The intricate arrangement of elements within various appliances is essential to their operation. Understanding how different pieces work together can provide valuable insights, especially when trying to resolve issues or enhance performance. This section is dedicated to unraveling these connections, shedding light on how internal configurations contribute to overall functionality.

By taking a closer look at the internal framework, we can uncover the relationships between different elements, allowing for a deeper understanding of their roles. From power regulation to cooling systems, each piece plays a significant part in the seamless operation of the whole. This overview aims to guide you through the complexity, highlighting key aspects of the internal arrangement.

With careful examination, it becomes easier to identify common issues and optimize the efficiency of the system. This knowledge not only helps in maintaining the functionality of your device but also aids in future improvements and modifications, ensuring long-term reliability.

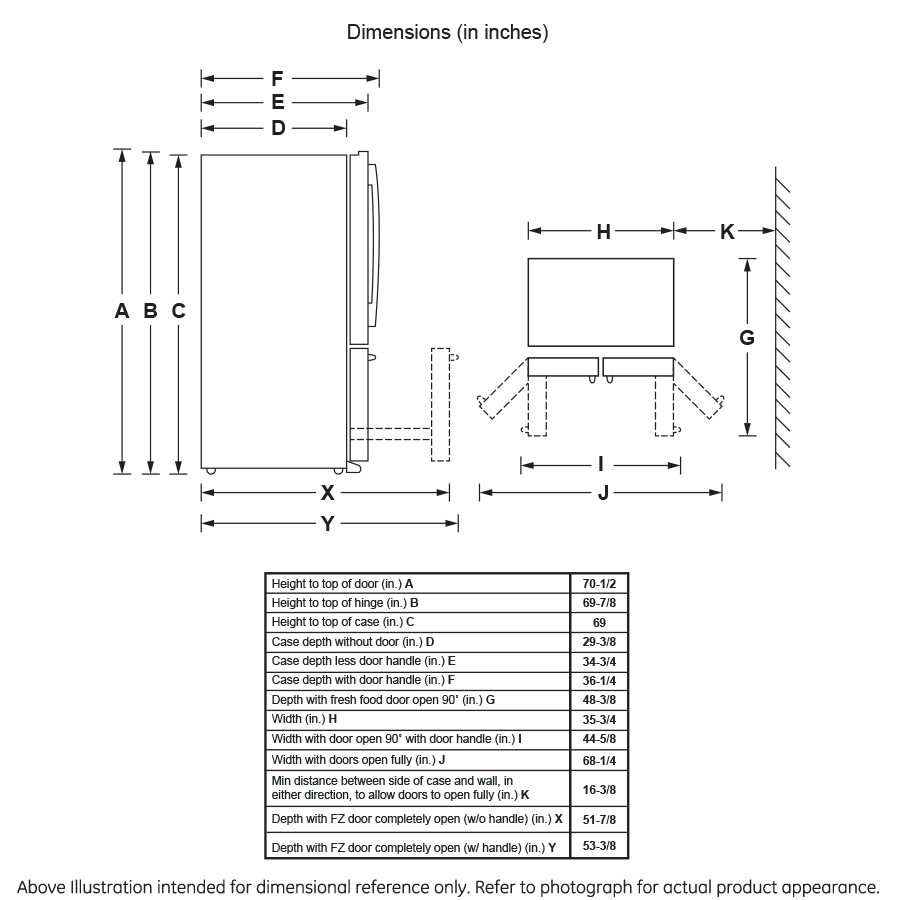

Understanding Key Components of GRFS2853AF

Exploring the essential elements of this system reveals a complex arrangement designed to ensure optimal functionality. Each component plays a crucial role in maintaining the overall performance, and a clear understanding of their relationships helps in troubleshooting and maintenance tasks.

Core Functional Units

The system is made up of several key units that work together harmoniously. These units are responsible for different tasks, from regulating internal processes to ensuring smooth operation. Knowing how each unit operates can provide valuable insights into potential improvements and optimizations.

