In the world of farming, the efficiency of machinery plays a crucial role in enhancing productivity. A thorough grasp of the various elements that constitute these machines is essential for optimal performance and maintenance. Each component has a specific function, contributing to the overall operation of the equipment.

Exploring the intricate relationships between different segments allows operators and technicians to diagnose issues quickly and implement effective solutions. With a clear visualization of how each piece interacts within the larger system, it becomes easier to manage repairs and upgrades, ensuring that machinery remains in peak condition throughout its service life.

Familiarity with these essential units not only aids in troubleshooting but also empowers users to make informed decisions regarding replacements and enhancements. By understanding the structure of these mechanisms, individuals can better appreciate the technology that drives modern agriculture.

This section aims to provide a comprehensive overview of a particular agricultural machine, focusing on its components and their functionality. Understanding the individual parts and their arrangement is crucial for effective maintenance and operation. By examining each element, users can gain insights into the machine’s performance and efficiency.

- Introduction to the Equipment

A brief description of the machine’s purpose and its significance in modern agriculture.

- Key Components Overview

Highlighting essential elements that play a vital role in the overall functionality.

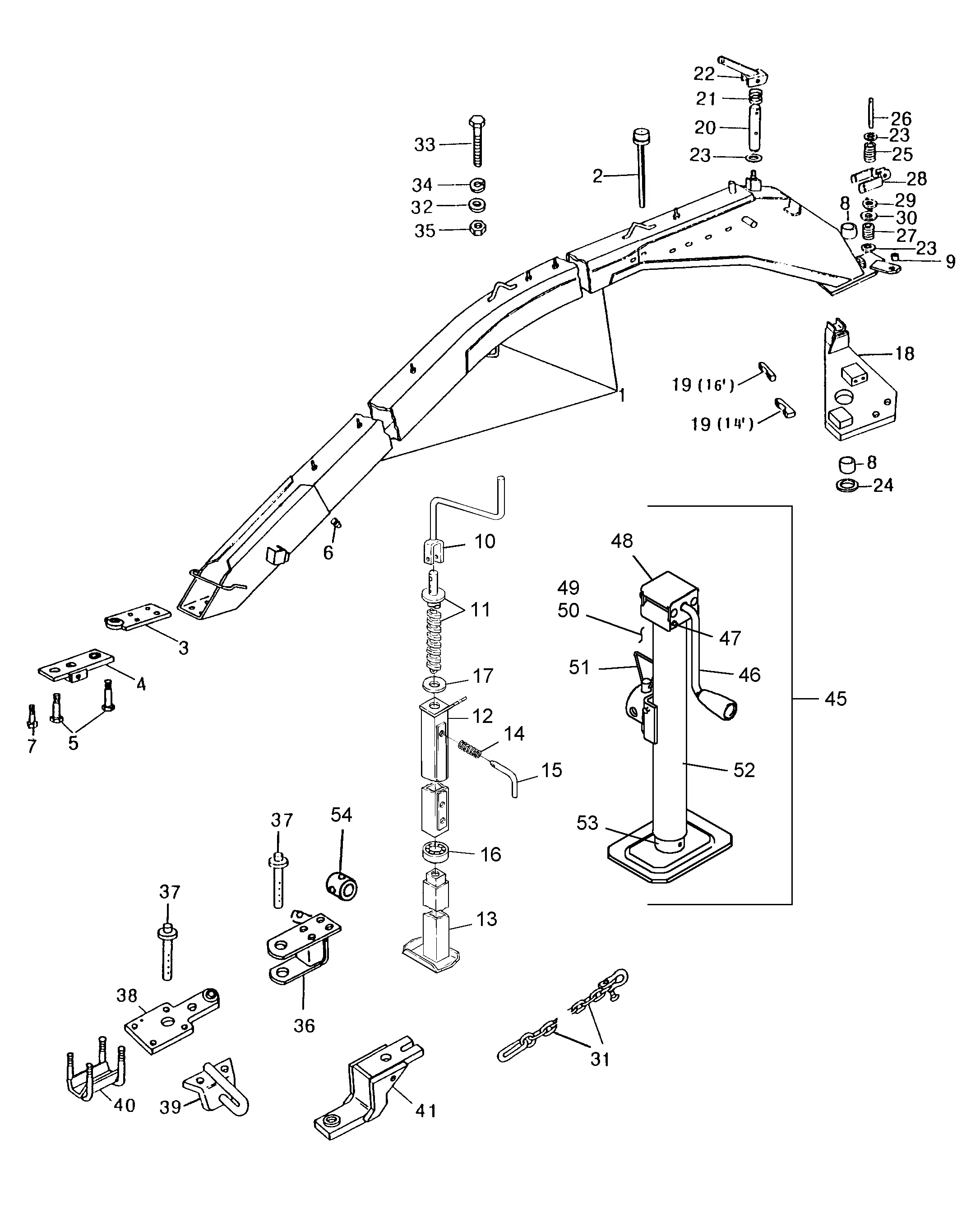

- Mechanical Structure

An exploration of the framework and how it supports various operations.

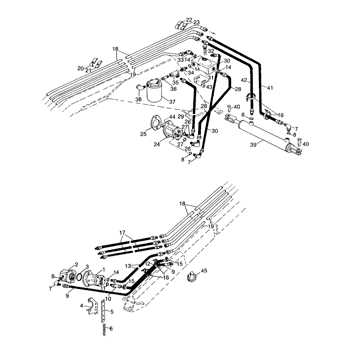

- Hydraulic System Functions

Detailing the hydraulic components and their importance in the machine’s operation.

- Electrical System Insights

Discussing the electrical parts that control various functionalities.

- Maintenance Best Practices

Providing tips on how to care for each part to ensure longevity.

- Common Issues and Troubleshooting

Identifying frequent problems and how to address them effectively.

- Replacement and Repair Guidance

Offering advice on when and how to replace components.

- Upgrades and Modifications

Exploring potential enhancements that can improve performance.

- Resource Recommendations

Suggesting manuals and online resources for further information.

