In any mechanical device designed for high-pressure applications, comprehending the arrangement and functionality of its various elements is crucial. This knowledge not only aids in efficient operation but also facilitates effective troubleshooting and maintenance. By familiarizing oneself with these components, users can ensure longevity and optimal performance of their equipment.

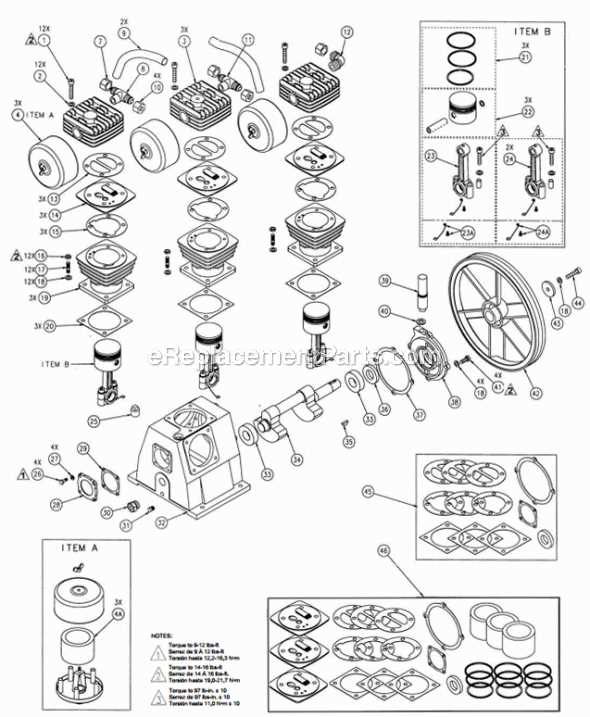

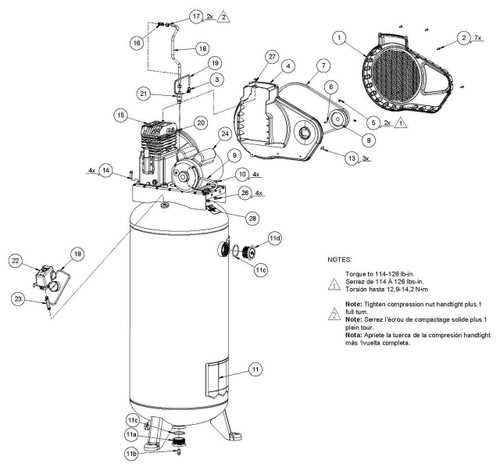

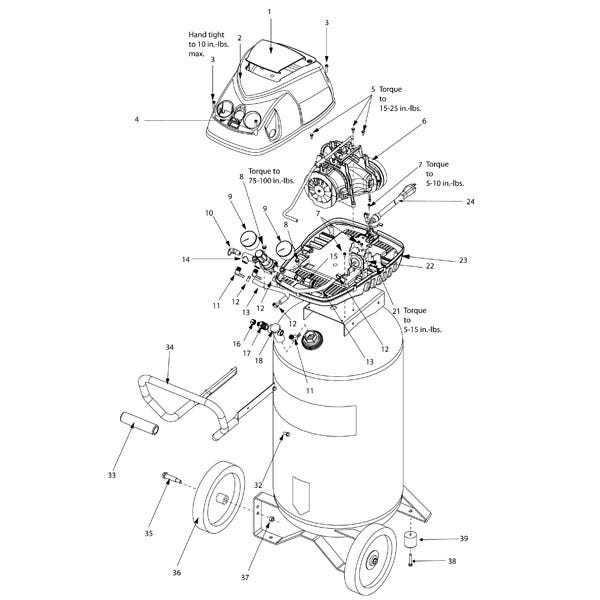

Visual representations of the internal structure are invaluable tools for both novice and experienced users. They provide a clear overview, highlighting how different elements interact within the system. Such illustrations serve as a guide, making it easier to identify individual parts and understand their respective roles in the overall mechanism.

Furthermore, having a grasp of the organization of these elements can empower users to undertake basic repairs and modifications with confidence. Whether addressing a minor issue or conducting routine upkeep, knowing the layout of the unit enhances one’s ability to maintain and enhance functionality.

Overview of Husky 30 Gallon Compressor

This section provides a comprehensive examination of a popular model designed for a variety of tasks. Its robust construction and versatile functionality make it suitable for both professional and home use. Users appreciate the blend of power and efficiency, which allows for the completion of multiple projects with ease.

The unit features a well-organized layout, ensuring that essential components are easily accessible for maintenance and operation. Understanding its structure and the role of each part is crucial for optimal performance.

| Component | Description |

|---|---|

| Motor | Drives the entire mechanism, providing the necessary force. |

| Tank | Stores the pressurized substance, ensuring a steady supply during usage. |

| Regulator | Controls the pressure output, allowing adjustments based on requirements. |

| Pressure Gauge | Displays the current pressure levels for monitoring purposes. |

| Drain Valve | Facilitates the removal of moisture from the tank, preventing corrosion. |

Understanding Air Compressor Components

To fully grasp the functionality of a pressurization system, it is essential to familiarize oneself with its various elements. Each component plays a crucial role in the overall operation, contributing to the efficient conversion of energy into usable compressed resources. Recognizing how these parts interact can greatly enhance maintenance and troubleshooting efforts.

