In the realm of construction and industrial applications, the efficiency and durability of powerful equipment are paramount. A well-designed machine not only enhances productivity but also ensures the safety of its operators. This section delves into the intricate assembly of a specific high-performance device, breaking down its essential elements and functions.

Familiarity with the inner workings of these robust tools can greatly assist users in maintenance and troubleshooting. By exploring the various segments that contribute to the overall functionality, one can gain valuable insights into optimal usage and care. Understanding how each component interacts can lead to improved performance and longevity of the equipment.

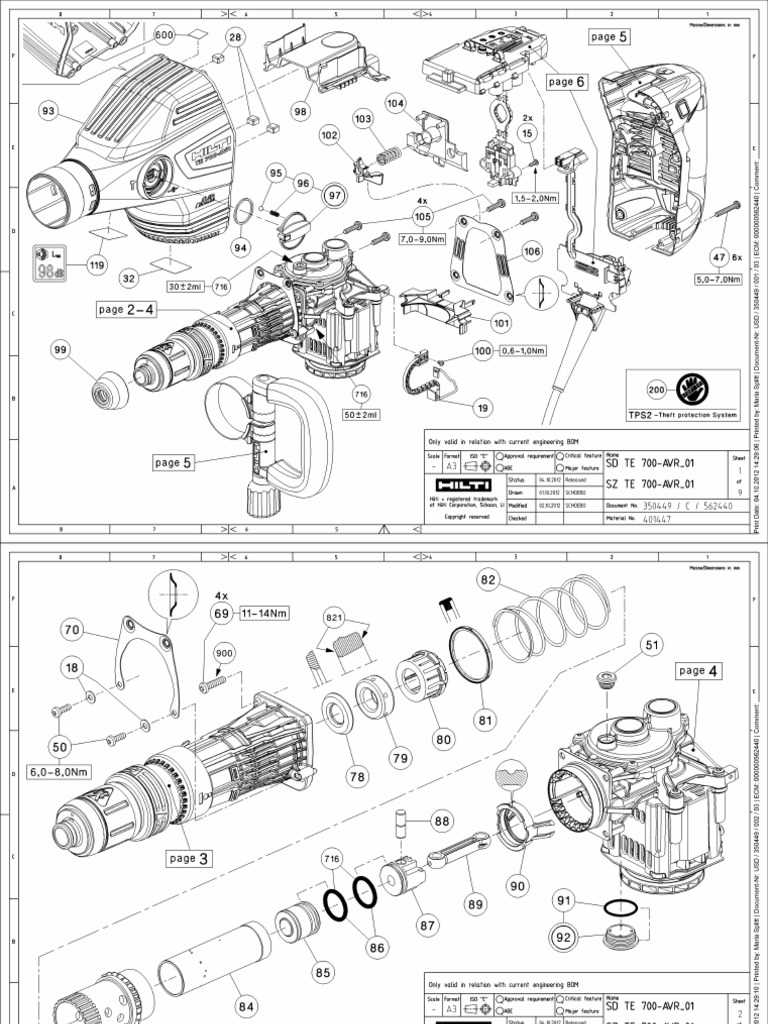

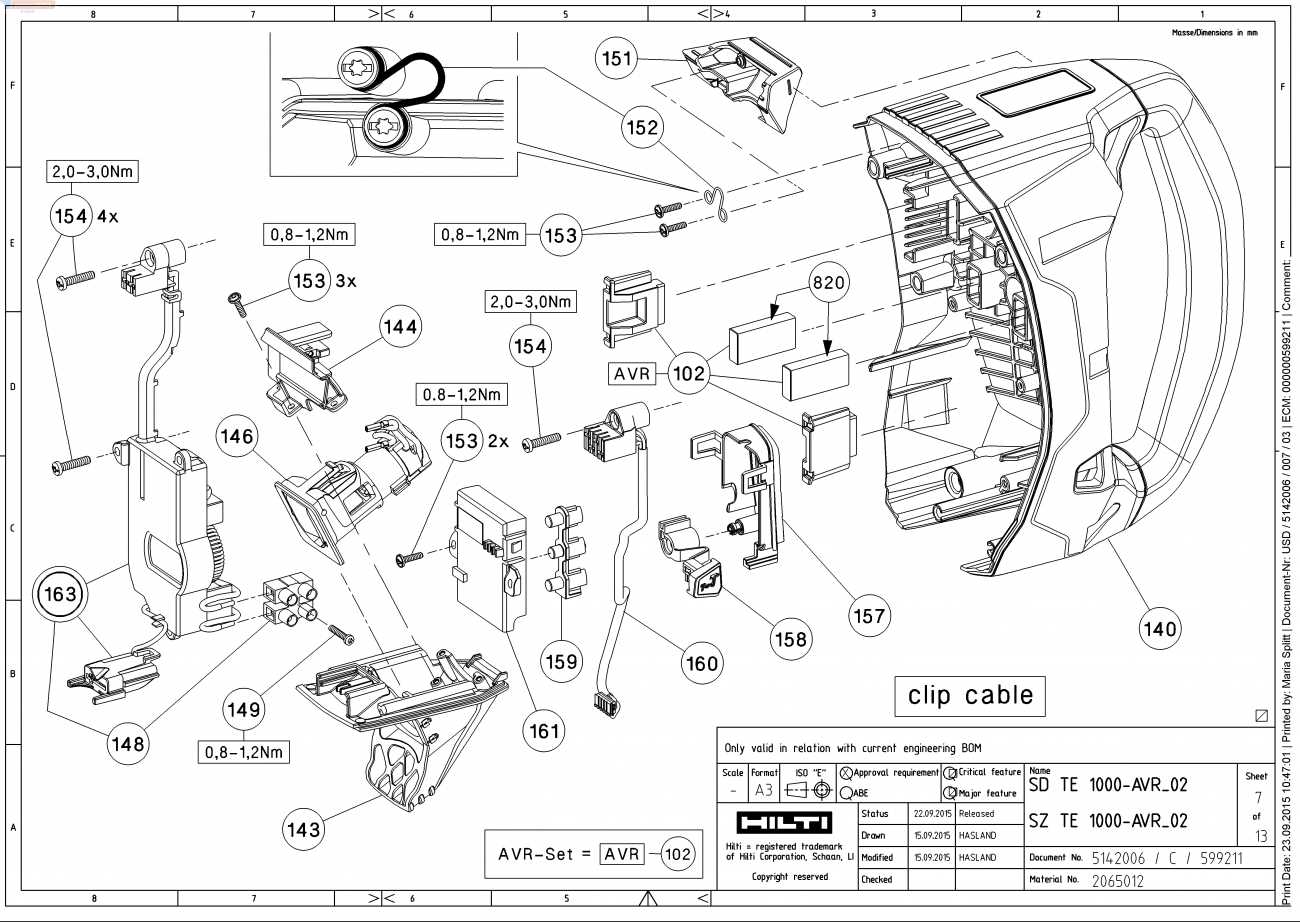

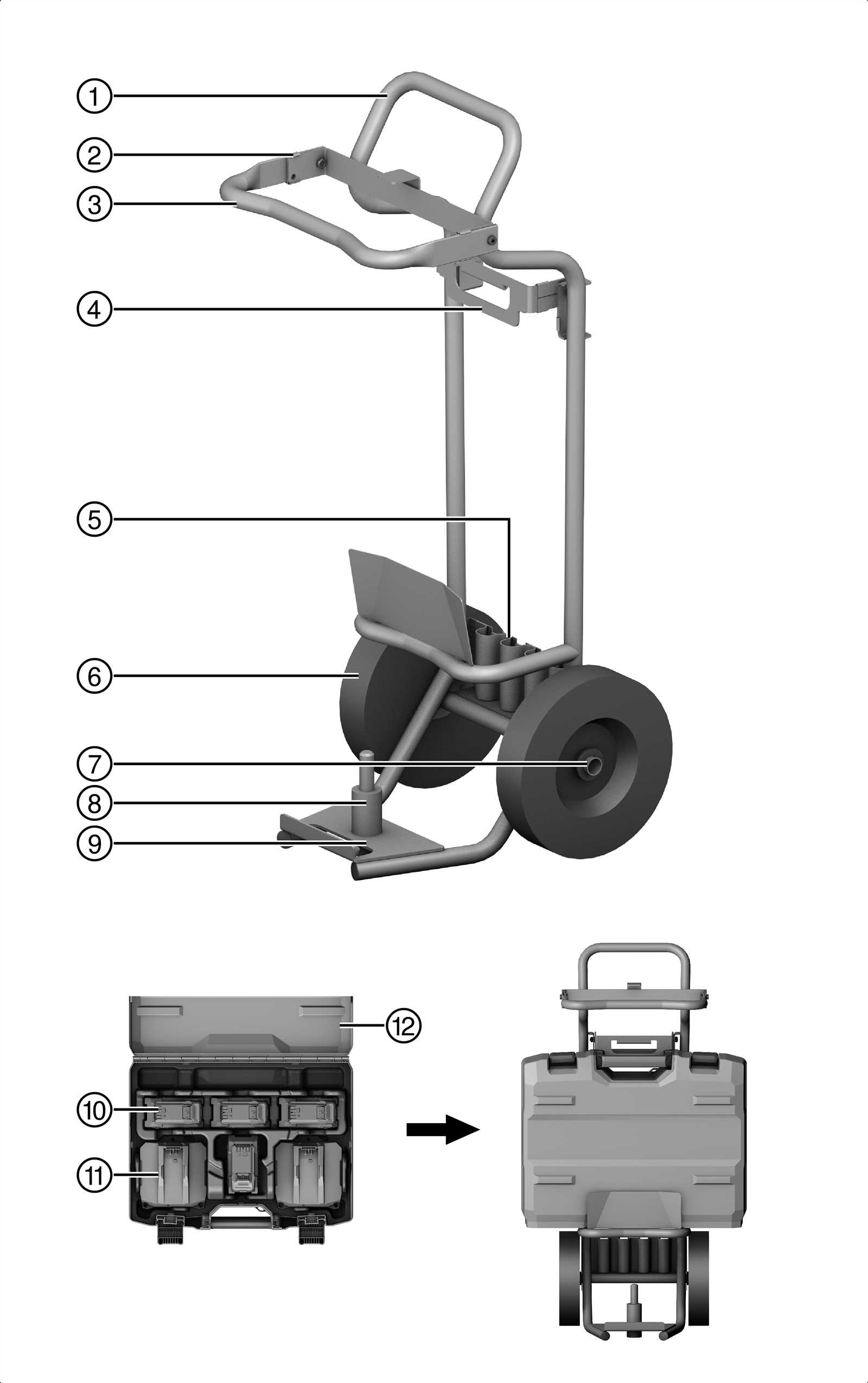

