In the world of culinary tools, having a clear grasp of the individual elements that contribute to the functionality of your equipment is crucial. Knowing how these parts interact can enhance both performance and longevity, making your kitchen tasks smoother and more efficient.

Exploring the intricate relationships between each component allows chefs and home cooks alike to maintain their tools effectively. This knowledge not only aids in troubleshooting potential issues but also empowers users to make informed decisions when it comes to replacements and upgrades.

By delving into the specifics of these components, you’ll gain insights into the ultimate operational efficiency of your appliances. Understanding the layout and function of each section will help ensure that your equipment remains a reliable partner in your culinary adventures.

Understanding the Hobart H600 Mixer

In the world of culinary equipment, there exists a machine designed to streamline food preparation and enhance efficiency in professional kitchens. This powerhouse not only simplifies the mixing process but also elevates the quality of various recipes, making it an essential tool for chefs and bakers alike.

Key components play a crucial role in the functionality of this device. Each element, from the motor to the attachments, is engineered to ensure durability and optimal performance. Understanding how these components interact can ultimately lead to better maintenance and longer service life.

Maintenance is vital for sustaining peak performance. Regular cleaning and timely replacement of worn-out parts can prevent common issues and extend the longevity of this invaluable kitchen ally. Familiarity with its internal structure can help users identify potential problems before they escalate.

Key Features of the H600 Model

This particular model stands out due to its robust construction and exceptional functionality. Designed for high-demand environments, it incorporates several advanced characteristics that enhance performance and efficiency.

- Powerful Motor: Equipped with a high-torque motor, this unit ensures consistent mixing, even with dense ingredients.

- Variable Speed Control: The ability to adjust speeds allows for versatile applications, catering to various mixing needs.

- Durable Build: Constructed from high-quality materials, this device promises longevity and resilience in busy settings.

- Large Capacity Bowl: The spacious bowl accommodates substantial quantities, making it ideal for large-scale operations.

- Easy-to-Use Controls: Intuitive controls facilitate straightforward operation, reducing the learning curve for new users.

These features collectively contribute to an efficient workflow, making this model a preferred choice for professionals seeking reliability and performance.

Importance of Maintenance for Mixers

Regular upkeep of culinary appliances is crucial for ensuring their longevity and optimal performance. Neglecting maintenance can lead to a decline in functionality, increased risk of breakdowns, and higher operational costs. A proactive approach not only enhances efficiency but also guarantees that the equipment operates smoothly during critical tasks.

Enhancing Performance and Efficiency

Proper servicing ensures that all components work harmoniously, resulting in improved mixing consistency and faster preparation times. By regularly checking and replacing worn parts, users can maintain peak operational efficiency, reducing the risk of unsatisfactory results in food preparation.

Preventing Costly Repairs

Routine maintenance helps identify potential issues before they escalate into significant problems. This preventative strategy can save time and money by avoiding expensive repairs and unplanned downtime. Investing in regular inspections and servicing ultimately leads to a more reliable and cost-effective operation.

Common Issues with Hobart Mixers

Many users encounter challenges with their kitchen equipment, which can affect efficiency and performance. Understanding these common problems can help in identifying solutions and maintaining optimal functionality.

- Motor Overheating: Excessive heat can lead to motor failure. This often occurs due to prolonged use without breaks or blockages in the ventilation system.

- Speed Control Malfunctions: Inconsistent mixing speeds can hinder food preparation. This issue may arise from faulty wiring or worn-out components.

- Unusual Noises: Grinding or squeaking sounds can indicate mechanical wear or misalignment of parts, requiring immediate attention.

- Leakage: Fluid leaks can occur due to damaged seals or gaskets. Regular inspection can help prevent this issue from escalating.

- Power Issues: Difficulty in starting the equipment or sudden shutdowns may be linked to electrical faults or inadequate power supply.

Addressing these concerns promptly can extend the lifespan of the equipment and ensure smooth operation in any kitchen environment.

Essential Replacement Parts Explained

Understanding key components of your culinary device is crucial for maintaining its efficiency and longevity. Regular wear and tear can affect performance, making it necessary to identify and replace specific elements. This section outlines the vital components that often require attention, ensuring your equipment continues to function optimally.

Common Components

Several elements are commonly found in these machines, each serving a distinct purpose. Recognizing their functions can help you determine when replacement is necessary.

| Component | Description | Function |

|---|---|---|

| Whisk Attachment | Metal tool designed for mixing and aerating ingredients. | Incorporates air into mixtures for fluffiness. |

| Gear Assembly | System of gears that transmit power from the motor. | Ensures smooth and consistent operation of the device. |

| Bowl Lift Mechanism | System that raises and lowers the mixing bowl. | Facilitates easy access to ingredients and mixing process. |

Maintenance Tips

To extend the life of your culinary appliance, regular inspections and timely replacements of these components are advisable. Keeping a close eye on wear indicators will help you maintain optimal performance and avoid unexpected downtimes.