Operational Interactions

Each component interacts with others through carefully designed mechanisms. These interactions are crucial to achieving the desired performance, and any disruption in these connections can lead to inefficiencies. Regular checks and adjustments are important to ensure that everything functions as intended.

| Component | Function | Maintenance Tips |

|---|---|---|

| Main Control Unit | Regulates overall system activity | Inspect regularly for signs of wear |

| Temperature Regulator | Ensures consistent internal climate | Clean and calibrate periodically |

| Flow Controller | Maintains steady circulation | Monitor for blockages or irregularities |

Detailed Breakdown of Internal Parts

Understanding the various components that make up this system provides a clear insight into how each element contributes to its overall functionality. This section offers a closer look at the intricate pieces that work together to ensure seamless operation. By examining the inner mechanisms, one can appreciate how each piece fits into the larger framework, contributing to the unit’s performance and reliability.

One of the key features of this exploration is recognizing how the internal elements are meticulously arranged. Each unit serves a distinct role, whether in managing the flow of energy, controlling movement, or maintaining temperature. These pieces, though varied in function, are all essential to the system’s integrity.

A thorough understanding of these components can lead to better maintenance practices and more informed decisions when it comes to repairs or upgrades. Whether you’re looking to enhance efficiency or simply keep everything running smoothly, knowing how these elements interact is crucial.

How Cooling Elements Work Together

The cooling system relies on various components that collaborate to maintain an optimal temperature. Each part serves a specific function, ensuring that the entire system operates efficiently and consistently. Understanding the interaction between these elements can offer insights into how the process remains effective under different conditions.

Airflow Management plays a crucial role in maintaining steady cooling. Air is directed through different channels, each designed to maximize efficiency. This helps dissipate heat, ensuring that internal components remain at safe operating levels.

Temperature regulation is another key factor. Specialized components monitor and adjust the cooling process, responding to changes in the system’s environment. This dynamic process helps to prevent overheating and ensures consistent performance.

These elements form a cohesive network, working together seamlessly to maintain a balanced and controlled environment. Their combined efforts ensure that the system operates reliably, even during periods of high demand.

Common Replacement Components and Their Functions

Understanding the essential elements that often require renewal in household appliances is key to maintaining their longevity. Each element plays a specific role in ensuring the overall system operates smoothly and efficiently. By identifying which components are most likely to wear out over time, owners can anticipate future needs and ensure their device remains in optimal condition.

Cooling Unit: This element is critical for temperature regulation. Its performance ensures that internal systems stay within the necessary range to function properly, preventing overheating or freezing.

Thermostatic Sensor: Responsible for monitoring the temperature, this sensor sends signals to the control unit, enabling accurate adjustments to the cooling mechanism.

Fan Motor: This component aids in circulating air to ensure even distribution of temperature, helping avoid localized overheating and promoting consistent cooling.

Sealing Gasket: Ensuring a tight closure, the gasket prevents air leakage, which is crucial for maintaining the proper internal environment and energy efficiency.

Water Filtration Unit: For devices that involve water usage, this unit removes impurities, enhancing the quality and safety of water output.

Regular inspection and timely replacement of these key elements can significantly extend the lifespan of the equipment while preventing potential malfunctions.

Electrical Connections and Their Role

Electrical connections form the backbone of any complex system, ensuring that various components can communicate and function together. Without proper connectivity, even the most advanced technologies would fail to operate efficiently. Understanding how these connections work and the role they play is crucial for anyone dealing with electronic systems.

- Signal Transmission: One of the primary roles of these connections is to enable the transfer of data and commands between different modules. Whether it’s a sensor relaying information or a control unit issuing directives, the connections ensure a smooth flow of communication.

- Power Distribution: Electrical links are also responsible for delivering the necessary power to various parts of the system. A well-designed network ensures that every element receives the correct voltage and current to function optimally.

- Stability and Safety: Reliable connections are essential for maintaining system stability and safety. Poor connections can lead to failures, short circuits, or other hazards, making proper setup and maintenance a priority.

By understanding the intricacies of these connections, you can optimize system performance and prevent potential issues that may arise from misconfigurations or malfunctions.