Moreover, having access to a visual representation of these elements aids in comprehending their arrangement and role within the system. Whether you are a seasoned professional or a novice, this knowledge empowers users to make informed decisions, ensuring their tools remain in peak condition throughout their operational lifespan.

Understanding Hilti TE 2000-AVR

This section aims to explore a powerful tool designed for heavy-duty applications, highlighting its unique features and functionalities. Users can benefit from a comprehensive understanding of its components and their roles in achieving optimal performance.

- Robust construction for durability

- Advanced vibration reduction technology

- Efficient energy consumption

By examining these aspects, users can enhance their operational skills and ensure longevity in their equipment.

- Identify key components for maintenance.

- Understand the operational mechanics for improved efficiency.

- Learn troubleshooting techniques for common issues.

Ultimately, a deeper insight into this tool empowers users to maximize their productivity and minimize downtime.

Overview of TE 2000-AVR Features

This section provides a comprehensive examination of a powerful tool designed for efficiency and performance in demanding tasks. Its innovative design incorporates advanced technology, making it an essential asset for professionals seeking reliability and precision.

Vibration Reduction: The integrated system significantly minimizes vibrations, enhancing user comfort and reducing fatigue during extended use.

Robust Power: Equipped with a high-performance motor, this device delivers exceptional drilling capabilities, ensuring effective results in tough materials.

Ergonomic Design: Its thoughtful construction facilitates ease of handling, promoting optimal control and maneuverability for various applications.

Durability: Built with high-quality materials, it offers remarkable resilience, ensuring longevity even in the most challenging environments.

