In the realm of machinery and automotive innovation, the significance of comprehending the arrangement and functionality of various elements cannot be overstated. A clear grasp of how each part interrelates enhances both maintenance and troubleshooting processes. Whether for enthusiasts or professionals, having a visual representation serves as an invaluable resource.

Exploring the intricate setup of these systems reveals not only the complexity of engineering but also the precision required for optimal performance. Each component plays a pivotal role, contributing to the overall efficacy of the machine. By studying the layout, one can identify potential issues and understand the assembly better.

This guide aims to shed light on the essential features and relationships between components, offering insights that empower users to make informed decisions. Recognizing how these elements fit together facilitates smoother operations and prolonged longevity of the equipment.

Understanding Hunter Auto34 Parts

This section aims to explore the essential components of a specific machinery model, providing insights into their functions and significance. A comprehensive grasp of these elements enhances maintenance and operational efficiency.

- Key Components:

- Engines: The core driving force.

- Transmission: Facilitates power transfer.

- Suspension: Ensures stability and comfort.

- Maintenance Importance:

- Regular checks can prevent breakdowns.

- Proper care extends the lifespan of the machinery.

- Common Issues:

- Wear and tear on moving parts.

- Fluid leaks affecting performance.

Understanding these elements allows users to optimize their experience and troubleshoot potential challenges effectively.

Overview of Hunter Auto34 Functionality

This section provides a comprehensive look at the operational capabilities and features of the device in question. Understanding how it functions allows users to maximize its potential and ensure efficient use in various applications. From its advanced mechanics to user-friendly interfaces, every aspect is designed for optimal performance.

| Feature | Description |

|---|---|

| Precision Measurement | Offers highly accurate readings for various parameters, ensuring reliability in operations. |

| Durability | Constructed from robust materials, the device withstands challenging environments and heavy usage. |

| Ease of Use | Designed with intuitive controls, enabling quick adaptation for users of all skill levels. |

| Modular Design | Facilitates easy upgrades and replacements, promoting longevity and adaptability. |

| Connectivity | Supports various interfaces for seamless integration with other systems and software. |

The diverse functionalities outlined here illustrate the commitment to quality and innovation, ensuring that users can achieve their goals efficiently and effectively.

