The intricate machinery behind your air device plays a crucial role in its functionality and longevity. A comprehensive exploration of its components allows for better maintenance and troubleshooting, ensuring that the equipment operates smoothly for years to come. Knowledge of each segment’s role can empower users to make informed decisions when it comes to repairs or upgrades.

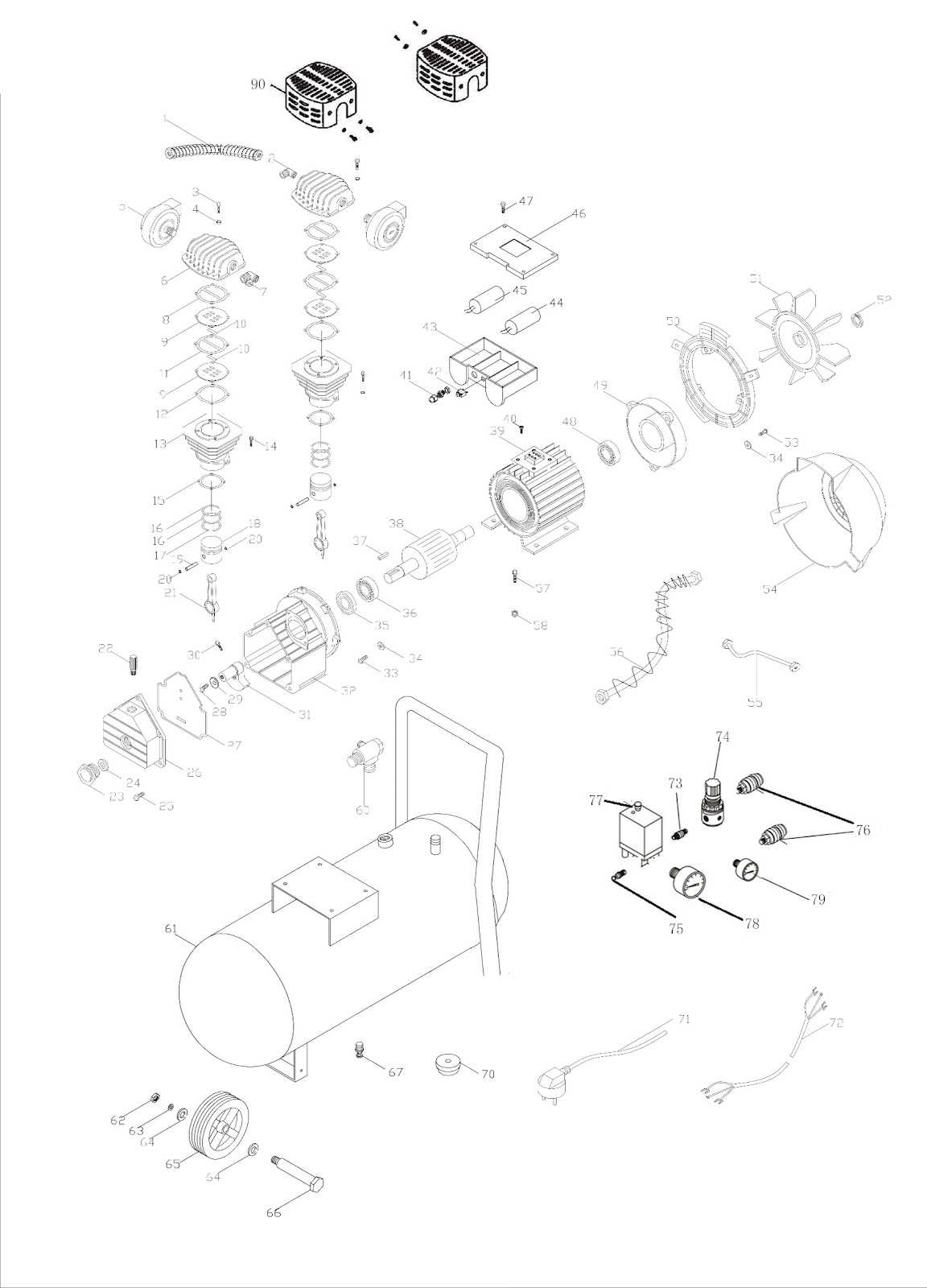

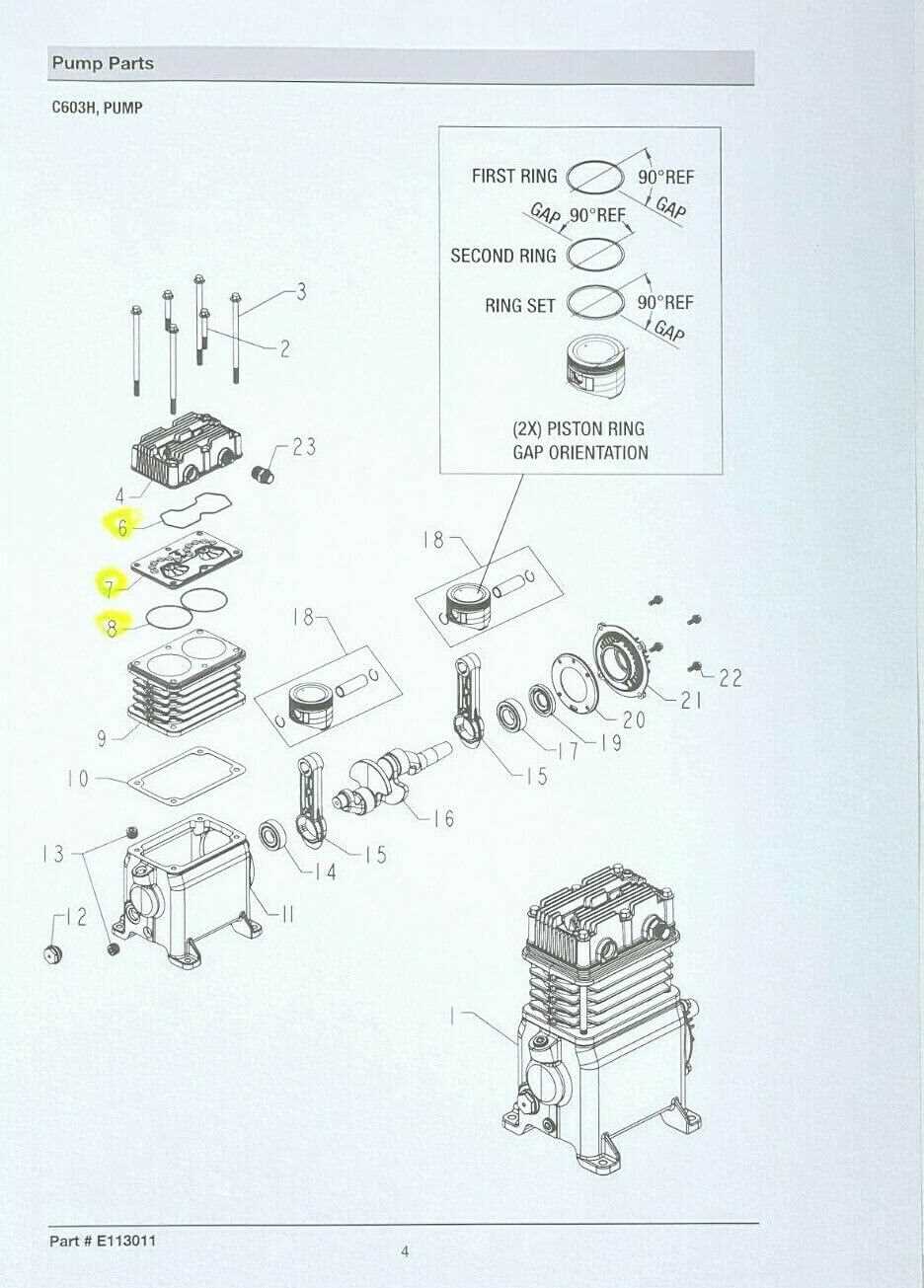

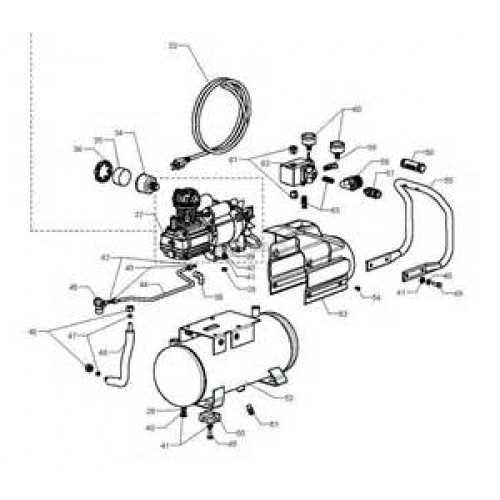

Visual representations of the essential elements can significantly enhance your understanding. By examining a detailed layout, one can easily identify the specific sections and their interrelations, leading to a more effective approach to both use and upkeep. Familiarity with these components not only aids in resolving issues but also fosters a deeper appreciation for the technology at hand.

In this guide, we will delve into the various sections that constitute your air tool, providing insights and tips for effective management. Whether you are a novice or a seasoned user, a clear grasp of the system’s architecture will be invaluable in ensuring optimal performance and reliability.

Understanding Husky Compressors Overview

This section delves into the essential components and functionality of a well-known brand in the field of air pressure systems. Recognized for its reliability and efficiency, this equipment serves a variety of applications across industries. A clear grasp of its structure and operation is crucial for both users and technicians.

The machinery typically consists of several integral elements that work in unison to generate and manage air pressure. Familiarity with these components not only aids in effective usage but also enhances maintenance practices, ensuring longevity and optimal performance. Understanding the inner workings enables users to troubleshoot common issues and appreciate the technology behind these devices.

