Exploring the intricacies of equipment configuration is essential for ensuring optimal functionality and maintenance. In this section, we will delve into the essential elements that make up a specific model of heating apparatus, providing clarity on their arrangement and significance.

Comprehending the various components and their interconnections allows users to navigate maintenance tasks with confidence. By familiarizing oneself with the structure, one can easily identify areas needing attention and understand how each element contributes to the overall operation.

Visual representations serve as valuable tools for anyone looking to enhance their understanding of how these devices function. This knowledge empowers users to make informed decisions regarding repairs, upgrades, or replacements, ultimately leading to a more efficient and reliable performance.

This section aims to provide a comprehensive overview of the essential elements involved in a specific heating appliance. By breaking down the various components, readers can gain insights into their functionalities and interconnections, leading to a better understanding of the overall system.

The following table outlines the main components, their functions, and key details to facilitate a clearer grasp of how each element contributes to the operation of the device:

| Component | Function | Details |

|---|---|---|

| Burner | Ignites and maintains the flame for heating | Made from durable materials to withstand high temperatures |

| Heat Exchanger | Transfers heat from the combustion process to the surrounding area | Designed for efficient heat transfer and minimal energy loss |

| Fan Assembly | Circulates air to distribute warmth evenly | Includes adjustable speed settings for optimal airflow |

| Control Board | Manages the appliance’s operation and settings | Features user-friendly interface and programmable options |

| Fuel Feed System | Supplies fuel to the burner | Equipped with safety mechanisms to prevent leaks |

| Chimney | Ventilation for exhaust gases | Designed to ensure proper airflow and prevent backdrafts |

| Glass Door | Allows visibility of the flame while maintaining safety | Heat-resistant and easy to clean |

| Grate | Supports the fuel while allowing ash to fall | Constructed to withstand heavy loads and high temperatures |

| Ash Pan | Catches ash and debris for easy disposal | Removable for convenient cleaning |

| Thermostat | Regulates temperature based on user settings | Provides accurate readings for effective heating control |

| Safety Sensors | Monitors system performance to prevent malfunctions | Includes features like overheat protection and shut-off mechanisms |

Overview of Heating System Parts

Understanding the components of a heating system is crucial for effective maintenance and troubleshooting. This section delves into the essential elements that contribute to the efficient operation of such systems, ensuring optimal performance and longevity.

Main Components

The primary elements of a heating system include:

- Heat Source: The origin of warmth, which can be generated through various methods such as combustion or electricity.

- Heat Exchanger: A device that transfers thermal energy from one medium to another, enhancing heat distribution.

- Piping and Ductwork: Systems of tubes and channels that facilitate the movement of heated air or fluid throughout the space.

- Thermostat: A control mechanism that regulates temperature by managing the heating source based on set preferences.

Auxiliary Elements

In addition to the main components, several auxiliary elements play a vital role:

- Filters: These components purify the air or fluid, ensuring that only clean elements circulate within the system.

- Pumps: Devices that move fluids through the system, maintaining proper flow and pressure.

- Valves: Mechanisms that control the direction and flow rate of heated substances, allowing for precise adjustments.

