Maintaining a well-functioning cleaning device requires a basic understanding of its internal elements. Each element plays a crucial role in ensuring smooth performance and efficient operation, and recognizing these individual components can help users troubleshoot and maintain the device more effectively.

In this section, we’ll explore the essential elements found in modern vacuum systems. Knowing how these components work together allows users to keep their machines in optimal condition, reducing wear and improving longevity. With this knowledge, routine upkeep and potential repairs become much more manageable.

By delving into the intricate design of these devices, you can gain a deeper understanding of how each part contributes to the overall functionality. This will empower you

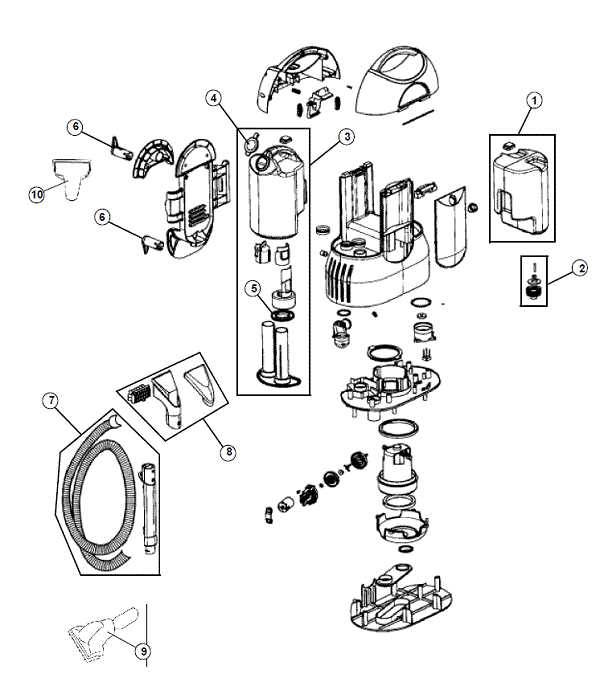

Hoover WindTunnel 3 Parts Overview

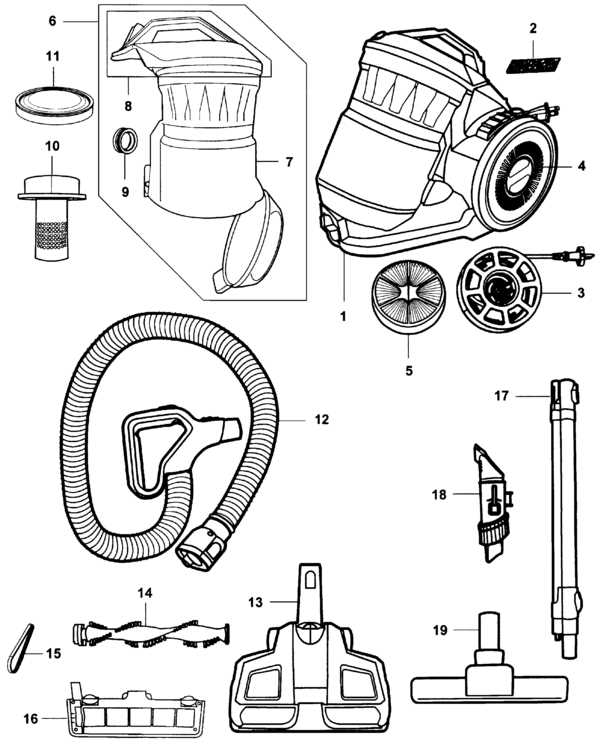

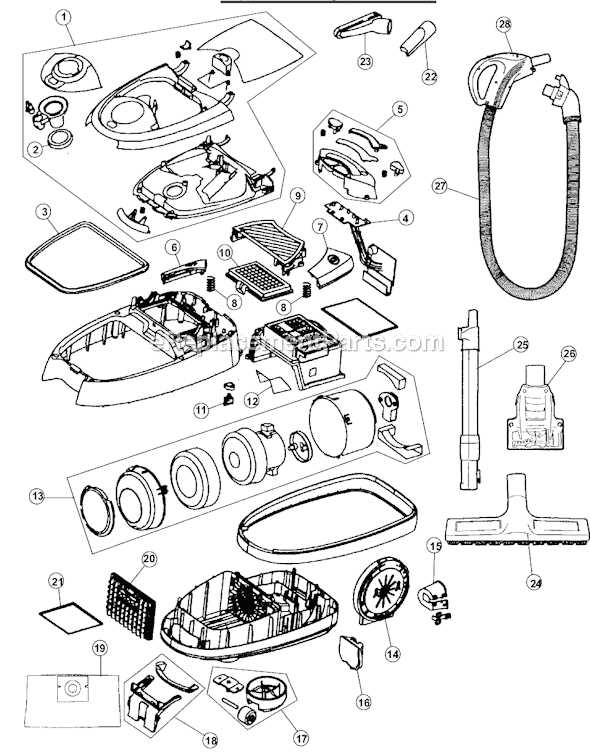

This section provides a detailed look at the essential components that make up the advanced cleaning system. Understanding the various elements involved will help users maintain optimal performance and extend the lifespan of the device. Each component plays a crucial role in delivering efficient cleaning results, ensuring that all types of surfaces are properly addressed.

