Maintaining clean and clear water in any outdoor or recreational setup requires the use of an efficient system designed to remove impurities. A specialized unit, known for its durability and performance, plays a crucial role in ensuring that the water remains free from debris, contaminants, and other unwanted particles. This system operates through a series of elements working in harmony to deliver optimal water quality.

Each part of this unit is meticulously designed to perform specific functions, contributing to the overall purification process. From the main vessel that holds the filtering medium to various connectors and valves, every element serves a critical role in maintaining the flow and cleanliness. Understanding these individual components can be essential for troubleshooting or performing maintenance on the system.

In the following section, we will explore the structure and function of key elements, helping you gain a deeper insight into how the system

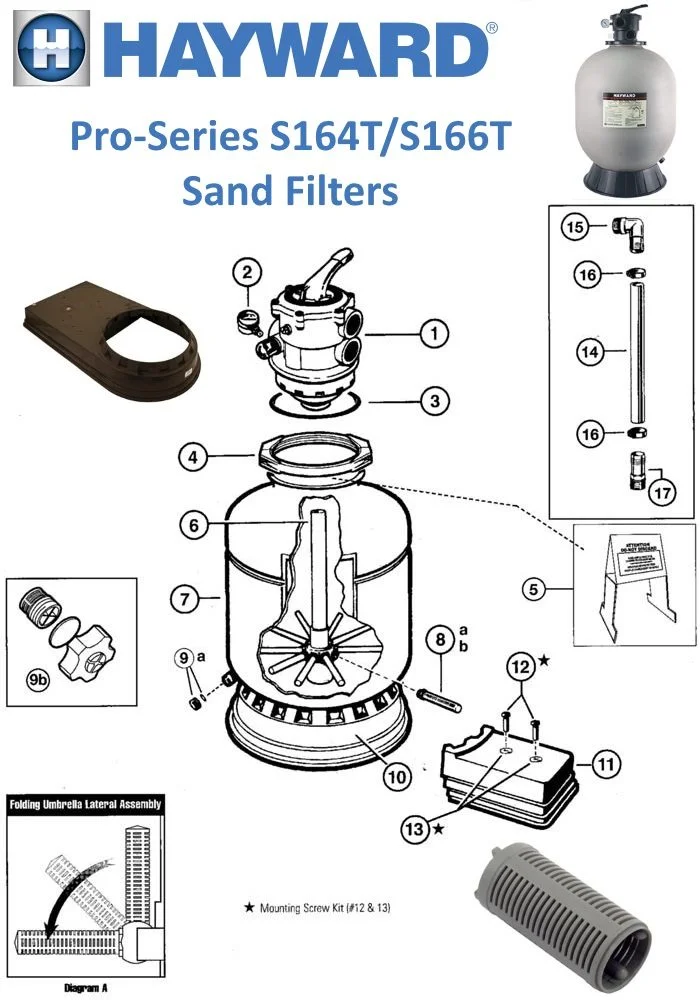

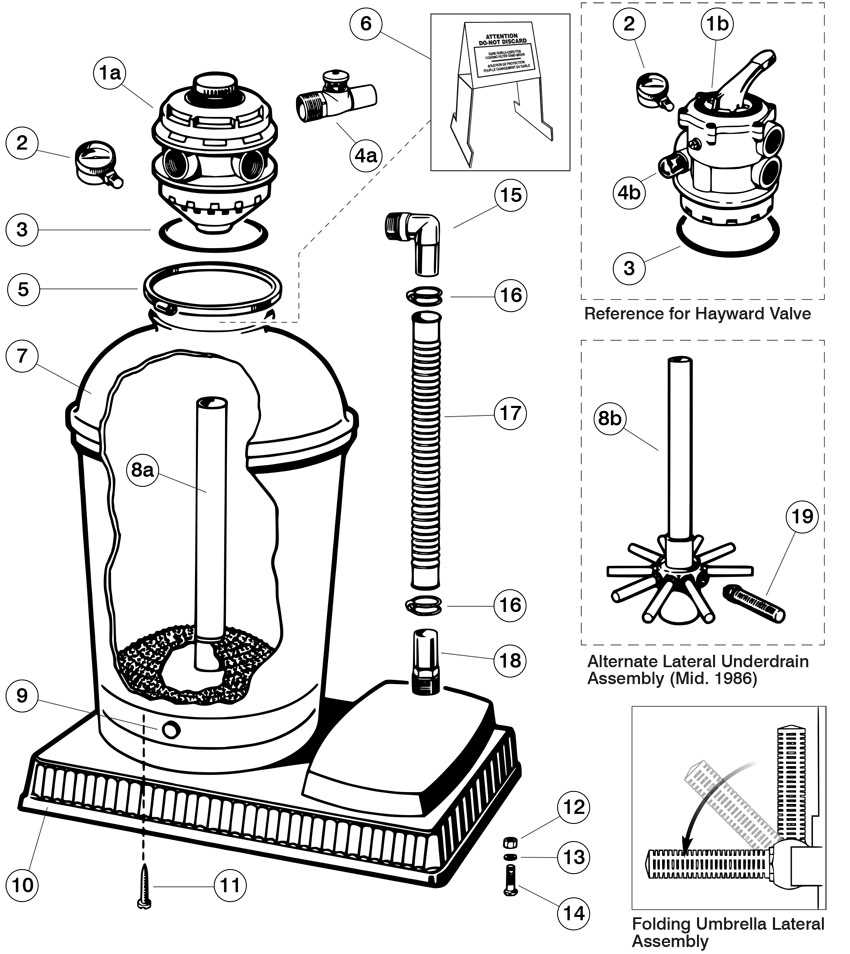

Understanding the Components of a Pool Sand Filter

To maintain an efficient water cleaning system, it’s essential to familiarize yourself with the various elements that make up the equipment responsible for the filtration process. Each component plays a specific role, ensuring that the system operates smoothly and delivers clean, clear results.

The first critical piece is the valve assembly, which directs the flow of water through the system. This part allows for switching between different modes, such as cleaning or normal operation. Its position affects the overall performance of the system.

Another essential element is the tank, a durable container designed to hold the medium used for filtering. This vessel needs to be sturdy enough to handle high pressure while providing a stable environment for the entire filtration process.

The lateral system at the base ensures even distribution and collection of water during the filtration cycle. It helps prevent blockages and maintains an even flow, contributing to the system’s overall ef

Key Functions of a Pool Filter System

The primary purpose of a water purification mechanism in an aquatic setup is to ensure clean and clear water by removing impurities and maintaining a healthy environment for swimmers. The system operates continuously to capture unwanted particles, improve water quality, and reduce the need for frequent manual maintenance.