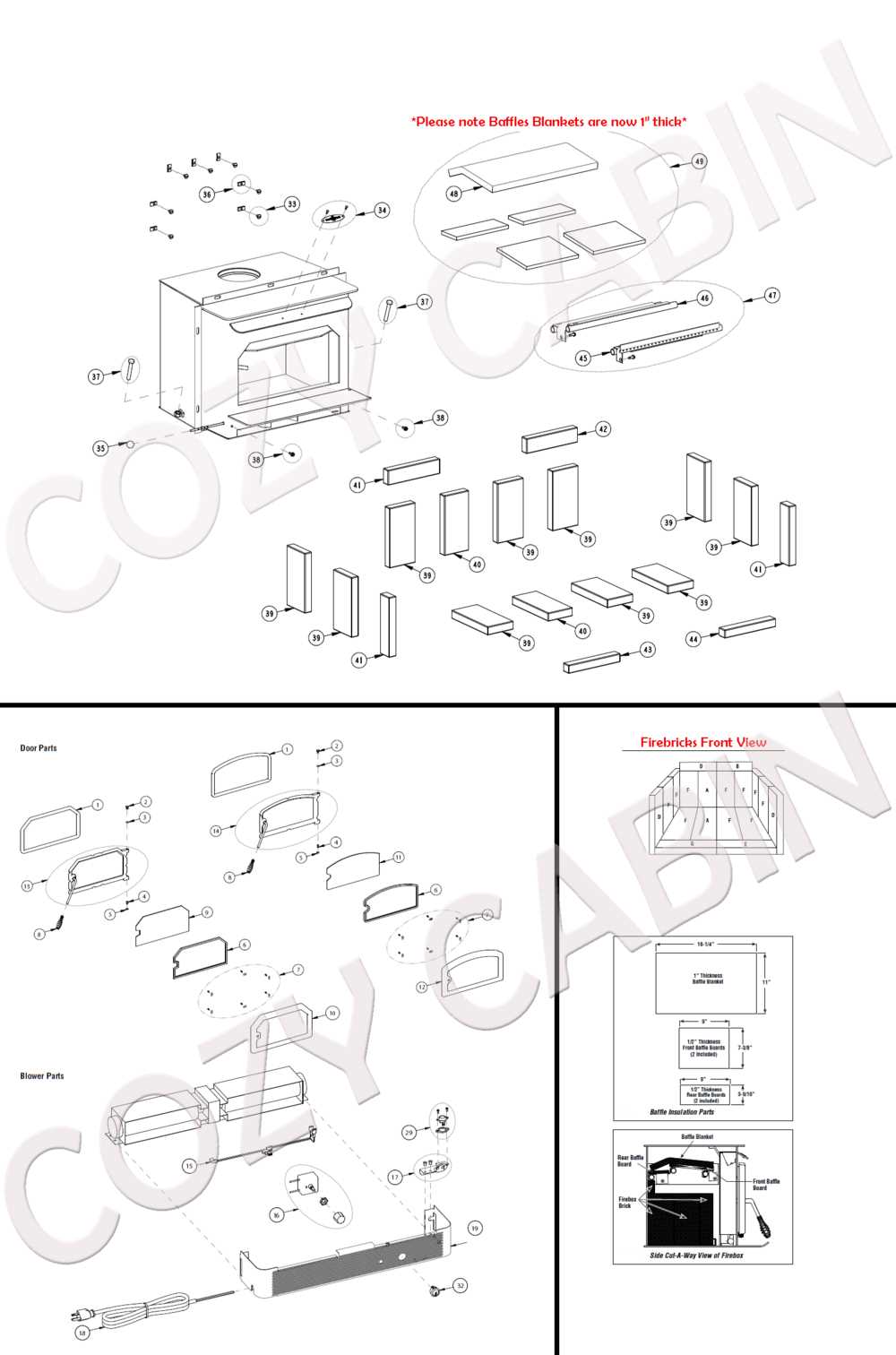

Essential Elements of Accentra Model

This section delves into the fundamental components that contribute to the efficiency and functionality of the heating system design. Understanding these key elements is vital for optimal performance and maintenance.

Among the primary features, the following aspects play a significant role:

- Burner System: A crucial element that facilitates efficient combustion, ensuring maximum heat output.

- Heat Exchanger: This component is essential for transferring heat from the combustion process to the surrounding area.

- Control Mechanism: The system’s operational efficiency relies on advanced controls that manage temperature and fuel flow.

- Fuel Storage: Properly designed storage solutions ensure a reliable supply of energy for the system’s operation.

- Ventilation Setup: Adequate airflow is necessary for safe and efficient combustion, preventing any build-up of harmful gases.

Each of these elements works in harmony to create a reliable and effective heating solution, making it imperative for users to understand their functions and importance.

