Understanding the various elements that make up a heating and cooling system is crucial for maintaining efficient operation. Each component works in harmony to provide a comfortable indoor environment, ensuring temperature control and energy efficiency throughout the home or building.

The intricate network of these systems includes several key units that manage airflow, combustion, and ventilation. Regular inspection and proper care of these elements can prevent breakdowns, ensuring longevity and reliable performance.

In this section, we will explore the critical elements involved in these systems, highlighting their functions and how they contribute to overall performance. This knowledge is essential for anyone looking to better understand the workings of such systems and maintain their durability.

Goodman GMS90904CXA Overview

This high-efficiency heating system is designed to deliver reliable warmth for residential spaces. Engineered with advanced technology, it offers energy-efficient operation, ensuring comfort while helping to reduce energy consumption. The unit’s features focus on optimizing performance and durability, making it a suitable choice for long-term use.

Durability is one of the key aspects, with the system built to withstand harsh conditions and operate efficiently year-round. Its construction minimizes wear and tear, offering homeowners peace of mind through dependable service.

Energy savings are also a priority, with this system offering impressive energy performance ratings, which help to keep utility bills in check while maintaining a comfortable indoor climate.

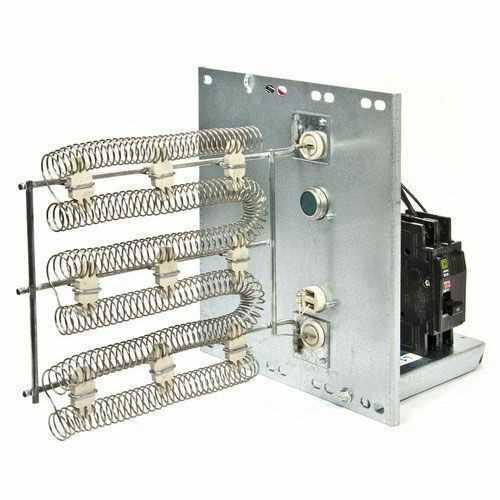

Key Components of the Furnace

Understanding the essential elements of a heating system helps to ensure proper maintenance and operation. Each part plays a critical role in providing warmth and comfort during colder months. By recognizing these vital components, it becomes easier to diagnose potential issues and maintain efficiency.

Heat Exchanger: This crucial element transfers heat from the burner to the air that circulates through your home. It ensures that combustion gases remain separated from the airflow, maintaining safety and efficiency.

Burners: These are responsible for igniting the fuel and producing the heat required to warm the air. Proper function of the burners is essential for effective heating performance.

Blower Motor: The blower motor pushes air through the ductwork, distributing warmed air throughout the building. A well-functioning blower is key to maintaining even heating.

Control Board: Acting as

Heat Exchanger Functions and Maintenance

The heat exchanger plays a crucial role in transferring thermal energy between two mediums without mixing them. This process ensures efficient temperature regulation within a system, allowing for optimal performance and comfort.

Functions of the Heat Exchanger

The primary function of the heat exchanger is to extract warmth from the fuel combustion process and transfer it to the air that circulates through the system. This mechanism ensures that the system operates efficiently, minimizing energy waste while maintaining desired indoor conditions.

Maintenance for Long-Term Performance

Regular upkeep of the heat exchanger is essential to ensure its longevity and efficiency. Proper cleaning of the surfaces, inspection for cracks or corrosion, and ensuring unrestricted airflow are key practices. Scheduling professional inspections

Ignition System Parts Explained

The ignition system is a crucial component of any heating unit, ensuring that the combustion process starts efficiently and safely. Understanding how these elements work together helps in diagnosing issues and maintaining optimal performance. The system is composed of several interconnected elements, each playing a vital role in igniting the fuel and sustaining the flame.

Igniter: This is the part responsible for generating the initial spark or heat to ignite the fuel. Depending on the type of ignition used, it can be either a hot surface or a spark-based igniter.

Flame Sensor: Once the flame is established, the flame sensor detects its presence. This safety feature ensures that the burner is properly lit and prevents fuel from flowing if no flame is detected.