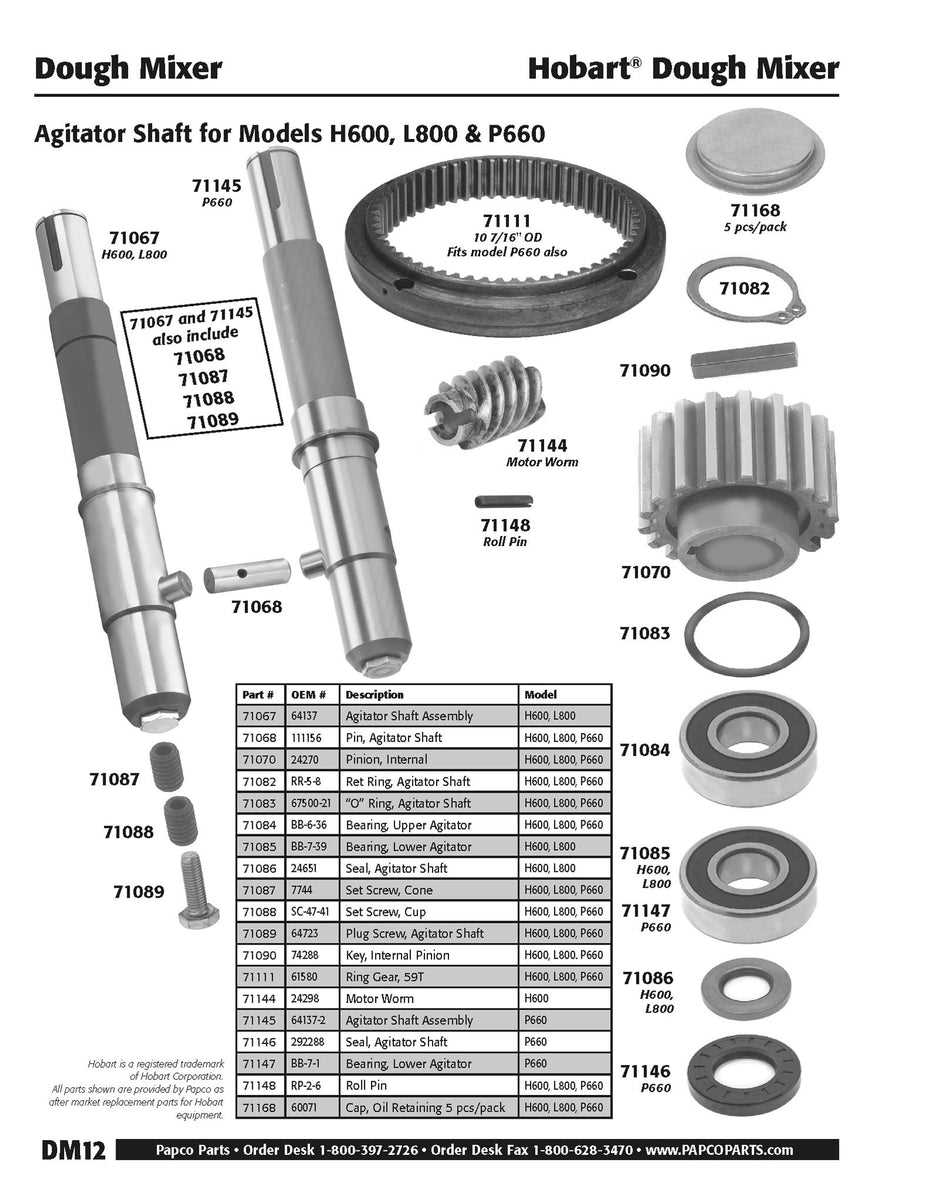

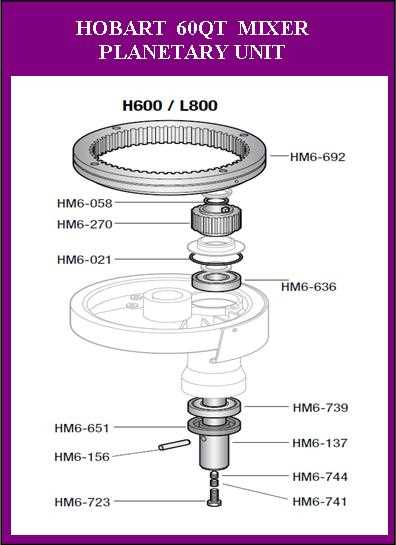

How to Read Parts Diagrams

Understanding technical illustrations can be crucial for effective maintenance and repair tasks. These visual representations serve as guides to identify various components and their interrelationships within a complex system. By familiarizing yourself with the symbols, labels, and layout used in these illustrations, you can significantly enhance your troubleshooting skills.

1. Familiarize Yourself with Symbols: Each illustration employs specific symbols to represent different components. Taking the time to learn these can save you frustration. Common symbols may denote electrical parts, mechanical elements, or fluid connections.

2. Pay Attention to Labels: Most illustrations include labels that provide essential information about each component, such as part numbers or descriptions. These labels are invaluable for ordering replacements or understanding functionality.