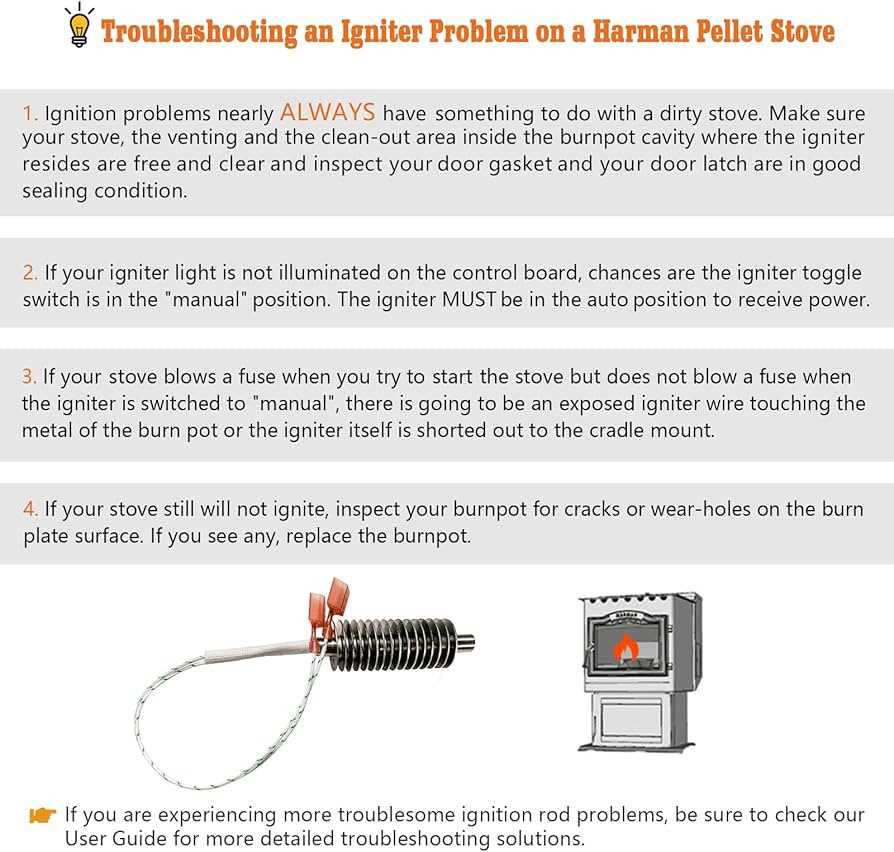

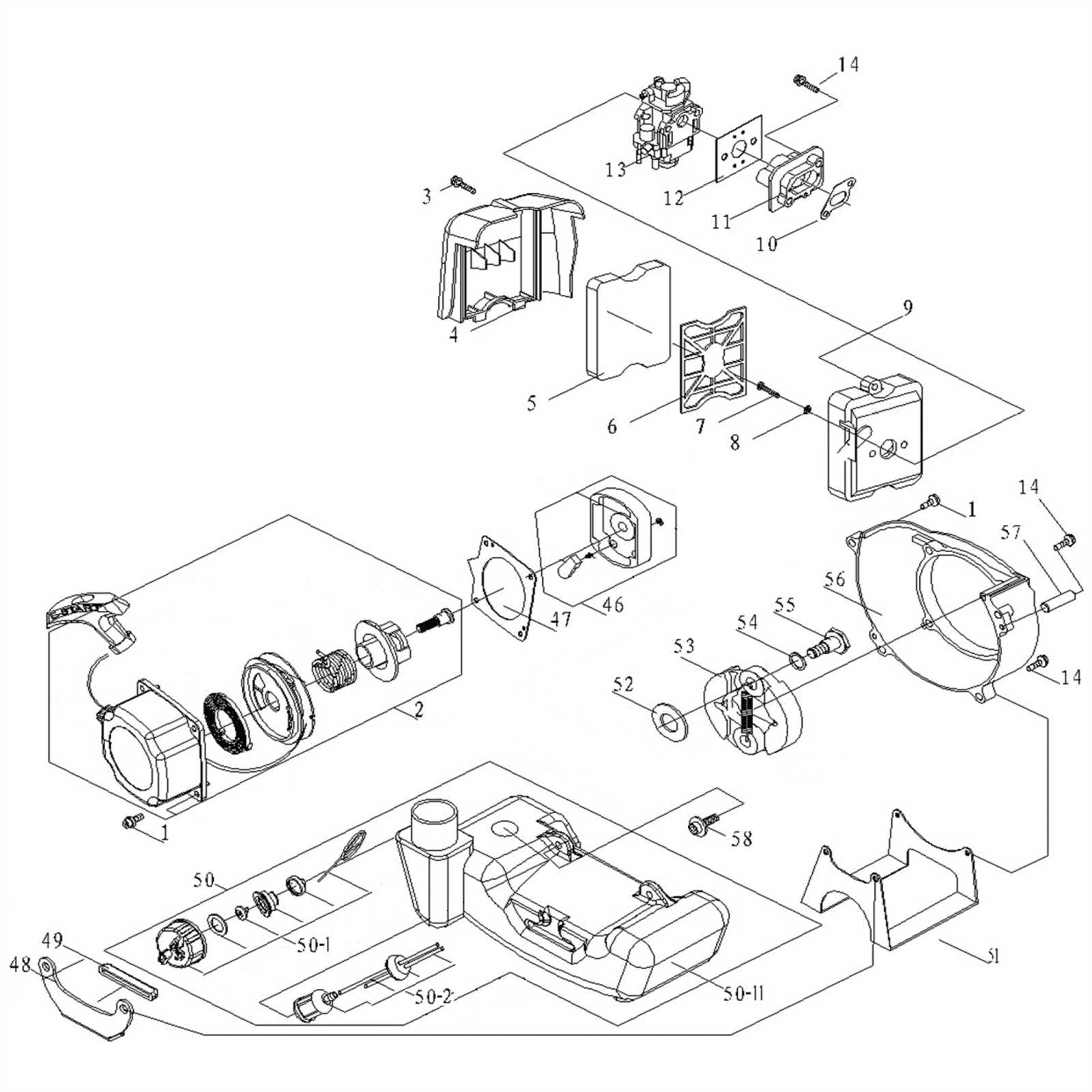

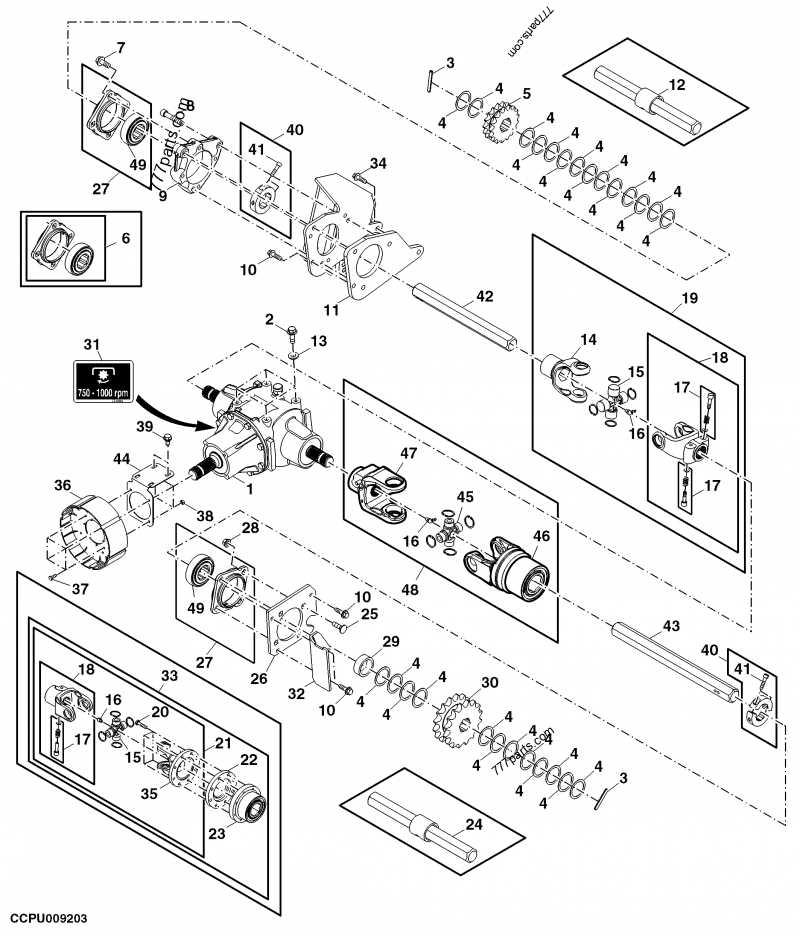

Identifying Key Mechanical Components

Understanding the essential elements of a mechanical system is crucial for effective maintenance and troubleshooting. Each component plays a significant role in the overall functionality, contributing to performance and efficiency. Recognizing these parts allows for better comprehension of how they interact and support the system as a whole.

Primary Elements encompass various elements, including the combustion chamber, heat exchanger, and fan assembly. These components work in unison to ensure optimal operation. The combustion chamber, for instance, is responsible for burning fuel, while the heat exchanger transfers generated heat to the surrounding environment.

Additional Features such as the ignition system and control panel are vital for regulating operations. The ignition system initiates the combustion process, ensuring the system operates smoothly. Meanwhile, the control panel allows users to manage settings and monitor performance effectively.

By familiarizing oneself with these mechanical elements, users can better troubleshoot issues and conduct necessary maintenance, ultimately enhancing the lifespan and functionality of the entire system.

Electrical Parts and Their Functions

This section explores the various components within a heating system that play vital roles in its operation. Each element contributes to the efficient functioning of the device, ensuring that it meets performance expectations while maintaining safety standards.

| Component | Function |

|---|---|

| Power Supply Unit | Provides the necessary electrical energy to operate the system. |

