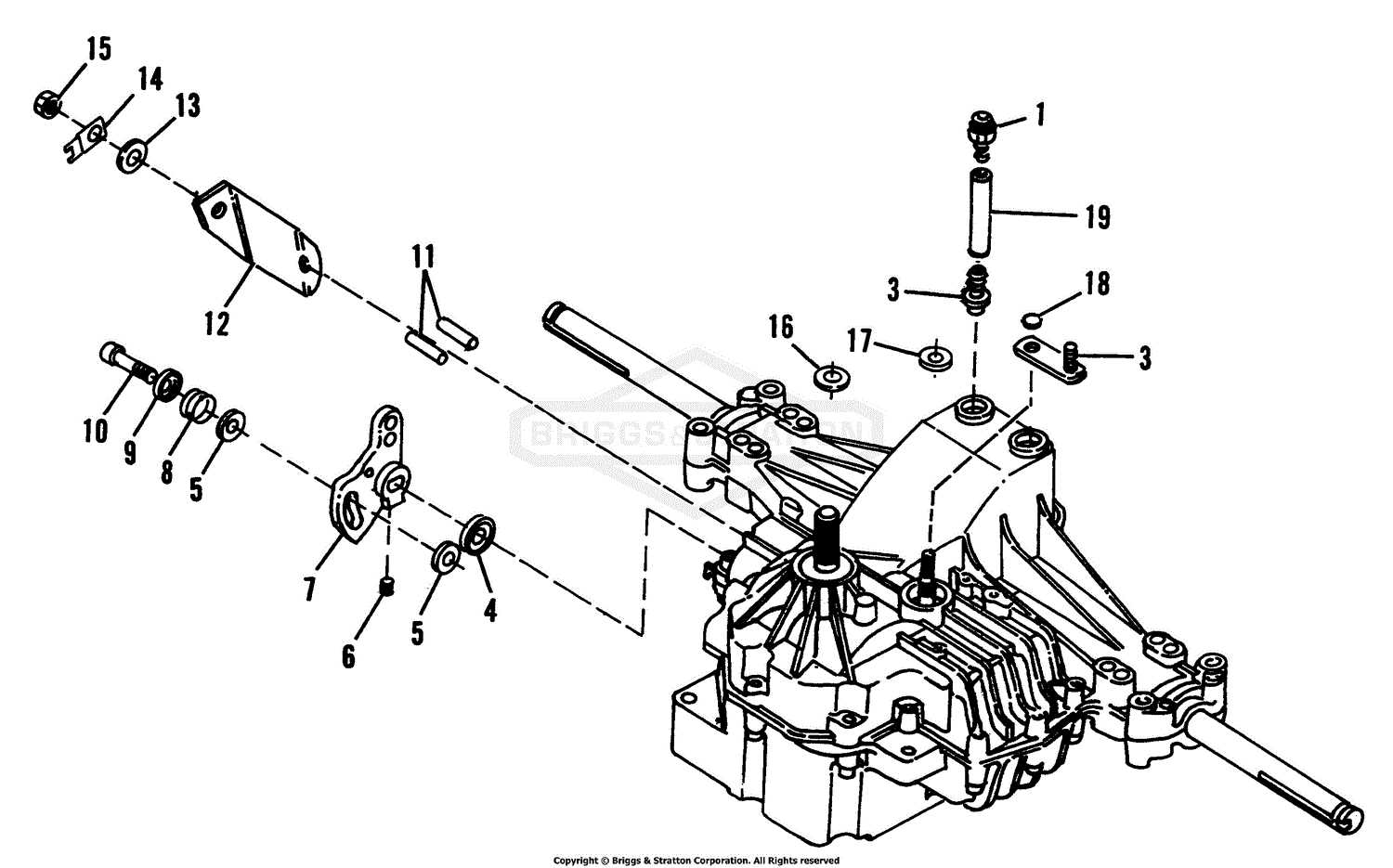

In the realm of machinery and equipment, a clear representation of individual elements is crucial for efficient maintenance and assembly. These visual guides serve as invaluable resources, providing insights into how various elements interact and function together within a system.

