In the realm of construction and woodworking, the efficient operation of equipment is paramount. Knowing the intricate elements that contribute to a tool’s functionality can enhance performance and prolong its lifespan. This section aims to explore the various components that make up these essential devices.

Grasping the arrangement of these elements is crucial for both maintenance and effective usage. Familiarity with each part allows users to address issues promptly and effectively. Furthermore, it empowers individuals to engage more deeply with their tools, ultimately leading to improved results in their projects.

By delving into the specifics of these assemblies, readers will gain insights into their structure and operation. This knowledge serves as a foundation for troubleshooting and optimizing performance, ensuring that every task is completed with the utmost precision.

Understanding Hitachi Framing Nailers

This section delves into the intricacies of a popular type of pneumatic tool used in construction and woodworking. These devices are designed to drive fasteners into various materials efficiently, facilitating faster project completion and enhanced structural integrity.

There are several key aspects to consider when exploring these tools:

- Functionality: These machines streamline the fastening process, allowing users to tackle projects with precision and speed.

- Types: Various models cater to different applications, from light-duty to heavy-duty tasks, ensuring versatility.

- Mechanism: Understanding the internal workings helps users troubleshoot issues and perform maintenance effectively.

- Safety Features: Built-in safety mechanisms are essential for preventing accidents during operation.

By gaining a comprehensive understanding of these tools, users can enhance their skill set and improve the quality of their work, making informed choices about the equipment best suited for their needs.

Importance of Nail Gun Components

The various elements of a fastening tool play a crucial role in its overall performance and reliability. Each component contributes to the efficiency and accuracy of the device, ensuring that tasks are completed effectively. Understanding how these elements work together can significantly enhance user experience and safety.

For instance, the firing mechanism directly impacts the precision with which fasteners are deployed. Likewise, the power source determines the tool’s ability to handle different materials. Regular maintenance and knowledge of these components can prevent malfunctions and extend the lifespan of the equipment.

In summary, familiarity with the individual features of a fastening device not only aids in proper usage but also empowers users to troubleshoot potential issues, making it essential for both professionals and DIY enthusiasts alike.

Identifying Key Parts of Nailers

Understanding the essential components of fastening tools is crucial for effective usage and maintenance. Each element plays a specific role in ensuring optimal performance and reliability.

Main Components

- Magazine: Holds fasteners and facilitates quick loading.

- Trigger: Initiates the fastening process.

- Motor: Powers the mechanism for driving fasteners.

- Depth Adjustment: Controls how deep the fasteners are driven.

- Exhaust Port: Discharges air from the tool.

Supportive Features

- Safety Mechanism: Prevents accidental firing.

- Handle: Provides grip and control.

- Housing: Encloses internal components and provides protection.

- Guide: Ensures accurate placement of fasteners.

Common Issues with Nail Gun Parts

When utilizing a fastening tool, various complications can arise that hinder its performance and efficiency. Understanding these common challenges can help users troubleshoot effectively and maintain optimal functionality. Below are some frequent concerns encountered with these devices.

Jamming Problems

Jamming is one of the most prevalent issues faced by users. It often occurs when fasteners misalign within the feed mechanism, preventing the tool from operating smoothly. Regular cleaning and inspection can help reduce the likelihood of this problem. Ensuring that the fasteners are compatible with the device is also crucial to avoid such disruptions.

Air Leaks

Another frequent issue is air leaks, which can lead to diminished power and inefficient operation. These leaks may occur in various components, including hoses and connectors. Regularly checking for wear and tear, and replacing any damaged parts, can enhance the tool’s performance. It is essential to maintain a tight seal to ensure the tool operates at peak efficiency.

