In the realm of construction and heavy-duty tasks, the efficiency of machinery heavily relies on the intricate design and arrangement of its components. A comprehensive overview of these elements not only enhances operational effectiveness but also ensures longevity and reliability. Knowledge of how each piece interacts within the system is essential for both maintenance and troubleshooting.

The visual representation of these mechanisms serves as a valuable resource for users. By breaking down the complex assembly into understandable sections, one can easily identify specific areas that may require attention. This clarity is particularly crucial when dealing with repairs or upgrades, as it allows for a systematic approach to managing the equipment.

Moreover, understanding the configuration of these essential components fosters a greater appreciation for the engineering that goes into creating robust tools. Such insights empower users to make informed decisions regarding usage and care, ultimately leading to improved performance in various tasks.

Understanding Hilti TE 70 Components

Exploring the intricate elements of a powerful tool reveals the synergy between various components that contribute to its overall efficiency and performance. Each segment plays a vital role, ensuring that the machinery operates smoothly and effectively, catering to the demands of various applications. A comprehensive understanding of these features enhances the user experience and extends the lifespan of the equipment.

Main Elements

The core components of this equipment are engineered for durability and functionality. Here’s an overview of the primary sections that form its structure:

| Component | Description |

|---|---|

| Motor | Provides the necessary power to drive the device. |

| Housing | Protects internal parts from damage and wear. |

| Chisel | Used for breaking and chiseling through various materials. |

| Trigger | Controls the operation of the tool. |

| Handle | Ensures a secure grip for better control during use. |

Additional Features

In addition to the main elements, certain auxiliary features enhance usability and performance. These include vibration dampening systems, adjustable settings, and safety mechanisms that ensure user protection and comfort. Understanding these additional functionalities is essential for maximizing the tool’s potential and ensuring optimal results in various applications.

Overview of Hilti TE 70 Functionality

This section explores the capabilities and features of a powerful tool designed for heavy-duty tasks in construction and renovation. Its robust design and advanced engineering make it suitable for a variety of applications, ensuring efficiency and reliability in challenging environments.

Key Features

- High Impact Energy: Engineered to deliver exceptional impact force, making it ideal for breaking through tough materials.

- Ergonomic Design: Crafted with user comfort in mind, allowing for extended use without fatigue.

- Durability: Built to withstand rigorous use, ensuring longevity even in demanding conditions.

- Versatile Applications: Suitable for various tasks including drilling, chiseling, and demolition.

Operational Advantages

- Enhanced productivity through rapid and efficient performance.

- Reduced vibration levels for increased operator comfort and control.

- Easy maintenance features that simplify upkeep and prolong the tool’s lifespan.

- Compatibility with a wide range of accessories, enhancing its functionality for different jobs.