The motor serves as the driving force behind the entire system, providing the necessary power to initiate the compression process. It is typically an electric unit that transforms electrical energy into mechanical energy, enabling the subsequent actions of the machine.

The tank functions as a storage vessel, accumulating the pressurized resources generated by the system. This component is vital for maintaining a consistent supply of energy, allowing for the smooth operation of tools and equipment requiring pressurized inputs.

Pressure switches are integral in regulating the system’s performance, monitoring pressure levels, and ensuring they remain within specified limits. By controlling the activation and deactivation of the motor, these devices help prevent overload and maintain optimal functionality.

Furthermore, hoses and fittings facilitate the movement of the compressed substance from the tank to various applications. Their design and material quality are critical for ensuring efficient flow and preventing leaks, which can compromise the system’s effectiveness.

Lastly, understanding the valves involved in the process is essential. These components regulate the flow and direction of the compressed resources, playing a key role in maintaining safety and efficiency during operation.

Key Features of Husky Models

The range of models from this brand showcases a variety of notable characteristics designed to enhance performance and usability. Each variant offers unique attributes that cater to diverse needs, ensuring that users can find an ideal fit for their requirements.

Performance and Efficiency

One of the standout aspects of these models is their efficient operation, allowing for quick task completion. The following features contribute to their exceptional performance:

- Powerful motor options for enhanced output

- High-pressure capabilities suitable for various applications

- Low operational noise for a quieter working environment

Durability and Design

Constructed with robust materials, these models are built to withstand rigorous use. Key design elements include:

- Rugged frames that provide stability and longevity

- User-friendly controls for easy operation

- Compact designs that facilitate storage and mobility

Identifying Replacement Parts Easily

Understanding the components of a device is crucial for efficient maintenance and repair. Whether for upgrading performance or replacing worn-out elements, recognizing the specific components can streamline the process. This section provides insights into effectively identifying necessary elements to ensure optimal functionality.

Utilizing a clear reference guide or schematic can significantly enhance the identification process. These resources often include labeled visuals, making it easier to pinpoint each individual component. Familiarity with the layout and the purpose of each part can reduce time spent searching and improve overall repair efficiency.

| Component Name | Description | Common Issues |

|---|---|---|

| Motor | Drives the mechanism and powers the unit. | Overheating, noise issues |

| Tank | Holds the compressed substance for usage. | Leaks, corrosion |

| Regulator | Controls the pressure output for various tasks. | Pressure inconsistencies |

| Valves | Manage the flow and release of the substance. | Blockages, failure to seal |

| Fittings | Connect various components securely. | Loose connections, wear |

In summary, utilizing reference materials and being aware of the function of each component can significantly aid in identifying what needs replacement. Keeping a checklist of common problems associated with each part can further assist in maintaining peak performance.

Maintenance Tips for Longevity

Proper care and regular upkeep of equipment are essential for ensuring optimal performance and extending its lifespan. By following a few simple practices, users can prevent common issues and maintain efficiency over time. This section offers practical advice to help maximize the durability and functionality of your unit.

Routine Inspections

- Check for any signs of wear or damage regularly.

- Inspect hoses and connections for leaks or cracks.

- Ensure all fittings are secure to avoid air loss.

Regular Cleaning

- Keep the exterior and interior free from dust and debris.

- Clean filters and screens to maintain airflow.

- Empty and clean the tank to prevent corrosion and buildup.

Implementing these maintenance strategies can significantly contribute to the reliability and efficiency of your equipment, ensuring it remains in excellent condition for years to come.

Common Issues and Troubleshooting

When operating any machinery, it’s not uncommon to encounter various challenges that may hinder performance. Identifying and addressing these concerns promptly can ensure the longevity of the equipment and maintain its efficiency. Below are some frequent problems users might face along with helpful troubleshooting steps.

- Power Issues:

If the device fails to start, check the power source and ensure all connections are secure. Inspect the circuit breaker or fuse for any faults.

- Insufficient Pressure:

Low pressure may result from a clogged filter or a malfunctioning regulator. Regular maintenance of these components is crucial to avoid such problems.

- Unusual Noises:

Strange sounds can indicate internal wear or loose components. Examine all fittings and bolts, tightening any that appear loose. If noise persists, seek professional inspection.

- Overheating:

Excessive heat can be caused by continuous operation or blocked ventilation. Allow the unit to cool down and ensure that air intake vents are unobstructed.

- Leaking Fluid:

Fluid leaks may arise from damaged hoses or seals. Inspect all connections and replace any worn or damaged parts promptly.