- Particle Removal: The system traps debris, such as leaves, dirt, and small particles, preventing them from circulating in the water.

- Water Circulation: It maintains a steady flow, which is essential for uniform distribution of chemicals and heat, ensuring consistent water quality.

- Pressure Regulation: By controlling water pressure, the system ensures efficient filtration while protecting the pump and other comp

The Role of Sand in Filtration

The granular medium plays a crucial part in removing impurities from liquids, relying on its natural ability to trap and separate unwanted particles. This process is essential for maintaining clear and clean fluids, effectively preventing the circulation of contaminants. By leveraging its granular structure, the material serves as a physical barrier that enhances the quality of the treated substance.

How Granules Capture Debris

The fine grains create multiple layers through which liquid passes. Each layer adds a new level of filtration, where larger particles are caught on the surface, while smaller impurities are trapped deeper within the medium. This ensures a comprehensive purification, as the liquid slowly navigates through various levels of density and texture.

Maintaining the Efficiency of Granular Filtration

Over time, the collected debris can reduce the effectiveness of the filtration process. Regular maintenance is crucial to restore the medium’s ability to capture impurities. Backwashing and cleaning the grains help extend the lifespan of

Common Filter Tank Configurations

Understanding the various configurations of tank systems is essential for maintaining clean and efficient operation in water treatment systems. The design and setup of these tanks can vary, each offering unique features and benefits depending on the application and system requirements. In this section, we will explore the most common configurations and their characteristics.

Vertical Tank Configuration

This configuration is often chosen for its space-saving design and high capacity. The vertical structure allows for better flow distribution and increased efficiency in capturing debris. These tanks are typically used in systems where floor space is limited but performance cannot be compromised.