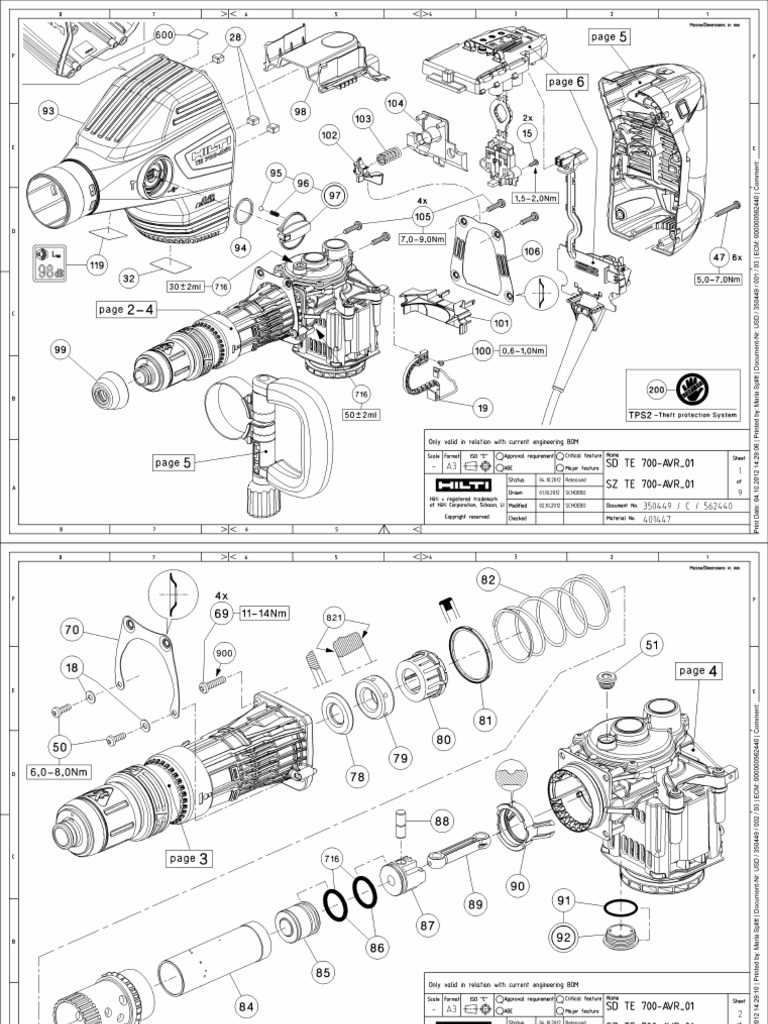

Detailed Parts Diagram Explained

This section aims to provide an in-depth understanding of the intricate visual representation used in various mechanical tools. Such illustrations serve as a vital resource for technicians and users alike, offering clarity on the arrangement and function of individual components within the equipment.

Each element depicted in these visuals plays a crucial role in the overall operation of the device. By analyzing the layout, one can easily identify how each segment interconnects with others, facilitating a better grasp of assembly and maintenance procedures. These representations not only enhance comprehension but also streamline troubleshooting efforts, allowing users to pinpoint issues more efficiently.

Moreover, the inclusion of annotations and reference numbers within these illustrations aids in the accurate identification of specific components, ensuring that replacements and repairs can be executed with precision. Understanding this visual guide empowers users to engage with their equipment confidently, promoting longevity and optimal performance.

In summary, a comprehensive breakdown of the visual representation enables both novices and seasoned professionals to navigate the complexities of mechanical tools, ultimately enhancing their operational experience and maintenance practices.

Key Features of TE 70 Parts

The TE 70 is renowned for its robust construction and efficiency in heavy-duty applications. Understanding its components is essential for maintenance and optimal performance. Each element plays a vital role in the tool’s overall functionality, ensuring reliability and durability during operation.

Durability and Reliability

One of the standout characteristics of this equipment is the exceptional durability of its components. Engineered to withstand intense usage, the materials used in manufacturing ensure longevity and reduce the need for frequent replacements. This reliability translates into consistent performance, even in the most challenging environments.

Ease of Maintenance

Another significant feature is the user-friendly design that facilitates easy maintenance. The construction allows for straightforward access to individual components, making routine checks and repairs hassle-free. This convenience is essential for keeping the equipment in peak condition and minimizing downtime.

| Feature | Description |

|---|---|

| Robust Construction | Designed to endure heavy workloads without compromising integrity. |

| Material Quality | High-grade materials ensure resistance to wear and tear. |

| Accessibility | Components are easy to reach for efficient maintenance. |

| Performance Consistency | Delivers reliable output under various working conditions. |

Common Issues with Hilti TE 70

The robust tool designed for heavy-duty applications is known for its efficiency, but like any machinery, it may encounter specific challenges over time. Users often report several recurring problems that can affect performance and productivity. Understanding these common issues can help in maintaining optimal functionality and prolonging the tool’s lifespan.

1. Reduced Hammering Power: One frequent complaint involves diminished impact energy, which can hinder drilling and chiseling effectiveness. This issue may stem from wear in the internal mechanisms or inadequate lubrication, necessitating a thorough inspection and possible servicing.

2. Overheating: Excessive heat generation during operation can lead to performance issues. Overheating may result from prolonged use without breaks, obstructed cooling vents, or a malfunctioning motor. Ensuring proper ventilation and allowing the tool to cool down can mitigate this risk.

