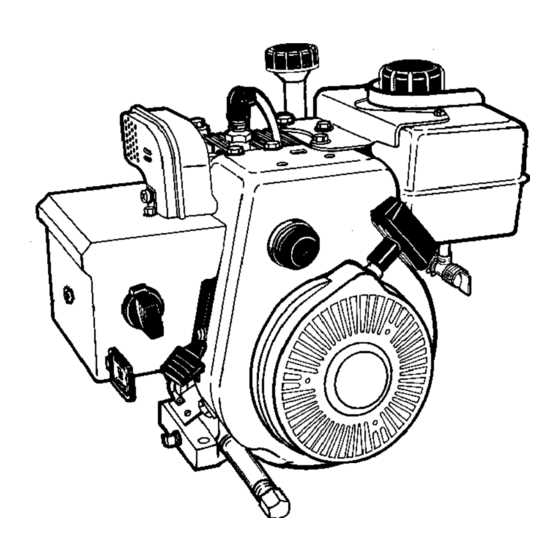

Understanding the layout and organization of various mechanical elements is essential for effective maintenance and troubleshooting. This section provides an in-depth look into the structure of key components, offering a clear representation of how different elements come together to ensure smooth operation.

Detailed placement and connections between individual elements are crucial for proper assembly and disassembly. By exploring these connections, you’ll gain a better understanding of the overall functionality and how to approach specific tasks efficiently.

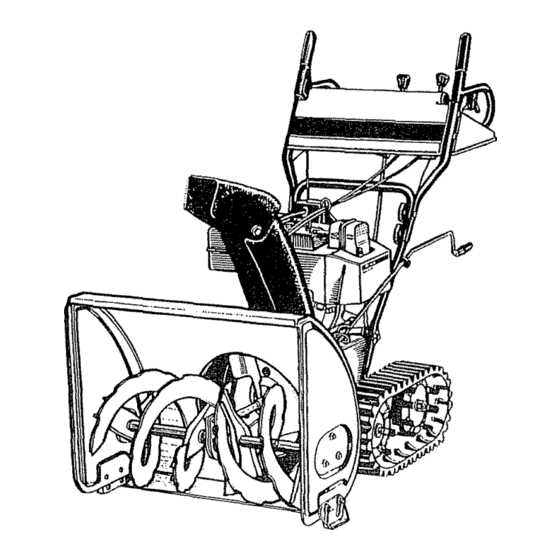

Hssk50 Parts Diagram Overview

The illustration provides a comprehensive breakdown of the essential components, offering a clear visual representation for easier understanding. It simplifies the structure, allowing users to quickly identify and analyze each section, ensuring better comprehension of the system’s layout.

Each section is carefully labeled, ensuring users can effortlessly navigate through the different elements. This layout encourages efficient maintenance and troubleshooting, helping users to pinpoint any potential issues with greater precision.

This overview also highlights the connections between various segments, ensuring smooth operation and offering insight into how the entire system functions as a cohesive unit.

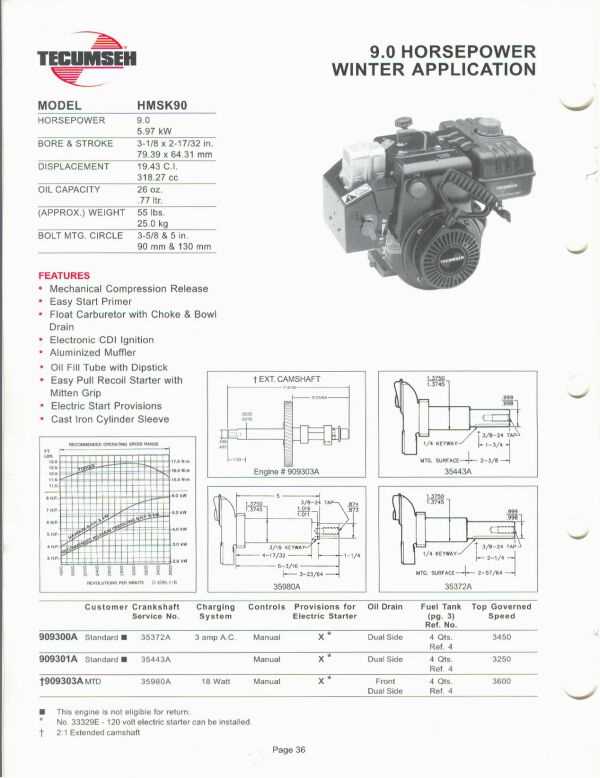

Key Components of the Hssk50

The primary elements of this model consist of interconnected systems that ensure efficient operation. Each part works in harmony to maintain the functionality and performance, with several essential units playing a pivotal role in the overall mechanism.

