Exploring the components and mechanisms of various devices is key to maintaining and repairing them effectively. Each element plays a significant role in ensuring the tool functions as intended, contributing to its overall efficiency and durability.

Identifying key elements within such equipment allows users to better understand how these parts interact with each other. This knowledge empowers individuals to troubleshoot issues and perform maintenance with greater confidence and accuracy.

By familiarizing yourself with the structure and internal setup, you can ensure proper use and extend the lifespan of your tools. Knowing where each component fits into the bigger picture is vital for seamless operation.

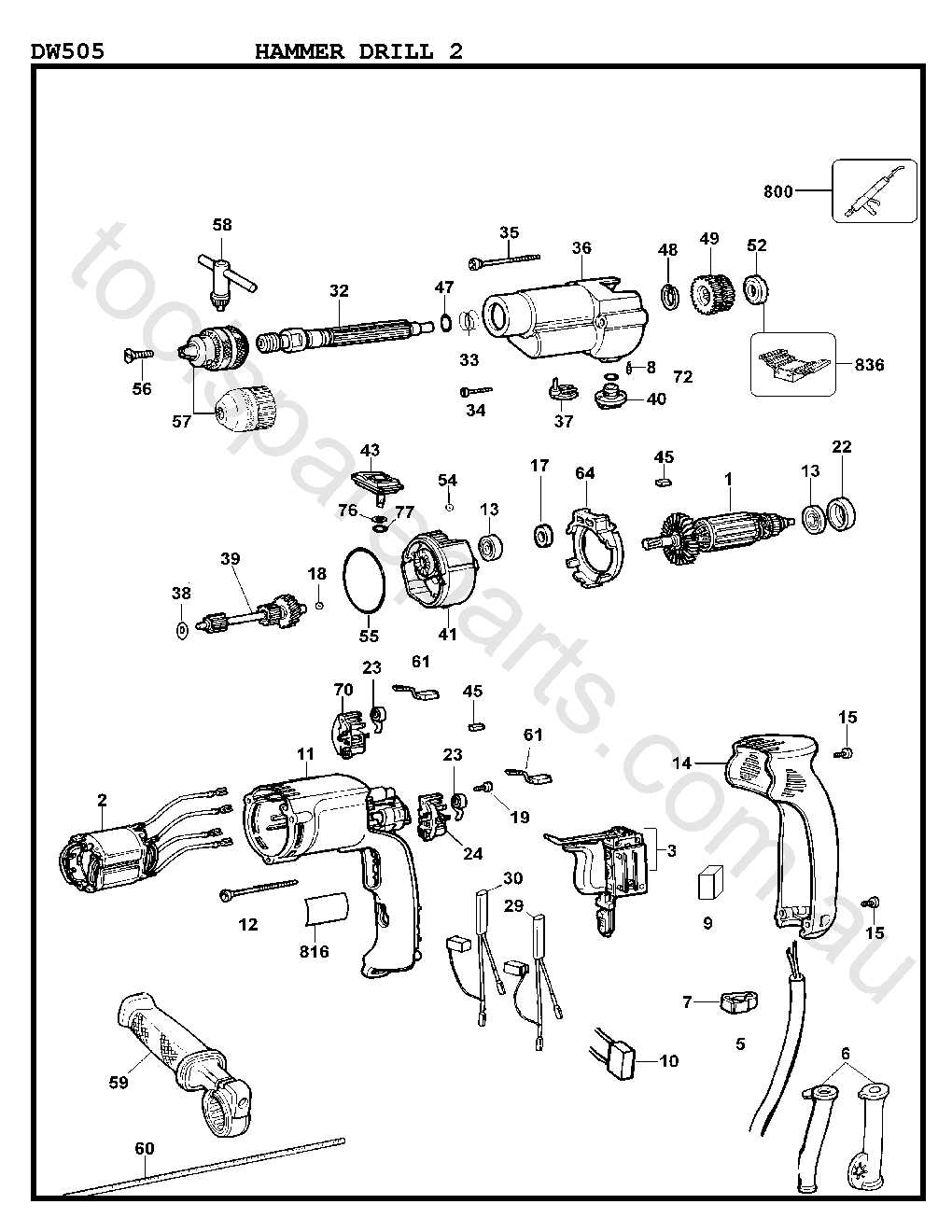

Hilti DX2 Parts Overview

The tool in question consists of multiple essential elements, each contributing to its efficient operation. Understanding the structure and arrangement of these components ensures a smoother experience during maintenance and repairs. The device’s core setup is built around robust materials, designed to handle various tasks with ease and precision.

