Understanding the intricate elements that contribute to the functionality of marine equipment is crucial for both maintenance and performance. Each component plays a pivotal role in ensuring seamless operation, enhancing safety and efficiency at sea.

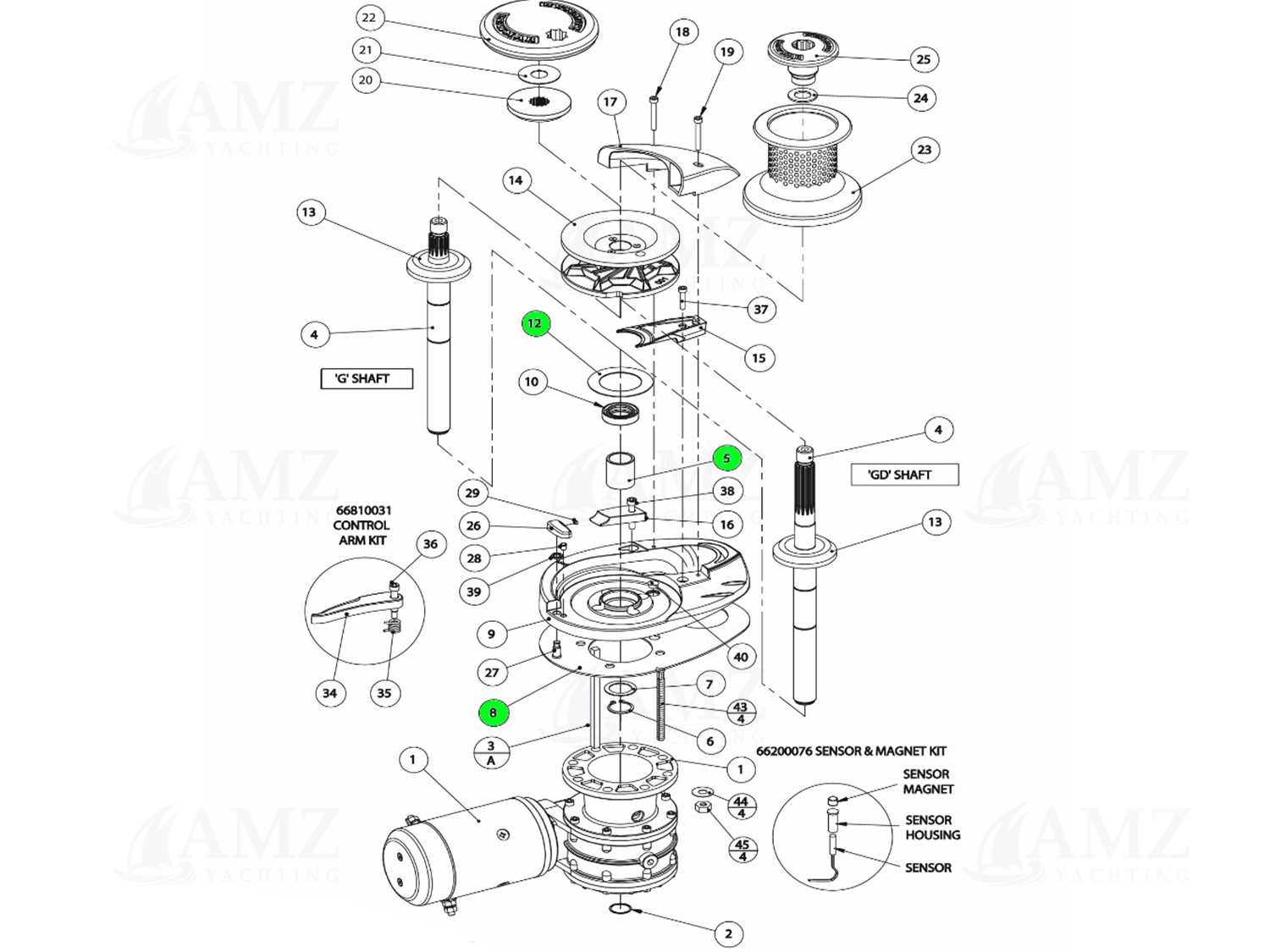

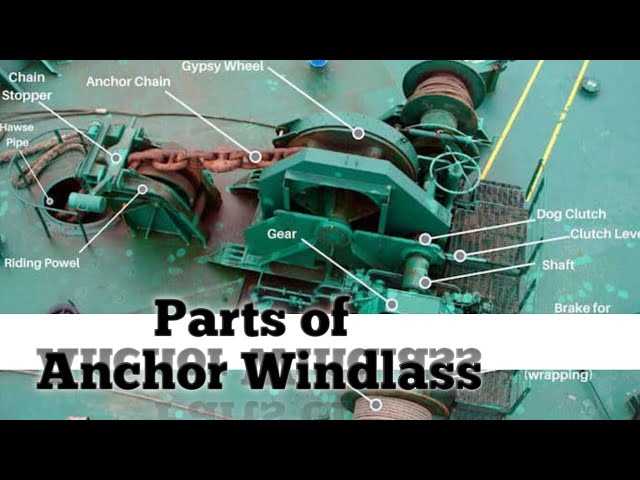

Visual representations serve as invaluable tools for those looking to grasp the layout and interconnections of these vital mechanisms. By analyzing these illustrations, one can better appreciate how each segment interacts within the system.

Exploring these representations allows enthusiasts and professionals alike to delve into the nuances of construction and design. This knowledge ultimately empowers individuals to make informed decisions regarding repairs and upgrades, leading to optimal performance.

Understanding Windlass Components

To fully grasp the functionality of anchoring mechanisms, it’s essential to explore their various elements. Each component plays a crucial role in ensuring efficient operation and reliability, enabling the seamless lifting and lowering of equipment.

Key Elements of the Mechanism

Among the primary features, the motor serves as the driving force, converting electrical energy into mechanical motion. Additionally, the gear system enhances torque, allowing for easier handling of heavy loads.