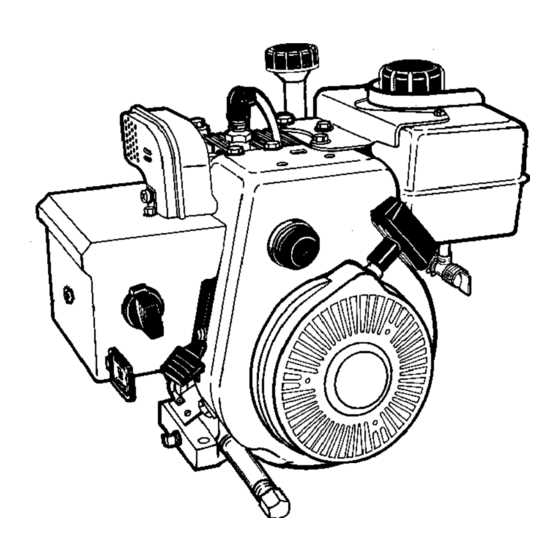

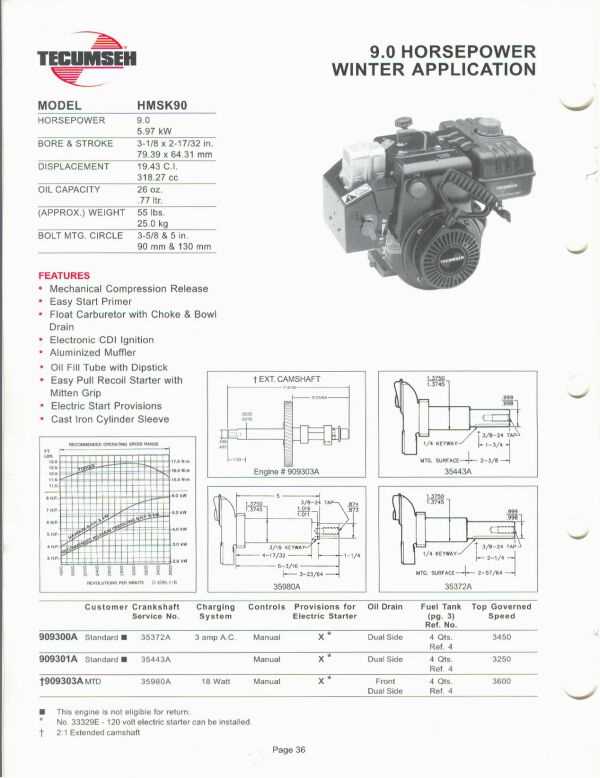

Engine Section

The engine forms the core of the system, delivering the necessary power for operation. It includes various subcomponents, each designed to optimize energy output and maintain consistent performance under different conditions.

Supportive Systems

Additional mechanisms provide stability and control. These include systems that regulate flow, manage heat, and ensure proper alignment, allowing the entire structure to function smoothly.

Understanding the Engine Layout

The structure of a mechanical power unit can be quite complex, but by breaking it down, it becomes easier to understand. This section provides an overview of how the key elements are organized within the system. Each component plays a specific role, working together to ensure efficient operation. Recognizing the main sections and how they are interconnected is crucial for maintenance and repair tasks.

Main Sections of the Engine

The mechanical power unit is typically divided into distinct sections. These sections include the core mechanical functions, fluid systems, and control mechanisms. Below is a general outline of the main parts found in most systems:

| Section |

Description |

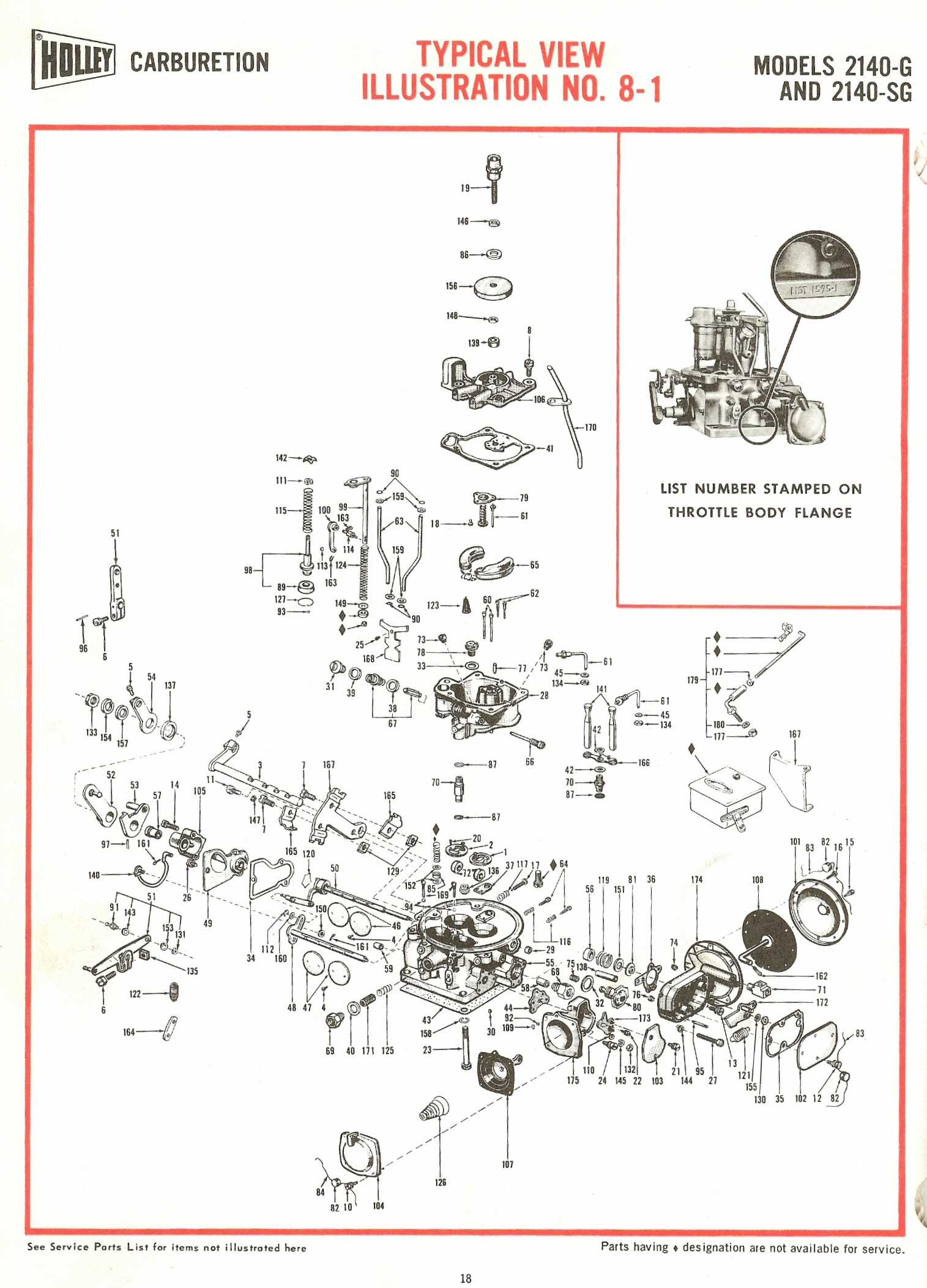

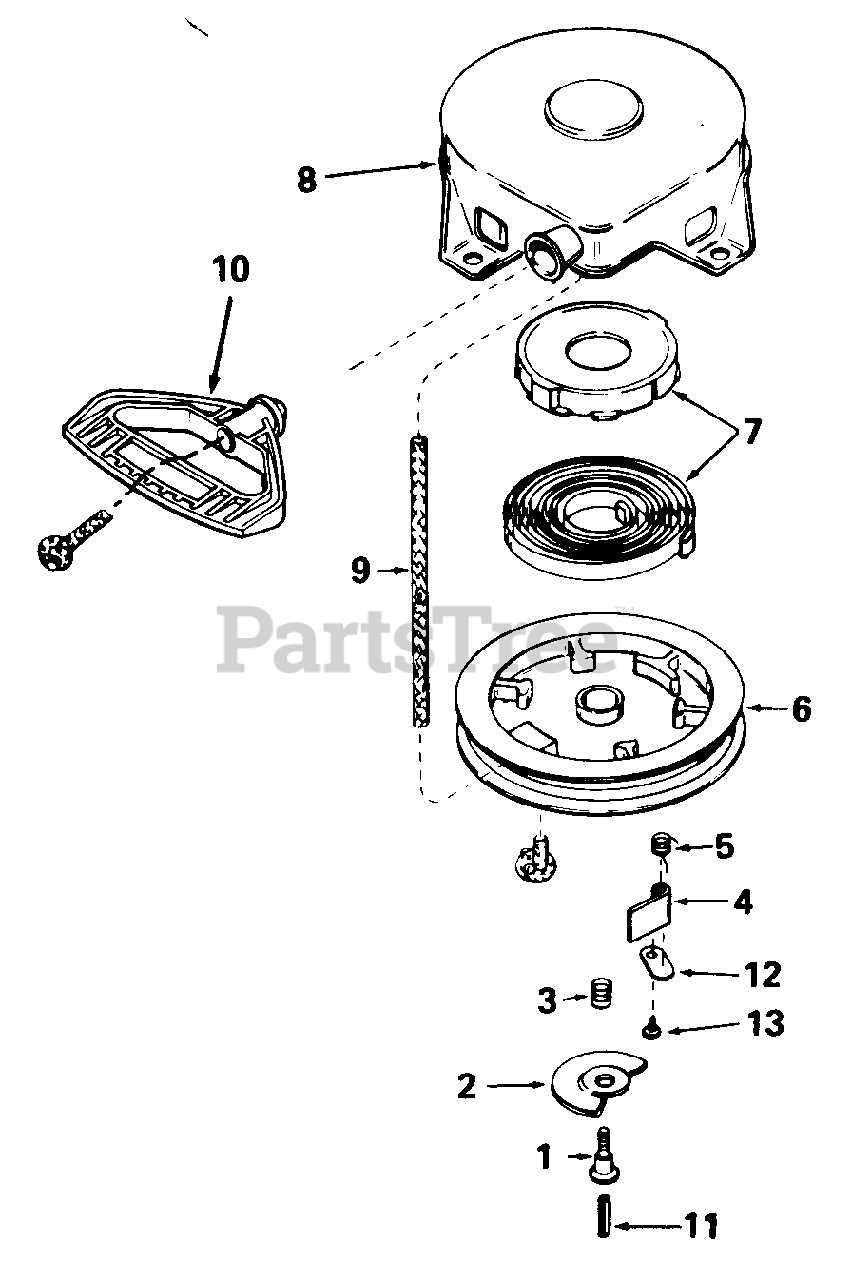

Detailed View of Internal Parts

Understanding the intricate layout of internal components is essential for ensuring smooth functionality and maintenance. Each piece plays a crucial role in the system, contributing to overall performance and reliability.

Main Components

- Central mechanisms that control the core operations

- Supporting elements designed to enhance durability

- Various connectors ensuring proper alignment and flow

Key Functional Sections

- The primary section responsible for the main processes

- Auxiliary

How the Exhaust System Works

The exhaust system plays a crucial role in ensuring efficient performance and reducing emissions. Its purpose is to guide gases away from the engine while minimizing noise and harmful substances. By directing these gases through various components, it helps maintain both engine functionality and environmental standards.

Main Components of the Exhaust System

- Muffler: Reduces noise generated by the engine.

- Exhaust Manifold: Collects gases from the engine and directs them into the system.

- Catalytic Converter: Converts harmful gases into less harmful emissions before they exit.

Exhaust System Operation

- Gases are expelled from the engine into the exhaust manifold.

- The gases pass through the catalytic converter, where pollutants are neutralized.

- The muffler then reduces the noise of the escaping gases.

- Finally, the gases exit through the tailpipe, completing the process.