| Thermostat | Regulates temperature by controlling the heating cycle. |

| Heating Element | Converts electrical energy into heat for warming the space. |

| Control Board | Coordinates the various functions and components for optimal performance. |

| Safety Switch | Ensures the system shuts down in case of malfunction, preventing hazards. |

Maintenance Tools for Accentra Parts

Proper upkeep of heating systems requires specific instruments to ensure efficiency and longevity. Utilizing the right tools facilitates seamless maintenance and minimizes the risk of malfunctions.

Here are essential implements for effective maintenance:

- Wrenches: Adjustable wrenches are vital for tightening or loosening connections.

- Screwdrivers: A set of various sizes is necessary for securing panels and components.

- Multimeter: This tool is crucial for diagnosing electrical issues and checking voltage levels.

- Vacuum: A shop vacuum helps in cleaning dust and debris from internal mechanisms.

- Brushes: Wire or soft brushes assist in removing buildup from sensitive areas.

- Gloves: Protective gloves ensure safety while handling hot or sharp parts.

Utilizing these tools not only enhances maintenance efforts but also contributes to the overall safety and functionality of the system.

Exploring Diagram Symbols and Notations

Understanding the various symbols and notations used in technical illustrations is essential for accurate interpretation and communication. These graphical representations serve as a universal language that conveys complex information in a simplified manner, enabling users to comprehend the components and their relationships within a system.

Common symbols employed in these visual representations include:

- Geometric shapes: Often signify different components or functions.

- Arrows: Indicate the direction of flow or connection between elements.

- Letters and numbers: Typically used to label specific parts for easy identification.

Understanding these elements can enhance your ability to analyze and utilize the illustrations effectively. Here are some key notations to consider:

- Standardized symbols: Established conventions that ensure consistency across various documents.

- Custom symbols: Tailored representations that may vary based on specific applications or preferences.

- Color coding: Utilized to differentiate between various categories or functions, aiding in quicker comprehension.

By familiarizing yourself with these symbols and notations, you can navigate technical illustrations with greater ease, leading to improved understanding and functionality in your projects.

Common Issues with Component Assembly

When assembling various elements of a device, several challenges can arise that may impact the overall functionality and performance. Understanding these potential issues is crucial for ensuring a smooth integration process and enhancing the longevity of the system.

Misalignment is a frequent concern during assembly, where components may not fit together as intended, leading to operational failures. This can result from improper handling or inadequate measurements taken during the preparation phase.

Another issue is incompatibility between different parts, which can arise if components are sourced from various manufacturers. It is essential to verify that all elements are designed to work together effectively to avoid performance discrepancies.