Key Components

- Firing mechanism

- Energy source

- Fastening unit

Additional Elements

- Safety features

- Trigger system

- Handle and support

By understanding these fundamental aspects, users can maintain the equipment in optimal condition and handle any potential issues more effectively.

Components of the DX2 Tool

The operational mechanism of this tool consists of several key elements, each contributing to its overall functionality and performance. These components work together to ensure precision, efficiency, and durability in various tasks.

Core parts include the main unit responsible for energy transfer, the firing mechanism, and a set of small yet essential internal elements that help maintain balance and control during use. Each piece is designed with a specific role in mind, ensuring the device can handle high-intensity applications without compromise.

Additionally, the external sections, such as the grip and protective covers, are engineered for user comfort and safety, providing a firm hold and shielding the internal system from potential damage.

Key Elements in the DX2 Mechanism

The functioning of this tool relies on several crucial components that work together to ensure smooth operation and high efficiency. Each element is carefully designed to contribute to the overall performance, allowing the device to deliver consistent results.

Core components include elements responsible for power delivery, stability, and precision. These parts ensure that the mechanism remains reliable, even under demanding conditions. Each section plays a unique role, enhancing both durability and ease of use.

Exploring the DX2 Power System

In this section, we delve into the core elements that drive the performance of the DX2 tool. Understanding the dynamics of its power system is crucial for optimizing its functionality. Let’s explore the key components and their roles in ensuring efficient operation.

- The heart of the DX2 lies in its robust energy mechanism, which powers each operation seamlessly.

- A critical aspect is the management of power distribution, ensuring consistent performance across various tasks.

- Exploring the integration of advanced energy control systems enhances user experience and operational safety.

- Components such as power regulators and energy converters play pivotal roles in optimizing performance.

- The synergy between power generation and utilization defines the DX2’s reliability and endurance.

By comprehensively exploring these facets, users can harness the full potential of the DX2 power system, ensuring reliable and efficient operation across diverse applications.

Internal Structure of the DX2

The inner configuration of this tool is designed to optimize functionality and enhance user experience. It comprises several integral components that work cohesively to ensure efficient operation and durability.

At the core of the assembly lies a robust mechanism that facilitates the primary functions of the device. This central unit is supported by an array of carefully engineered parts, each serving a specific role in the overall performance.

The exterior casing is constructed from high-quality materials, providing protection to the internal elements while ensuring a comfortable grip for the user. This ergonomic design not only enhances usability but also contributes to the longevity of the tool.

Additionally, the internal elements are strategically positioned to allow for easy maintenance and accessibility. This thoughtful arrangement ensures that users can quickly address any necessary adjustments or repairs without extensive disassembly.

Overall, the structural design reflects a commitment to quality and practicality, making this tool a reliable choice for various applications.

DX2 Fastener Loading and Firing Parts

The efficient operation of a fastening tool relies heavily on its loading and firing mechanisms. Understanding how these components interact is crucial for ensuring optimal performance and reliability during use.

Loading mechanisms facilitate the seamless insertion of fasteners into the tool, enabling quick and precise application. These systems are designed to minimize downtime and enhance productivity, allowing users to complete tasks with greater efficiency.

Equally important, the firing assembly is responsible for delivering the necessary energy to secure fasteners securely. This assembly ensures consistent power and control, allowing for accurate placement even in challenging environments. Proper maintenance and familiarity with these mechanisms can greatly improve user experience and outcomes.

Essential Maintenance Parts for the DX2

Proper upkeep of equipment ensures longevity and optimal performance. Understanding the key components that require regular attention can significantly enhance functionality and reduce downtime. Identifying these critical elements aids in maintaining efficiency and safety during operation.

One of the primary items to consider is the firing mechanism, which is vital for reliable operation. Ensuring this component is in top condition prevents misfires and enhances accuracy. Additionally, the power source should be regularly inspected and maintained to ensure consistent energy supply and prevent unexpected failures.

Another important aspect is the protective casing, which safeguards internal mechanisms from external damage. Regular checks for wear and tear can prevent costly repairs. Finally, lubrication points are essential for smooth movement of parts, reducing friction and prolonging the life of the equipment. Regular maintenance of these components contributes significantly to overall performance and reliability.