Horizontal Tank Configuration

Horizontal tanks are ideal for installations where height is restricted but a wide filtration surface is required. The horizontal design offers stability and easy access for maintenance, making them suitable for a variety of settings. These tanks are also known for their ability to handle larger volumes with reduced pressure loss.

Valve Assembly and Its Importance

The valve assembly plays a crucial role in maintaining the efficiency and functionality of the overall system. It serves as the primary control mechanism, allowing for the proper regulation of water flow and ensuring smooth operation. This essential component ensures that water circulates correctly, following the desired pathways to achieve optimal performance.

Key Functions of the Valve Assembly

The primary purpose of the valve mechanism is to direct water flow through various stages of the system. Whether it’s diverting liquid for cleaning or regulating pressure, the assembly helps manage multiple processes with precision. It facilitates easy maintenance, allowing users to perform backwashing, rinsing, or circulation adjustments effortlessly.

Why Proper Functioning Matters

A well-maintained valve assembly is vital for achieving peak performance. Any malfunctions or blockages can lead to reduced efficiency, increased wear on internal components, and eve

Pressure Gauge: Monitoring System Performance

The pressure gauge plays a crucial role in assessing the operational efficiency of a circulation system. By providing real-time readings, it helps users identify potential issues and maintain optimal conditions. Monitoring pressure levels is essential for ensuring that the system functions smoothly and efficiently.

Importance of Pressure Monitoring

Regularly observing pressure readings can yield several benefits:

- Early detection of clogs or blockages

- Assessment of pump performance

- Identification of wear and tear on components

- Optimization of water flow and energy usage

Understanding Pressure Readings

Interpreting pressure gauge readings is vital for maintaining system health. Here are key points to consider:

- Normal Operating Range: Familiarize yourself with the standard pressure range for your specific setup.

- High Pressure: Elevated readings may indicate blockages, necessitating immediate attention.

- Low Pressure: This could suggest pump failure or leaks within the system.

- Regular Calibration: Ensure accuracy by periodically calibrating the gauge to prevent misleading readings.

Multiport Valve Positions and Their Uses

The multiport valve is an essential component in maintaining the efficiency of water circulation systems. Its various settings allow users to manage different operational modes, each designed for specific tasks within the system. Understanding these positions is crucial for optimal performance and longevity of the entire setup.

One common position is the ‘filter’ mode, which facilitates the standard operation of water circulation, ensuring clean and clear water flows through the system. This mode should be utilized during routine filtration processes, effectively trapping dirt and debris.

Another important setting is ‘backwash.’ This position reverses the flow of water, flushing out accumulated contaminants from the filter medium. Regular backwashing is necessary to maintain flow rate and performance, especially after heavy usage or following adverse weather conditions.

The ‘rinse’ function is typically employed after backwashing. It helps to settle the media back into place and eliminates any remaining debris. This step is vital to ensure that the water returning to the system is clean and free of particles that could affect its clarity.

‘Waste’ mode directs the water away from the system entirely, allowing for the removal of unwanted materials without returning them to the circulation. This position is beneficial during extensive clean-up processes or when significantly lowering the water level is necessary.

Lastly, the ‘closed’ position is essential for maintenance tasks. It stops water flow completely, ensuring safety when performing repairs or inspections. Utilizing this setting effectively can prevent potential damage and ensure a secure environment during maintenance activities.

Backwash Process and Why It’s Crucial

The backwash procedure is an essential maintenance step in ensuring optimal performance of water purification systems. This method involves reversing the flow of water through the system, allowing for the removal of accumulated debris and contaminants. By regularly executing this technique, users can maintain clear and clean water while extending the lifespan of the equipment.

Understanding the importance of this process cannot be overstated. Over time, impurities such as dirt, algae, and other particles can clog the medium, hindering effective water circulation. This obstruction can lead to decreased efficiency and increased energy consumption. Therefore, implementing a backwash routine not only enhances filtration effectiveness but also reduces operational costs.

Moreover, regular execution of this procedure contributes to better hygiene and safety. Clean water is essential for recreational activities and overall enjoyment. Neglecting maintenance can result in health risks associated with contaminated water. Thus, ensuring that the system is routinely backwashed is a proactive approach to maintaining quality and safety.