The system is designed with several interconnected elements that contribute to its overall functionality. From the main cleaning mechanisms to the supporting features, every aspect is engineered for maximum efficiency and durability. By exploring these elements, users can gain valuable insight into how the system operates and how to troubleshoot any potential issues.

Main Components of the Hoover WindTunnel 3

Understanding the essential elements of this advanced cleaning device helps in maintaining its efficiency and functionality. These core mechanisms work together to provide optimal suction and thorough cleaning across various surfaces.

Suction Motor

The powerful motor is the driving force behind the vacuum’s performance, creating the necessary airflow to lift dirt and debris from carpets and floors. This component is key to ensuring the machine operates at its full potential.

Filtration System

The filtration system plays a critical role in trapping dust and allergens, ensuring cleaner air is released back into the environment. Equipped with high-efficiency filters

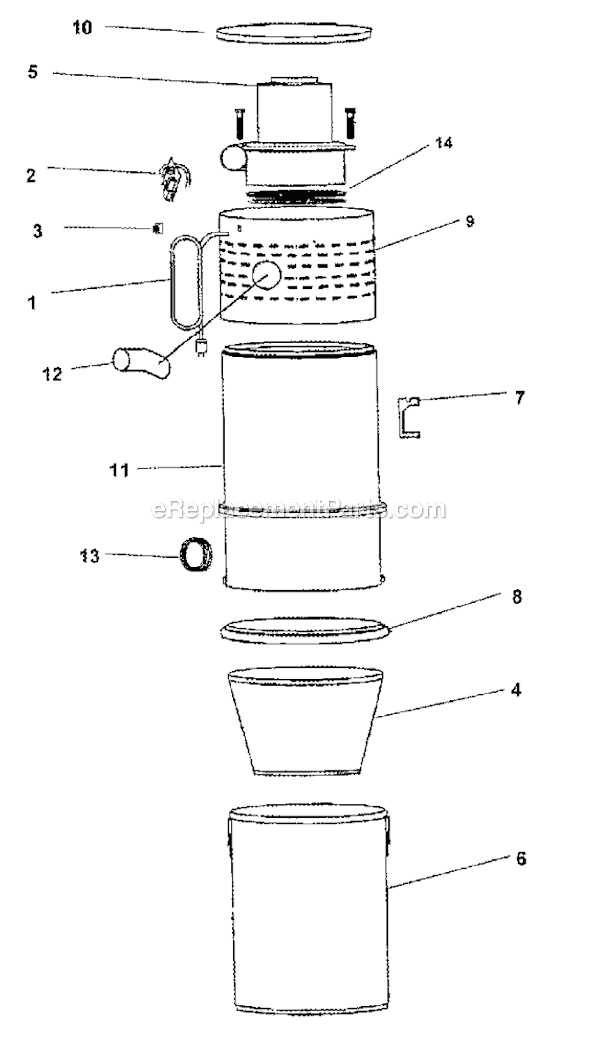

Understanding the Internal Structure

The inner mechanics of modern vacuum systems are designed to maximize efficiency and functionality. Each component has a specific role, working together to ensure optimal performance. By understanding the layout and function of these elements, users can maintain the system more effectively and troubleshoot any potential issues.