Additionally, poor quality of individual pieces can lead to premature wear and tear, affecting the entire assembly. Ensuring that each part meets high standards of quality is vital for maintaining functionality.

Finally, inadequate documentation regarding the assembly process can result in confusion and mistakes. Clear and detailed instructions are essential for guiding the assembly team and minimizing errors.

Guidelines for Replacement Parts Selection

Choosing the right components for your heating system is crucial for ensuring optimal performance and longevity. Understanding the specific requirements of your unit can greatly influence the efficiency and reliability of its operation. Here are some key considerations to keep in mind when selecting new elements for your system.

Compatibility with Your Model

It is essential to verify that the selected components are suitable for your specific model. This ensures seamless integration and proper functionality. Always refer to the manufacturer’s recommendations or consult with a professional if uncertain.

Quality and Durability

Opt for components made from high-quality materials to guarantee durability and reliability. Investing in reputable brands can provide peace of mind, as these parts are often subjected to rigorous testing to meet industry standards.

| Consideration | Details |

|---|---|

| Model Compatibility | Ensure the component matches the specifications of your heating unit. |

| Material Quality | Choose components made from robust materials for enhanced lifespan. |

| Manufacturer Reputation | Select from well-known brands for reliability and performance. |

| Warranty | Look for parts that come with a warranty to cover potential defects. |