In conclusion, the backwash process is a vital practice that ensures the efficient operation of water purification systems. By facilitating the removal of build-up and promoting clean water, it plays a key role in both performance and safety.

Filter Laterals: Ensuring Efficient Water Flow

In any water circulation system, the efficient movement of fluid is paramount for optimal performance. A critical component that contributes to this seamless flow is a network of lateral structures. These elements play a vital role in distributing water evenly while minimizing pressure loss and preventing blockages.

Functionality of Lateral Components

The lateral structures serve as conduits, guiding water toward the central outlet. Their design allows for maximum surface area, promoting effective collection of water while filtering out impurities. Proper alignment and maintenance of these components are essential to ensure they function as intended, enhancing the overall efficiency of the system.

Importance of Material Selection

Choosing the right materials for these lateral components is crucial. Durable and corrosion-resistant substances can withstand harsh conditions, extending the lifespan of the system. Additionally, flexibility in design helps accommodate variations in water flow, ensuring consistent performance. Regular inspections and timely replacements of these parts can significantly impact the effectiveness of the entire assembly.

Inspecting and Replacing Broken Parts

Maintaining your system’s efficiency requires regular examination and timely replacement of any damaged components. Identifying and addressing issues promptly ensures optimal performance and prolongs the lifespan of the unit.

To effectively assess the condition of your equipment, follow these steps:

- Visual Inspection: Begin with a thorough visual assessment. Look for cracks, corrosion, or any unusual wear on the components.

- Functional Testing: Operate the system and observe its performance. Listen for abnormal sounds and check for leaks or inefficient operation.

- Component Removal: If you identify any problematic areas, carefully disassemble the necessary sections to access the affected components.

- Detailed Examination: Inspect the removed components closely. Look for signs of damage, such as discoloration or broken seals.

Once you have completed the inspection and identified any faulty components, it is time to replace them. Here’s how to proceed:

- Gather Replacement Parts: Ensure you have the correct replacement items that are compatible with your system.

- Follow Manufacturer Instructions: Refer to the manual for guidance on the installation process of new components.

- Seal and Secure: Make sure to properly seal all connections to prevent leaks and secure components tightly to avoid any future issues.

- Test the System: After reassembly, run the system again to verify that everything functions as expected.

By regularly inspecting and replacing damaged elements, you can ensure the longevity and effectiveness of your equipment, providing a reliable performance for years to come.

Troubleshooting Common Sand Filter Issues

Addressing issues related to the filtration system is crucial for maintaining optimal water clarity and hygiene. Various problems may arise during operation, often linked to component malfunctions or improper maintenance. Understanding these common challenges and their solutions can significantly enhance performance and prolong the lifespan of the apparatus.

Low Water Flow Rate

A significant reduction in water flow may indicate blockages or buildup within the mechanism. Start by checking the intake for debris and ensuring that all valves are fully open. If restrictions persist, consider performing a thorough cleansing of the medium to restore proper circulation.

Excessive Noise During Operation

Unusual sounds emanating from the unit can signify mechanical issues or air leaks. Inspect all connections for signs of wear or damage and ensure that the sealing elements are intact. Tightening loose fittings may also help eliminate unwanted vibrations and noise during functioning.

By systematically examining these common concerns and implementing the suggested remedies, users can effectively enhance the reliability and efficiency of their filtration system.

Maintaining Your Pool Sand Filter for Longevity

Ensuring the optimal performance of your water purification system requires regular upkeep and attention. By implementing a few essential maintenance practices, you can significantly extend the lifespan of your filtration equipment while enhancing its efficiency. Proper care not only protects your investment but also promotes a healthier aquatic environment.

Regular Inspections

Conducting periodic assessments of your apparatus is crucial. Look for signs of wear, leaks, or blockages that could impede functionality. Pay attention to connections and seals, ensuring they remain tight and free from corrosion. Identifying issues early can prevent more extensive damage and costly repairs down the line.

Cleaning and Backwashing

Routine cleansing is vital for maintaining optimal performance. Backwashing should be performed as needed, typically when the pressure gauge indicates a significant increase from the normal operating range. This process helps remove accumulated debris and contaminants, ensuring clear and healthy water circulation. Additionally, replacing the filtration medium periodically is essential for continued effectiveness.