Main Functional Components

The system consists of several key elements that contribute to its overall operation. These include the motor, airflow pathways, and filtration systems. Together, they create a seamless flow of air and suction, removing dirt and debris from surfaces.

Component Arrangement

The arrangement of internal elements is crucial for smooth functionality. The motor powers the system, while the filters and tubes direct airflow. Maintaining these parts in their proper configuration ensures the machine works at peak efficiency.

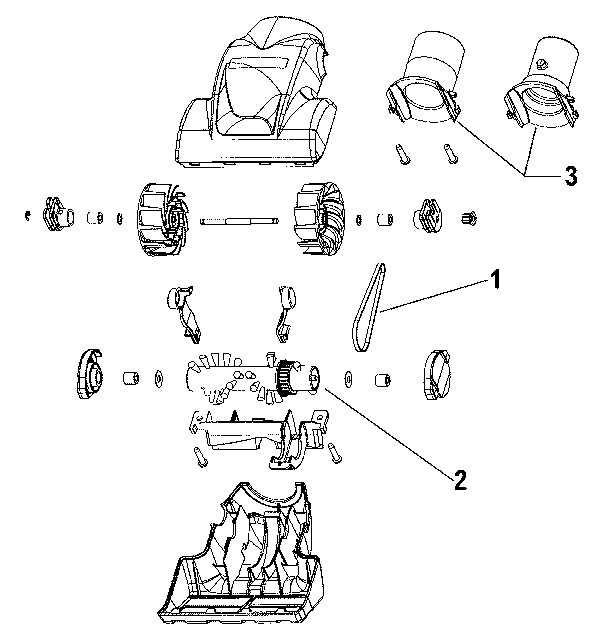

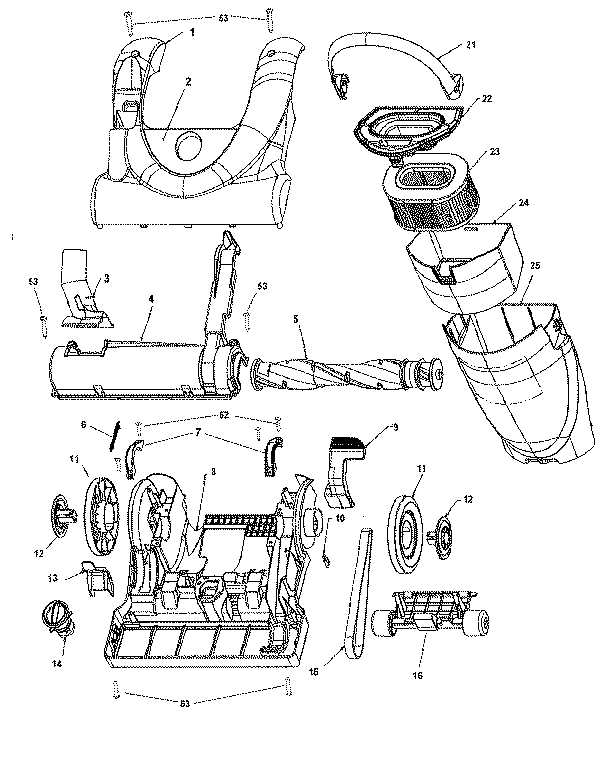

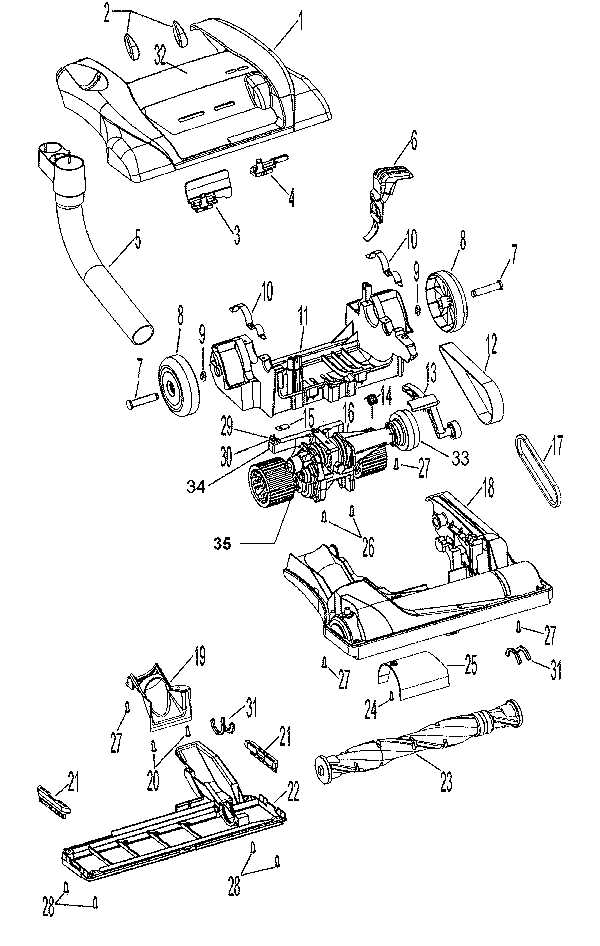

Brushroll Assembly and Its Function

The brushroll assembly is an essential component designed to enhance cleaning efficiency by agitating debris and dirt from surfaces. This rotating mechanism works in tandem with the vacuum’s suction system, ensuring deeper and more thorough cleaning of carpets and other soft materials. Understanding its structure and role in the cleaning process can help maintain optimal performance.

Main Elements of the Brushroll Assembly

- Brushroll Cylinder: The central part of the assembly that houses the bristles, responsible for loosening dirt.

- Bristles: Positioned around the cylinder, these work to lift dirt and particles from deep within the carpet fibers.

