In the world of household appliances, having a clear understanding of how various elements are connected and function together can make maintenance and repairs much more manageable. By examining the internal arrangement, users can gain valuable insights into the relationships between different elements, allowing for more efficient troubleshooting and upkeep.

The following guide provides a comprehensive overview of the structure within this particular model, focusing on key sections and their roles. Exploring how these elements interact will help identify potential areas for improvement or replacement, ensuring a longer lifespan and optimal performance of your device.

Through a detailed examination of individual segments, you’ll better understand how each part contributes to the overall functionality. This knowledge not only enhances your ability to maintain your appliance but also empowers you to address potential issues with greater confidence.

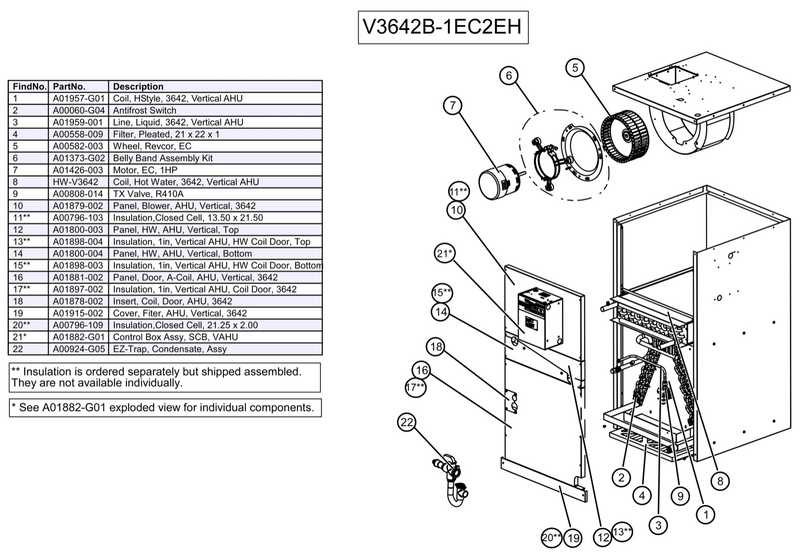

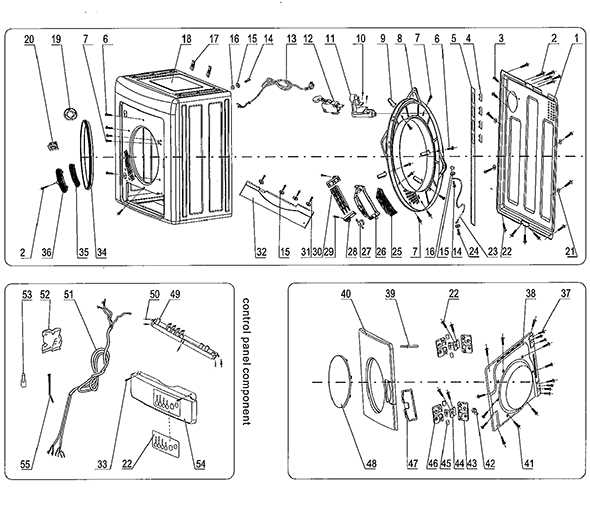

Exploring Components of Haier RWT360BW

Understanding the internal structure of this model allows users to gain deeper insights into its functionality and overall performance. Each part plays a crucial role in ensuring smooth operation and long-lasting efficiency. By exploring these elements, one can better appreciate how they work together to deliver the desired results.

The core mechanical sections are responsible for the essential movements and processes, while electronic elements manage control and coordination. Together, these systems create a harmonious balance between precision and power, resulting in reliable and efficient performance.

For those seeking maintenance or upgrades, familiarizing oneself with the key components will help in understanding how to maintain the system’s optimal performance and address any potential issues before they escalate.

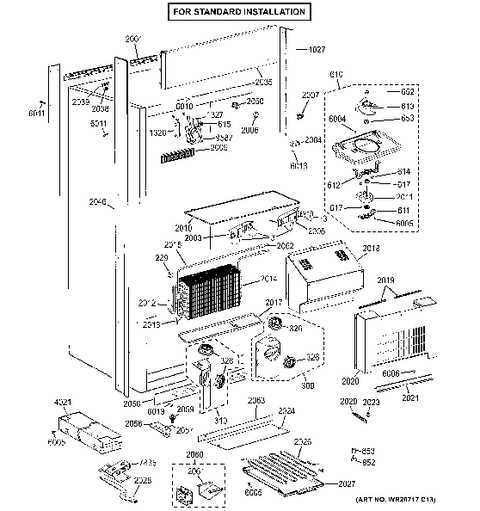

Understanding Key Internal Parts

Gaining a clear understanding of the critical components inside a household appliance is essential for both maintenance and troubleshooting. Recognizing how various elements work together allows users to better identify potential issues and make informed decisions about upkeep or repair.