Having a comprehensive overview of these essential features allows technicians and enthusiasts alike to pinpoint specific items quickly, facilitating repairs and upgrades. A detailed layout enhances the understanding of each component’s role, ultimately leading to improved operational effectiveness.

For those seeking to enhance their knowledge, exploring such resources can prove beneficial. Whether for educational purposes or practical applications, delving into these visual aids can empower users to tackle challenges with confidence and expertise.

Understanding Hydro-Gear Parts

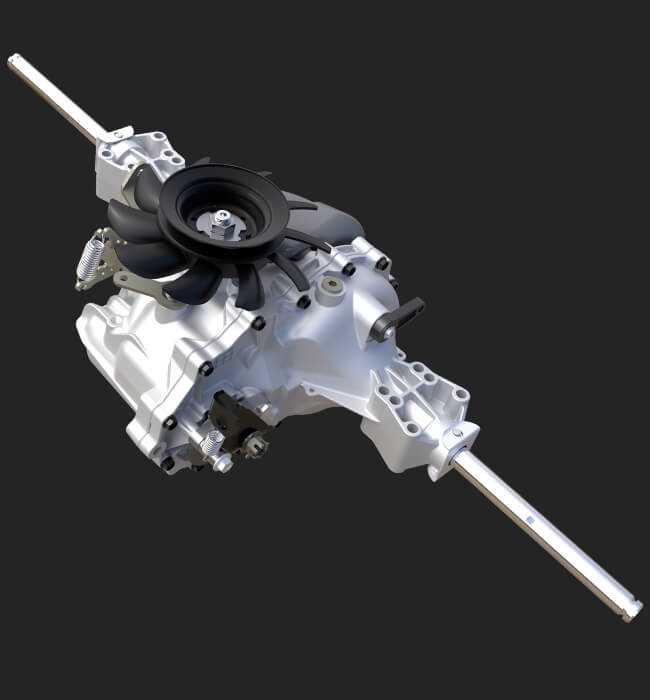

This section aims to explore the components that play a crucial role in the functionality of various machinery. A comprehensive grasp of these elements enhances efficiency and ensures optimal performance in equipment operations.

Key Components Overview

Familiarity with essential elements is vital for effective maintenance and troubleshooting. Each component serves a specific function, contributing to the overall system’s effectiveness. Recognizing how these elements interact can lead to improved understanding and performance.

Maintenance and Performance

Regular upkeep of these crucial elements is necessary to prolong equipment life and prevent breakdowns. Knowledge of the parts not only aids in repairs but also allows users to maximize performance through informed adjustments and replacements.

Importance of Accurate Diagrams

In the realm of machinery and equipment maintenance, precise visual representations are essential for effective troubleshooting and repair. These illustrations serve as vital references, guiding technicians and engineers in understanding complex systems and ensuring optimal functionality.

Accurate schematics contribute significantly to several key areas:

- Clarity: Well-crafted visuals simplify intricate details, making it easier to comprehend how components interact within a system.

- Efficiency: With reliable references, technicians can quickly identify issues and determine necessary actions, reducing downtime.

- Training: Visual aids are invaluable in educating new personnel, providing a clear framework for understanding system operations.

- Documentation: Maintaining an accurate record of equipment layouts ensures consistency in repairs and upgrades over time.

In summary, the reliability of these visual tools not only enhances maintenance practices but also supports a deeper understanding of the machinery involved, ultimately leading to improved performance and longevity.

How to Access PDF Resources

Finding and utilizing digital documents can enhance your understanding of various mechanical components and systems. With the right approach, you can easily locate these valuable materials online, ensuring that you have the information you need at your fingertips.

1. Search Engines: Utilize popular search engines by entering specific keywords related to the materials you seek. This can lead you to a plethora of online resources.