- End Caps: These secure the brushroll

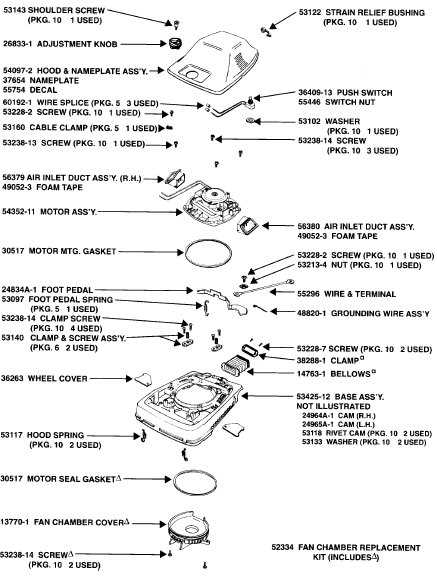

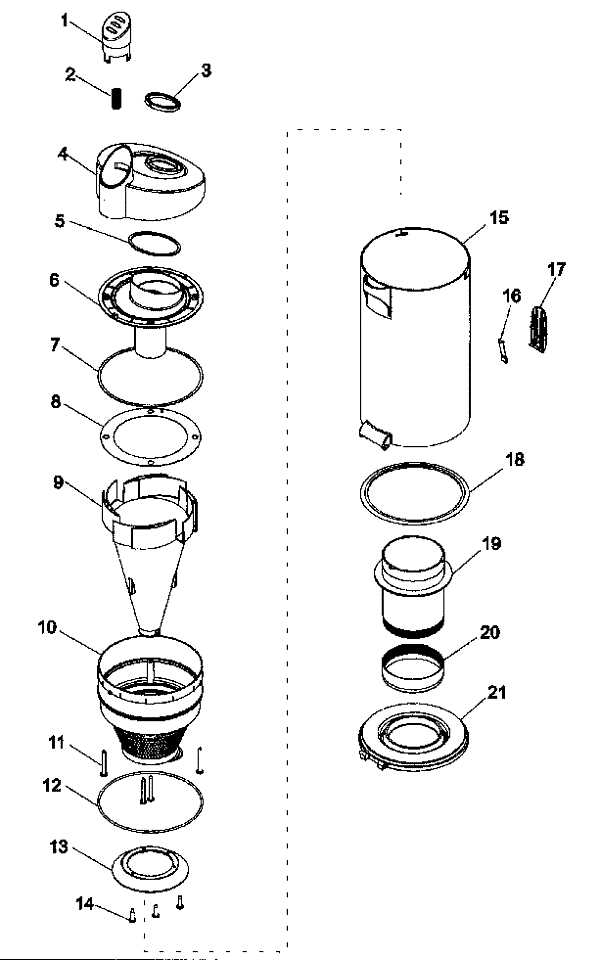

Key Motor Elements in WindTunnel 3

The motor plays a crucial role in ensuring optimal performance and efficiency in vacuum cleaners. Understanding the essential components of the motor mechanism is key to maintaining consistent operation and addressing potential issues in a timely manner. Below is an overview of the primary elements that make up the motor system.

Main Components of the Motor System

- Drive Shaft: Transmits the rotational force from the motor to other moving parts, ensuring smooth and effective suction.

- Carbon Brushes: Serve as electrical conductors that provide power to the rotating part of the motor, enabling continuous operation.

- Bearings: Support the rotating parts and reduce friction, ensuring smooth and quiet motor function.

- Check the user manual for specifications.

- Look for model numbers on existing components.

- Consult manufacturer websites or customer service for compatibility.

Filters and Their Maintenance

Filters play a crucial role in ensuring optimal performance and longevity of vacuum cleaning devices. Regular upkeep of these components not only enhances the efficiency of the appliance but also improves indoor air quality. Understanding the types of filters available and adhering to maintenance guidelines is essential for achieving the best results.

There are several types of filters commonly found in cleaning units, each serving a unique function. It’s important to familiarize yourself with their specifications and care requirements to ensure proper operation.

Filter Type Function Maintenance Tips HEPA Filter Captures small particles and allergens Replace every 6-12 months Pre-Motor Filter Protects the motor from dust and debris Clean every 2-3 months; replace if damaged Post-Motor Filter Ensures clean air is expelled back into the environment Check every 6 months; replace if worn out Implementing a regular cleaning schedule for filters will prolong the life of your appliance and maintain its efficiency. Always refer to the user manual for specific instructions regarding your model.

Belt System: How It Operates

The belt system is a crucial component in various cleaning devices, ensuring the effective transfer of power from the motor to the brush roll. This mechanism plays a significant role in enhancing performance by facilitating the rotation of the brush, which in turn aids in effective dirt and debris removal from surfaces.

Components of the Belt System

The system consists of several key elements, including the belt itself, pulleys, and the motor. The belt, typically made of durable materials, connects the motor to the brush roll. When the motor activates, it spins the pulley, causing the belt to turn and consequently rotating the brush roll.

Functionality and Maintenance

This system operates seamlessly under normal conditions, but wear and tear can affect its efficiency. Regular maintenance is essential to ensure optimal performance. Checking for signs of fraying or damage to the belt can prevent breakdowns and extend the lifespan of the entire mechanism.