Moreover, the versatility of the system allows it to be utilized in diverse settings, from home workshops to professional environments. This adaptability highlights the importance of comprehending its design and functionality, as it directly influences the efficiency of various tasks, from inflating tires to powering pneumatic tools.

Key Components of Husky Compressors

This section explores the essential elements that contribute to the functionality and efficiency of air pressure systems. Understanding these components can help users optimize performance and troubleshoot issues effectively.

Main Elements

- Motor: Powers the unit, driving the compression cycle.

- Pump: Responsible for drawing in air and compressing it to the desired pressure.

- Tank: Stores compressed air, ensuring a steady supply during operation.

- Regulator: Controls the pressure level to suit specific applications.

Additional Features

- Pressure Switch: Automatically turns the motor on and off based on pressure levels.

- Air Filter: Removes contaminants from the incoming air, protecting internal components.

- Safety Valve: Prevents over-pressurization, ensuring safe operation.

Importance of Compressor Parts Diagram

A visual representation of essential components is crucial for understanding the functionality and maintenance of any machinery. Such illustrations provide clarity, enabling users to identify each element and its role within the overall system. This knowledge enhances troubleshooting efficiency and fosters a deeper appreciation of the equipment’s operation.

Having access to a detailed schematic empowers technicians to perform repairs and replacements with confidence. It minimizes the risk of errors, ensuring that each piece is handled correctly and contributes to the machinery’s optimal performance. Furthermore, these visual aids serve as valuable training tools for new personnel, promoting a smoother learning curve.

Ultimately, comprehending the layout and connection of components not only streamlines maintenance processes but also extends the lifespan of the machinery. Understanding these intricacies supports informed decision-making during servicing, ultimately leading to enhanced operational reliability.

How to Read a Parts Diagram

Understanding an illustration that details components is crucial for effective maintenance and repair. These visuals provide a clear representation of various elements, their arrangement, and how they interact with each other. Familiarizing yourself with the structure of these graphics can significantly enhance your ability to troubleshoot and perform necessary replacements.

Typically, such illustrations include a legend that defines each element with corresponding numbers or letters. This key helps to identify each component easily, allowing for straightforward navigation through the visual representation. Below is a simple table outlining common symbols and their meanings to aid in comprehension.

| Symbol | Description |

|---|---|

| Fastener or bolt | |

| ⚙️ | Gear or mechanical part |

| Moving or rotating part | |

| Tool or instrument needed for assembly | |

| ️ | Repair or maintenance action |

Additionally, pay attention to the orientation and connections shown. Lines often indicate how components connect or interact, guiding you in reassembly or installation. By thoroughly analyzing these illustrations, you can effectively manage repairs and ensure optimal functionality.