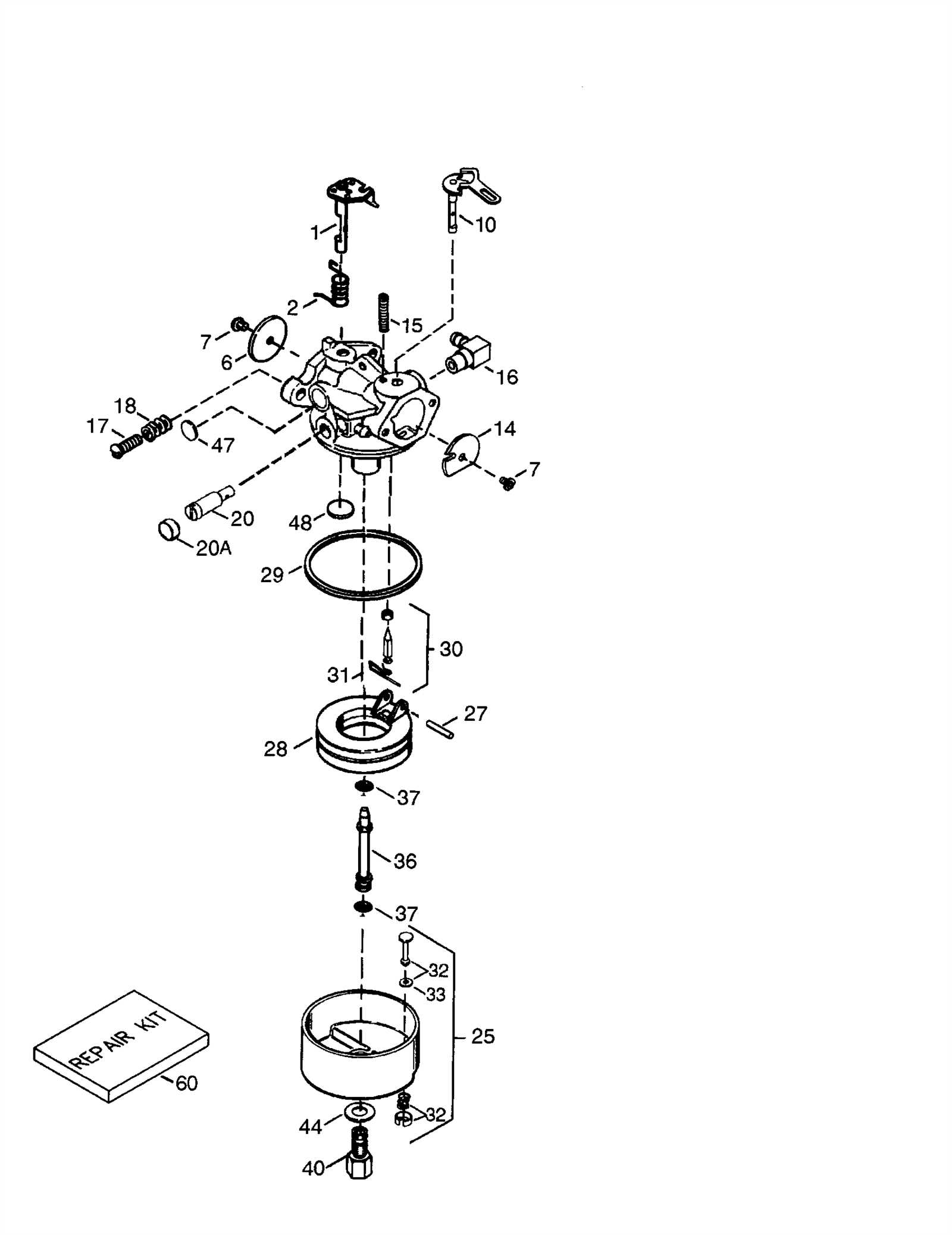

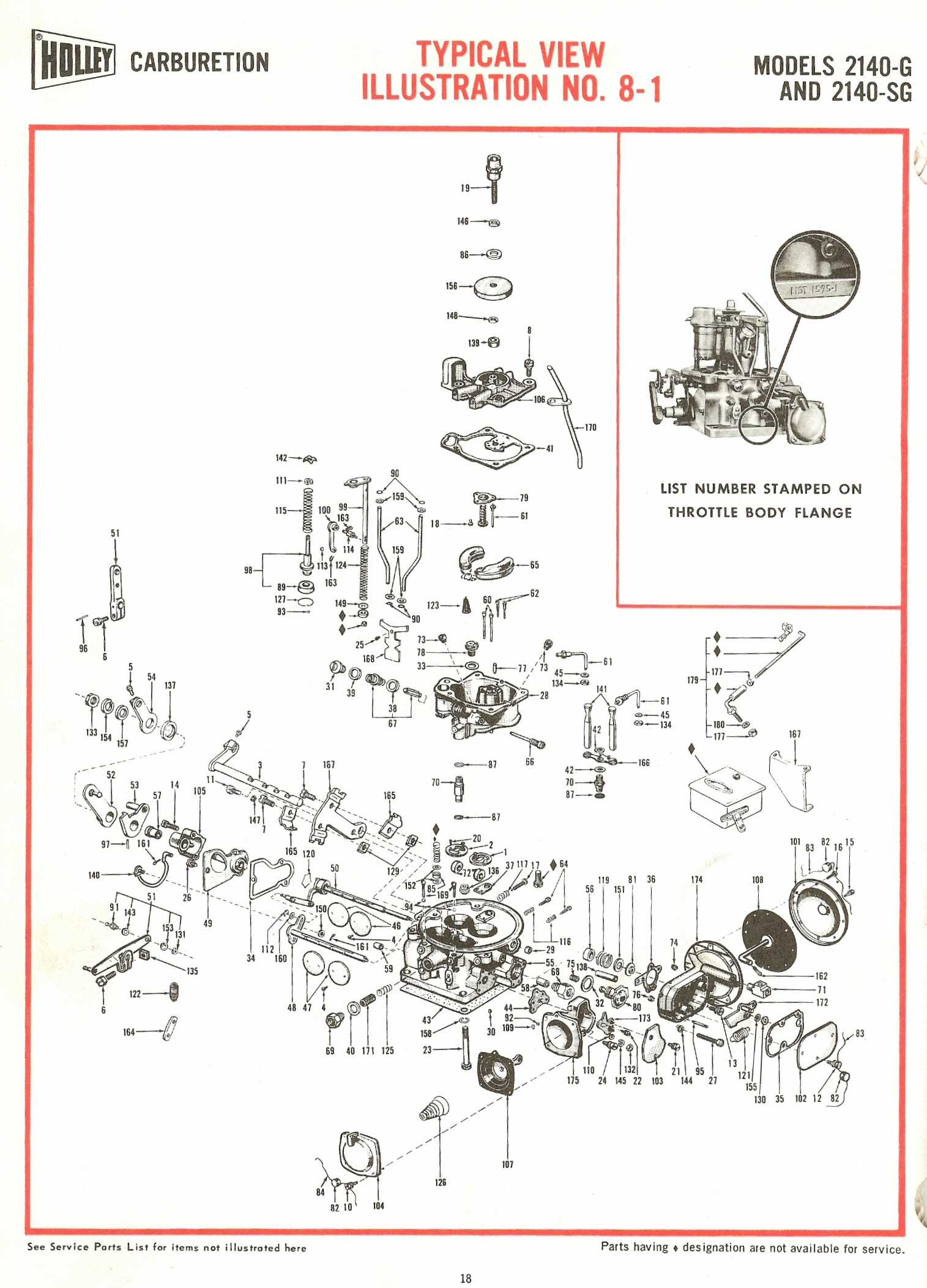

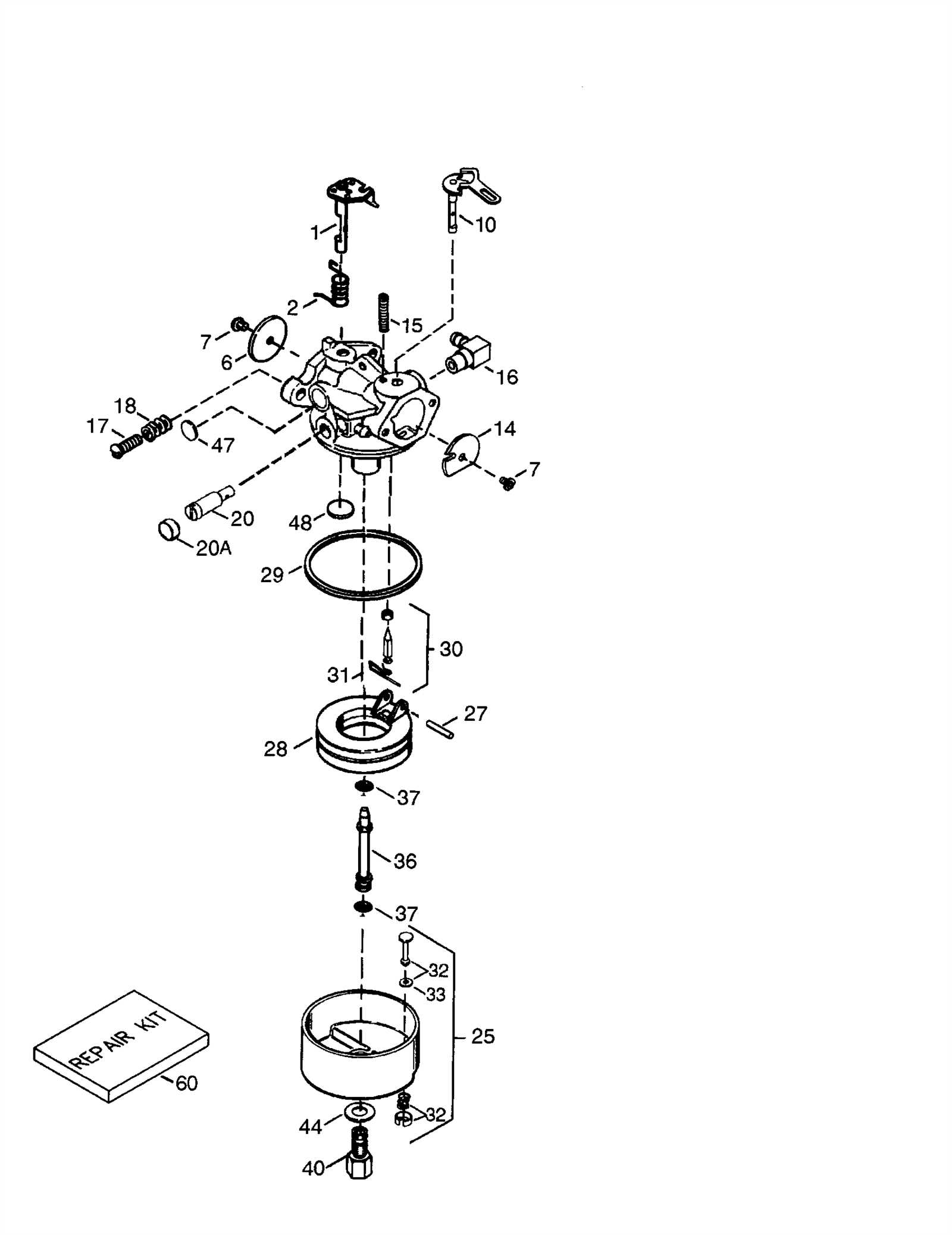

Fuel System and Key Elements

The fuel system is crucial for the efficient operation of any engine. It ensures the proper delivery of fuel, optimizing performance and functionality. Understanding the essential components of this system is vital for maintenance and troubleshooting.

Main Components

- Fuel Tank: The reservoir that holds the fuel until it is needed.

- Fuel Pump: Responsible for transferring fuel from the tank to the engine.

- Fuel Filter: Ensures that impurities are removed before the fuel reaches the engine.

- Fuel Injectors: These components deliver the precise amount of fuel into the combustion chamber.

- Fuel Lines: Pathways through which the fuel travels from the tank to the engine.

Operational Importance

Each element of the fuel system plays a specific role in maintaining the overall efficiency of the engine. Regular inspections and maintenance of these components are necessary to prevent malfunctions and ensure optimal performance.

Illustration of the Electrical System

This section provides a visual representation of the components within the electrical framework. Understanding the layout and connections is essential for grasping how energy flows through the system, facilitating the operation of various functionalities.