Core Mechanical Components

The central mechanical elements are the driving force behind the appliance’s function. These components manage the physical operations, ensuring everything runs smoothly. Understanding the purpose of each of these core elements helps in diagnosing issues related to performance or wear.

Electrical and Control Systems

Beyond the mechanical parts, the electrical and control systems regulate the overall operation. These intricate systems coordinate the timing, power distribution, and specific functions, making them crucial for the consistent performance of the appliance.

Common Issues with Major Components

The internal workings of most appliances can be prone to various challenges over time. Identifying the root cause of malfunctions often starts with understanding which key elements are most likely to experience wear or failure. Below are some of the most frequent concerns users encounter when certain crucial elements start to degrade.

Problems with the Motor Assembly

The motor is one of the primary elements responsible for driving essential functions. Over time, it can face difficulties such as overheating, excessive noise, or even complete failure. These issues can often be attributed to poor ventilation, debris buildup, or worn-out bearings, each of which requires careful attention to maintain optimal performance.

Concerns Related to the Control Module

The control module acts as the brain of the system, governing various operational sequences. When problems arise, users might notice irregular operation patterns, delayed responses, or inconsistent performance. These faults are often linked to electrical surges, faulty wiring, or outdated software, all of which can lead to malfunctioning or disrupted functionality.

Guide to Replacing Essential Parts

Maintaining the functionality of your appliance often involves replacing certain components. This guide will walk you through the process of identifying and exchanging critical elements that keep your machine operating smoothly. By understanding the steps involved, you can ensure efficient repairs and prolong the life of your equipment.

Key Components to Consider

When your machine shows signs of wear or malfunction, it’s important to identify which elements need to be swapped out. Some common areas to inspect include:

- Internal mechanisms responsible for water flow and agitation

- Sections that manage electrical input and power distribution

- Structural elements ensuring stability and secure movement

Steps for Safe Replacement

To ensure a smooth replacement process, follow these basic steps:

- Turn off all power sources and disconnect the machine from any utilities.

- Carefully remove the faulty component, taking note of its position and connections.

- Install the new piece, ensuring it fits securely and matches the original configuration.

- Test the machine thoroughly before resuming regular use.

By following these

Overview of Electrical and Mechanical Elements

The integration of both electrical and mechanical components is essential for the functionality of any complex system. These elements work together to ensure seamless operation, with each part playing a critical role in overall performance. By understanding how these systems interact, we gain valuable insights into their maintenance and troubleshooting.