3. Observe the Layout: The arrangement of parts often indicates how they fit together. Look for lines or arrows that show connections or sequences, helping you visualize the assembly process.

4. Cross-Reference with Manuals: If available, use accompanying documentation for clarification. Manuals typically provide detailed explanations and troubleshooting tips that complement the visual information.

5. Practice Makes Perfect: The more you work with these illustrations, the more comfortable you’ll become. Start with simple designs and gradually tackle more complex ones to build your confidence and skill level.

Finding Authentic Hobart Parts

When seeking high-quality components for your equipment, authenticity is crucial. Genuine pieces ensure optimal performance, longevity, and safety. Many suppliers offer alternatives, but these often compromise reliability and functionality. Understanding where to source original items can enhance your operational efficiency and prevent unnecessary costs in the long run.

Start by identifying reputable dealers who specialize in professional culinary equipment. Look for authorized distributors, as they are more likely to stock certified replacements. Additionally, consulting the manufacturer’s website can provide insights into authorized vendors and specific product recommendations. Always verify the authenticity of any item before making a purchase to avoid pitfalls.

Online marketplaces may offer competitive prices, but exercise caution. Check reviews and ratings to ascertain the credibility of sellers. It’s beneficial to seek out those with a proven track record in providing original merchandise. Investing time in research can lead to superior results and peace of mind regarding your acquisitions.

Tools Needed for Repairs

When it comes to maintaining and fixing your kitchen equipment, having the right tools is essential for a successful repair process. Proper instruments not only enhance efficiency but also ensure that the work is carried out safely and accurately. Below is a list of necessary tools that can assist in tackling various repair tasks effectively.

| Tool | Purpose |

|---|---|

| Screwdriver Set | Used for removing and securing screws in various components. |

| Socket Wrench | Ideal for loosening and tightening nuts and bolts with ease. |

| Pliers | Useful for gripping, twisting, and cutting wires or small parts. |

| Torque Wrench | Ensures that fasteners are tightened to the specified torque settings. |

| Utility Knife | Handy for cutting through packaging or materials during disassembly. |

| Multimeter | Essential for testing electrical components and diagnosing issues. |

| Flashlight | Provides illumination in tight spaces for better visibility. |

| Safety Goggles | Protects eyes from debris and potential hazards during repairs. |

Having these tools readily available will significantly streamline your repair efforts, ensuring that you can address any issues that arise with confidence and precision.

Step-by-Step Repair Process

This section outlines a comprehensive approach to restoring your equipment efficiently. By following a structured method, you can ensure that every aspect is addressed, minimizing downtime and enhancing performance.

- Assessment:

Begin by evaluating the condition of the device. Identify any visible issues and note performance anomalies.

- Disassembly:

Carefully take apart the unit, ensuring to document the order of components for reassembly.

- Inspection:

Examine each part for wear, damage, or malfunction. Look for cracks, rust, or any irregularities.

- Replacement:

Replace any faulty components with high-quality alternatives to guarantee longevity and reliability.

- Reassembly:

Put the device back together, following your initial documentation to maintain accuracy.

- Testing:

Conduct thorough testing to ensure all functions operate correctly and efficiently.

- Final Check:

Perform a final inspection and make any necessary adjustments before putting the unit back into service.

Upgrading Your Mixer Components

Enhancing your culinary appliance can significantly improve performance and efficiency. By focusing on specific elements within the machine, you can achieve optimal results in your kitchen endeavors. This process not only extends the lifespan of the equipment but also elevates your overall cooking experience.

Identifying Key Components

Begin by assessing the essential elements that impact functionality. Common upgrades include the bowl, attachments, and motors. Upgrading these components can lead to enhanced versatility and power, allowing for a broader range of culinary tasks.

Benefits of Enhanced Features

Investing in high-quality components can transform your appliance into a more powerful tool. Upgraded parts often provide improved durability and better performance, ultimately allowing you to explore new recipes and techniques with confidence. Delve into the possibilities and discover the ultimate potential of your kitchen equipment.

Customer Reviews on H600 Parts Quality

When it comes to the durability and effectiveness of components for commercial kitchen equipment, customer feedback plays a crucial role. Users often share their experiences regarding the reliability and longevity of these essential items, shedding light on their overall satisfaction and performance in demanding environments.

Positive Experiences

Many users highlight the exceptional quality of these components, noting that they withstand heavy usage without compromising performance. A common sentiment is that investing in high-quality items significantly reduces maintenance needs and downtime, which is vital in a busy kitchen. One reviewer stated, “I’ve had no issues after months of daily use; the reliability has been a game-changer for my operations.”

Areas for Improvement

While the majority of feedback is positive, some customers have pointed out occasional inconsistencies in certain products. One user remarked, “I faced a problem with a specific part failing sooner than expected, but customer service was quick to assist.” This suggests that while the quality is generally high, there may be instances where improvement is necessary to maintain consistency across the range.