2. Manufacturer Websites: Many manufacturers host a library of documentation for their products. Visit their official sites to access comprehensive resources.

3. Online Forums and Communities: Engage with user communities that focus on your area of interest. Members often share links to essential documents and can provide recommendations.

4. Educational Institutions: Universities and technical colleges may have resources available to the public. Check their libraries or digital archives for relevant content.

5. Downloading Tips: Once you find the document, ensure you have a reliable PDF viewer installed. Always scan downloads for malware to keep your device secure.

By exploring these avenues, you can effectively delve into a wealth of information that enhances your knowledge and skills in your field.

Common Hydro-Gear Components Explained

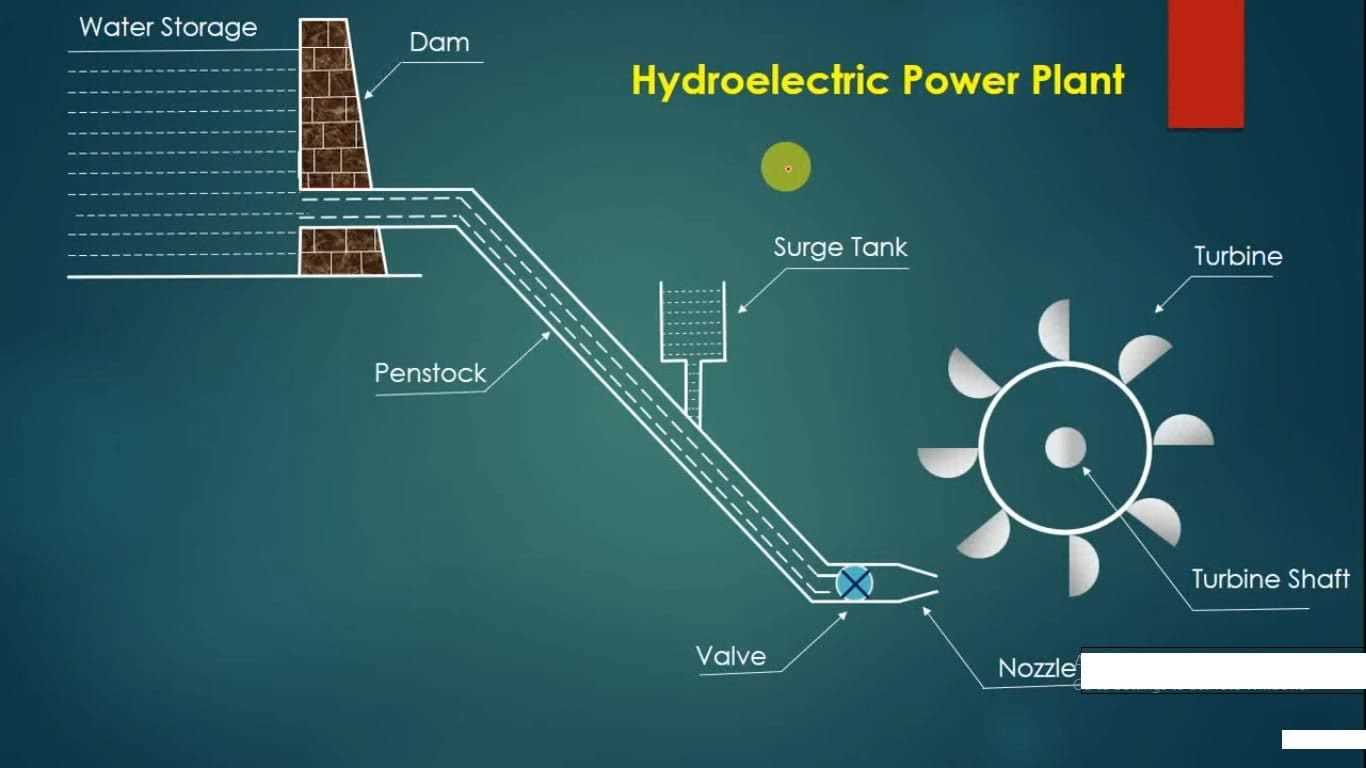

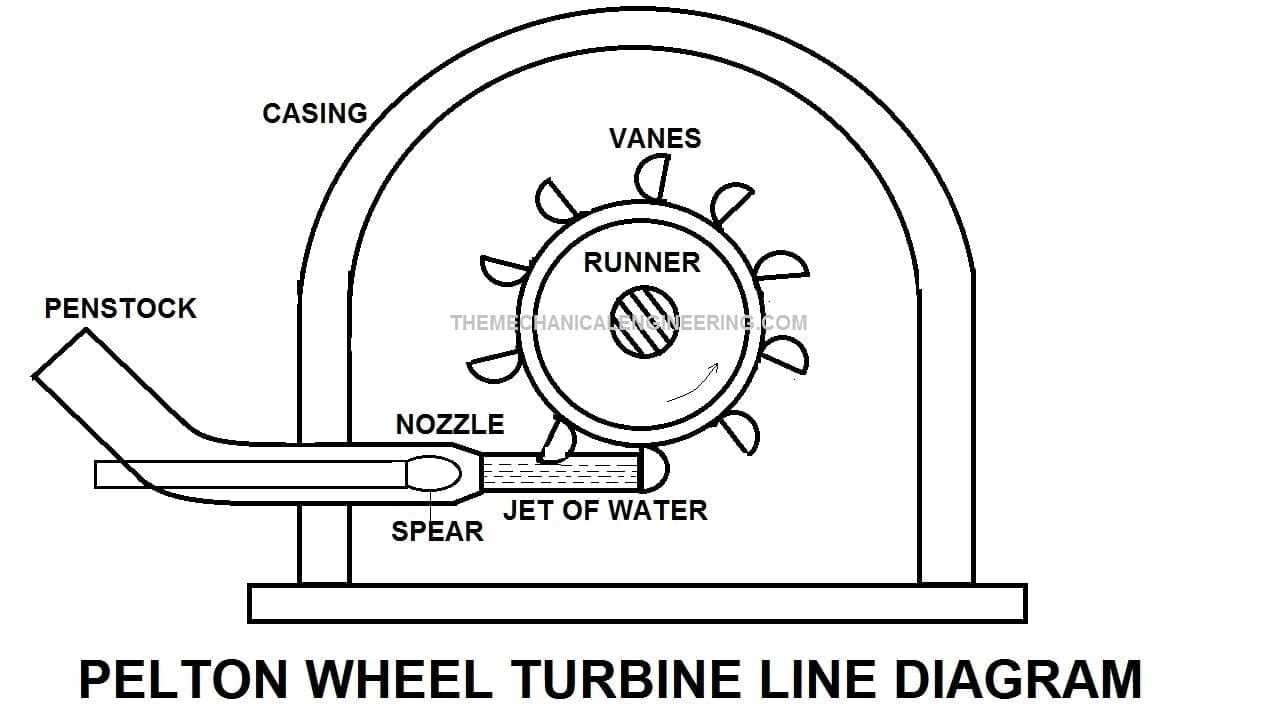

Understanding the various elements of hydraulic drive systems is crucial for maintaining optimal performance in machinery. Each component plays a specific role in the overall functionality, contributing to efficiency and reliability. This section will explore key components commonly found in these systems, providing insights into their purposes and interactions.

The hydraulic pump is the heart of the system, converting mechanical energy into hydraulic energy. It generates fluid flow, which powers other components. Next, the motor transforms hydraulic energy back into mechanical energy, driving the machinery. The efficiency of these components is essential for achieving desired operational results.