- Conclusion

Summarizing the importance of understanding the various components for optimal use.

Components Overview of Hesston 1160

This section provides a comprehensive examination of the key elements that contribute to the functionality and efficiency of agricultural machinery. Understanding these components is essential for effective operation and maintenance.

| Component | Description | Function |

|---|---|---|

| Engine | Power unit that drives the entire system. | Provides the necessary power for operation. |

| Header | Front attachment for cutting crops. | Facilitates the efficient collection of crops. |

| Conveyor System | Mechanism for transporting harvested material. | Ensures smooth transfer of crops to the storage area. |

| Chassis | Frame that supports all components. | Provides structural integrity and stability. |

| Hydraulic System | System that operates various moving parts. | Controls the movement and operation of attachments. |

Importance of Accurate Diagrams

Detailed visual representations play a crucial role in understanding complex machinery and equipment. They provide essential information, allowing operators and technicians to comprehend the various components and their relationships. When these illustrations are precise, they facilitate effective maintenance and troubleshooting, ultimately enhancing the overall efficiency of operations.

Enhancing Efficiency

When individuals have access to clear visual guides, they can quickly identify parts and functions, reducing the time spent on repairs and adjustments. This efficiency translates to less downtime and improved productivity, making accurate visuals an invaluable asset in any operational environment.

Reducing Errors

Clear and precise visuals minimize the chances of mistakes during assembly or maintenance tasks. With reliable references, workers can ensure they are handling the correct components, thereby avoiding costly errors that can arise from misinterpretations. The accuracy of these representations contributes significantly to the reliability and longevity of equipment.

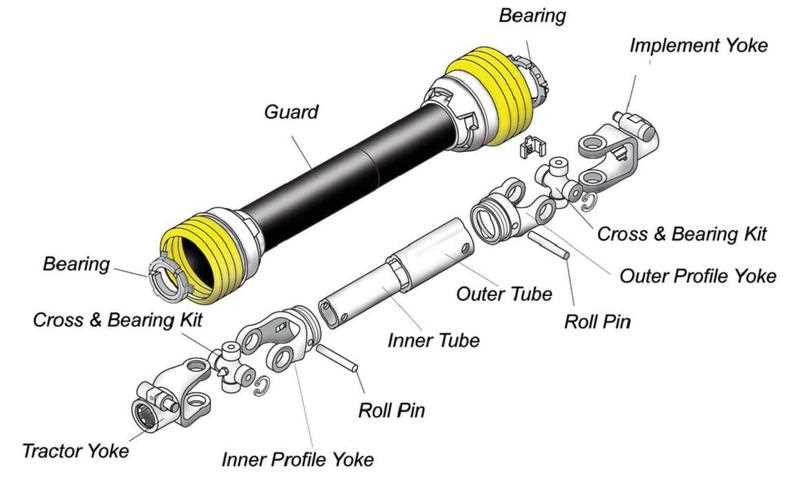

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations provide a clear overview of the various elements and their arrangements within a system, making it easier to identify specific parts and their functions. Mastering this skill can enhance your ability to troubleshoot and perform necessary adjustments efficiently.