3. Electrical Failures: Users may experience electrical malfunctions, including power loss or erratic operation. Such problems can be linked to wiring issues, damaged components, or battery failures. Regular checks on the electrical system can help identify and rectify these concerns early.

4. Vibration and Noise: Excessive vibrations or unusual sounds during operation can indicate internal damage or component wear. These symptoms should not be ignored, as they can lead to further damage if not addressed promptly.

5. Bit Jamming: A common frustration is the jamming of drill bits. This can occur due to incorrect bit size, improper technique, or debris buildup in the chuck. Regular maintenance and correct usage practices can significantly reduce the likelihood of this issue.

Addressing these challenges proactively can enhance performance and ensure the tool continues to operate effectively in demanding environments.

Importance of Proper Maintenance

Regular upkeep of tools and equipment is essential for ensuring their longevity and optimal performance. Neglecting maintenance can lead to decreased efficiency, increased wear and tear, and ultimately, costly repairs or replacements. Establishing a consistent maintenance routine not only enhances productivity but also promotes safety in the workplace.

Preventive care is key to avoiding unexpected breakdowns. By regularly inspecting and servicing machinery, users can identify potential issues before they escalate. This proactive approach not only minimizes downtime but also ensures that tools operate at their best, delivering reliable results.

Additionally, proper maintenance fosters a safer working environment. Well-maintained equipment is less likely to malfunction, reducing the risk of accidents or injuries. By prioritizing care and attention, organizations can cultivate a culture of safety and efficiency among their teams.

In summary, investing time and resources into maintaining tools is crucial for sustaining their performance and extending their lifespan. This commitment ultimately contributes to improved productivity and a safer workplace.

How to Identify Original Parts

Ensuring the authenticity of components is crucial for maintaining the efficiency and longevity of your tools. Recognizing genuine elements can prevent performance issues and enhance safety during usage. This guide will help you discern original items from replicas, ensuring your equipment operates at its best.

Examine Packaging and Labels

Authentic components usually come in high-quality packaging, complete with clear labels that feature specific branding elements. Look for precise logos, part numbers, and any certification marks. Additionally, check for holograms or unique identifiers that are often present on legitimate products.

Compare with Manufacturer Specifications

Review the specifications provided by the manufacturer to ensure compatibility and quality. Genuine items will match the details in official documentation, including dimensions and materials used. If possible, consult authorized dealers or online resources to validate the authenticity of the components in question.

Replacing Damaged Components Safely

Ensuring the integrity of equipment is crucial for optimal performance and safety. When a part becomes compromised, it is essential to address the issue promptly to prevent further damage or accidents. This section outlines best practices for the safe replacement of damaged elements, emphasizing the importance of preparation and adherence to guidelines.

1. Preparation is Key: Before beginning the replacement process, gather all necessary tools and components. Familiarize yourself with the user manual to understand the specific requirements and procedures involved. A clean and organized workspace will also facilitate a smoother operation.

2. Ensure Safety First: Always prioritize personal safety. Wear appropriate protective gear, such as gloves and goggles, to shield yourself from potential hazards. Make sure the equipment is powered off and disconnected from any power sources to eliminate the risk of accidental activation.

3. Identify and Assess: Carefully examine the damaged component to determine the extent of the issue. Understanding how the part fits within the overall assembly will help in executing the replacement accurately. Take note of any other surrounding components that may need inspection or replacement.

4. Follow Proper Procedures: Adhere strictly to the outlined procedures for removing the damaged part. Utilize the correct tools to avoid causing further harm. When installing the new component, ensure it is positioned correctly and securely to maintain the integrity of the overall system.

5. Test and Verify: After the replacement, conduct thorough checks to verify that everything functions as intended. This includes testing the equipment under normal conditions to confirm that the new part operates effectively and safely. If any issues arise, consult the manual or seek professional assistance.

By following these guidelines, you can ensure a safe and efficient replacement process, contributing to the longevity and reliability of your equipment.