Another vital element is the reservoir, which stores hydraulic fluid. Proper fluid levels and quality are necessary to prevent system failures. Additionally, filters are installed to remove contaminants, ensuring the longevity and efficiency of the system. Control valves manage the flow and direction of the hydraulic fluid, allowing precise movements and adjustments.

Furthermore, hoses and fittings connect various components, facilitating fluid transfer. Their integrity is crucial, as leaks can lead to significant performance issues. Finally, understanding these components enables operators to troubleshoot effectively and maintain their systems in peak condition.

Step-by-Step Assembly Instructions

This section provides clear and concise instructions for assembling your equipment effectively. Following each step carefully will ensure optimal functionality and durability of the final product.

Before starting the assembly process, gather all necessary components and tools. Familiarize yourself with the parts, as this will facilitate a smoother assembly experience.

| Step | Description | Tools Needed |

|---|---|---|

| 1 | Lay out all components in an organized manner. | N/A |

| 2 | Attach the base unit to the support frame using screws. | Screwdriver |

| 3 | Connect the hydraulic lines, ensuring there are no kinks. | Wrench |

| 4 | Install the control panel and secure it tightly. | Phillips screwdriver |

| 5 | Double-check all connections and fasteners for security. | N/A |

| 6 | Conduct a final inspection to ensure everything is in place. | N/A |

By adhering to these instructions, you can achieve a successful assembly. Always prioritize safety and consult the manufacturer’s guidelines if needed.

Troubleshooting with Diagrams

Understanding complex machinery can often be daunting. Utilizing visual aids can significantly simplify the process of identifying and resolving issues. These illustrations serve as valuable tools, guiding users through the intricacies of their equipment.

Here are some benefits of employing visual representations in troubleshooting:

- Enhanced clarity: Visuals break down complicated systems into understandable components.

- Quick reference: Users can easily locate specific elements and their functions.

- Step-by-step guidance: Illustrations can outline procedures for diagnosing problems.

To effectively troubleshoot, consider the following steps:

- Identify the symptoms: Take note of any irregular behavior.

- Consult the visual guide: Use it to locate the relevant sections.

- Follow diagnostic paths: Trace the issues step-by-step as depicted.

- Implement solutions: Apply the recommended fixes as illustrated.

Incorporating these visuals into your maintenance routine can lead to the ultimate understanding and efficient problem-solving.

Comparing Different Hydro-Gear Models

In the world of hydraulic systems, various models offer unique features tailored to specific applications. Understanding these differences can greatly enhance performance and efficiency in various machinery. This section delves into key aspects that distinguish each model, enabling users to make informed decisions based on their needs.

Performance Specifications

When evaluating models, performance metrics such as torque output, speed capabilities, and hydraulic flow rates are crucial. Each variant is engineered for specific tasks, making it essential to align these specifications with the intended application for optimal results.

Durability and Maintenance

The longevity of hydraulic systems varies significantly across different models. Factors like build quality, material selection, and ease of maintenance play vital roles in determining the overall reliability and upkeep requirements, impacting long-term operational costs.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires regular care and attention. By following a few essential practices, you can significantly extend the lifespan of your machinery and maintain optimal performance. Proper maintenance not only reduces the likelihood of unexpected breakdowns but also enhances efficiency.

1. Regular Inspections: Conduct frequent checks to identify wear and tear early. Look for signs of damage, leaks, or unusual noises that may indicate potential issues. Addressing these concerns promptly can prevent more significant problems down the line.

2. Cleanliness is Key: Keep all components free of dirt and debris. Accumulated grime can lead to overheating and decreased functionality. Regular cleaning helps ensure that everything operates smoothly.

3. Lubrication: Apply appropriate lubricants to moving parts according to the manufacturer’s recommendations. Proper lubrication reduces friction, minimizes wear, and promotes smoother operation.

4. Follow Manufacturer Guidelines: Adhere to the maintenance schedule provided by the manufacturer. This includes changing fluids, filters, and any other necessary components. Staying on schedule is crucial for maintaining warranty coverage and ensuring peak performance.

