The efficiency and reliability of lifting equipment heavily depend on its individual elements. An intricate understanding of these components is crucial for maintenance, repair, and optimal performance. By visualizing how each piece interacts within the larger system, operators can enhance both safety and functionality.

In this exploration, we will delve into the specifics of a particular model, breaking down its structure to highlight the significance of each section. This will not only aid technicians in their repair tasks but also assist operators in understanding their machinery better.

Moreover, comprehending the layout of these essential parts can streamline troubleshooting processes. This approach ensures that any potential issues can be identified and resolved swiftly, minimizing downtime and maximizing productivity in various applications.

Understanding Haulotte 4527A Parts Diagram

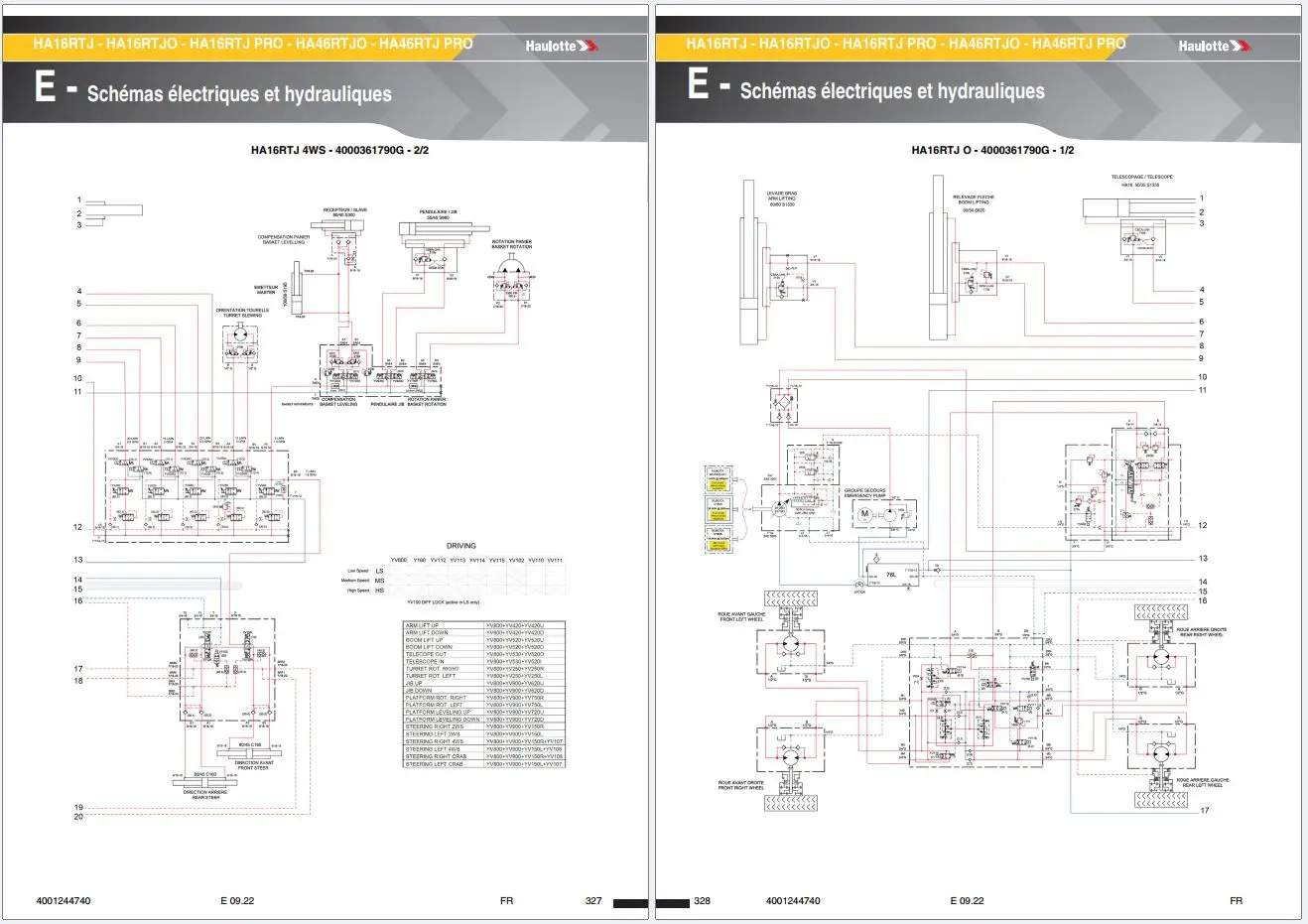

Comprehending the layout of components for equipment is crucial for effective maintenance and troubleshooting. This visualization serves as a roadmap, guiding users through the intricate arrangement of mechanical elements and their functions. A clear understanding of these illustrations can significantly enhance operational efficiency and safety.