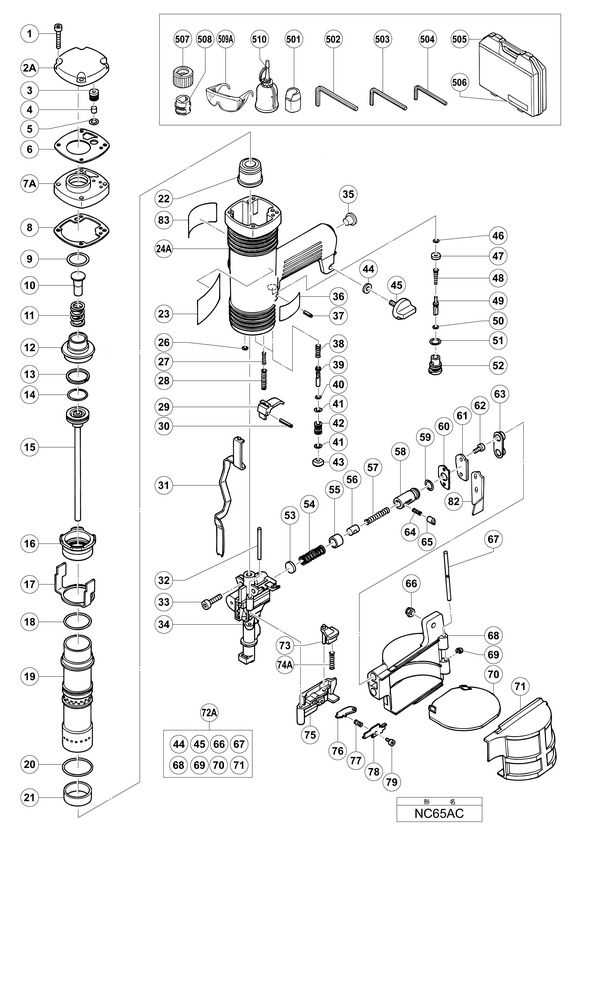

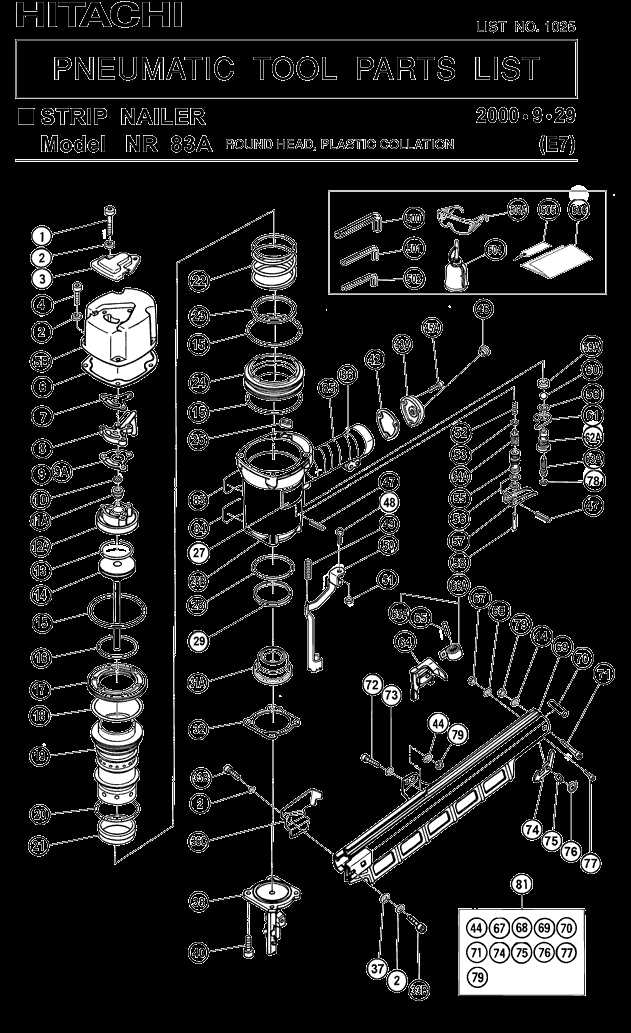

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repair tasks. This overview will guide you through the key elements to focus on, enabling you to interpret the schematic efficiently.

Key Components to Identify

- Labels: Look for identifiers that specify each element.

- Numbers: Sequential numbering often indicates assembly order or priority.

- Connections: Arrows or lines that show how parts interact with each other.

Steps for Effective Interpretation

- Start by familiarizing yourself with the overall layout.

- Identify and mark critical components that require attention.

- Cross-reference with the accompanying text or manual for detailed descriptions.

- Make notes of any unfamiliar terms to research further.

Maintenance Tips for Nail Gun Parts

Proper upkeep of your tool is essential for ensuring longevity and optimal performance. Regular maintenance not only enhances efficiency but also prevents unexpected breakdowns. Following a few straightforward practices can significantly extend the life of your equipment and improve its reliability during use.

Regular Cleaning

Keeping your tool clean is fundamental for its operation. Dust and debris can accumulate, affecting functionality. Here are some cleaning tips:

- Remove any accumulated dust from the exterior using a soft cloth.

- Clear the air intake regularly to prevent clogs.

- Use a brush to dislodge debris from inside the mechanism.

Lubrication and Inspection

Regular lubrication ensures smooth operation and reduces wear on internal components. Additionally, routine inspection helps identify potential issues before they escalate.