The schematic offers insights into the relationships between different elements, highlighting key areas such as power distribution and control mechanisms. By analyzing this illustration, one can better comprehend the overall functionality and efficiency of the electrical setup.

Cooling Mechanism and Radiator Parts

The cooling system plays a vital role in maintaining optimal operating temperatures within machinery, ensuring longevity and efficiency. This mechanism is essential for preventing overheating and facilitating heat dissipation, which is crucial for overall performance.

Key components of this system include:

- Radiator: This element is responsible for transferring heat away from the engine to the surrounding air.

- Cooling Fans: These devices enhance airflow through the radiator, improving heat exchange.

- Hoses: Flexible tubes that transport coolant to and from various parts of the cooling system.

- Thermostat: A regulating component that controls the flow of coolant based on temperature.

Additionally, maintaining the integrity of these components is crucial. Regular inspection can help identify wear and tear, ensuring efficient operation. Proper maintenance practices can significantly enhance the effectiveness of the cooling system.

Examining the Transmission Setup

This section provides an overview of the mechanisms involved in the drive system, focusing on how they work together to ensure smooth operation. Understanding these components is essential for efficient performance and maintenance.

Key Components of the Drive System

The drive assembly consists of various elements that play crucial roles in transferring power effectively. These parts include the gearbox, clutches, and drive shafts, all of which must function harmoniously to transmit motion and force.

Importance of Proper Alignment

Ensuring that all components are correctly aligned is vital for optimal performance. Misalignment can lead to excessive wear, noise, and potential failure. Regular inspections and adjustments are recommended to maintain the integrity of the system.

Lubrication System Breakdown

The lubrication system is a critical component in ensuring the smooth operation and longevity of machinery. It plays a vital role in minimizing friction between moving parts, thereby enhancing overall efficiency and preventing wear and tear.

Understanding the various elements of this system can aid in effective maintenance and troubleshooting. Here are the key components typically involved:

- Oil Reservoir: Stores the lubricant until it is needed.

- Pumps: Circulate the lubricant throughout the system.

- Filters: Remove impurities from the lubricant to maintain its effectiveness.

- Lines and Hoses: Transport the lubricant to different parts of the machinery.