Versatility: This tool is compatible with a range of accessories, enabling users to tackle diverse projects with ease.

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the intricate systems of machinery. These illustrations serve as invaluable tools for technicians and users alike, offering clarity and precision when it comes to maintenance, assembly, and troubleshooting. By showcasing each element’s location and function, they simplify complex tasks and enhance overall efficiency.

Enhancing Communication

Clear visuals improve communication between team members, reducing the chances of misinterpretation. When everyone has access to the same detailed illustrations, it fosters a collaborative environment where knowledge is shared effectively.

Streamlining Maintenance

Access to accurate visual guides significantly speeds up repair and maintenance processes. Technicians can quickly identify the required components, reducing downtime and ensuring that machinery operates smoothly. The ability to visualize the assembly and disassembly procedures further aids in performing tasks with confidence.

| Benefit | Description |

|---|---|

| Clarity | Helps users understand complex systems easily. |

| Efficiency | Reduces time spent on maintenance and repairs. |

| Training | Serves as a learning tool for new employees. |

Main Components of the Tool

Understanding the fundamental elements of a powerful tool is essential for both efficient operation and effective maintenance. Each component plays a crucial role in the overall functionality, contributing to its performance and durability. This section will explore the primary features that define this robust device.

Motor and Power System

The heart of the equipment lies in its motor, which provides the necessary energy to drive the mechanism. This component is designed for high efficiency and reliability, ensuring that the tool operates smoothly under various conditions. Coupled with an advanced power system, the motor enables optimal performance, allowing users to tackle demanding tasks with ease.

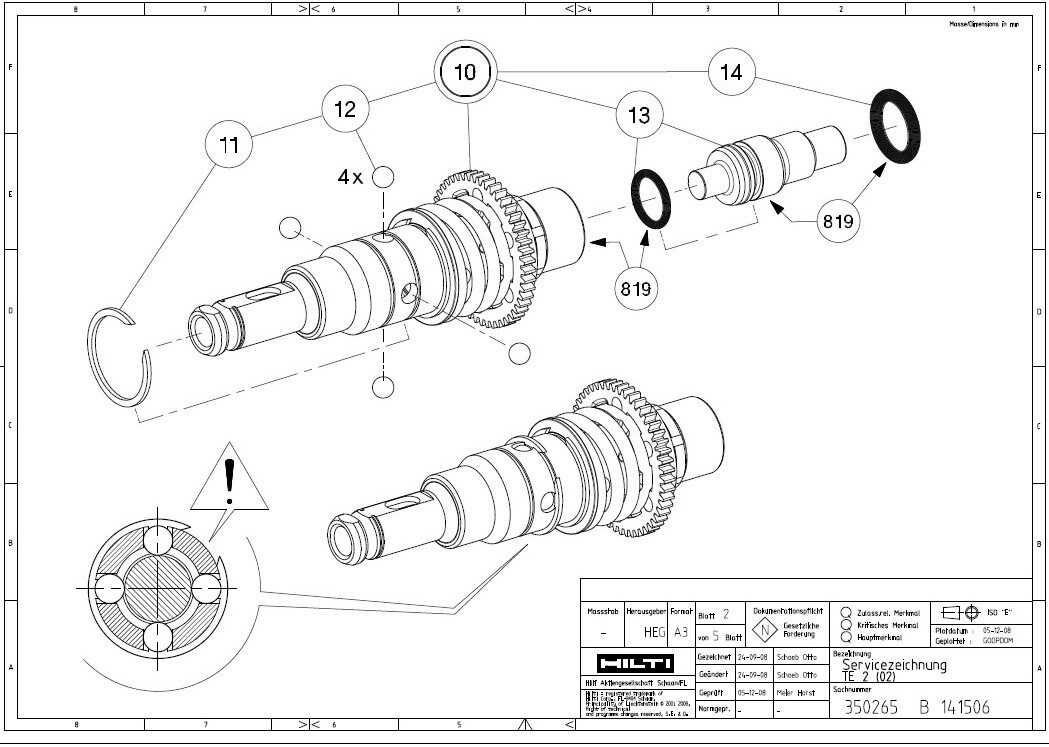

Drilling Mechanism

Another critical element is the drilling mechanism, which facilitates the actual penetration into different materials. This part is engineered to handle a variety of substrates, offering versatility in applications. The design incorporates features that minimize vibration and maximize precision, ensuring that each operation is both effective and safe.