- Apply lubricant to moving parts according to the manufacturer’s recommendations.

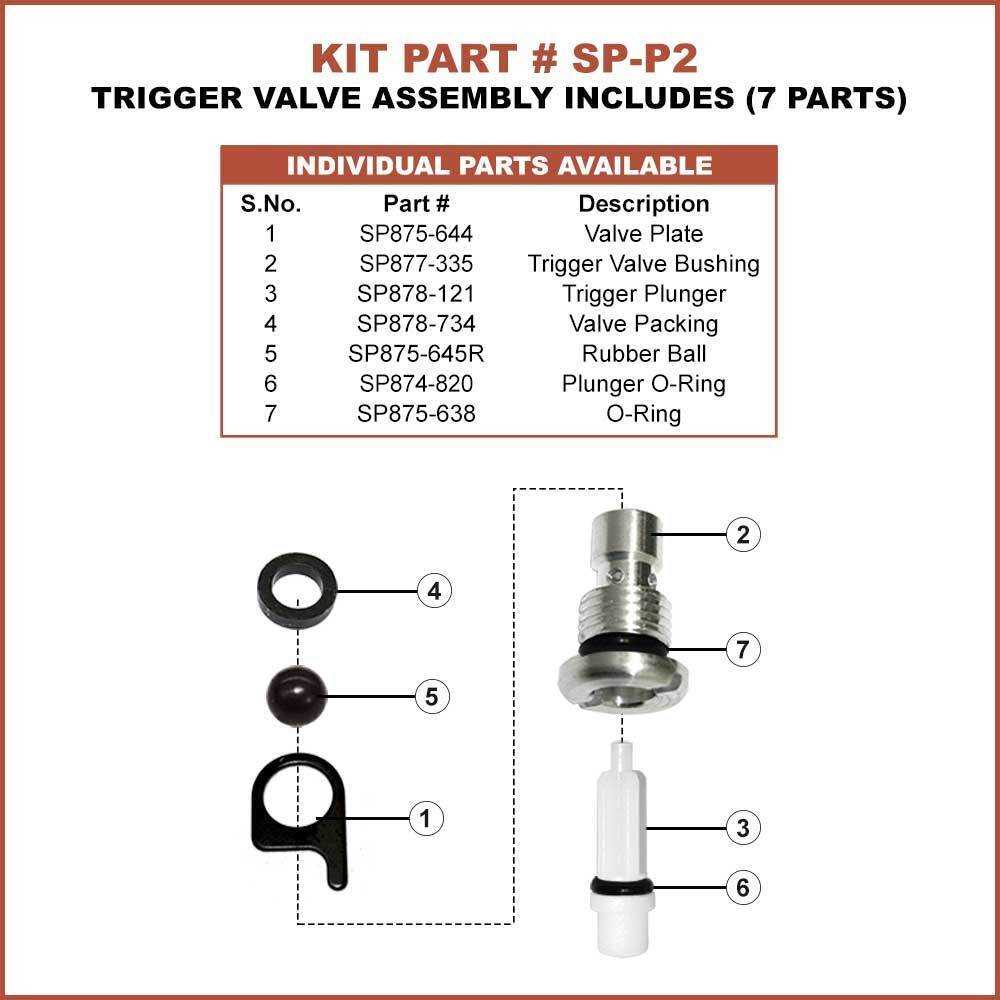

- Check seals and o-rings for wear or damage and replace them as needed.

- Inspect the trigger and safety mechanisms for proper function.

By adhering to these maintenance tips, you can keep your tool in peak condition, ensuring reliable performance whenever you need it.

Replacement Parts: When to Consider

Understanding the right time for replacements can significantly enhance the efficiency and longevity of your tools. Regular usage can lead to wear and tear, making it essential to identify when components no longer perform optimally. Knowing when to act can prevent further damage and ensure your equipment remains in peak condition.

Signs of Wear: If you notice decreased performance, such as inconsistent operation or unusual noises, it may be time to evaluate your equipment. Regular maintenance checks can help catch these issues early.

Frequency of Use: For tools that see heavy use, considering replacements sooner rather than later can save you from potential breakdowns. Tools used in demanding environments may require more frequent assessments.

Availability of Parts: Keeping track of the availability of necessary components can also guide your decision. If certain pieces are becoming harder to find, it might be wise to replace them before they become obsolete.