Control Board: The control board orchestrates the timing and sequence of the ignition process. It

Blower Motor Role in Operation

The blower motor plays a crucial role in the overall functionality of heating and cooling systems by ensuring proper airflow throughout the system. Its primary function is to circulate air through the ventilation system, ensuring that warm or cool air reaches the designated areas efficiently. Without the motor, air distribution would be compromised, leading to uneven temperatures and reduced system performance.

Air Circulation Process

Once the system begins its heating or cooling cycle, the blower motor activates, pushing air through the ducts and into the living spaces. This process ensures that the conditioned air is evenly distributed, maintaining comfort in the environment. The speed of the motor can adjust depending on the required airflow, enhancing the system’s efficiency and responsiveness.

Impact on System Efficiency

A well-functioning blower motor helps to optimize energy usage by maintaining consistent airflow. If the motor is faulty or underperforming, the system may need to work harder to reach desired temperatures, resulting in increased energy consumption and wear on other components. Regular maintenance

How the Draft Inducer Works

The draft inducer is a crucial component in heating systems, designed to enhance the airflow and ensure efficient combustion. Its primary function is to create a draft that facilitates the expulsion of exhaust gases, promoting safe operation and optimal performance of the heating appliance.

Functionality of the Draft Inducer

This device operates by utilizing a motor-driven fan that generates a negative pressure within the flue system. As the fan spins, it draws air from the combustion chamber and pushes it out through the venting system. This action not only helps in removing harmful gases but also maintains proper air supply for combustion.

Importance of Proper Operation

Ensuring the draft inducer operates correctly is vital for safety and efficiency. A malfunctioning inducer can lead to improper venting, which may cause backdrafts or even hazardous situations. Regular maintenance and monitoring are essential to prevent issues and maintain the longevity of the heating system.

Control Board: Purpose and Functions

The control board serves as the brain of HVAC systems, orchestrating various components to ensure optimal performance and efficiency. It plays a vital role in regulating operations, facilitating communication between different elements, and ensuring that the system runs smoothly.

Key Responsibilities

- System Monitoring: Continuously assesses the functionality of the heating and cooling processes.

- Temperature Regulation: Maintains the desired temperature by adjusting the operation of the unit.

- Safety Features: Detects any potential malfunctions or unsafe conditions, shutting down the system if necessary.

- Communication: Acts as a communication hub between sensors, thermostats, and other components.

Functional Components

- Relays: Switch the power supply to different parts of the system based on commands from the control board.

- Sensors: Provide real-time data on temperature and pressure, allowing the control board to make informed decisions.

- Microcontroller: Processes inputs and outputs, executing programmed functions to regulate system behavior.

- Indicators: Display system status and any error codes, aiding in troubleshooting and maintenance.

