Understanding the internal mechanisms and core elements of complex equipment is crucial for ensuring its proper functioning and maintenance. Each element within a powerful device plays a specific role in contributing to its overall performance. Whether you are familiarizing yourself with essential features or exploring individual details, a clear view of the internal structure offers valuable insight.

In this section, we will explore the primary mechanisms that drive high-performance tools. Identifying the purpose of each element will help you maintain and troubleshoot issues more effectively. The internal setup, while intricate, is designed to provide reliability and precision, ensuring long-term usability and efficient operation.

By gaining a better understanding of the configuration, you can extend the life of the equipment and keep it operating at optimal levels. Each component plays a role in achieving balance and durability, contributing to the overall robustness of the system.

This section aims to provide a comprehensive overview of a specific tool known for its power and versatility in various applications. The focus will be on understanding the different components that contribute to its functionality and performance. By examining the structure and key elements, users can gain insights into how to effectively operate and maintain this essential equipment.

Key Features and Specifications

Understanding the fundamental attributes of this tool is crucial for users to appreciate its capabilities. This segment will delve into its power rating, operational modes, and unique technologies that enhance performance.

Components and Their Functions

Each element of the tool plays a significant role in its overall operation. This section will break down the main components and describe their specific functions, ensuring users are familiar with each part’s contribution.

| Component | Function |

|---|---|

| Motor | Drives the tool, providing necessary power. |

| Housing | Protects internal components while ensuring user safety. |

| Handle | Offers control and stability during operation. |

| Trigger | Controls the start and stop of the tool. |

This layout serves as a foundational resource for users to understand the integral aspects of this powerful equipment. By recognizing the distinct elements and their purposes, operators can enhance their efficiency and maintenance practices.

Key Features and Specifications

This section highlights the essential characteristics and specifications of the tool, emphasizing its performance, durability, and functionality. Understanding these elements is crucial for users seeking efficiency and reliability in their projects.

| Feature | Description |

|---|---|

| Power Source | Electric motor designed for high energy output, ensuring consistent performance. |

| Weight | Moderate weight, balancing ease of use with robust construction for heavy-duty applications. |

| Vibration Control | Advanced technology to minimize vibrations, enhancing user comfort and control during operation. |

| Tool Speed | Variable speed settings, allowing users to adjust performance based on material and task requirements. |

| Durability | Engineered with high-quality materials to withstand tough working conditions and prolong lifespan. |

| Compatibility | Designed to work with a range of accessories, expanding its versatility for various applications. |

Common Applications of the Tool

This versatile device is essential in various construction and renovation tasks, showcasing its ability to enhance efficiency and precision. Its robust design allows it to perform effectively in demanding environments, making it a preferred choice for professionals in different fields.

Some of the typical uses of this equipment include:

| Application | Description |

|---|---|

| Concrete Drilling | Ideal for creating precise holes in concrete structures, facilitating installation processes. |

| Chiseling | Effective in removing material or creating channels, especially in renovation projects. |

| Heavy-duty Fastening | Utilized for securing components in challenging environments, ensuring durability and strength. |

| Demolition Work | Facilitates the breakdown of concrete and masonry, streamlining demolition tasks. |

| Foundation Work | Supports foundation construction by enabling precise and deep drilling for anchors and reinforcements. |

