reverse order, ensuring all connections are tight and leak-free. Refill the hydraulic fluid, bleed the system, and conduct thorough testing to confirm functionality.

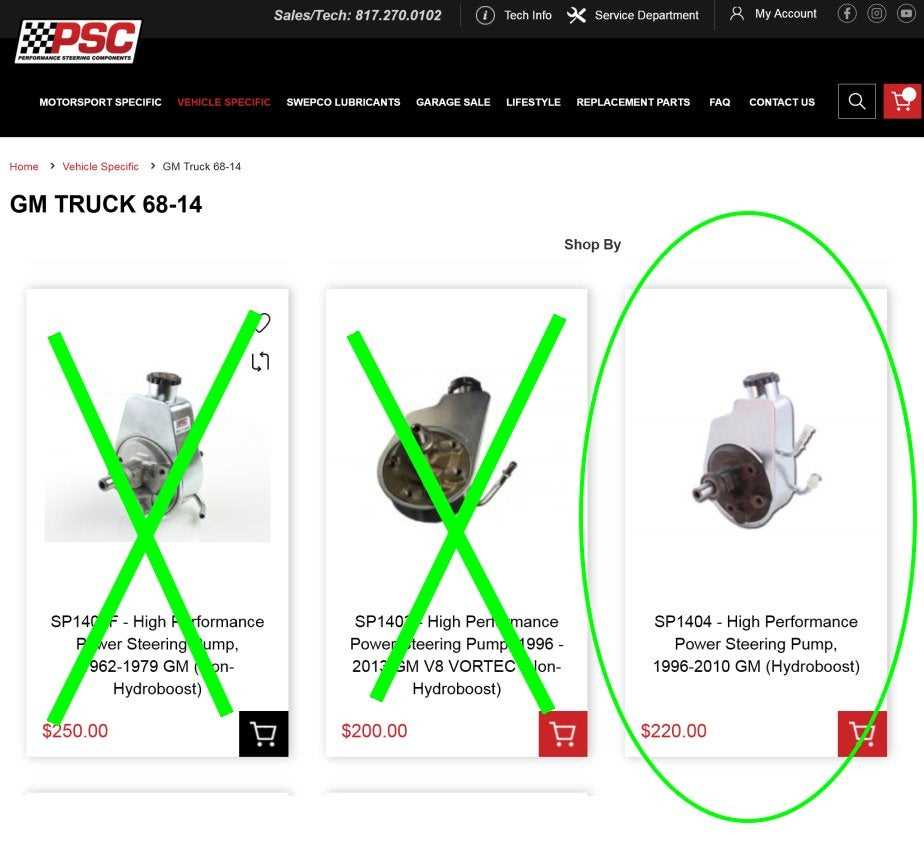

Choosing Quality Hydroboost Replacement Parts

When it comes to maintaining optimal performance in your vehicle’s braking system, selecting high-quality components is crucial. These elements play a vital role in ensuring reliability and efficiency during operation. Investing in durable alternatives can greatly enhance the overall driving experience and prolong the lifespan of your system.

First and foremost, consider sourcing replacements from reputable manufacturers known for their rigorous quality control standards. This not only guarantees the integrity of the components but also ensures compatibility with your vehicle’s specific requirements.

Additionally, research customer reviews and expert recommendations to gauge the performance and reliability of different options. Prioritizing quality over price can lead to better long-term value, preventing frequent replacements and potential safety hazards.

Lastly, ensure that any selected components come with a solid warranty, reflecting the manufacturer’s confidence in their product. This can provide peace of mind and protection against defects.

Hydroboost System Performance Enhancements

Enhancing the efficiency of a power-assisted braking mechanism can significantly improve vehicle performance. By focusing on various components and their interactions, one can achieve superior responsiveness and overall functionality.

- Upgrade fluid reservoirs to ensure optimal pressure and volume.

- Implement high-performance hoses for better fluid flow and reduced resistance.

- Consider advanced accumulator designs for enhanced energy storage and release.

Regular maintenance also plays a crucial role in sustaining performance. Ensure that all connections are secure and free from leaks.

- Inspect seals and gaskets regularly.

- Flush the system to remove contaminants.

- Monitor fluid levels and replace fluids as necessary.

By taking these steps, drivers can ultimately experience improved braking efficiency and vehicle control.

Resources for Hydroboost Diagrams and Manuals

Accessing comprehensive materials related to automotive booster systems can greatly enhance understanding and maintenance. These resources provide invaluable insights into the structure and functionality of these components, catering to both enthusiasts and professionals. Manuals and illustrations can facilitate troubleshooting and repairs, ensuring optimal performance of the vehicle.

Online forums and community websites often feature user-generated content that includes detailed guides and experiences. Additionally, manufacturer websites may offer official documentation, which is essential for accurate information. Utilizing these platforms allows for a deeper exploration of related technologies and applications.

Books and technical publications also serve as excellent references, often compiling extensive information and diagrams for better clarity. When looking for specific information, libraries and automotive shops can be beneficial as well, providing access to both historical and contemporary resources. Engaging with these materials will ultimately improve both knowledge and practical skills in managing these systems.