Familiarize Yourself with Symbols

Each illustration often includes unique symbols that represent different components. Taking the time to learn these symbols will allow you to quickly decipher the information presented. Pay attention to legends or keys included in the visual that explain the meaning of each symbol, as this will serve as a valuable reference during your work.

Follow the Flow of the Assembly

When examining the visual representation, it’s crucial to follow the sequence of the assembly. Typically, components are arranged in a manner that reflects their physical connection and function within the system. Observing how these parts interrelate will provide insight into their roles and help you identify any potential issues.

In summary, gaining proficiency in interpreting these visual guides can significantly streamline your repair and maintenance tasks. With practice, you’ll find it easier to navigate through the complex arrangements and enhance your overall understanding of the system.

Common Issues in Parts Identification

Accurately identifying components in machinery can pose several challenges for operators and technicians. Variations in model specifications, manufacturing updates, and inconsistencies in labeling can complicate the process of sourcing the correct elements needed for maintenance or repair tasks.

Mislabeling and Confusion

Inconsistencies in labeling can lead to significant confusion when attempting to match components. Different manufacturers might use various terminology or part numbers, which can result in misidentification. Additionally, similar-looking parts may serve different functions, further complicating the selection process.

Understanding Compatibility

Another common issue arises from compatibility concerns. Even when parts appear identical, subtle differences in design or function can affect performance. It is essential to ensure that the selected components are compatible with the specific machinery to avoid potential failures or inefficiencies during operation.

Tips for Maintenance and Repairs

Regular upkeep and timely repairs are essential for ensuring the longevity and efficiency of your equipment. Adopting proactive measures can significantly reduce downtime and enhance overall performance.

1. Regular Inspections: Schedule frequent assessments to identify wear and tear early. Look for any signs of damage or malfunction, as addressing these issues promptly can prevent more significant problems.

2. Keep It Clean: Ensure that all components are free of dirt and debris. A clean environment helps in preventing unnecessary strain on the machinery, which can lead to premature wear.

3. Lubrication: Apply appropriate lubricants to moving parts regularly. Proper lubrication reduces friction and can significantly prolong the lifespan of various components.

4. Follow the Manual: Refer to the manufacturer’s guide for specific maintenance recommendations. Adhering to these guidelines ensures that you are using the equipment as intended and helps in maintaining warranty coverage.

5. Utilize Quality Replacement Parts: When repairs are necessary, always opt for high-quality components. Using inferior parts can compromise performance and lead to further issues down the line.

6. Keep Records: Maintain a detailed log of all maintenance activities and repairs performed. This documentation can be invaluable for tracking performance over time and can assist in troubleshooting future issues.

By implementing these practices, you can ensure that your machinery remains in optimal condition, ultimately leading to increased efficiency and reliability.

Where to Find Replacement Parts

When it comes to maintaining machinery, sourcing the right components is crucial for ensuring optimal performance. Identifying reliable suppliers and understanding the options available can significantly impact the longevity and efficiency of your equipment.

Authorized Dealers

One of the most dependable sources for obtaining components is through authorized dealers. These vendors are equipped with a comprehensive inventory and are familiar with the specific requirements of your machinery. Additionally, they can provide expert advice on compatibility and installation.

Online Marketplaces

The internet offers a wealth of options for sourcing equipment components. Various online platforms facilitate connections between buyers and sellers, often featuring a broad selection of products. Be sure to check reviews and ratings to ensure the credibility of the sellers, which can help in making informed purchasing decisions.

In summary, whether you opt for an authorized dealer or an online marketplace, conducting thorough research is essential for securing the necessary components effectively.

Benefits of Using OEM Parts

Utilizing original equipment manufacturer components ensures superior quality and compatibility with your machinery. These items are specifically designed to meet the exact specifications and standards set by the original manufacturer, offering reliable performance and durability.