- Nozzles: Deliver the lubricant precisely where it is required.

Regular inspection and maintenance of these components are essential to ensure optimal performance. Identifying issues early can prevent costly repairs and extend the life of the equipment.

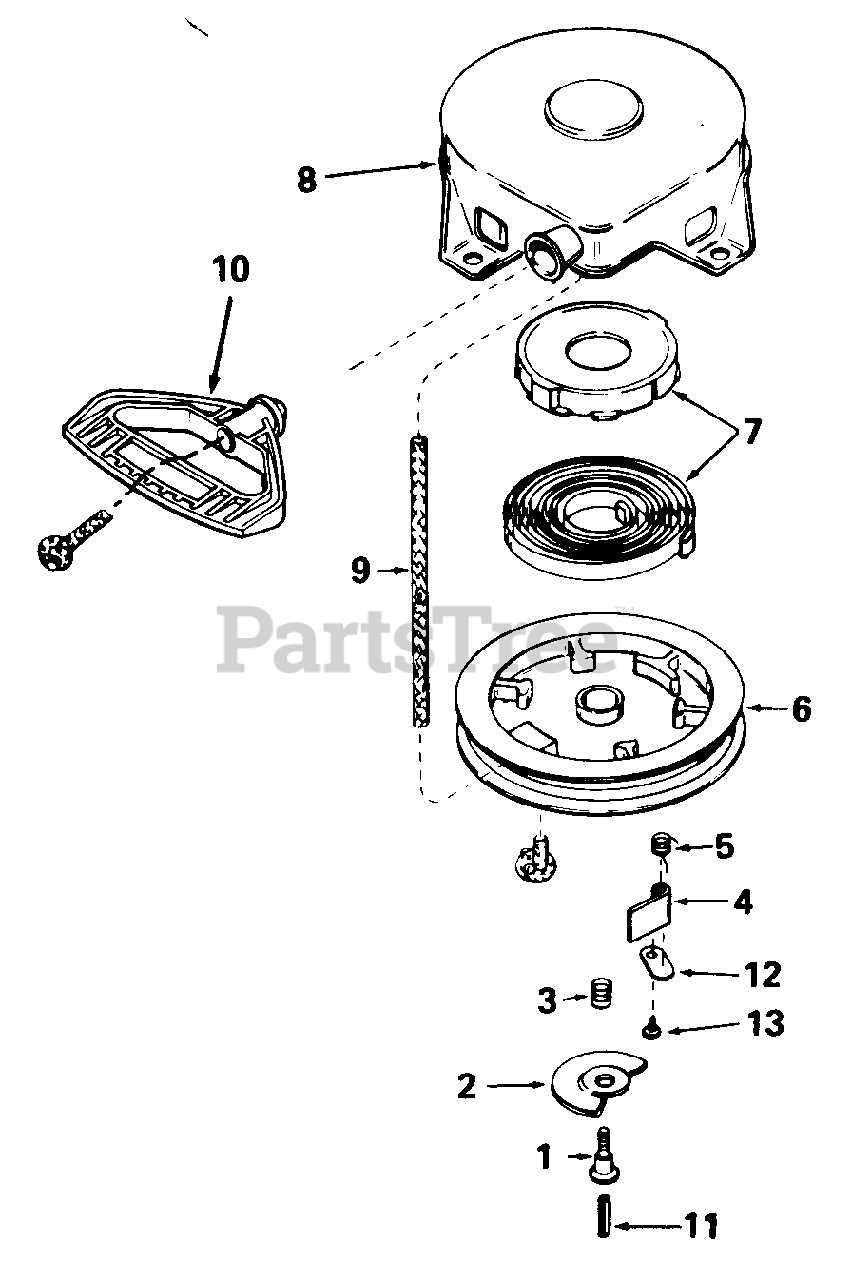

Assembly Guide for Critical Parts

This section provides essential insights for assembling key components effectively. Understanding the arrangement and interaction of these elements is vital for optimal performance and longevity.

To ensure a seamless assembly process, follow these steps:

- Begin by gathering all necessary tools and materials.

- Refer to the detailed illustrations that depict the correct positioning of each element.

- Organize the components in a logical order to streamline the assembly procedure.

When assembling, consider the following tips:

- Ensure all surfaces are clean and free from debris before proceeding.

- Double-check alignment before securing each part to prevent misconfiguration.

- Apply the recommended torque settings to avoid over-tightening.

Finally, conduct a thorough inspection of the assembled unit to confirm everything is properly in place and functioning as intended.