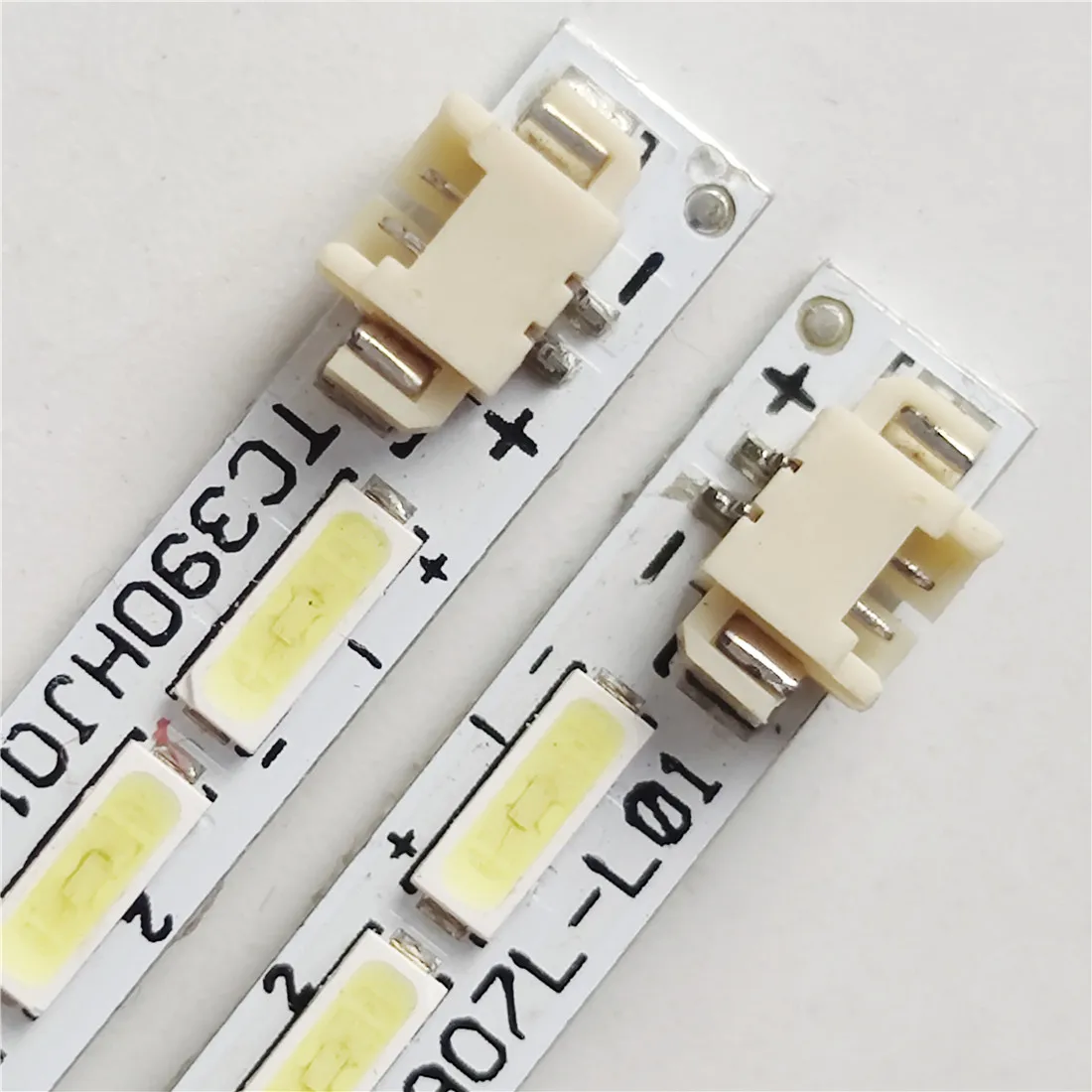

Key Electrical Components

The electrical framework is the backbone that powers various functions. It includes wiring systems, control modules, and switches, all designed to regulate the flow of energy and ensure safety. Proper upkeep of these elements is crucial to avoid operational issues and ensure a consistent performance.

Mechanical Framework

Mechanical components provide the structure and movement required for smooth operation. These include belts, gears, and other moving parts, all working in unison to deliver the desired outcomes. Regular inspection of these elements ensures that wear and tear are minimized, prolonging the life of the equipment.

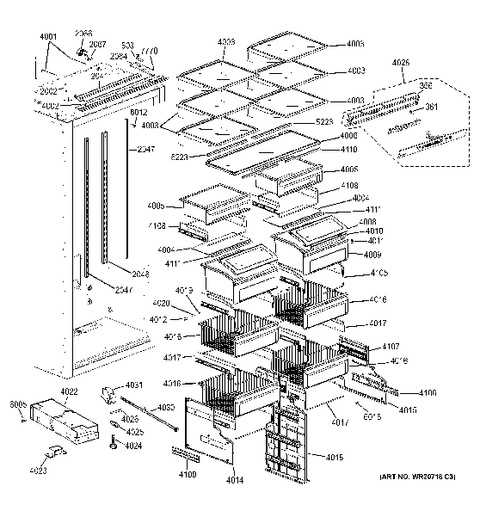

Visual Breakdown of Functional Components

This section provides an insightful exploration of the essential elements that contribute to the overall functionality of the appliance. Understanding each component’s role can enhance the appreciation of its design and operation.

Key features include:

- Power Supply: This element ensures the appliance receives the necessary energy for operation.

- Control Module: The brain of the system, responsible for managing operations and settings.

- Heating Mechanism: This part generates warmth, playing a crucial role in the appliance’s efficiency.

- Water Reservoir: A vital component for storing water, impacting the device’s capacity and performance.

- Filtration System: Ensures that the water used is clean and free from impurities.

Each of these components works in harmony to ensure optimal performance and user satisfaction. A clear understanding of their functions can aid in effective troubleshooting and maintenance.

How to Identify Worn Out Parts

Recognizing when components have deteriorated is essential for maintaining optimal performance. A keen eye for signs of wear can prevent further damage and enhance the longevity of the appliance. Various indicators may suggest that certain elements require attention, ranging from unusual noises to decreased efficiency.