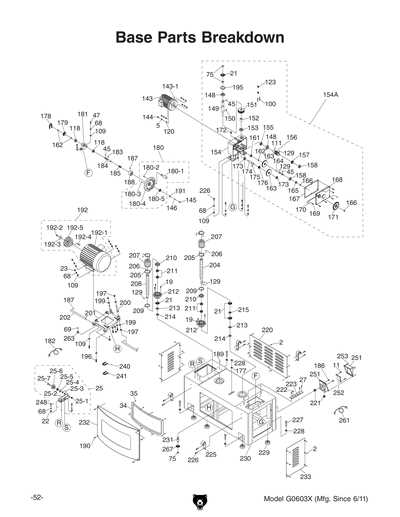

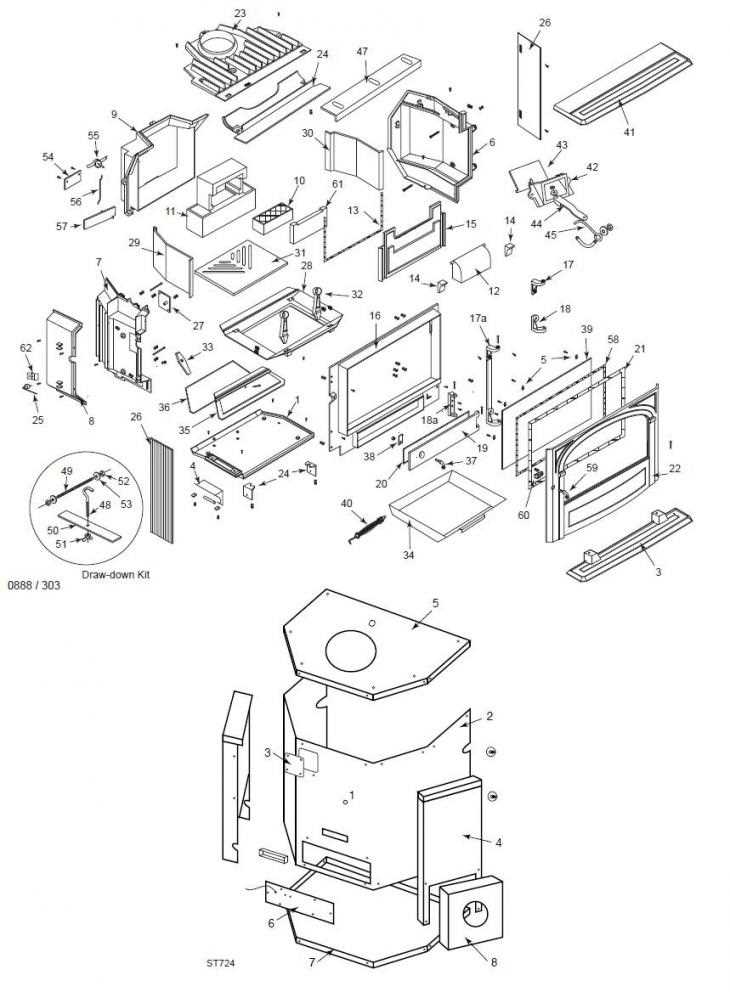

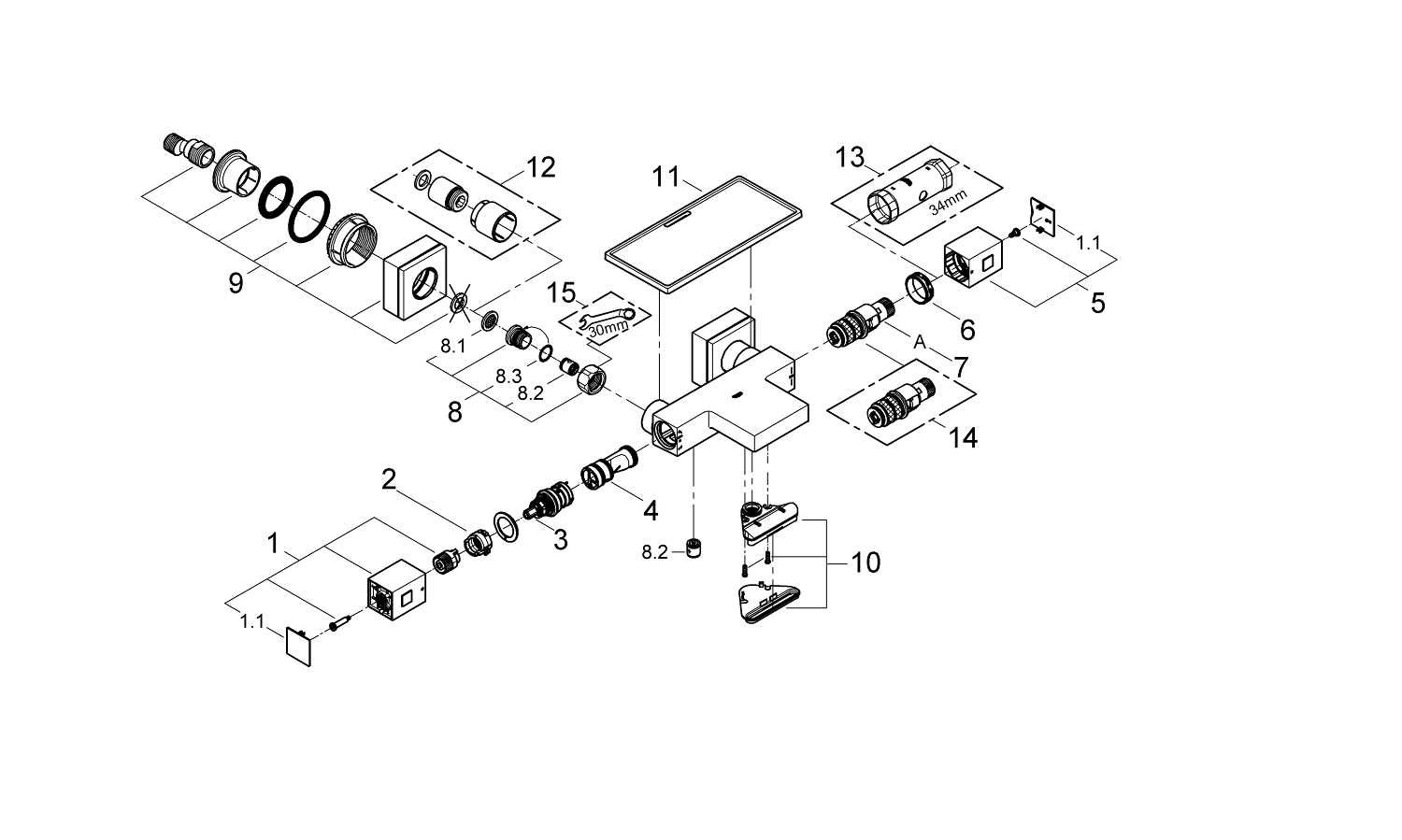

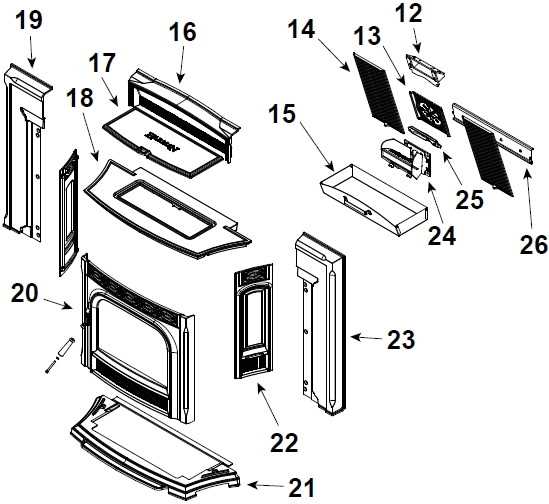

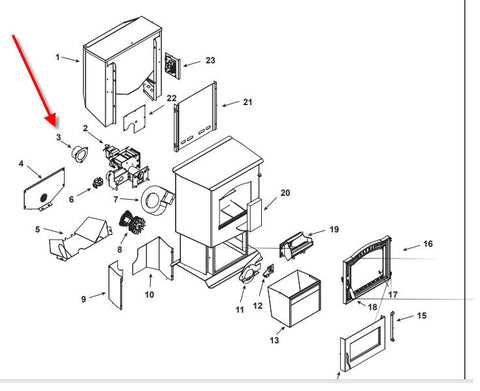

Visual Reference for Component Layout

This section provides a comprehensive overview of the arrangement and positioning of various elements within the system. Understanding how components interact within the assembly is essential for effective maintenance and troubleshooting.

Overview of Key Components

Each element within the setup serves a specific function, contributing to the overall performance of the device. Identifying these components allows for easier navigation and understanding of the system’s workings. It is important to familiarize oneself with the layout to ensure proper handling and adjustments.

Understanding the Layout

The organization of the parts not only affects functionality but also influences ease of access during repairs. By referencing the visual guide, users can quickly locate essential areas and understand the relationships between different elements. This knowledge aids in performing efficient diagnostics and repairs.

Safety Precautions During Maintenance

Ensuring a secure environment while performing upkeep tasks is crucial for both the equipment and personnel involved. Adhering to specific guidelines minimizes risks and fosters a safer work atmosphere.

Before commencing any maintenance activities, consider the following safety measures:

- Wear appropriate personal protective equipment (PPE), such as gloves, goggles, and masks.

- Ensure that the workspace is well-ventilated to prevent the accumulation of harmful fumes.

- Disconnect the power source to eliminate the risk of accidental activation during servicing.

- Keep the work area clean and free of clutter to reduce the likelihood of slips and falls.

Additionally, follow these recommendations:

- Read and understand the maintenance manual before starting any procedures.

- Use the right tools and equipment for the task to avoid injuries and damage.

- Always have a first-aid kit readily available in case of emergencies.

By following these safety precautions, individuals can effectively mitigate risks and ensure a smooth maintenance process.

Resources for Further Information

For those seeking additional insights and knowledge on the subject, a variety of resources are available to enhance understanding and facilitate effective usage. These materials range from instructional guides to community forums, offering valuable information for both novice and experienced users.

Online Guides and Manuals

Many comprehensive guides are accessible online, providing detailed instructions and technical specifications. These documents can help users familiarize themselves with different components and their functionalities. Websites dedicated to equipment support often include downloadable manuals that serve as excellent references.

Community Forums and Support Groups

Participating in online forums and support communities allows users to engage with others who share similar interests. These platforms are invaluable for exchanging tips, troubleshooting issues, and discovering practical advice from experienced individuals. Engaging with a community can significantly enhance one’s expertise and confidence in navigating various challenges.