How to Read Parts Diagrams

Understanding visual schematics is essential for effectively identifying components and their relationships within a mechanical assembly. These illustrations provide a simplified representation, allowing users to grasp the layout and functionality of various elements. By interpreting these visuals, one can efficiently locate specific pieces, facilitating repairs or replacements.

Begin by familiarizing yourself with the symbols and notations used in the illustration. Each element typically corresponds to a particular component, often labeled for easy identification. Pay attention to the lines connecting the symbols, as they indicate how parts interact or fit together.

Next, note any accompanying annotations or legends that clarify the representation. These supplementary details can provide insight into specifications, such as dimensions or material types, enhancing your understanding of the assembly.

Lastly, practice analyzing different visuals to build confidence. The more you engage with these representations, the better you will become at quickly deciphering information and locating necessary components in any assembly.

Common Parts and Their Functions

This section explores essential components found in heavy-duty tools, focusing on their roles and significance in ensuring optimal performance. Understanding these elements is crucial for efficient operation and maintenance.

Motor: The heart of the equipment, the motor generates the necessary power to drive the tool, influencing its speed and efficiency.

Gearbox: This component adjusts the torque and speed, enabling the tool to handle various tasks by providing the right balance between power and precision.

Chucks: These fixtures hold the drilling bits securely in place, allowing for safe and effective operation across different materials.

Handles: Ergonomically designed for comfort, they provide the user with control and stability during use, reducing fatigue and enhancing accuracy.

Cooling System: Essential for maintaining optimal temperature, this system prevents overheating, ensuring longevity and reliability of the tool.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended lifespan and optimal performance of your equipment. By adopting a few simple practices, you can enhance reliability and minimize the likelihood of unexpected failures.

Regular Cleaning

Keep the device clean and free of debris. Accumulation of dust and dirt can impede functionality and lead to damage over time.

Routine Inspections

Conduct frequent checks to identify wear and tear. Early detection of issues can save time and costs associated with major repairs.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Cleaning | Weekly | Improves performance |

| Lubrication | Monthly | Reduces friction |

| Inspection | Quarterly | Identifies potential issues |

Replacing Worn Out Parts

Maintaining the efficiency of your tools is crucial for optimal performance and longevity. Over time, components can wear down, affecting functionality and safety. Addressing these issues promptly ensures your equipment operates smoothly and effectively.

When considering the replacement of deteriorated components, follow these steps for a successful process:

- Identify the Issue: Regularly inspect your tools for signs of wear, such as unusual noises, decreased performance, or visible damage.

- Gather Information: Refer to the manual or manufacturer’s resources to understand the specific components that may need replacement.

- Acquire Quality Replacements: Choose high-quality alternatives from reputable suppliers to ensure compatibility and reliability.

- Follow Proper Procedures: Adhere to manufacturer guidelines for disassembly and installation to avoid further damage.

- Test the Equipment: After replacing components, conduct thorough tests to ensure everything operates correctly.

By regularly assessing and replacing worn elements, you can extend the lifespan of your tools and maintain peak performance.

Identifying Part Numbers Easily

When working with heavy-duty equipment, recognizing the correct components can significantly streamline maintenance and repair tasks. Understanding how to efficiently identify these essential elements ensures that projects are completed without unnecessary delays. By familiarizing oneself with systematic approaches, users can enhance their productivity and avoid the pitfalls of misidentification.

Utilizing Reference Guides: One effective method is to consult comprehensive reference guides or manuals associated with the machinery. These resources typically offer detailed descriptions and visuals, making it easier to match components with their corresponding identifiers.

Online Resources: In today’s digital age, many manufacturers provide online databases or interactive tools. These platforms allow users to input specific details or search by category, yielding precise part numbers swiftly.

Collaborative Networks: Engaging with forums and communities can also be beneficial. Many professionals share their experiences and insights, which can lead to quicker identification of required components through collective knowledge.

