The intricate design of high-performance equipment often requires a detailed examination of their components. Knowing how each segment interacts not only enhances efficiency but also extends the lifespan of the machine. This section delves into the essential elements that comprise a robust tool, offering insights into their functionality and arrangement.

Every construction professional understands the importance of maintaining their gear. To achieve optimal performance, it is crucial to have a comprehensive overview of the internal structure. By dissecting the various pieces, one can appreciate the engineering prowess behind these devices and learn how to address potential issues.

Furthermore, a clear visual representation of the assembly allows users to identify components quickly, facilitating easier repairs and upgrades. Understanding these relationships empowers users, making them more adept at managing their equipment and ensuring it operates smoothly under demanding conditions.

Understanding Hilti TE 52 Overview

This section provides a comprehensive look at a powerful tool designed for professional applications, emphasizing its robust features and functionalities. Understanding its structure is essential for users aiming to optimize performance and efficiency in various tasks.

Key Features

Equipped with advanced technology, this device ensures exceptional durability and reliability. The ergonomic design promotes ease of use, while the high-impact capabilities enable it to tackle challenging materials effortlessly.

Operational Insights

Familiarity with the operational aspects is crucial for maximizing effectiveness. Users should delve into the maintenance protocols to ensure longevity and peak performance, ultimately enhancing overall productivity.

Key Components of Hilti TE 52

This section focuses on the essential elements that contribute to the efficiency and performance of the model in question. Understanding these components is crucial for users seeking optimal functionality and maintenance practices.

Power Mechanism

The core of any high-performance tool lies in its power mechanism. This aspect is designed to deliver robust energy transfer, ensuring that tasks are completed with speed and precision. The efficiency of this system directly impacts the overall effectiveness of the equipment.

Attachment System

An effective attachment system is vital for versatility. It allows users to switch between different accessories seamlessly, adapting the tool for various applications. This flexibility enhances the overall utility and makes the tool suitable for a range of tasks, from heavy-duty to precision work.

Maintenance of these key components is essential to ensure longevity and sustained performance. Regular checks and proper care can prevent malfunctions and extend the lifespan of the equipment.

Importance of Parts Diagram

Understanding the intricate components of any equipment is essential for effective maintenance and repair. A visual representation of these elements enhances clarity, allowing users to identify each section and its function. This comprehensive overview promotes better handling, reduces the risk of errors, and ensures longevity.

Enhanced Clarity and Efficiency

By providing a clear illustration of the device’s structure, users can navigate their tasks with confidence. This visual aid eliminates confusion and streamlines the process, ultimately leading to more efficient repairs and upkeep.

Facilitating Troubleshooting

When issues arise, a detailed representation serves as a vital tool for troubleshooting. It allows technicians to quickly pinpoint malfunctioning components, minimizing downtime and enhancing productivity.

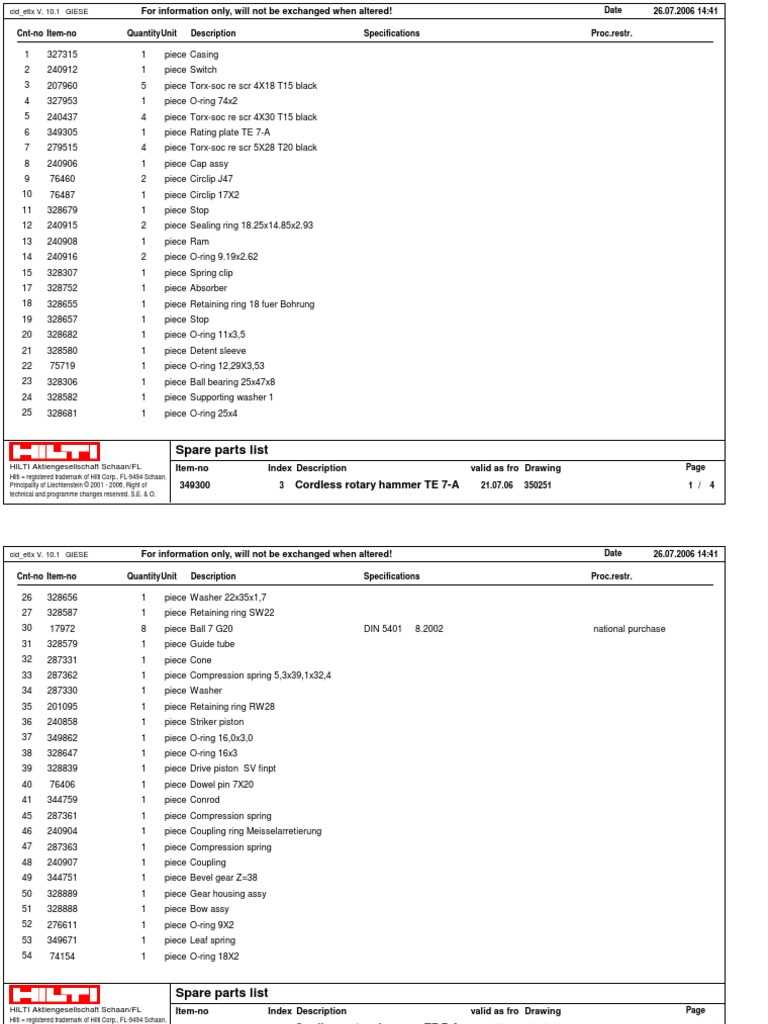

How to Read the Diagram

Understanding visual representations of components is crucial for effective maintenance and repair tasks. These illustrations provide a clear layout of individual elements, showcasing their interrelationships and functions within a system.