5. Store Properly: When not in use, store your equipment in a dry and safe environment. Protect it from extreme temperatures and moisture, which can cause rust and other damage.

6. Training and Education: Ensure that operators are well-trained in the proper use and care of the equipment. Knowledgeable users can prevent misuse and can recognize potential issues before they escalate.

By implementing these maintenance tips, you can enhance the reliability and efficiency of your machinery, ultimately leading to longer service life and greater satisfaction with your investment.

Using Diagrams for DIY Repairs

Visual representations serve as invaluable tools for individuals seeking to perform their own maintenance and repairs. They simplify complex procedures, allowing for a clearer understanding of the components involved. By referencing these illustrations, DIY enthusiasts can navigate through disassembly and reassembly with greater confidence and accuracy.

Clarity is one of the primary benefits of utilizing these visual aids. When faced with a mechanical issue, it can be overwhelming to decipher intricate parts and their functions. A well-designed visual can highlight connections and placements, making it easier to identify what needs attention. This enhanced clarity can significantly reduce the chances of mistakes during the repair process.

Furthermore, these visuals often come with annotations that explain specific tasks or point out potential pitfalls. This guidance is particularly beneficial for those who may not have extensive experience in handling machinery. By following the steps outlined in these resources, individuals can save time and avoid frustration, ultimately leading to a more successful repair experience.

In addition, the act of consulting these representations fosters a sense of independence and empowerment. Armed with the right information, anyone can tackle their maintenance challenges, transforming a daunting task into a manageable project. Embracing this approach not only enhances skill sets but also instills a greater appreciation for the mechanics at work.

Where to Find OEM Parts

Locating genuine components for your machinery is essential for ensuring optimal performance and longevity. Various sources can provide reliable options for acquiring these necessary items.

- Official Manufacturer Websites: These often have dedicated sections for ordering original components.

- Authorized Dealers: Partner organizations are typically equipped to sell authentic items and offer expert advice.

- Online Retailers: Many platforms specialize in selling original components, allowing for easy comparison of options.

- Local Repair Shops: Many establishments maintain a stock of genuine items or can order them on your behalf.

- Trade Shows: Industry events frequently feature vendors showcasing and selling original components directly.

By exploring these avenues, you can ensure that your equipment continues to operate at its best with high-quality, original replacements.

Impact of Incorrect Parts Usage

The utilization of unsuitable components can lead to significant operational challenges and reduce overall efficiency. When mismatched elements are employed, various mechanical systems may experience failures, resulting in costly repairs and downtime.

Consequences of Mismatched Components

- Performance Issues: Incorrect elements may hinder the functionality of the entire system.

- Increased Wear: Unfit components can accelerate wear and tear, leading to premature failures.

- Safety Risks: Using inappropriate items can pose serious safety hazards for operators.

Preventive Measures

- Always consult the manufacturer’s specifications.

- Conduct regular maintenance checks to identify potential issues.

- Invest in training for personnel on correct component identification.

Future Trends in Hydro-Gear Technology

Innovations in fluid power systems are poised to revolutionize the landscape of machinery and equipment. As the demand for efficiency and sustainability grows, advancements will likely focus on enhancing performance, reducing environmental impact, and integrating smart technologies.

Smart Integration

The future will see an increased reliance on automation and smart controls within these systems. By leveraging IoT and AI, manufacturers can optimize operation in real-time, leading to improved efficiency and predictive maintenance capabilities.

Sustainability Initiatives

As environmental considerations become paramount, there will be a significant shift toward eco-friendly materials and energy-efficient designs. This focus will drive innovation in both product development and manufacturing processes.

| Trend | Description |

|---|---|

| Smart Integration | Use of IoT and AI for real-time optimization and maintenance. |

| Sustainability Initiatives | Shift towards eco-friendly materials and energy-efficient designs. |

| Modular Systems | Development of adaptable components for easier upgrades and repairs. |