To systematically assess the condition of each element, consider the following key factors:

| Indicator | Description |

|---|---|

| Visual Damage | Look for cracks, corrosion, or discoloration that may indicate failure. |

| Performance Issues | Monitor any decline in functionality, such as inconsistent operation or reduced output. |

| Unusual Sounds | Pay attention to any grinding, rattling, or buzzing noises that may signal a problem. |

| Heating or Cooling Inefficiency | Note any fluctuations in temperature regulation, suggesting a malfunctioning element. |

| Frequent Repairs | If a particular component requires constant fixing, it may be time to replace it altogether. |

By being vigilant and attentive to these signs, one can effectively identify deteriorating elements and take proactive measures to ensure reliable operation.

Steps for Maintaining Machine Longevity

Ensuring the durability and efficiency of any appliance requires regular attention and care. Implementing a systematic approach to maintenance not only enhances performance but also extends the lifespan of the equipment. Here are several essential practices to consider for optimal upkeep.

Regular Cleaning and Inspection

Routine cleaning is vital for preventing the buildup of dust and debris, which can impair functionality. Schedule periodic inspections to check for any signs of wear or damage. Addressing minor issues promptly can prevent them from escalating into major problems.

Proper Usage and Care

Understanding the correct operational procedures is crucial. Always adhere to the manufacturer’s guidelines regarding usage limits and load capacities. Consistent overloading can lead to unnecessary strain and reduce the overall efficiency of the machine. Additionally, incorporating regular service checks will help identify potential issues early, contributing to sustained performance.

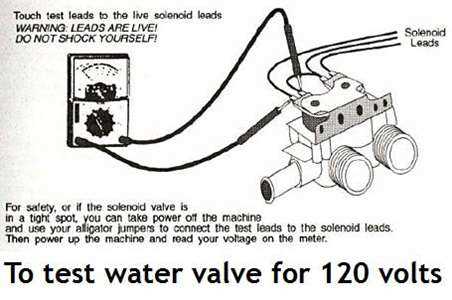

Inspecting and Testing Critical Elements

When it comes to maintaining a reliable appliance, examining and evaluating essential components is crucial. This process ensures that each part functions optimally and helps in identifying any potential issues that may arise. Regular inspections can significantly extend the lifespan of the device and enhance its performance.

Start by checking the primary elements, such as the electrical connections and mechanical systems. Look for any signs of wear, corrosion, or loose fittings that could impede functionality. Testing these components can often reveal underlying problems before they escalate, allowing for timely interventions.

Additionally, utilize appropriate tools to measure performance metrics. Voltage testers, multimeters, and other diagnostic instruments can provide valuable insights into the operational state of the device. Ensuring that all critical parts are in excellent condition not only boosts efficiency but also promotes safe usage.

In summary, a thorough assessment of key components is vital for any appliance. By prioritizing this practice, users can ensure their devices remain in optimal working order, preventing unexpected breakdowns and enhancing overall satisfaction.

Troubleshooting Malfunctions in Core Systems

Identifying and addressing issues within essential components can be a complex task. Understanding the underlying principles and common symptoms associated with malfunctions is vital for effective resolution. This section provides insights into systematic approaches for diagnosing and fixing problems that may arise in key operational areas.

When dealing with failures, consider the following steps:

- Initial Assessment: Observe the system’s performance for any irregularities. Take note of unusual sounds, operational delays, or error messages.

- Basic Checks: Ensure that all connections are secure and that power sources are functioning. Inspect for any visible damage or wear.

- Component Testing: Isolate and test individual elements to identify specific faults. Use appropriate tools to measure performance metrics.

- Consult Documentation: Refer to manuals or guides that provide detailed information on troubleshooting techniques and part specifications.

Common issues that may require attention include:

- Inconsistent operation or failure to start.

- Overheating or unusual temperature fluctuations.

- Leakage or unusual fluid levels.

- Electrical faults, such as blown fuses or tripped breakers.

By following a methodical approach, one can effectively pinpoint and resolve issues in core systems, ensuring optimal performance and longevity.

Essential Tips for Part Compatibility

When it comes to ensuring that components function seamlessly together, understanding compatibility is crucial. This section outlines important considerations to keep in mind for achieving optimal performance and longevity in your appliance.

Key Considerations

- Model Specifications: Always refer to the specific requirements of your appliance model to avoid mismatches.

- Manufacturer Recommendations: Following guidelines provided by the manufacturer can prevent issues with fit and function.

- Quality Standards: Opt for high-quality components to ensure durability and reliability over time.

Checking Compatibility

- Review the technical specifications of each component before purchasing.

- Consult user manuals or online resources for compatibility insights.

- Consider contacting customer support for expert advice on specific components.

By taking these essential steps, you can ensure that the various elements work harmoniously, leading to enhanced efficiency and reduced risk of malfunction.