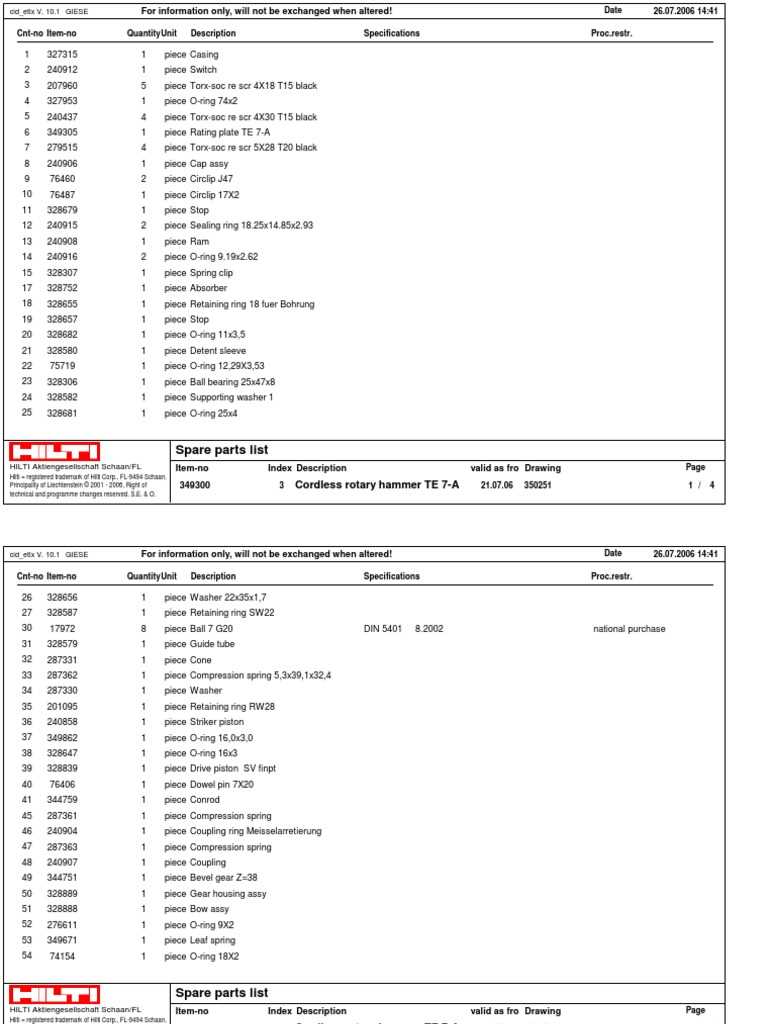

Understanding the Parts Diagram

Comprehending the illustration of components is crucial for effective maintenance and repair. This visual representation serves as a guide, highlighting various elements and their interconnections within the tool. It simplifies troubleshooting and assists users in identifying specific sections that may require attention or replacement.

Key aspects to consider when examining the illustration include:

- Component Identification: Each element is typically labeled or numbered for easy recognition.

- Functionality: Understanding the role of each part helps in grasping how they work together.

- Assembly Process: The illustration can aid in understanding the proper order for assembling or disassembling the unit.

By familiarizing oneself with this visual representation, users can enhance their ability to maintain and repair the equipment efficiently. Knowledge of the components and their arrangements fosters a deeper understanding of the overall functionality, leading to better performance and longevity of the tool.

Essential Components Explained

Understanding the key elements of a power tool is crucial for both effective operation and maintenance. Each component plays a specific role in the overall functionality, contributing to the tool’s performance and durability. This section will break down these fundamental parts and their significance.

- Motor: The heart of the tool, responsible for generating the necessary power to perform tasks efficiently.

- Gearbox: This component translates the motor’s rotational force, enabling various speeds and torque levels to suit different applications.

- Chuck: A critical part that securely holds the attachment, ensuring stability and precision during operation.

- Trigger: An essential control mechanism that allows users to start and stop the tool with ease.

- Handle: Designed for comfort and grip, this part enhances user control and reduces fatigue during extended use.

Each of these components contributes to the tool’s effectiveness, making it vital for users to familiarize themselves with their functions. Regular maintenance and understanding of these elements can significantly enhance performance and longevity.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires regular upkeep and care. By following some essential practices, you can significantly extend the lifespan of your tools and maintain optimal performance.

Regular Cleaning

Keeping your device clean is crucial for preventing dirt and debris from causing wear and tear. Here are some steps to follow:

- Remove any dust and grime after each use.

- Use appropriate cleaning solutions for different surfaces.

- Check for any build-up in moving parts and clean thoroughly.

Routine Inspections

Conducting periodic checks can help identify potential issues before they escalate. Consider the following:

- Examine all components for signs of damage or wear.

- Ensure all connections are secure and functioning properly.

- Replace any worn-out or damaged elements immediately.

By implementing these simple maintenance strategies, you can enhance the reliability and extend the operational life of your tools, ensuring they remain effective for years to come.

Troubleshooting Common Issues

When operating power tools, it’s not uncommon to encounter certain challenges that can affect performance. Identifying these issues early on can help ensure optimal functionality and prolong the lifespan of the equipment. This section provides guidance on common problems and their potential solutions.

| Issue | Possible Cause | Recommended Solution |

|---|---|---|

| Tool not starting | Battery failure or power supply issues | Check battery charge and connections; ensure proper power source. |

| Overheating | Clogged air vents or prolonged usage | Clean air vents and allow the tool to cool down before use. |

| Excessive vibration | Loose components or worn parts | Tighten all screws and inspect for wear; replace damaged parts as needed. |

| Inconsistent performance | Improper settings or low battery | Adjust settings according to material requirements; recharge or replace the battery. |

Ordering Replacement Parts

When it’s time to restore your equipment’s functionality, knowing how to request suitable replacements is essential. Proper selection and timely delivery can extend the tool’s life and keep your projects running smoothly. This section covers how to navigate the process efficiently.