Exploring the Door Mechanism Assembly

Understanding how the door mechanism operates is crucial for ensuring smooth functionality and long-term durability. The assembly involves a series of interconnected components working together to provide seamless movement and secure closure. Each element has a distinct role, contributing to the overall performance and reliability of the system.

The hinges serve as the primary pivot points, enabling the door to swing open and close with ease. Proper alignment of these elements is essential to avoid any friction or wear that could affect the mechanism over time.

Another important aspect is the latching system, which ensures the door stays securely closed when not in use. This part must be kept in optimal condition to prevent issues like accidental openings or loose closures.

Finally, regular maintenance of the assembly, such as checking for loose screws and ensuring all parts move fluidly, can help prolong the lifespan of the mechanism and maintain its efficiency.

Insights into the Refrigerant System

The refrigerant system is a vital component in maintaining an optimal cooling environment. Understanding its core elements and functions allows for improved performance and troubleshooting in cooling devices. This section provides a clear overview of how the refrigerant circulates, transfers heat, and maintains the efficiency of the cooling cycle.

Key Components

- Compressor: Responsible for pressurizing the refrigerant, which increases its temperature as it moves through the system.

- Condenser: Facilitates the cooling of the refrigerant by releasing heat, causing the refrigerant to change from gas to liquid form.

- Expansion Valve: Regulates the flow of refrigerant into the evaporator, reducing its pressure and temperature.

- Evaporator: Absorbs heat from the surrounding air, allowing the refrigerant to evaporate and cool the system.

Refrigerant Flow and Efficiency

- High-pressure gas exits the compressor and moves into the condenser, where it dissipates heat.

- As the refrigerant cools, it becomes a liquid and travels to the expansion valve.

- The expansion valve reduces the pressure, cooling the liquid, which then enters the evaporator.

- In the evaporator, the refrigerant absorbs heat, converting back into a gas and completing the cycle.

Identifying Key Sensors and Their Purpose

The efficient functioning of modern systems relies heavily on a network of interconnected components, each playing a specific role in maintaining optimal performance. Among these, various detectors are responsible for monitoring critical parameters, ensuring the overall system runs smoothly and efficiently.

Understanding the functionality of these detectors can help with troubleshooting and enhancing performance. Below are some of the essential sensors and their primary roles:

- Temperature Sensor: Monitors heat levels to prevent overheating and ensures stability within safe operating limits.

- Pressure Sensor: Detects changes in force, safeguarding the system by triggering adjustments when necessary.

- Flow Sensor: Measures the movement of fluids or air, ensuring proper circulation and identifying potential blockages.

- Humidity Sensor: Tracks moisture levels, protecting sensitive components from condensation or excessive dryness.

- Proximity Sensor: Detects the presence or absence of nearby objects, helping with alignment and positioning.

By recognizing the role of each detector, it becomes easier to identify potential issues and ensure the system operates at peak efficiency.

Understanding the Control Panel Layout

The arrangement of controls on the panel plays a crucial role in the user experience, providing intuitive access to essential functions. A well-designed layout ensures that operators can quickly and efficiently navigate through various settings and features without confusion.

Every element on the control interface is strategically positioned to facilitate ease of use. Labels accompanying buttons and switches guide users in selecting the appropriate options. Color coding and symbolization further enhance recognition, making it easier to distinguish between different functionalities at a glance.

Incorporating a logical grouping of controls allows for smoother interactions. For instance, related functions might be clustered together, enabling quick adjustments without the need to search through unrelated features. Feedback mechanisms, such as visual indicators or auditory signals, can also aid in confirming user inputs, ensuring that commands are executed as intended.

Ultimately, understanding the layout of the control panel is essential for maximizing efficiency and minimizing errors. Familiarity with its design empowers users to harness the full potential of the system, enhancing overall performance and satisfaction.

The Importance of Seals and Insulation

In any mechanical assembly, the role of seals and insulation cannot be overstated. These components are essential for maintaining efficiency and functionality within a system. They work to prevent unwanted leaks and protect against environmental factors, ensuring the longevity and reliability of the machinery.