Tools Needed for Nail Gun Repairs

Effective maintenance and repairs of a fastening device require a specific set of instruments to ensure optimal functionality. Understanding which tools to gather will facilitate a smoother repair process and extend the lifespan of your equipment.

| Tool | Purpose |

|---|---|

| Screwdriver | To remove and secure screws in the casing. |

| Wrench | For loosening or tightening nuts and bolts. |

| Pliers | To grip and manipulate small components. |

| Lubricant | To maintain smooth operation of moving parts. |

| Cleaning Cloth | For wiping down surfaces and removing debris. |

Understanding Framing Nailer Mechanisms

Every powerful tool relies on a series of intricate components that work together to achieve efficiency and precision. In this context, grasping the underlying mechanisms can significantly enhance the user’s experience and effectiveness. This section explores the essential elements that contribute to the functionality of these specialized devices.

Key elements of these mechanisms include:

- Power Source: The energy that drives the tool can come from various sources, such as compressed air or battery power, each offering unique advantages.

- Drive Mechanism: This is responsible for the forceful placement of fasteners, determining the tool’s speed and accuracy.

- Feed System: It ensures a steady supply of fasteners, crucial for uninterrupted operation and efficiency.

- Trigger Mechanism: This allows the operator to control the firing action, providing safety and precision during use.

- Depth Adjustment: A vital feature that enables users to set the depth of fasteners, ensuring proper embedding into various materials.

Understanding these components not only helps in effective operation but also aids in troubleshooting and maintenance. By familiarizing oneself with the inner workings, users can ensure longevity and optimal performance of their tools.

Comparing Different Hitachi Models

This section explores the various models available from a leading manufacturer, highlighting their unique features and specifications. By examining the differences, users can make informed choices based on their specific needs and project requirements.

One popular model offers a lightweight design, making it ideal for extended use without fatigue. Another variant stands out with its enhanced power, perfect for tackling tougher materials. Additionally, some models include advanced safety mechanisms, ensuring a secure operation.

Durability is a common theme among these machines, with several options featuring robust construction that can withstand heavy use. Users should also consider the versatility of each model, as some are equipped to handle a wider range of applications, providing greater flexibility on the job site.

Ultimately, selecting the right tool depends on personal preferences and specific tasks. By delving into the characteristics of each model, users can find the most suitable option that aligns with their operational style.

Safety Precautions During Repairs

Ensuring safety during maintenance tasks is crucial to prevent accidents and injuries. Proper precautions should be taken to protect yourself and those around you.

- Always wear appropriate personal protective equipment, such as gloves and goggles.

- Disconnect power sources before starting any repair work to avoid electrical hazards.

- Ensure your workspace is well-lit and free of clutter to minimize trip hazards.

Additionally, being aware of your surroundings and using tools correctly can enhance safety.

- Read the manufacturer’s instructions thoroughly before beginning repairs.

- Use tools that are in good condition and designed for the specific job.

- Keep children and pets away from the work area during repairs.

By following these guidelines, you can create a safer environment while working on your equipment.

Finding Authentic Replacement Parts

Ensuring your tools operate at peak performance requires sourcing genuine components. Authentic replacements not only enhance functionality but also extend the lifespan of your equipment. Understanding how to identify and procure these essential items is crucial for maintaining efficiency.

Identifying Genuine Components

Look for specific markers that indicate authenticity, such as manufacturer branding and serial numbers. Researching trusted suppliers and checking for reviews can also help confirm the legitimacy of the products.

Where to Purchase

Opt for reputable retailers or official distributors that specialize in tool components. Online marketplaces often offer a wide selection, but caution is advised to avoid counterfeit items.

| Source Type | Pros | Cons |

|---|---|---|

| Authorized Dealers | Genuine products, warranty support | Higher prices |

| Online Marketplaces | Variety, competitive pricing | Risk of counterfeits |

| Local Hardware Stores | Immediate access, personal assistance | Limited selection |

Upgrading Your Framing Nailer

Enhancing your tool’s performance can significantly improve your efficiency and results in construction projects. Upgrades can range from replacing components to incorporating advanced features that offer better usability and durability. Understanding the options available will help you make informed decisions for optimal functionality.

Key Components to Consider

When looking to enhance your equipment, focus on crucial elements such as the motor, magazine, and safety features. Upgrading the motor can lead to faster operation, while an improved magazine can allow for quicker reloading. Prioritizing safety features is essential for both user protection and compliance with industry standards.

Benefits of Upgrading

Investing in enhancements not only boosts performance but also extends the lifespan of your tool. Improved efficiency means completing tasks quicker, which can lead to increased productivity on job sites. Additionally, a well-maintained and upgraded tool can contribute to better quality work, ultimately resulting in higher customer satisfaction.