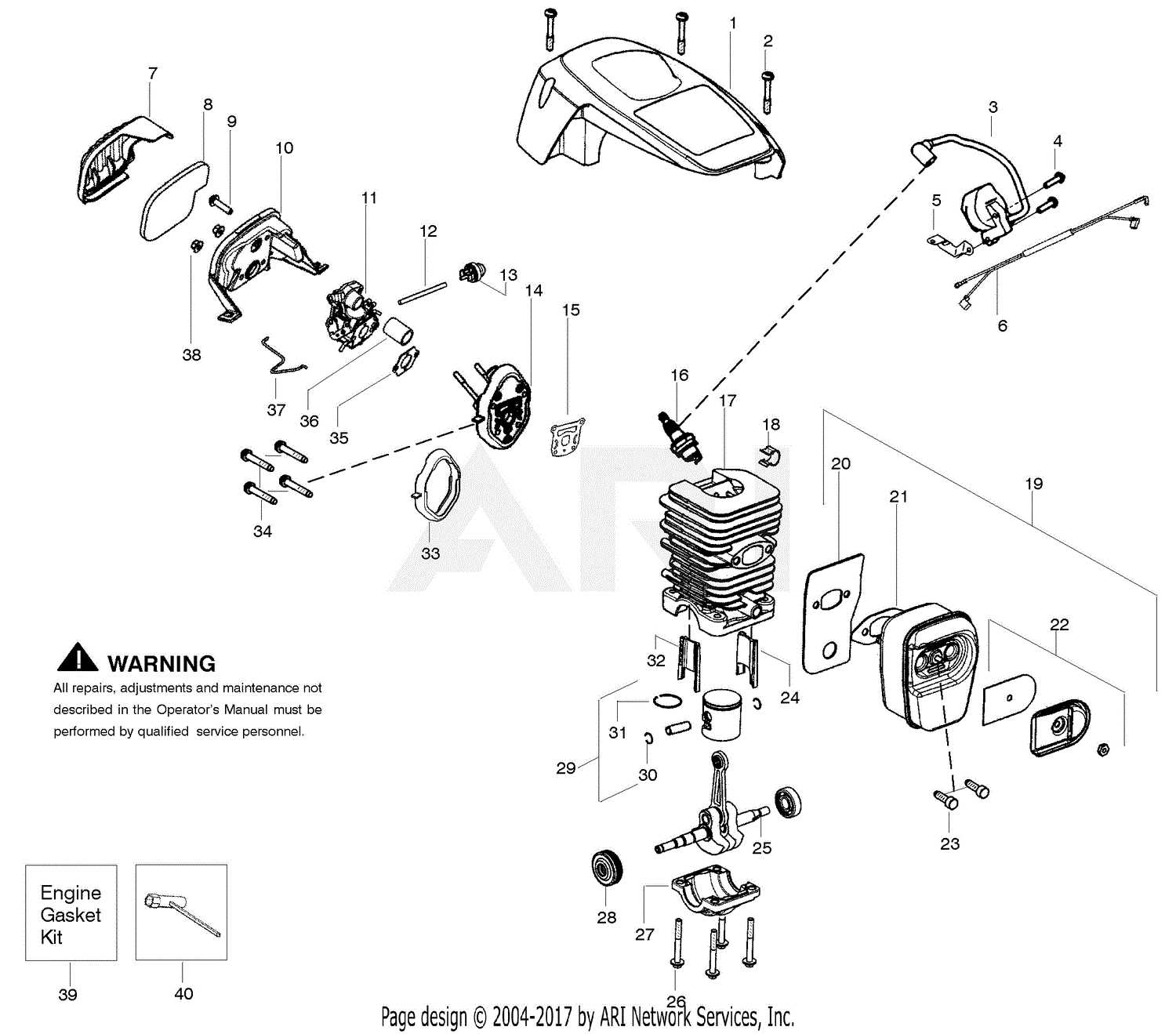

Importance of Accurate Parts Diagrams

Precise illustrations of components play a crucial role in ensuring the efficiency and reliability of mechanical systems. Such visuals facilitate understanding, making it easier for technicians and users to identify and replace elements without confusion. The clarity provided by these representations not only enhances maintenance procedures but also minimizes the risk of errors during repairs.

| Benefits | Description |

|---|---|

| Enhanced Understanding | Clear visuals simplify the identification of individual elements. |

| Time Efficiency | Accurate illustrations speed up the repair process. |

| Reduced Errors | Minimizes the likelihood of mistakes in replacement procedures. |

| Improved Training | Serves as a valuable resource for training new technicians. |

Common Components in Auto34 Models

In various models of this machinery, certain elements consistently play crucial roles in functionality and performance. Understanding these components can enhance maintenance practices and improve overall operational efficiency.

Key Elements

- Power Unit

- Drive Mechanism

- Control System

- Hydraulic Components

- Frame Structure

Maintenance Tips

- Regularly inspect the power unit for signs of wear.

- Ensure the drive mechanism is properly lubricated.

- Calibrate the control system periodically to maintain accuracy.

- Check hydraulic components for leaks and functionality.

- Assess the frame structure for any structural integrity issues.

By familiarizing oneself with these vital parts, operators can ensure optimal performance and longevity of their equipment.