Seals play a critical role in safeguarding various internal mechanisms from contaminants and fluid loss. They create a barrier that minimizes the risk of leakage, which can lead to significant performance issues. Proper sealing is vital for achieving optimal pressure and temperature control, thereby enhancing the overall operational efficiency.

Insulation, on the other hand, serves to protect sensitive parts from heat and cold, thereby maintaining the desired operating conditions. By reducing thermal transfer, insulation helps to prevent energy loss and promotes energy efficiency. This is particularly important in systems where temperature fluctuations can adversely affect performance and safety.

Together, seals and insulation contribute significantly to the reliability of machinery, ensuring that systems operate smoothly under varying conditions. Investing in high-quality sealing and insulating materials can lead to improved performance, reduced maintenance costs, and a longer lifespan for mechanical systems.

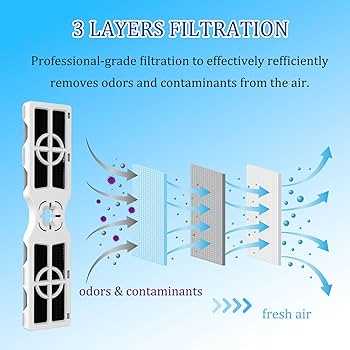

Air Circulation System: Key Features

The air circulation mechanism plays a crucial role in maintaining optimal environmental conditions within a system. Its design focuses on enhancing airflow, ensuring efficiency and reliability in performance.

One of the primary attributes of this mechanism is its ability to regulate temperature effectively. By facilitating consistent air movement, it helps to dissipate heat generated during operation, preventing overheating and prolonging the lifespan of components. Moreover, this system often incorporates advanced filtering elements to remove impurities from the air, contributing to a cleaner operational environment.

Furthermore, the configuration typically allows for adjustable airflow, giving users the flexibility to customize the system according to specific requirements. This adaptability is essential for various applications, whether in residential, commercial, or industrial settings. Overall, a well-designed air circulation system significantly enhances the overall functionality and efficiency of the unit.

Role of Compressors in Temperature Regulation

Compressors play a vital role in managing thermal conditions within various systems. By facilitating the movement and transformation of refrigerants, they ensure optimal performance and efficiency in temperature control. These devices are essential for maintaining desired climate levels, whether in refrigeration units or HVAC systems, contributing to overall comfort and safety.

Functionality and Operation

The primary function of compressors is to increase the pressure of refrigerants, allowing them to absorb heat from the environment. This process is crucial for effective cooling, as it enables the refrigerant to transition from a gas to a liquid state, facilitating heat exchange. The cyclical nature of this operation ensures that systems can maintain steady temperatures over time.

Types of Compressors

Various types of compressors are employed in temperature regulation, each designed to meet specific needs and requirements. The following table highlights some common types along with their characteristics:

| Type | Description |

|---|---|

| Reciprocating | Utilizes pistons to compress the refrigerant, offering high efficiency and reliability. |

| Rotary | Employs rotating elements to compress refrigerant, known for its compact design and quiet operation. |

| Centrifugal | Uses centrifugal force to compress refrigerant, ideal for large-scale applications requiring high flow rates. |

Maintaining the Water Filtration System

Ensuring the optimal performance of your water purification setup is essential for delivering clean and safe drinking water. Regular upkeep not only extends the lifespan of the system but also enhances its efficiency. This section outlines key practices to maintain your filtration apparatus effectively.

Here are some important maintenance tasks to consider:

- Regular Inspections: Check the system frequently for any signs of wear or damage. Look for leaks, cracks, or any abnormal sounds during operation.

- Filter Replacement: Adhere to the recommended schedule for changing filters. Old or clogged filters can compromise water quality.

- Cleaning Components: Clean the various parts of the system, such as tanks and housings, to prevent buildup and contamination.

- Monitor Water Quality: Conduct routine tests of the filtered water to ensure it meets safety standards and remains free from impurities.

- Professional Servicing: Consider scheduling periodic professional maintenance to thoroughly assess the system and perform any necessary repairs.

By implementing these practices, you can ensure that your water filtration setup operates at its best, providing you and your family with reliable access to purified water.