Common Issues with Husky Compressors

Many users encounter typical challenges when operating these air-moving devices. Understanding these common problems can help in troubleshooting and maintaining optimal performance.

Frequent Problems

- Insufficient pressure output

- Overheating during use

- Unusual noises during operation

- Air leaks from fittings or hoses

Potential Causes

- Worn or damaged seals

- Improper maintenance practices

- Inadequate lubrication

- Faulty pressure regulators

Replacing Husky Compressor Components

Maintaining and upgrading machinery can significantly enhance its performance and longevity. Whether it’s a matter of replacing worn-out elements or upgrading to more efficient alternatives, understanding the intricacies involved in the process is essential for optimal functionality. Proper replacement techniques can prevent malfunctions and ensure smooth operation, ultimately saving time and resources.

Identifying the Right Components

Before starting the replacement process, it’s crucial to identify the specific components that require attention. Regular inspections can help pinpoint wear and tear, allowing for timely replacements. Utilize manufacturer guidelines and specifications to ensure compatibility with your model. This step is vital to prevent further issues and maintain the effectiveness of the entire system.

Step-by-Step Replacement Process

Begin by disconnecting the power source to ensure safety. Carefully remove the old component, taking note of its placement and connections. Install the new part following the manufacturer’s instructions, ensuring all connections are secure. Once everything is in place, conduct a thorough test to verify that the new installation operates smoothly. Regular maintenance checks after replacement will help identify any potential problems early on.

Maintenance Tips for Longevity

Ensuring the long-lasting performance of your equipment requires regular upkeep and attention. By implementing a few simple practices, you can enhance reliability and efficiency, ultimately prolonging the lifespan of your machinery.

Regular Inspections: Conduct frequent assessments to identify any signs of wear or damage. Checking seals, hoses, and connections can prevent minor issues from escalating into major problems.

Keep It Clean: Dirt and debris can lead to overheating and mechanical failures. Regularly clean external surfaces and ensure air intakes are free from obstructions to maintain optimal airflow.

Lubrication: Proper lubrication is essential for reducing friction and wear. Use the recommended lubricants and follow guidelines for frequency and application to keep moving parts functioning smoothly.

Monitor Operating Conditions: Always be aware of the environment in which your equipment operates. Extreme temperatures or high humidity can affect performance. Adjust usage patterns accordingly to avoid undue stress.

Scheduled Maintenance: Adhere to a routine maintenance schedule as outlined in the user manual. Regularly replacing filters and fluids not only ensures peak performance but also prevents unforeseen breakdowns.

Training and Awareness: Ensure that all operators are trained on proper usage and maintenance procedures. An informed team is less likely to cause damage through misuse and can quickly spot issues that need attention.

By following these maintenance tips, you can enhance the durability of your equipment, ensuring it remains a reliable asset for years to come.

Tools Needed for Repairs

Having the right equipment is crucial for effective maintenance and restoration tasks. Proper tools not only enhance efficiency but also ensure safety and accuracy during the process. Below are essential implements that will aid in achieving optimal results.

Basic Hand Tools

Start with a set of wrenches and screwdrivers, as they are fundamental for loosening or tightening various components. Pliers and cutters are also invaluable for gripping and cutting tasks, allowing for precise adjustments.

Specialized Equipment

Consider acquiring a pressure gauge to monitor system performance accurately. A multimeter is essential for electrical diagnostics, while a mechanical assembly tool can significantly simplify complex installations or repairs.

Finding Replacement Parts Online

Locating suitable components for your equipment can be a straightforward process if you know where to look. The online marketplace offers a variety of platforms where you can easily search for what you need, ensuring that your machinery runs smoothly.

Here are some effective strategies to consider when seeking out components:

- Use Reputable Retailers: Start with well-known e-commerce sites that specialize in tools and machinery. Their extensive inventory can save you time.

- Check Manufacturer Websites: Often, the original maker will have an online store or a dedicated section for accessories and replacements.

- Explore Forums and Community Groups: Engaging with online communities can provide insights into where others have successfully sourced their items.

When searching, remember to:

- Use specific keywords related to the item you need.

- Compare prices across different platforms for the best deals.

- Read customer reviews to gauge the reliability of the sellers.