Deciphering these illustrations involves identifying each element’s role within the machine’s overall framework. Familiarity with these representations not only aids in quick repairs but also fosters a deeper appreciation of the equipment’s engineering.

Ultimately, mastering the details of these schematics empowers operators to make informed decisions regarding maintenance schedules, potential upgrades, and efficient usage, leading to improved performance and longevity of the machinery.

Overview of Haulotte Equipment

This section provides insights into the various types of aerial work platforms and lifting machinery used across multiple industries. These devices enhance operational efficiency and safety, making them essential in construction, maintenance, and warehousing sectors.

- Types of Equipment:

- Scissor lifts

- Boom lifts

- Telehandlers

- Key Features:

- High lifting capacity

- Compact design for tight spaces

- Advanced safety systems

- Applications:

- Construction sites

- Maintenance tasks

- Event setups

Overall, this equipment is designed to provide reliable solutions for elevating personnel and materials, ultimately enhancing productivity in various work environments.

Key Components of the 4527A Model

The intricate design of this aerial work platform showcases several essential elements that contribute to its functionality and efficiency. Each component plays a critical role in ensuring safe operation and optimal performance, making it vital to understand their individual purposes.

Chassis: The robust frame forms the foundation, providing stability and support during operation.

Hydraulic System: This system enables smooth lifting and lowering actions, crucial for accessing elevated workspaces.

Platform: The spacious working area accommodates personnel and equipment, ensuring productivity at height.

Controls: User-friendly interfaces allow for precise maneuvering, enhancing operational safety and efficiency.

Safety Features: Integrated mechanisms such as emergency stops and load sensors ensure the well-being of operators and bystanders alike.

Understanding these key components allows users to appreciate the engineering behind this model, ultimately leading to better maintenance and usage practices.

Importance of Parts Diagrams

Understanding the components of machinery is crucial for maintenance and repair. Visual representations serve as essential tools, enabling users to identify, locate, and understand each element’s function. This clarity enhances efficiency in service processes, ultimately leading to improved operational performance.

Enhancing Maintenance Efficiency

Utilizing visual schematics simplifies the identification of individual components, making it easier for technicians to perform tasks. When every piece is clearly depicted, time spent searching for information is significantly reduced.

Facilitating Accurate Repairs

Accurate visual references ensure that replacements or repairs are conducted correctly. This minimizes the risk of errors and enhances the longevity of equipment by promoting proper installation of each element.

| Benefit | Description |

|---|---|

| Clarity | Visual aids help in understanding complex structures. |

| Efficiency | Streamlined identification processes save time. |

| Accuracy | Correct installations reduce the likelihood of future issues. |

Common Issues with Haulotte Machines

In the world of aerial work platforms, certain challenges frequently arise that can affect performance and safety. Understanding these common issues can help operators maintain equipment effectively and ensure smooth operations. Proper awareness and proactive measures are essential to mitigate risks and enhance productivity.

Mechanical Failures

One prevalent issue involves mechanical failures, which can stem from wear and tear or inadequate maintenance. Regular inspections are crucial to identify signs of stress or damage. Hydraulic systems are particularly susceptible to leaks, which can lead to decreased functionality.

Electrical Problems

Electrical issues often manifest as erratic behavior or complete system failures. These problems can result from faulty wiring, damaged components, or battery malfunctions. Ensuring that batteries and electrical connections are in good condition can significantly reduce downtime and enhance reliability.

How to Interpret Parts Diagrams

Understanding technical illustrations is essential for anyone working with machinery. These visuals serve as a roadmap, detailing the various components and their relationships within a system. Proper interpretation enables efficient repairs, maintenance, and assembly, ultimately enhancing performance and safety.

First, familiarize yourself with the layout. Typically, these visuals will showcase a comprehensive view of the equipment, with each element labeled for easy identification. It’s crucial to recognize the main sections and how they connect to one another, as this lays the groundwork for more detailed analysis.

Next, pay attention to the legends and notes. Most illustrations include annotations that provide additional context, such as part numbers, specifications, or assembly instructions. These notes are invaluable when sourcing replacements or understanding assembly sequences.

Additionally, look for common symbols and color codes. Many technical visuals use standardized representations for components like bolts, gears, or electrical parts. Familiarity with these symbols can greatly speed up your ability to navigate the illustration and grasp the relationships between parts.