Importance of Maintenance

Regular upkeep of these components is vital for longevity and optimal performance. Inspecting wear and tear, as well as lubricating moving parts, ensures that the mechanism operates smoothly under various conditions. Neglecting these practices can lead to premature failure and costly repairs.

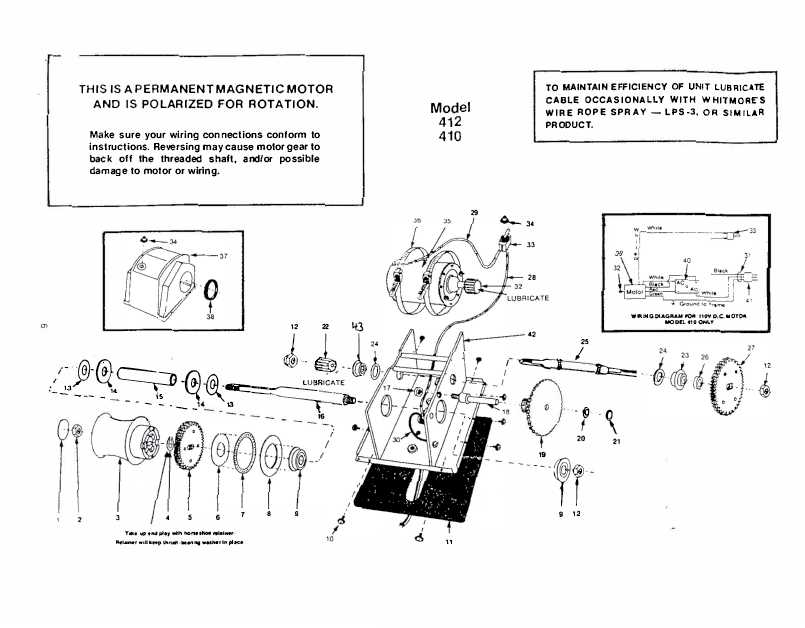

Importance of a Good Diagram

Having a clear visual representation is essential in any technical field. It aids in understanding complex systems, ensuring that users can effectively operate and maintain their equipment. A well-structured illustration serves not only as a guide but also enhances learning and efficiency.

Benefits of a detailed visual representation include:

- Improved comprehension of component functions.

- Facilitated troubleshooting by pinpointing specific elements.

- Enhanced communication among team members regarding system operations.

- Streamlined maintenance procedures, reducing downtime.

Furthermore, clear illustrations can:

- Assist in training new personnel by providing a visual aid.

- Minimize errors during assembly or repair tasks.

- Serve as a reference point for future modifications or upgrades.

In summary, an effective visual guide is invaluable for anyone involved in the operation or maintenance of mechanical systems, providing clarity and supporting optimal performance.