By following these guidelines, you can enhance your chances of finding the right components to maintain the efficiency and performance of your equipment.

Safety Precautions During Repairs

When undertaking maintenance tasks on machinery, it is essential to prioritize safety to prevent accidents and injuries. Proper precautions not only protect the individual performing the work but also ensure the equipment operates efficiently after repairs.

Wear Appropriate Personal Protective Equipment (PPE): Always don suitable gear such as gloves, goggles, and ear protection to shield yourself from potential hazards. This minimizes risks associated with flying debris or exposure to harmful substances.

Ensure Proper Ventilation: Work in a well-ventilated area to avoid inhaling fumes or dust that may be generated during repairs. Fresh air circulation is vital for maintaining a safe environment.

Disconnect Power Sources: Before beginning any maintenance, disconnect all power sources to eliminate the risk of accidental startup. This step is crucial for safeguarding against electrical shock or mechanical movement.

Utilize Correct Tools: Using the right tools for the job ensures efficiency and reduces the likelihood of accidents. Always inspect tools before use to confirm they are in good working condition.

Keep Workspace Organized: Maintain a tidy work area free of clutter to prevent trips and falls. An organized space allows for easier access to tools and components, enhancing safety and efficiency.

Follow Manufacturer’s Guidelines: Adhere to the instructions provided by the manufacturer during repairs. This ensures that safety protocols are met and the machinery is serviced correctly.

Upgrading Husky Compressor Parts

Enhancing the efficiency and performance of your equipment can significantly improve its longevity and effectiveness. Whether you’re aiming for increased power, reduced noise, or better energy consumption, there are various components that can be modified or replaced. This process not only optimizes functionality but also ensures that the unit operates smoothly for years to come.

First, consider evaluating the internal mechanisms. Components such as pistons, valves, and filters are critical to the operation and can often be upgraded to higher-quality alternatives. By choosing durable materials, you can minimize wear and enhance the overall performance of the system.

Next, pay attention to the external features. Accessories like pressure regulators and gauges can provide more accurate readings and better control over the performance. Investing in advanced models can lead to improved safety and efficiency.

Additionally, don’t overlook the importance of regular maintenance. Regular inspections and timely replacements of worn-out elements can prevent costly breakdowns and ensure that your machine continues to operate at peak performance. Keeping a maintenance log can help track the condition of various components and identify when upgrades are necessary.

In conclusion, strategic enhancements to your equipment can lead to significant gains in performance, reliability, and lifespan. By prioritizing quality and regular upkeep, you ensure that your investment remains a valuable asset over time.

Comparing Different Husky Models

When it comes to selecting a specific model for your needs, understanding the distinctions between various options is crucial. Each variant offers unique features and capabilities that cater to different applications and user preferences. This section delves into the characteristics that set these models apart, providing insights that can guide your decision-making process.

Performance and Efficiency

One of the primary factors to consider is the performance level each option provides. While some variants excel in high-output tasks, others may focus on efficiency and quieter operation. Users who prioritize heavy-duty usage may lean towards models designed for higher power, while those in residential settings might appreciate quieter, energy-saving alternatives.

Durability and Build Quality

Another significant aspect is the durability of the construction. Models built with robust materials often have longer lifespans and can withstand more rigorous conditions. It’s essential to assess how frequently you plan to use the equipment and in what environments, as this can influence the overall longevity and reliability of your choice. Choosing a model that aligns with your usage patterns can save both time and resources in the long run.

Frequently Asked Questions About Husky Compressors

This section addresses common inquiries regarding air machinery and their functionality, offering insights for both new and experienced users. Understanding these elements can significantly enhance performance and maintenance practices.

What are the key features of these air devices?

Key features typically include power ratings, tank capacity, and portability options, which cater to various applications.

How often should I perform maintenance?

Regular upkeep is essential, ideally every few months, to ensure longevity and efficient operation.

What common issues might arise?

Users often encounter air leaks, pressure inconsistencies, and motor failures, which can usually be resolved with basic troubleshooting.

Are replacement components readily available?

Yes, replacement components are generally accessible through various suppliers, making repairs manageable for most users.

Can I use these machines for professional tasks?

Absolutely, many individuals utilize them for both personal and commercial projects, depending on their specifications.