Tools Required for Repairs

To successfully carry out repairs, having the right tools is essential. A well-equipped workspace can significantly enhance efficiency and ensure precision in every task. Below is a comprehensive list of necessary tools that facilitate the repair process.

- Screwdrivers: A variety of sizes and types, including flathead and Phillips, are crucial for removing and securing screws.

- Wrenches: Both adjustable and fixed wrenches are needed for loosening and tightening bolts.

- Pliers: Needle-nose and regular pliers help with gripping, bending, and cutting materials.

- Hammer: A reliable hammer is important for driving nails and assembling components.

- Utility Knife: This tool is ideal for cutting through various materials with precision.

- Measuring Tape: Accurate measurements are crucial; hence, a sturdy measuring tape is necessary.

- Level: To ensure surfaces are even, a level is indispensable.

- Drill: A power or manual drill will assist in creating holes or driving screws.

- Safety Gear: Goggles, gloves, and masks protect the user from potential hazards.

By equipping yourself with these essential tools, you can streamline the repair process, ensuring that tasks are completed efficiently and effectively.

Comparison with Other Hilti Models

This section explores the distinctions and similarities between various power tools offered by the brand, focusing on their performance, functionality, and suitability for different applications. Understanding these differences can aid users in selecting the most appropriate model for their needs.

When comparing models, several key aspects should be considered:

- Power and Performance: Different tools provide varying levels of power, affecting their efficiency in heavy-duty tasks.

- Weight and Ergonomics: The design and weight impact user comfort during prolonged use, influencing overall productivity.

- Durability: Build quality and material choice play crucial roles in the longevity of the equipment under tough working conditions.

- Functionality: Features such as adjustable settings and compatibility with attachments can enhance versatility for various jobs.

For example, while one model may excel in drilling capabilities, another might be superior for demolition purposes. Understanding these characteristics can help professionals make informed decisions based on their specific requirements.

Additionally, examining user feedback and performance reviews can provide insights into how each tool stands up in real-world scenarios:

- Model A: Known for its exceptional torque, making it ideal for heavy-duty applications.

- Model B: Offers a lightweight design, enhancing mobility without sacrificing power.

- Model C: Features advanced technology, providing precision and control for intricate tasks.

Ultimately, the choice between different models should align with the tasks at hand, ensuring efficiency and effectiveness in achieving desired results.

Tips for Efficient Operation

Maximizing performance in power tools requires a strategic approach that enhances productivity while minimizing wear and tear. Understanding the nuances of operation can lead to improved results and longer lifespan for the equipment. Here are some practical suggestions to achieve optimal functioning.

First, ensure that all components are clean and free of debris before use. Regular maintenance, including lubrication and inspection, can prevent malfunctions and ensure smooth operation. Familiarize yourself with the user manual, as it provides essential insights into the correct usage and recommended practices.

Additionally, using the right accessories tailored to your specific tasks can significantly improve efficiency. Each project may require different tools or attachments, so selecting the appropriate ones is crucial. When working, maintain a steady pace to avoid overheating the equipment, which can lead to reduced performance.

Lastly, consider the environment in which you operate. Adequate lighting and a well-organized workspace can greatly enhance your focus and efficiency. By following these guidelines, you can ensure that your equipment operates at its best, leading to successful and efficient project completion.

Where to Purchase Replacement Parts

Finding the right components for your tools can be crucial for maintaining their performance and longevity. Whether you’re looking to replace worn-out pieces or upgrade certain functionalities, there are various avenues to explore when sourcing these essential items.

Authorized Dealers

One of the most reliable sources for obtaining components is through authorized dealers. These retailers are typically well-versed in the products they offer and can provide expert advice. Benefits of shopping at authorized dealers include:

- Genuine components that ensure compatibility and reliability.

- Access to knowledgeable staff who can assist with specific needs.

- Warranty options that may accompany the purchase.

Online Marketplaces

Another convenient option is to utilize online marketplaces. Many platforms offer a wide selection of items, often at competitive prices. When considering this route, keep the following in mind:

- Check seller ratings and reviews for quality assurance.

- Ensure that the components are suitable for your specific tool model.

- Be aware of shipping times and return policies.