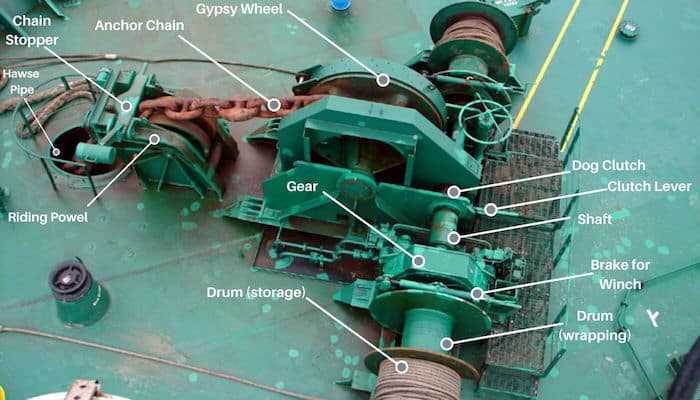

Identifying Key Windlass Parts

Understanding the essential components of a hoisting mechanism is crucial for efficient operation and maintenance. Each element plays a significant role in ensuring smooth functionality and reliability.

Main Components

- Drum: The cylindrical part that houses the cable.

- Motor: Provides the necessary power for operation.

- Gearbox: Converts motor speed into the required torque.

- Brake: Controls the descent of the load safely.

Support Elements

- Base: Offers stability and support to the entire assembly.

- Control System: Facilitates user interaction and operation commands.

- Chain or Rope: The lifting medium that connects to the load.

Common Materials Used in Windlasses

Understanding the various substances utilized in marine machinery is essential for ensuring durability and functionality. Different materials are chosen for their unique properties, which contribute to the overall performance and longevity of these essential components.

Metals

Steel is widely favored due to its strength and resistance to wear. Additionally, stainless steel is preferred for its corrosion resistance, making it suitable for harsh marine environments.

Composites

Fiberglass and other composite materials are often employed for their lightweight nature and resistance to environmental degradation. These materials enhance performance while reducing overall weight, crucial for efficient operation.

Maintenance Tips for Windlass Systems

Ensuring the longevity and efficiency of your anchoring mechanism requires regular upkeep and attention. By following specific maintenance practices, you can enhance performance and prevent unexpected breakdowns during critical moments.

Regular Inspections

Frequent checks of all components are essential. Look for signs of wear, corrosion, or damage. Pay particular attention to the gears and cables, as these are critical for functionality.

Lubrication and Cleaning

Keep moving parts well-lubricated to reduce friction and wear. Regularly clean the system to remove debris and salt buildup, which can lead to rust and inefficiency. Use appropriate cleaning agents to protect the materials.

How Diagrams Aid in Repairs

Visual representations play a crucial role in facilitating the repair process across various fields. They serve as essential tools that provide clarity and understanding, making complex systems more manageable for technicians and DIY enthusiasts alike. By breaking down intricate structures into comprehensible segments, these illustrations enhance the efficiency of troubleshooting and maintenance.

Firstly, having a clear visual reference simplifies the identification of components and their functions. Technicians can quickly locate specific elements, reducing the time spent searching and increasing overall productivity. Furthermore, these visuals often highlight potential issues and common failure points, allowing for proactive measures to be taken.

Secondly, these graphical guides promote accuracy during repairs. By following a systematic approach outlined in the illustrations, individuals can ensure that each step is executed correctly. This reduces the risk of errors that could lead to further complications or damage.

Finally, visual aids foster a deeper understanding of the systems being worked on. They encourage a learning environment where individuals can familiarize themselves with various mechanisms, thus enhancing their skill set for future projects. Overall, the integration of these tools into repair practices significantly contributes to more effective and informed work processes.

Types of Windlass Configurations

Various arrangements exist for anchoring mechanisms, each tailored to meet specific operational needs and vessel designs. Understanding these configurations is essential for selecting the right setup for maritime activities.

Common Configurations

- Vertical Arrangement: This type is characterized by a straight up-and-down axis, ideal for compact spaces.

- Horizontal Arrangement: Featuring a side-by-side layout, this configuration is often used for larger vessels, allowing for easier access and operation.

- Dual Drum: Utilizes two drums for enhanced versatility, accommodating multiple anchor lines or varying weights.

Specialized Configurations

- Electric Systems: These setups offer automated control, improving efficiency and reducing manual labor.