Enhanced Performance: OEM components are engineered to work seamlessly with your equipment, resulting in improved functionality and efficiency. This compatibility minimizes the risk of malfunctions and enhances the overall operation of the machinery.

Longer Lifespan: Original parts are typically manufactured from high-quality materials, which contribute to a longer service life. This longevity translates to reduced replacement frequency, saving both time and money in the long run.

Warranty Protection: Using OEM components often preserves the manufacturer’s warranty on your equipment. This protection is vital, as it safeguards your investment and ensures you receive necessary support in case of future issues.

Safety Assurance: Original components undergo rigorous testing to ensure they meet safety standards. This commitment to quality not only protects your machinery but also enhances the safety of the operator.

In conclusion, opting for original equipment manufacturer components offers a multitude of advantages that contribute to the longevity, efficiency, and safety of your machinery.

Upgrading Hesston 1160 Components

Improving the efficiency and performance of agricultural machinery often involves enhancing various elements. By focusing on specific components, operators can achieve better productivity, reliability, and overall functionality. This section explores key considerations for modernizing equipment, ensuring optimal operation in diverse agricultural settings.

Identifying Key Areas for Improvement

To initiate the upgrade process, it is essential to assess the current condition of the equipment. Look for signs of wear and tear, as well as areas that may benefit from enhanced technology or improved materials. Upgrading essential components such as the hydraulic system or drive mechanisms can significantly boost overall efficiency.

Choosing Compatible Enhancements

When selecting new components, prioritize compatibility with existing systems. Researching available options and consulting with experts can aid in finding suitable replacements that meet specific operational needs. Additionally, consider features that enhance functionality, such as advanced controls or better energy efficiency. Investing in quality upgrades can lead to long-term savings and increased productivity.

Assembly Instructions for Key Parts

The following guidelines aim to provide a comprehensive approach to assembling essential components of agricultural machinery. Understanding the correct assembly process is crucial for ensuring optimal performance and longevity of the equipment.

1. Preparation: Begin by gathering all necessary components and tools. Ensure that the work area is clean and organized to facilitate a smooth assembly process.

2. Component Orientation: Pay close attention to the orientation of each component. Align the pieces according to the provided specifications, ensuring that all connecting points fit seamlessly together. Misalignment can lead to mechanical issues during operation.

3. Fastening Elements: Utilize the appropriate fastening elements, such as bolts and nuts, to secure each part firmly. It is essential to tighten these fasteners to the recommended torque settings to prevent any loosening during use.

4. Final Checks: After assembly, conduct a thorough inspection to verify that all components are correctly positioned and securely attached. Check for any signs of damage or wear that could affect functionality.

Following these instructions will help ensure that the assembly process is efficient and that the machinery operates as intended.

Frequently Asked Questions

This section addresses common inquiries regarding the components and functionality of agricultural machinery. It aims to provide clarity on various aspects, ensuring users have the information needed for effective operation and maintenance.

What are the key features to consider when looking for replacement components?

Replacement components should be durable and compatible with your equipment. It is essential to check specifications and verify that the parts meet the operational standards required for optimal performance.

How can I identify specific elements in my machinery?

Identifying elements in your machinery can be achieved by consulting technical documentation or by examining the equipment closely for labels and numbers. This information helps in sourcing the correct replacements and understanding the machinery’s layout.

Resources for Hesston 1160 Owners

For owners of specialized agricultural equipment, access to reliable information and support is essential. This section provides a variety of resources to enhance the ownership experience, ensuring that operators can maintain and optimize their machines effectively. Understanding the available materials can lead to improved performance and longevity of the equipment.

Online forums and communities are invaluable for sharing experiences, troubleshooting issues, and connecting with other enthusiasts. Additionally, manufacturer websites often offer a wealth of resources, including manuals, maintenance tips, and technical specifications, which can aid in understanding the machinery better. Accessing these platforms allows users to gain insights that can be beneficial for effective operation and maintenance.

Moreover, local dealers and service centers provide expert assistance, ensuring that any repairs or replacements are handled by professionals. Regular workshops and training sessions hosted by industry experts can also empower users with knowledge about best practices and innovative techniques. These resources collectively contribute to a better understanding of the equipment, fostering a proactive approach to ownership.