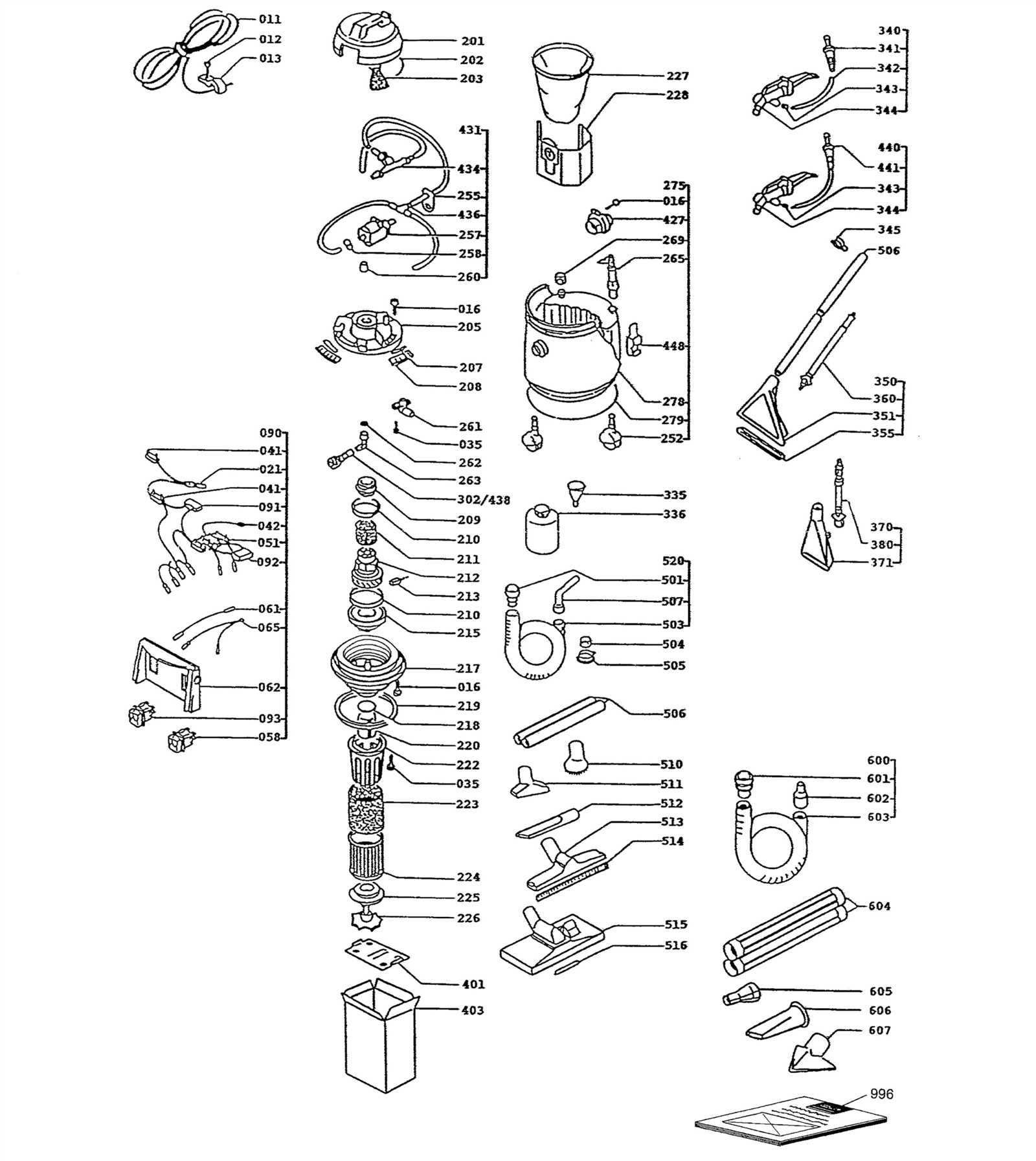

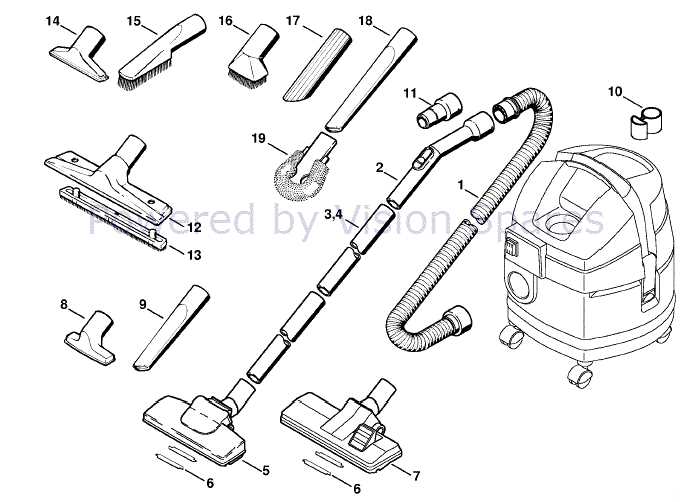

Hose and Wand Design Features

The design of the flexible tubing and extension tool plays a crucial role in enhancing the user experience during cleaning tasks. These components are engineered to provide optimal maneuverability and ease of use, ensuring effective dirt removal in various settings.