- Manual Systems: Often favored for simplicity and reliability, they require physical effort for operation.

- Hybrid Configurations: Combining elements of both electric and manual, these systems provide flexibility for different scenarios.

Each configuration presents unique advantages, making it crucial to consider the specific requirements of the vessel and its intended use when selecting an anchoring system.

Choosing the Right Windlass Parts

Selecting the appropriate components for your anchoring system is crucial for optimal performance and reliability. Each element plays a significant role in ensuring smooth operation and safety during marine activities.

Understand Your Needs: Assess the specific requirements of your vessel, including size, weight, and typical usage conditions. This will help you identify the necessary specifications for your components.

Material Selection: Opt for materials that offer durability and resistance to corrosion, especially if you frequently sail in harsh environments. Stainless steel and aluminum are popular choices due to their strength and longevity.

Compatibility: Ensure that each component is compatible with one another. Mismatched elements can lead to inefficiencies and increase the risk of failure.

Consult Experts: When in doubt, seek advice from professionals who can provide insights and recommendations tailored to your specific situation. This will ultimately enhance the reliability of your anchoring setup.

Safety Considerations with Windlasses

Ensuring safety during the operation of anchoring equipment is paramount. Proper awareness and precautions can significantly reduce risks associated with the use of mechanical lifting devices. This section outlines essential safety practices to enhance operational safety and protect personnel on board.

Personal Protective Equipment

Utilizing appropriate personal protective gear is vital for operators and crew members. This includes hard hats, gloves, and non-slip footwear, which help minimize injury risks during handling and operation. Regular inspection of the gear is also necessary to ensure its effectiveness.

Operational Guidelines

Following established protocols is crucial for safe operation. Operators should be thoroughly trained and familiar with equipment features and emergency procedures. Additionally, regular maintenance and inspections are necessary to identify any wear or damage that could compromise safety.

| Safety Practice | Description |

|---|---|

| Training | Ensure all personnel are trained in operation and safety protocols. |

| Inspections | Conduct routine checks for wear and tear on equipment. |

| PPE Usage | Mandate the use of protective gear to minimize injury risk. |

| Emergency Protocols | Establish clear procedures for emergency situations. |

Common Issues and Solutions

When operating marine equipment, various challenges may arise that can hinder performance and efficiency. Understanding these common problems and their respective solutions is crucial for maintaining optimal functionality and ensuring safety on the water.

Frequent Problems

- Inconsistent operation due to electrical issues

- Wear and tear on mechanical components

- Corrosion affecting metal parts

- Overheating of the motor

- Jamming of the retrieval mechanism

Effective Solutions

- Regularly inspect and maintain electrical connections to prevent disruptions.

- Replace worn components promptly to avoid further damage.

- Apply anti-corrosive treatments to metal surfaces and store equipment in a dry environment.

- Ensure proper ventilation and cooling for the motor to prevent overheating.

- Lubricate moving parts and check alignment to minimize jamming.

Upgrading Your Windlass System

Enhancing your anchoring mechanism can significantly improve your boating experience, offering better efficiency and reliability. Whether you are looking to increase pulling power or enhance durability, investing in modern components can yield substantial benefits.

Assessing Your Current Setup

Before making any changes, evaluate your existing configuration. Identify any weaknesses or areas that could be improved. Consider factors such as weight capacity, material wear, and mechanical performance. This assessment will guide you in selecting appropriate upgrades.

Choosing the Right Enhancements

When selecting new components, prioritize quality and compatibility. Look for materials that resist corrosion and wear, ensuring longevity. Upgrading to a more advanced motor or a higher-grade control system can also enhance performance. Consult with experts to ensure that your choices align with your vessel’s requirements.

By thoughtfully upgrading your anchoring system, you can achieve greater peace of mind and enhanced functionality during your voyages.

Where to Find Quality Diagrams

Locating high-quality illustrations can significantly enhance your understanding of mechanical systems. Various resources offer detailed representations, aiding both novices and experienced users in comprehending complex designs.

Online Resources

- Manufacturer Websites: Often provide official schematics.

- Marine Supply Stores: Stock technical guides and manuals.

- DIY Forums: Community members share valuable insights and diagrams.

Books and Manuals

- Technical Reference Books: Comprehensive resources on equipment.

- Service Manuals: Offer in-depth visuals and assembly instructions.

- Industry Journals: Publish articles featuring detailed illustrations.