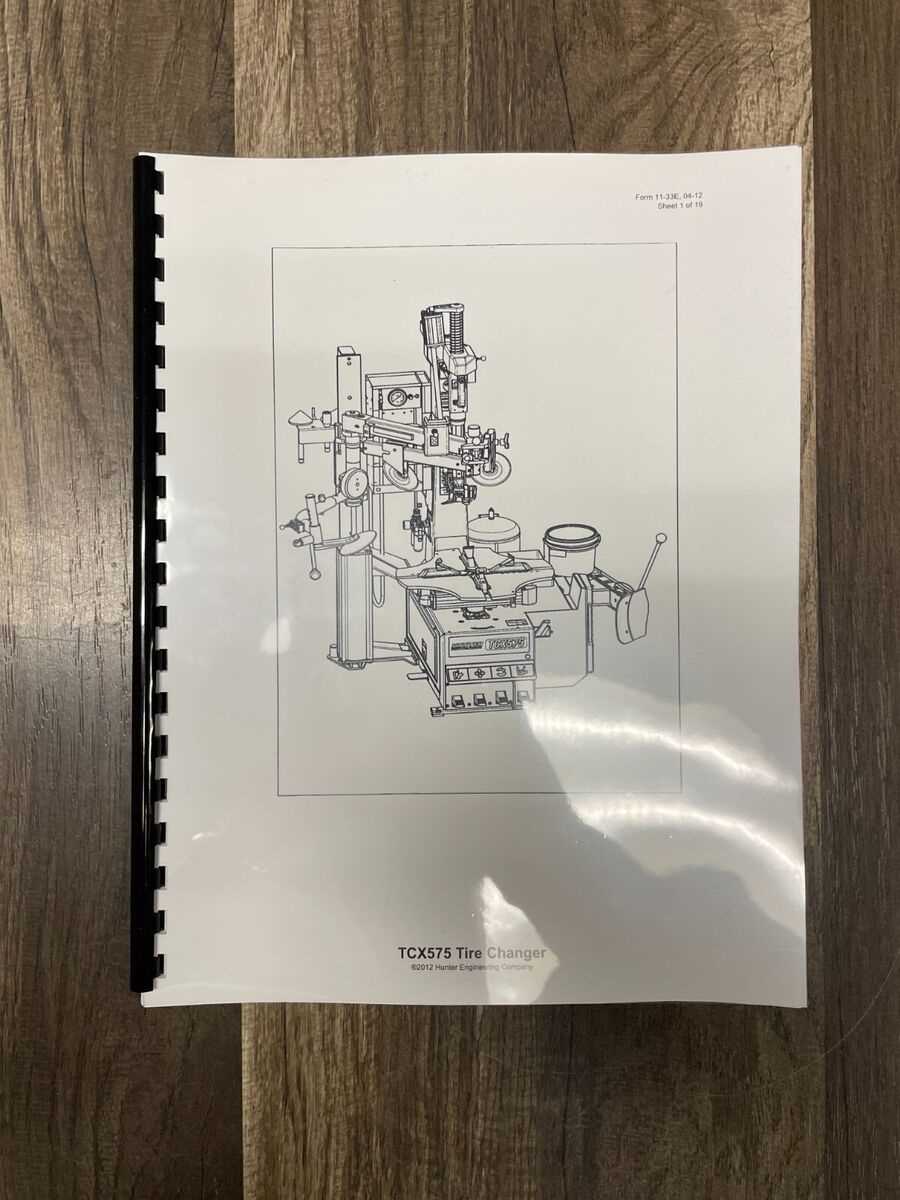

How to Read a Parts Diagram

Understanding a schematic representation is essential for efficient maintenance and repair of machinery. These visual guides provide a clear overview of components and their interconnections, making it easier to identify each element’s function and position. Familiarizing yourself with the symbols and layout is the ultimate key to effective interpretation.

First, look for the legend or key that explains various symbols and markings. This will help you recognize what each icon represents. Next, observe the flow of the layout, as it often indicates how parts interact within the system. Understanding this relationship is crucial for troubleshooting and assembly.

Finally, practice is vital. Regularly referring to these visuals while working on repairs will enhance your ability to quickly decipher them, leading to improved efficiency and confidence in your skills.

Identifying Replacement Parts for Auto34

When it comes to maintaining machinery, understanding how to locate suitable components is crucial for optimal performance. Each element plays a vital role in the overall functionality, and ensuring the right substitutes can enhance longevity and efficiency.

Start by familiarizing yourself with the specific features and characteristics of each component. This knowledge will aid in recognizing compatible alternatives when necessary. Utilize resources like manuals, technical guides, and online forums dedicated to similar equipment to gather insights.

Additionally, consulting with experts or experienced users can provide valuable recommendations. They can help identify trustworthy suppliers and highlight common issues related to component replacement, ensuring a smoother maintenance process.

Lastly, keeping an organized inventory of existing parts can streamline future replacements, allowing for quick access and reducing downtime. Emphasizing this practice will ultimately contribute to a more efficient operation.

Tools Needed for Parts Replacement

When it comes to replacing components in machinery, having the right instruments at your disposal is crucial. Utilizing appropriate tools not only ensures efficiency but also enhances safety during the process. Understanding which implements are necessary can significantly simplify the task at hand and lead to better outcomes.

Essential Instruments

Here is a list of indispensable tools you will need for component substitution:

| Tool | Description |

|---|---|

| Wrench Set | Used for loosening and tightening bolts and nuts. |

| Screwdriver Set | Various types for handling different screw heads. |

| Pliers | For gripping, twisting, and cutting wires or small parts. |

| Torque Wrench | Ensures that fasteners are tightened to the correct specification. |

| Jack Stands | Provides support when lifting machinery for better access. |

Additional Equipment

In addition to the basic tools, consider having these items for a smoother replacement experience:

| Tool | Description |

|---|---|

| Utility Knife | Handy for cutting through packaging or components. |

| Multimeter | For checking electrical connections and troubleshooting. |

| Flashlight | Illuminates dark areas to improve visibility. |

| Work Gloves | Protects hands during the replacement process. |

| Safety Glasses | Prevents eye injuries from debris or tools. |

Maintenance Tips for Hunter Auto34

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. Following a structured maintenance routine can prevent breakdowns and enhance efficiency. Understanding key components and their care will provide significant benefits in the long run.