To start, familiarize yourself with the legend, which typically explains symbols and notations used in the illustration. Pay attention to any color coding, as this often indicates specific categories or functions. Breaking down the illustration into sections can also help in grasping how various parts fit together.

Next, identify key components by their labels. This will allow you to quickly locate any items you may need to address. Always reference the accompanying documentation for additional context on maintenance or assembly procedures, as it can provide ultimate guidance on any nuances not visible in the visual aid.

Common Issues with TE 52 Parts

When working with power tools, particularly heavy-duty models, users often encounter various challenges that can affect performance and reliability. Understanding these common problems can help in troubleshooting and maintaining efficiency.

- Wear and Tear: Components may degrade over time due to extensive usage, leading to decreased functionality.

- Overheating: Continuous operation without adequate cooling can cause overheating, resulting in potential damage.

- Loose Connections: Vibration and movement can loosen connections, impacting the tool’s performance and safety.

Identifying these issues early can save time and costs associated with repairs and replacements. Regular maintenance is key to extending the lifespan of the equipment.

- Inspect frequently for signs of damage or wear.

- Ensure that all connections are secure before use.

- Allow for proper cooling periods during heavy tasks.

By staying vigilant and proactive, users can minimize disruptions and maintain the tool in optimal working condition.

Maintenance Tips for Longevity

Proper care and regular upkeep are essential for ensuring the durability and efficiency of your tools. Implementing a few key practices can significantly extend the lifespan of your equipment, allowing you to achieve optimal performance and reliability over time.

Regular Cleaning: After each use, take the time to clean the tool thoroughly. Remove dust, debris, and any materials that may have accumulated, especially in moving parts, to prevent wear and tear.

Routine Inspections: Conduct frequent checks for any signs of damage or wear. Identifying issues early can save you from costly repairs and maintain operational efficiency.

Proper Storage: Store your equipment in a dry, clean environment to protect it from moisture and extreme temperatures. Utilize protective cases or covers to shield against dust and accidental impacts.

Lubrication: Apply appropriate lubricants to moving parts regularly. This practice minimizes friction and reduces the risk of mechanical failure, contributing to smooth operation.

Follow Manufacturer Guidelines: Adhering to the specific maintenance instructions provided by the manufacturer is crucial. These guidelines are tailored to maximize performance and longevity, ensuring your equipment remains in top condition.

Replacement Parts Availability

Ensuring access to essential components is vital for maintaining the functionality of equipment. Users often seek reliable sources to obtain these critical items promptly and efficiently.

- Manufacturer’s Official Channels

- Authorized Distributors

- Online Retailers

- Local Service Centers

Each option offers unique benefits, such as warranties and expert guidance, helping users make informed decisions when selecting components.

- Assess the specific needs of your equipment.

- Research the most reputable sources available.

- Consider delivery times and availability.

By following these steps, users can secure the necessary components to ensure optimal performance and longevity of their tools.

Compatibility with Other Models

Understanding the interchangeability of components between different models can greatly enhance the efficiency of repairs and maintenance. This interconnectedness allows users to maximize their equipment’s performance while minimizing downtime.

Many devices share similar specifications, making certain elements compatible across various lines. Utilizing compatible components not only simplifies the repair process but also helps in maintaining operational consistency.

Before proceeding with any replacements, it’s essential to consult specific references to ensure optimal functionality and compatibility. By doing so, users can delve into the benefits of leveraging shared features and enhancements available across multiple models.

Tools Needed for Repairs

Effective maintenance and repair tasks require the right set of instruments to ensure precision and efficiency. Having the appropriate tools on hand not only simplifies the process but also enhances the quality of the results achieved.

Essential Tools

- Wrenches

- Screwdrivers

- Pliers

- Drills

- Measuring Tape

Additional Equipment

- Safety Goggles

- Gloves

- Toolbox

- Level

- Socket Set

Step-by-Step Repair Guide

This section provides a comprehensive guide to efficiently restore your tool to optimal working condition. Following these organized steps will ensure that you address common issues effectively while minimizing downtime. Whether you’re an experienced technician or a novice, the process is designed to be straightforward and informative.

Preparation for Repair

Before starting the repair, gather all necessary tools and materials. Ensure you have a clean workspace and wear appropriate safety gear. Identifying the symptoms of malfunction will help you focus on the right areas during the procedure. It’s advisable to consult the manufacturer’s recommendations for any specific requirements related to your device.

Step-by-Step Instructions

1. Disassemble the Unit: Begin by carefully removing any outer casing to access internal components. Keep track of screws and small parts to avoid misplacement.

2. Inspect Components: Examine each part for wear, damage, or buildup of debris. Take notes or photos to document the condition of each element for reference during reassembly.

3. Replace or Repair Parts: If any components are faulty, replace them with new or refurbished ones. Follow manufacturer specifications to ensure compatibility and performance.

4. Reassemble the Tool: Once repairs are completed, carefully reassemble the unit in the reverse order of disassembly. Make sure all screws are tightened securely and that no parts are left loose.

5. Test Functionality: After reassembly, conduct a thorough test to ensure everything is working correctly. Monitor for any unusual noises or performance issues during operation.

By adhering to these steps, you can effectively manage the repair process and restore functionality to your tool, ensuring it operates safely and efficiently.

Resources for Further Information

Exploring reliable sources can significantly enhance your understanding of complex tools and their components. Accessing a variety of educational materials, user manuals, and online forums allows individuals to gain deeper insights and practical knowledge, ultimately improving their expertise.

Consider visiting manufacturer websites for official documentation and specifications. Additionally, reputable industry blogs and video tutorials can provide hands-on demonstrations and tips. Engaging in community discussions on platforms dedicated to construction equipment can also yield valuable advice and experiences from fellow users.