Labeling Systems: Implementing a systematic labeling strategy within your workspace can aid in quick identification. Organizing tools and components with clear labels not only enhances efficiency but also reduces the likelihood of errors during maintenance.

By adopting these strategies, users can navigate the complexities of identifying component identifiers with greater ease, ultimately leading to improved workflow and productivity.

Where to Buy Replacement Parts

Finding components for specialized tools can be a challenge, but numerous avenues exist for sourcing high-quality replacements. Whether you require a specific element for repair or maintenance, understanding where to look can save both time and money.

Authorized Dealers

One of the most reliable options is to purchase from authorized distributors. These retailers offer genuine items that are designed to meet the manufacturer’s specifications, ensuring compatibility and performance.

Online Marketplaces

The internet provides a wealth of resources for obtaining various components. Reputable e-commerce platforms often feature a wide selection of products from different brands, making it easy to compare prices and find the best deal.

| Source | Description | Advantages |

|---|---|---|

| Authorized Retailers | Official sellers of the brand’s products. | Genuine items, warranty support. |

| Online Marketplaces | Websites that offer various brands and components. | Convenience, price comparison. |

| Local Hardware Stores | Community shops that may carry compatible items. | Immediate availability, local support. |

| Second-Hand Stores | Shops that sell used tools and components. | Lower prices, unique finds. |

Common Issues and Troubleshooting

When operating powerful tools, users may encounter various challenges that can affect performance and efficiency. Identifying these common issues is crucial for maintaining optimal functionality and ensuring safety during use. Understanding the potential problems and their solutions can significantly reduce downtime and enhance overall productivity.

One frequent concern is inadequate power delivery, which can stem from electrical malfunctions or poor connections. Users should first inspect the power source and ensure that all connections are secure. If the tool fails to start, checking the circuit breaker or fuses might reveal underlying electrical issues.

Another issue that may arise is excessive vibration or noise during operation. This could indicate wear and tear on internal components. Regular maintenance, including lubrication and inspection of moving parts, is essential to mitigate these problems. If unusual sounds persist, disassembling the unit for a thorough examination might be necessary.

Overheating is also a common problem, often caused by prolonged use without breaks. To avoid this, operators should adhere to recommended usage times and allow the tool to cool down periodically. Additionally, ensuring proper ventilation can help maintain optimal operating temperatures.

Lastly, users may face challenges related to tool alignment or accuracy. If the output is not as expected, recalibrating the device or checking for any obstructions can resolve the issue. Keeping the tool clean and free from debris is vital for achieving precise results.

Comparative Analysis with Similar Models

This section delves into the evaluation of a specific power tool in relation to its counterparts within the same category. By examining various features, performance metrics, and design elements, we aim to highlight the strengths and weaknesses that set these models apart from one another.

Performance Metrics

When assessing power tools, performance is a crucial factor. Models within this category often exhibit varying levels of efficiency, power output, and durability. Some may excel in terms of raw power, while others might prioritize precision and control. Analyzing these aspects allows users to select a tool that best fits their operational needs.

Design and Usability

The ergonomic design and user-friendliness of tools can significantly influence their overall effectiveness. Certain models may incorporate advanced features aimed at enhancing user comfort and reducing fatigue during extended use. Comparing these design elements can provide insights into which tool offers the most practical advantages for everyday tasks.

User Experiences and Reviews

This section aims to provide insights into the feedback and testimonials from users who have interacted with various tools and machinery. Understanding real-world experiences helps potential buyers make informed decisions, as they can gauge the performance, durability, and overall satisfaction associated with different models.

Performance Insights

Many users have noted the impressive efficiency and power of these devices, making challenging tasks significantly easier. One user stated, “The tool has exceeded my expectations in terms of speed and reliability.” This sentiment is echoed by several others who appreciate the robust design that withstands heavy-duty use.

Ease of Use and Maintenance

Feedback regarding user-friendliness is generally positive, with several reviewers highlighting the intuitive controls and lightweight design. “I found it very easy to handle, even during extended use,” remarked one satisfied customer. Maintenance is also straightforward, with many users mentioning that keeping the device in top shape requires minimal effort.