Routine Inspections

Conduct thorough inspections of all major elements. Look for signs of wear and tear, and address any issues promptly. Check fluid levels and replace filters as needed to maintain smooth operation.

Cleaning and Lubrication

Regularly clean components to remove dust and debris that may cause malfunctions. Additionally, lubricate moving parts to reduce friction and prevent corrosion, ensuring everything functions smoothly.

Where to Find Parts Diagrams Online

Finding comprehensive visuals and schematics for various equipment is essential for both professionals and enthusiasts. These resources provide valuable insights into the components and their organization, aiding in maintenance and repair tasks. Fortunately, the internet offers a plethora of platforms where users can access these crucial illustrations.

Manufacturer Websites: The first and most reliable source is the official site of the equipment’s maker. Many manufacturers provide detailed visuals, often in the support or resources section. This ensures accuracy and up-to-date information directly from the source.

Online Retailers: E-commerce platforms frequently feature illustrations as part of their product listings. Searching for specific components often reveals useful visuals that can assist in understanding how different pieces fit together.

Forums and Community Websites: Online communities dedicated to specific equipment often share resources, including visuals and schematics. Engaging with these forums can lead to discovering user-uploaded content that may not be found elsewhere.

Technical Manuals and Guides: Many technical publications are available online for free or for purchase. These documents typically include comprehensive visuals and descriptions, making them invaluable for troubleshooting and repairs.

Social Media Groups: Platforms like Facebook and Reddit host groups where users share resources, including visual references. Joining these groups can provide access to shared knowledge and materials from fellow users.

By exploring these avenues, anyone can enhance their understanding of equipment and make informed decisions during repairs and maintenance.

Exploring Aftermarket Parts Options

When it comes to enhancing vehicle performance and longevity, exploring alternatives beyond original equipment can be a game changer. The aftermarket sector offers a wealth of components that can not only match but often exceed the quality of factory-installed items. This section delves into the advantages and considerations of opting for these substitutes.

Benefits of Aftermarket Components

Choosing substitutes can lead to significant cost savings without compromising on quality. Many aftermarket manufacturers invest heavily in research and development, ensuring their offerings meet or surpass industry standards. Additionally, enthusiasts often appreciate the greater variety and customization options available, allowing for tailored upgrades that reflect personal style and performance preferences.

Considerations When Selecting Alternatives

While the potential for enhanced performance is appealing, it’s essential to conduct thorough research before making a purchase. Compatibility with existing systems must be verified to avoid issues during installation. Moreover, warranty implications could arise if aftermarket options are not endorsed by the vehicle’s manufacturer. Always weigh the pros and cons to ensure the best decision for your vehicle’s needs.

Common Issues and Troubleshooting Tips

In the realm of mechanical devices, users often encounter various challenges that can affect performance. Understanding these common problems and their solutions is essential for maintaining optimal functionality. This section provides insights into frequent complications and offers practical advice for resolution.

Electrical Failures

One prevalent issue involves electrical malfunctions, which can stem from faulty wiring or poor connections. Regular inspection of all electrical components is crucial. If symptoms like flickering lights or intermittent operation arise, consider testing the connections and replacing any damaged parts.

Mechanical Jams

Mechanical jams can hinder operation, often due to debris accumulation or wear over time. To address this, routine cleaning is recommended. If a jam occurs, ensure to carefully remove obstructions and inspect moving parts for signs of wear, replacing them as necessary to restore proper function.

Benefits of Regular Parts Inspection

Conducting routine evaluations of components is essential for ensuring optimal performance and longevity. This practice not only enhances efficiency but also minimizes the risk of unexpected failures, ultimately contributing to a smoother operation.

Increased Reliability

Consistent assessments help identify potential issues before they escalate, ensuring that machinery functions reliably. By addressing minor concerns promptly, users can avoid significant breakdowns that could disrupt workflow.

Cost Savings

Preventative maintenance reduces the likelihood of costly repairs and replacements. Investing time in regular check-ups allows for timely interventions, which ultimately leads to better resource management and reduced operational expenses.