Finally, practice makes perfect. The more you engage with these illustrations, the more intuitive they will become. Take time to review different examples, and soon, you’ll be able to interpret these crucial tools with confidence and efficiency.

Maintenance Tips for 4527A Models

Regular upkeep is essential to ensure optimal performance and longevity of equipment. Adopting a systematic approach to maintenance can prevent unexpected breakdowns and enhance safety during operation. Below are some key recommendations to keep your machinery in excellent condition.

- Routine Inspections: Conduct thorough inspections regularly to identify any signs of wear or damage. Pay close attention to critical components.

- Cleanliness: Keep the machine clean from dirt and debris. Regular cleaning helps prevent corrosion and maintains visibility of essential parts.

- Lubrication: Ensure that moving parts are well-lubricated to minimize friction and reduce wear. Follow the manufacturer’s guidelines for the appropriate type of lubricant.

- Tire Maintenance: Check tire pressure and tread regularly. Properly inflated tires contribute to better stability and maneuverability.

- Battery Care: Inspect battery connections and fluid levels. Clean terminals to prevent corrosion and ensure reliable power supply.

By following these practices, you can enhance the reliability and efficiency of your equipment, leading to safer and more productive operations.

Where to Find Replacement Parts

Locating components for your equipment can be a crucial task, ensuring optimal performance and longevity. Various sources offer reliable options for acquiring these necessary items, allowing for efficient maintenance and repairs.

| Source | Description |

|---|---|

| Authorized Dealers | These vendors provide genuine items, often with warranty and support. |

| Online Marketplaces | Websites like eBay and Amazon have numerous sellers offering both new and used components. |

| Specialized Retailers | Shops focusing on machinery parts often have a wide selection and expert advice. |

| Local Salvage Yards | Finding used items can be cost-effective, with a variety of options available. |

Impact of Quality Parts on Performance

The performance of machinery is heavily influenced by the quality of components utilized in its construction. High-quality elements contribute to reliability, efficiency, and longevity, ultimately affecting overall operational success. When the integrity of each component is prioritized, the entire system functions more smoothly, minimizing downtime and enhancing productivity.

Reliability and Durability

Investing in superior materials ensures that equipment withstands the rigors of regular use. Durable components resist wear and tear, leading to fewer breakdowns and lower maintenance costs. This reliability fosters trust among operators, allowing for consistent performance over time.

Efficiency and Cost Savings

Quality components improve the efficiency of machinery, allowing for better fuel consumption and reduced energy waste. Ultimately, this translates to significant cost savings for businesses. By choosing the best elements, operators can achieve peak performance without the burden of excessive repairs or replacements.

Safety Considerations for Operators

Ensuring a safe working environment is paramount for individuals operating aerial equipment. Recognizing potential hazards and adhering to safety protocols not only protects the operator but also promotes overall workplace safety.

Essential Safety Practices

- Always conduct a pre-operation inspection to identify any mechanical issues.

- Ensure that all safety equipment, such as harnesses and helmets, is in good condition.

- Follow manufacturer guidelines for operating limits and procedures.

Environmental Awareness

- Be vigilant of surrounding obstacles, including power lines and structures.

- Monitor weather conditions to avoid operations during storms or high winds.

- Communicate effectively with ground personnel to coordinate safe maneuvers.

Upgrading Components for Enhanced Efficiency

Improving various elements of machinery can significantly boost overall performance and reliability. By focusing on the enhancement of individual parts, users can achieve greater productivity and reduced downtime. This approach not only optimizes functionality but also extends the lifespan of equipment.

Key upgrades to consider include:

| Component | Benefit |

|---|---|

| Hydraulic Systems | Improved lifting speed and load handling. |

| Control Interfaces | Enhanced user experience and precision in operation. |

| Safety Features | Increased operator safety and compliance with regulations. |

| Power Systems | Higher energy efficiency and reduced operational costs. |

Implementing these upgrades can lead to the ultimate enhancement in efficiency, making the machinery more competitive in today’s demanding environments.

Resources for Further Learning

Expanding your knowledge about machinery and its components can significantly enhance your understanding and maintenance skills. Numerous resources are available to help individuals explore various aspects, from technical manuals to interactive online platforms.

Online Courses and Tutorials

Websites offering structured courses can provide in-depth insights. Platforms like Coursera and Udemy feature specialized content that caters to both beginners and advanced users, ensuring a comprehensive learning experience.

Technical Manuals and Community Forums

Accessing technical documents and engaging in community discussions can be invaluable. Online forums such as Reddit or dedicated industry websites allow enthusiasts to share experiences and solutions, fostering a collaborative environment for knowledge exchange.