Regular inspection and maintenance can significantly reduce the occurrence of these issues. Keeping a log of repairs and changes will also assist in identifying patterns that may require further attention.

Upgrading Parts for Better Performance

Enhancing the components of your equipment can significantly boost its efficiency and longevity. By selecting higher-quality elements, users can expect improved functionality, reduced maintenance costs, and overall better performance. This section will explore various upgrades that can contribute to achieving these benefits.

Common Upgrades to Consider

When looking to enhance performance, several key components can be upgraded. Focusing on these areas can yield noticeable improvements in how the system operates.

| Component | Upgrade Options | Benefits |

|---|---|---|

| Motor | Higher horsepower models | Increased efficiency and power output |

| Regulator | Precision regulators | Improved pressure control and consistency |

| Tank | Reinforced steel tanks | Enhanced durability and safety |

Considerations for Upgrading

Before proceeding with any upgrades, it’s essential to assess compatibility with existing equipment. Conducting thorough research and consulting with professionals can ensure that the chosen upgrades will integrate seamlessly and deliver the desired improvements.

Finding Compatible Accessories

When looking to enhance the functionality of your equipment, it’s crucial to identify suitable add-ons that can optimize performance and meet your specific needs. Understanding the characteristics of your machine and its operational requirements will guide you in selecting the right components.

One effective approach is to consult the manufacturer’s specifications and recommendations. This information often provides a comprehensive list of compatible accessories designed to work seamlessly with your device. Additionally, exploring user manuals can offer valuable insights into the dimensions and features required for optimal compatibility.

Furthermore, seeking advice from experienced users through forums and online communities can be beneficial. Engaging with fellow enthusiasts allows you to gain practical knowledge and recommendations based on real-world usage. Be sure to verify compatibility before making a purchase, as this can save time and resources in the long run.

Ultimately, taking the time to research and choose appropriate accessories will enhance the overall functionality and longevity of your equipment, ensuring it operates at its best.

How to Read Parts Diagrams

Understanding schematics is essential for effective maintenance and repair. These visual representations provide crucial information about the components and their arrangement, allowing users to identify specific elements easily. Mastering the art of interpreting these visuals can greatly enhance your troubleshooting skills and ensure efficient repairs.

Key Elements to Consider

- Labels: Each component is typically marked with a unique identifier. Familiarize yourself with these labels to quickly locate parts.

- Connections: Observe how different elements are linked. This helps in understanding the assembly and disassembly process.

- Annotations: Look for notes or legends that explain specific features or functions of certain components.

Steps to Effectively Interpret Schematics

- Begin by reviewing the overall layout. Get a sense of how the components fit together.

- Identify the labels for each part. Make a list of the components you will be working with.

- Note the connections between elements. This will guide you during any disassembly or reassembly tasks.

- Refer to any accompanying notes for additional context or instructions regarding specific components.

- Practice by comparing the diagram to the actual assembly to reinforce your understanding.

Exploring Warranty and Support Options

When investing in a mechanical device, understanding the warranty and support services available is crucial. These offerings ensure that users can access assistance and repairs when needed, providing peace of mind and maintaining the efficiency of the equipment.

Typically, manufacturers provide various warranty plans that cover repairs and replacements for a specified period. It’s important to familiarize yourself with the terms and conditions associated with these plans to make the most of your purchase.

Here are some key aspects to consider regarding warranty and support options:

- Duration of Coverage: Determine how long the warranty lasts and what specific issues are covered.

- Type of Support: Look for options such as phone support, online chat, or in-person assistance.

- Repair Services: Understand if repairs are handled by authorized service centers or if you need to return the unit to the manufacturer.

- Replacement Policy: Check if the warranty includes replacements for defective units or components.

- Additional Resources: Explore online resources, manuals, and FAQs that may aid in troubleshooting issues independently.

By evaluating these factors, users can make informed decisions and maximize the value of their investment, ensuring long-term functionality and reliability.

Safety Precautions During Repairs

Ensuring safety during maintenance tasks is crucial for both personal well-being and the proper functioning of the equipment. Following appropriate guidelines can help prevent accidents and damage while conducting repairs. It is essential to be aware of potential hazards and to take necessary measures to mitigate them.

Before starting any repair work, consider the following safety measures:

- Wear appropriate personal protective equipment (PPE), such as safety glasses and gloves.

- Ensure that the workspace is well-ventilated to avoid inhaling harmful fumes.

- Disconnect the power source to prevent accidental activation of the equipment.

- Keep the workspace organized and free from clutter to minimize the risk of trips and falls.

Additionally, be mindful of the following points:

- Read and understand the manufacturer’s guidelines and safety warnings.

- Use tools that are suitable for the job and in good condition.

- Never attempt repairs if you are unsure about the procedures or if the equipment is damaged beyond basic maintenance.

- Have a first aid kit readily available in case of emergencies.

By adhering to these safety precautions, individuals can ensure a secure environment while conducting repairs, leading to more efficient and successful maintenance practices.