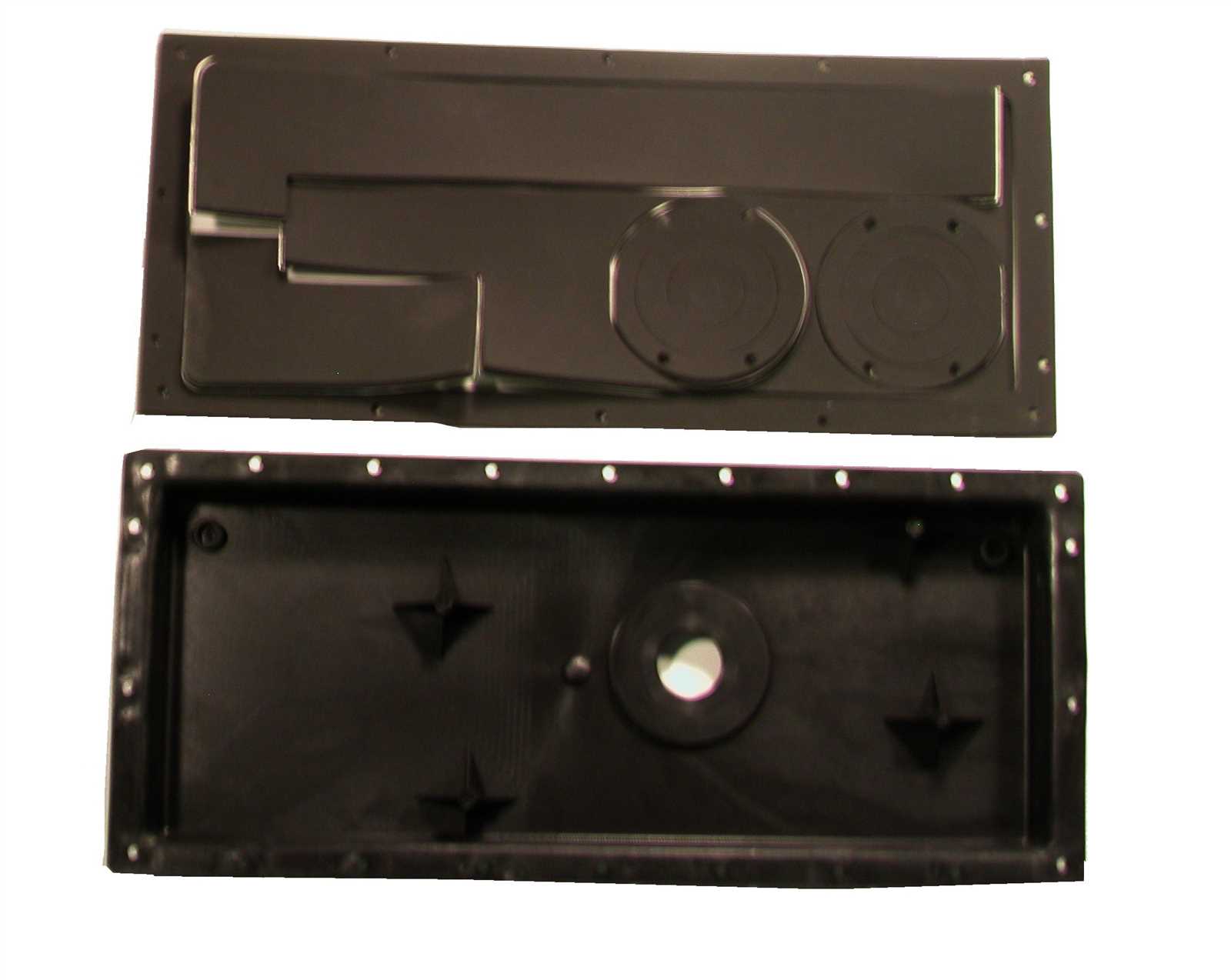

Filter Assembly and Proper Care

Maintaining optimal performance of heating and cooling systems requires attention to the assembly and upkeep of the filtration system. Properly managing this component ensures not only efficiency but also enhances the longevity of the entire unit. Understanding how to care for the filter assembly is crucial for anyone looking to maintain a comfortable indoor environment.

Understanding the Filter Assembly

The filter assembly is designed to trap dust, allergens, and other particles, preventing them from circulating throughout your space. A well-functioning filter supports the overall health of the system and improves air quality. Here are key aspects to consider:

- Types of Filters: Different systems use various filters, including HEPA, pleated, and washable filters.

- Filter Size: Ensure the filter fits snugly within the assembly to avoid bypassing unfiltered air.

- Replacement Frequency: Regularly check and replace filters according to manufacturer recommendations.

Care Tips for Optimal Performance

- Check Filters Monthly: Inspect filters every month to determine if they need cleaning or replacement.

- Clean Washable Filters: If applicable, clean washable filters regularly using mild soap and water, and allow them to dry completely.

- Keep the Surrounding Area Clean: Dust and debris around the filter can impact its efficiency, so maintain cleanliness in that area.

By implementing these practices, you can enhance the performance and lifespan of your heating and cooling system while ensuring a healthy indoor atmosphere.

Understanding the Gas Valve Mechanism

The gas valve is a critical component in controlling the flow of gas within heating systems. Its primary function is to regulate gas supply to the burner, ensuring efficient operation and safety. Understanding how this mechanism works is essential for troubleshooting and maintenance.