Identifying What You Need

Before placing any order, ensure you correctly determine which component is required. This can be done by referring to the product’s manual or consulting an online resource for guidance. Confirming the correct specifications will save time and avoid returns.

Steps for Ordering

- Review your product’s manual for details.

- Search for the appropriate vendor or distributor.

- Provide the correct model information when ordering.

- Check the estimated delivery times and ensure timely shipment.

Once your request is processed, stay informed about shipment tracking, and verify the delivery upon arrival to avoid complications with installation.

Safety Guidelines for Operation

Ensuring safe usage of power tools is paramount for preventing accidents and injuries. Adhering to specific operational guidelines helps maintain a secure working environment while maximizing efficiency. Users must be well-informed about safety practices to protect themselves and those around them.

Proper Personal Protective Equipment

Always wear appropriate personal protective equipment (PPE) before engaging with any machinery. This includes safety goggles to shield the eyes from debris, gloves to protect hands from sharp edges, and sturdy footwear to minimize the risk of foot injuries. Utilizing ear protection is also advisable to reduce exposure to high noise levels.

Understanding Operational Features

Familiarize yourself with the device’s functionalities and controls before use. Read the instruction manual thoroughly to understand the operational limits and maintenance requirements. Ensure that all components are in good condition and securely attached, as this will significantly reduce the risk of malfunctions during operation.

Comparison with Similar Models

In evaluating various tools within the same category, it is essential to consider their functionalities, specifications, and overall performance. This analysis provides insights into how these models stack up against each other, highlighting strengths and weaknesses that can influence a user’s decision.

Performance and Durability

When comparing similar tools, performance often emerges as a critical factor. Certain models may offer superior power output or enhanced durability, making them more suitable for demanding tasks. Users should assess their specific needs and consider whether they require a robust design capable of withstanding heavy use or if a lighter alternative suffices for occasional projects.

Feature Set and Usability

Feature sets can vary significantly among competing products. Some may include advanced technology for improved accuracy and efficiency, while others focus on user-friendliness and ergonomic design. Evaluating these characteristics allows users to select a model that best fits their workflow and comfort preferences.

Customer Feedback and Reviews

Customer experiences and opinions provide valuable insights into the performance and reliability of tools within the construction industry. Understanding user perspectives can help potential buyers make informed decisions based on real-life applications and outcomes.

Many users highlight several key aspects in their feedback:

- Durability: A common theme in reviews is the robust construction, ensuring longevity even in demanding environments.

- Ease of Use: Customers often mention intuitive controls that simplify operation, making it accessible for both professionals and beginners.

- Performance: Reviews frequently praise the efficiency and effectiveness of the equipment in various tasks, from heavy-duty applications to intricate work.

- Support and Service: Many users appreciate the quality of customer service provided, noting quick response times and helpful assistance.

Additionally, feedback often includes suggestions for improvement, such as:

- Enhanced portability options for easier transportation on job sites.

- More comprehensive manuals or tutorials for first-time users.

- Availability of additional accessories to expand functionality.

In summary, the collective feedback from users offers a comprehensive overview of the strengths and areas for development, guiding both current and prospective users in their choices.

Assembly Instructions for Parts

This section provides a comprehensive guide to the process of assembling various components of the tool. Proper assembly is essential for optimal performance and longevity, ensuring that all elements fit together seamlessly and function as intended. Following these instructions will help you achieve a secure and effective assembly, allowing for efficient use in various applications.

Preparation Steps

Before beginning the assembly, gather all necessary components and tools. It is important to work in a clean and organized area to avoid losing any small items. Review the components to ensure that everything is present and undamaged. If any components appear to be defective or missing, procure replacements before proceeding.

Assembly Procedure

Start by aligning the primary components according to the instructions. Use appropriate tools to secure connections without over-tightening, which could lead to damage. Pay attention to the alignment of each element; incorrect positioning may hinder functionality. Once all parts are connected, conduct a thorough check to confirm that everything is securely fastened and properly oriented.

Resources for Further Information

Accessing reliable information is crucial for understanding the intricacies of tools and their components. Whether you are looking for manuals, guides, or technical specifications, numerous resources are available to assist you in gaining a comprehensive understanding. Below are some valuable sources that provide detailed insights and assistance related to your inquiries.

| Resource Type | Description | Link |

|---|---|---|

| User Manuals | Comprehensive guides detailing operation and maintenance. | Visit Manuals |

| Technical Support | Expert assistance for troubleshooting and repairs. | Contact Support |

| Online Forums | Community discussions for sharing tips and experiences. | Join Forums |

| Video Tutorials | Visual guides for step-by-step instructions. | Watch Tutorials |