Durability is a key aspect of these components, as they are constructed from high-quality materials that withstand wear and tear. This ensures longevity and reliable performance over time.

Furthermore, the ergonomic design of the wand allows for comfortable handling, reducing strain during extended cleaning sessions. The lightweight nature of these tools enhances agility, making it easy to reach difficult areas.

Additionally, compatibility with various attachments increases versatility, allowing users to customize their cleaning approach based on specific needs. This adaptability contributes to a more efficient cleaning process.

In summary, the thoughtful design features of the hose and wand significantly enhance the overall functionality and convenience of cleaning, making them essential elements in any cleaning system.

Replacement Tips for Hoover WindTunnel 3 Parts

When it comes to maintaining your cleaning appliance, knowing how to properly swap out components is essential. Following some straightforward guidelines can ensure your device operates efficiently and extends its lifespan. This section provides valuable suggestions for effective replacements, allowing you to tackle common issues with confidence.

Identify Compatible Components

Before proceeding with any replacements, it is crucial to identify the correct components for your model. Here are some steps to help you:

Replacement Process

Once you have the right components, follow these steps to ensure a smooth replacement:

- Power off the appliance and unplug it to ensure safety.

- Carefully remove the old component, following any specific instructions.

- Install the new part, ensuring it fits snugly in place.

- Test the appliance to confirm proper operation.

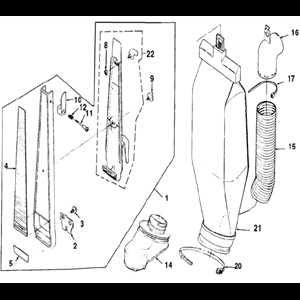

Handle and Control Mechanisms

The handle and control systems of modern vacuum cleaners play a vital role in ensuring user comfort and operational efficiency. These components are designed to provide a seamless interaction between the user and the appliance, allowing for effortless maneuverability and effective cleaning. Understanding the functionality of these mechanisms can enhance the overall experience and effectiveness of cleaning tasks.

Ergonomic Design Features

Many cleaning devices are equipped with ergonomic handles that prioritize user comfort during operation. Key features include:

- Comfort Grip: Handles are often padded or shaped to fit the hand comfortably, reducing strain during extended use.

- Adjustable Heights: Some models allow for height adjustments to accommodate various user preferences, ensuring a natural posture.

- Weight Distribution: Proper design balances weight to prevent fatigue and enhance control.

Control Elements

The control mechanisms integrated into these devices are essential for managing various functionalities. Common elements include:

- On/Off Switch: Easily accessible switches allow for quick activation or deactivation of the unit.

- Variable Speed Settings: Many appliances feature multiple speed options to adapt to different surfaces and cleaning tasks.

- Attachment Controls: Controls for switching between various attachments enable versatility in cleaning applications.

Identifying Common Wear and Tear Parts

Understanding the typical components that experience degradation over time is essential for maintaining optimal functionality. Various elements in household cleaning devices are subject to regular use, leading to their eventual wear. Recognizing these components can help in ensuring longevity and efficiency.

Filters are among the most crucial elements, as they trap dust and debris. Regular replacement is necessary to maintain suction power and air quality. Another component is the belt, which connects the motor to the brush roll. If it becomes worn or breaks, it can significantly reduce cleaning effectiveness.

Additionally, wheels and brush rolls often endure significant wear due to constant movement across various surfaces. Monitoring their condition is vital to ensure smooth operation. By staying aware of these components, users can proactively address any issues before they affect performance.