Durable Materials in the DX2 Design

The construction of this tool emphasizes resilience and long-lasting performance. The choice of materials plays a critical role in ensuring that it withstands demanding conditions while maintaining functionality. Utilizing high-quality components not only enhances durability but also contributes to overall efficiency.

Among the various materials selected for its assembly, several stand out due to their exceptional properties:

| Material | Properties |

|---|---|

| Steel | High strength, corrosion-resistant, ensures structural integrity |

| Polymer | Lightweight, impact-resistant, provides flexibility in design |

| Aluminum | Low weight, excellent thermal conductivity, resistant to oxidation |

| Rubber | Shock-absorbent, enhances grip, provides cushioning in operation |

These materials are thoughtfully integrated into the tool’s design, resulting in a product that is not only effective but also built to last. This approach reflects a commitment to quality and performance, essential for any demanding task.

DX2 Trigger and Safety Mechanism

The triggering system and safety features of this tool are essential for ensuring efficient and secure operation. They play a crucial role in enhancing user control and minimizing the risk of accidental activation, contributing to a safer working environment.

Operation of the Trigger

The trigger mechanism is designed to provide a smooth and responsive activation experience. Key aspects include:

- Intuitive design for effortless handling.

- Quick response time for immediate activation.

- Ergonomic placement for enhanced comfort during prolonged use.

Safety Features

Incorporating multiple safety measures is vital for preventing unintended discharges. Important features include:

- Manual safety lock to prevent accidental firing.

- Automatic shut-off in case of improper usage.

- Clear indicators to signal operational readiness and safety status.

Guide to DX2 Firing Pin Assembly

The firing mechanism in certain tools relies heavily on the precision and durability of its components. Understanding how the ignition component is assembled is essential for both maintenance and troubleshooting. A proper assembly ensures that the tool operates smoothly and efficiently, reducing the risk of malfunction during use.

When assembling, the alignment of all components must be precise. Each part has a specific role, working together to trigger the firing process reliably. It’s crucial to follow the manufacturer’s instructions, ensuring that all pieces are positioned correctly and secured properly to avoid damage or wear.

To complete the process, double-check that all parts are clean and free from debris, as even small particles can affect the tool’s performance. Regular inspection and correct reassembly will extend the life of the tool and ensure safe and efficient operation.

Replacement Parts for the DX2 Tool

Over time, any tool may require specific components to maintain optimal performance. Regular upkeep and timely replacements ensure smooth operation and extend the equipment’s lifespan. This section focuses on the key elements that may need attention and how to identify them for effective repairs.

- Firing Mechanism: Essential for the tool’s core functionality, this component may experience wear and tear, requiring periodic maintenance or replacement to ensure continued precision and power.

- Fastener Guide: This part ensures accurate alignment and application of fasteners. It is crucial to check for any signs of damage or misalignment to maintain accuracy.

- Power Load Chamber: Properly functioning chambers are critical for handling power loads safely and efficiently. A faulty chamber could lead to performance issues.

- Trigger Assembly: The trigger

Adjusting the DX2 Power Regulator

To ensure optimal performance when working with tough materials, the tool’s power settings must be fine-tuned. Adjusting the energy output is crucial for matching the strength of the material with the tool’s firing capacity. This process helps prevent damage to the tool and ensures proper depth and efficiency in applications.

Steps for Adjusting Power

- Locate the power regulator knob on the tool’s body.

- Turn the knob clockwise to increase power or counterclockwise to decrease power.

- Test on a sample surface to ensure the correct level of force is applied.

When to Adjust

- When working with materials of varying densities.

- To control the depth of fasteners for different surface types.

- For adjusting energy output when transitioning between projects.

Understanding the DX2 Piston System

The piston system is at the core of ensuring efficient operation in various fastening tools. This mechanism plays a crucial role in delivering the necessary force to drive nails or fasteners into different materials, providing both precision and power. By understanding its components and functionality, one can achieve better performance and maintenance of the tool.

Main Components of the Piston System

The piston system comprises several key elements that work together to transfer energy. These include the firing pin, piston rod, and chamber. Each of these parts must operate in sync to ensure smooth firing and retraction, allowing for continuous use with minimal wear.

Component Function Firing Pin Initiates the force required for driving