The gas valve operates through a series of interconnected parts that work together to manage gas flow. When the thermostat signals a need for heat, the valve opens, allowing gas to flow to the burner. Various safety features are in place to prevent malfunctions and ensure that gas is only supplied when required.

| Component | Description |

|---|---|

| Diaphragm | Responsive element that controls the opening and closing of the valve. |

| Gas Pressure Regulator | Maintains consistent gas pressure for safe operation. |

| Inlet and Outlet Ports | Allow gas to enter and exit the valve, connecting it to the gas supply and burner. |

| Electrical Connections | Facilitate communication with the thermostat and ignition system. |

Pressure Switch Significance in Performance

The pressure switch plays a critical role in the efficiency and reliability of HVAC systems. This component is essential for monitoring and regulating the pressure levels within the system, ensuring optimal operation. Its functionality directly impacts performance, safety, and energy consumption, making it a key element in maintaining the overall effectiveness of heating and cooling equipment.

Functionality and Importance

The primary function of a pressure switch is to detect changes in system pressure and respond accordingly. By opening or closing electrical contacts, it can initiate or halt the operation of various components, such as compressors or blowers. This responsiveness is vital in preventing potential issues such as overheating or system failure.

Impact on Energy Efficiency

Properly functioning pressure switches contribute significantly to the energy efficiency of HVAC systems. By maintaining optimal pressure levels, they help reduce energy waste and lower operational costs. Regular maintenance and timely replacement of malfunctioning switches are essential for ensuring that the system operates within its designed parameters.

| Benefits of a Pressure Switch | Potential Issues if Malfunctioning |

|---|---|

| Enhances system reliability | Risk of overheating |

| Improves energy efficiency | Increased energy costs |

| Ensures safety mechanisms | Possible system failure |

Wiring Diagram for Goodman GMS90904CXA

This section provides an overview of the electrical connections required for optimal functioning of the heating system. Understanding these connections is essential for installation, troubleshooting, and maintenance tasks. Proper wiring ensures efficiency and safety in operation.

Key components involved in the wiring setup include:

- Power supply connections

- Thermostat wiring

- Blower motor connections

- Control board terminals

Follow these general steps when wiring the system:

- Ensure all power sources are turned off to prevent electrical shock.

- Connect the power supply to the designated terminals on the control board.

- Wire the thermostat according to the manufacturer’s specifications.

- Connect the blower motor wires to the appropriate terminals.

- Double-check all connections for accuracy and security.

It is crucial to refer to the specific guidelines provided by the manufacturer to avoid any mishaps during installation. For complex issues or uncertainties, consulting a qualified technician is recommended.

Steps for Replacing Furnace Parts

When it comes to maintaining heating systems, knowing how to effectively replace components is essential for ensuring optimal performance and longevity. This process can involve several key actions that facilitate the smooth exchange of malfunctioning elements with new ones, ultimately leading to improved efficiency and safety.

1. Gather Necessary Tools and Materials: Before starting, ensure you have all the required tools, such as screwdrivers, wrenches, and replacement elements. Having everything at hand will make the process more efficient.

2. Turn Off the Power: Always begin by disconnecting the power supply to the heating unit. This precaution is vital to prevent electrical shock and ensure safety during the replacement process.

3. Remove the Access Panel: Locate and take off the access cover of the heating device. This will give you visibility into the interior, allowing you to identify which components need to be replaced.

4. Disconnect Old Components: Carefully detach the faulty items. Make note of how they are connected to ensure correct installation of the new ones. Labeling connections can be beneficial for this step.

5. Install New Elements: Position the new components into place, making sure they fit securely and align properly with the existing connections. Following the manufacturer’s instructions during this step is crucial for proper installation.

6. Reattach the Access Panel: Once the new elements are in place, replace the access cover. Ensure that it is fastened securely to prevent any operational issues.

7. Restore Power and Test: Finally, turn the power back on and check the functionality of the system. Monitor for any unusual sounds or issues, ensuring everything operates smoothly.