Industrial machinery often consists of numerous essential elements, each playing a critical role in the overall functionality. Knowing how these components fit together and operate is vital for ensuring smooth operations, reducing downtime, and enhancing efficiency. By becoming familiar with the arrangement and the relationship between these key elements, you can better maintain and troubleshoot the machinery.

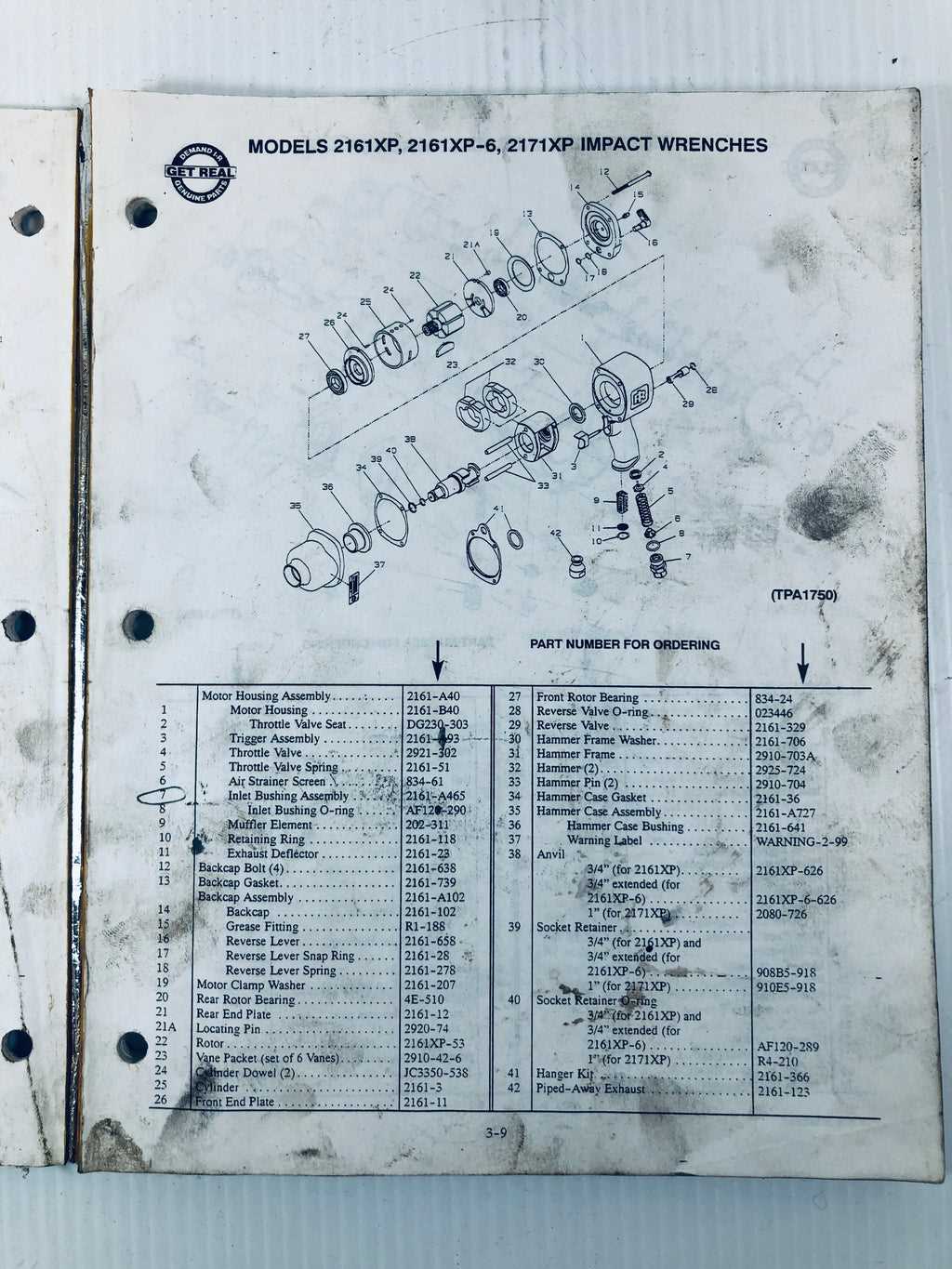

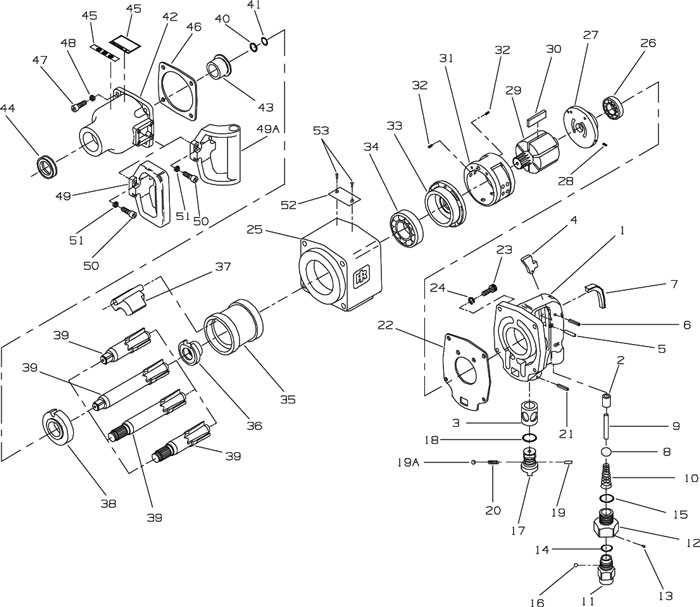

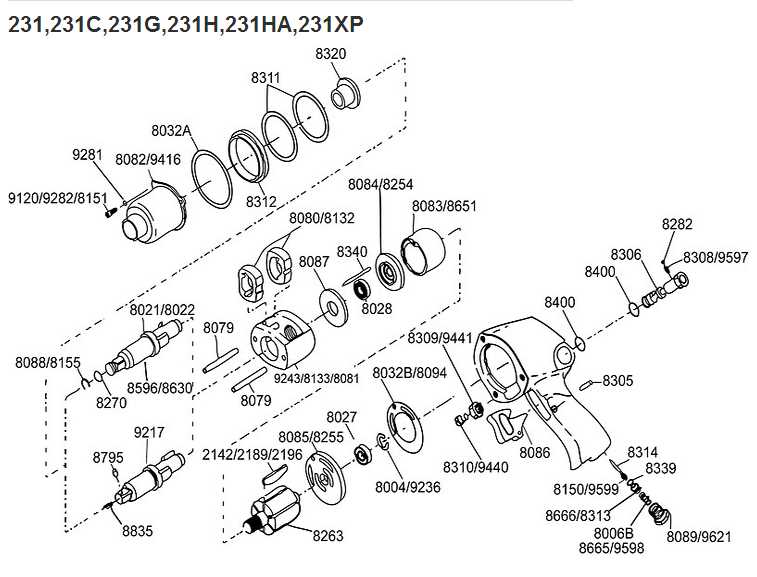

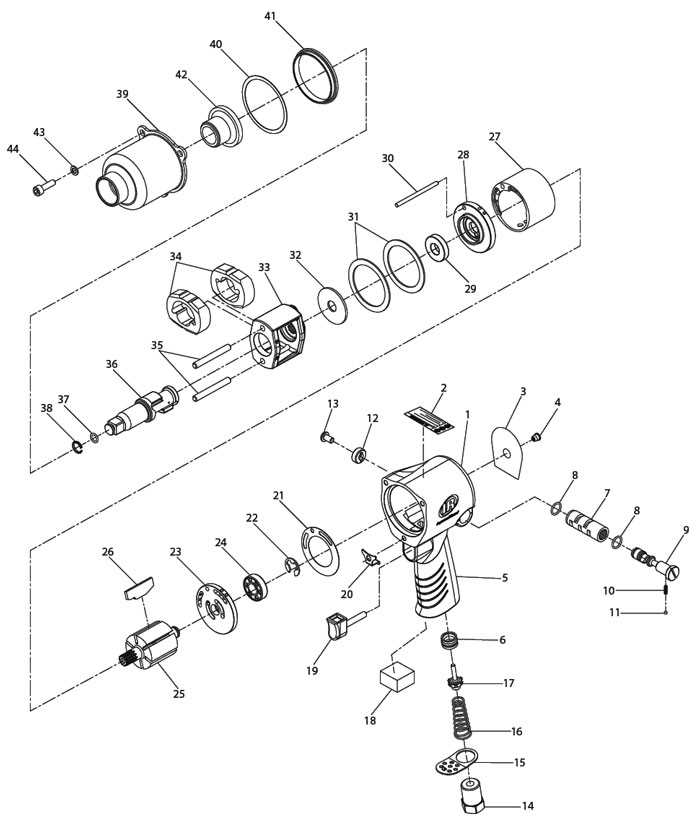

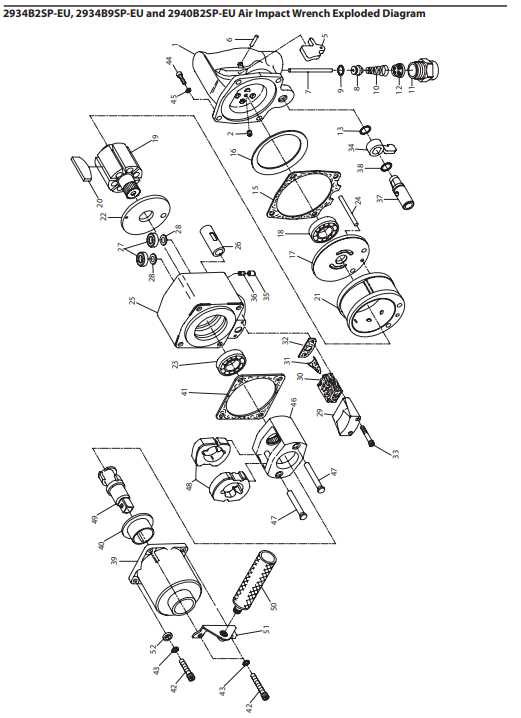

Identifying individual components is a crucial step when working with any type of complex equipment. Whether it’s for routine maintenance or addressing an unexpected issue, understanding the structure allows for more precise actions. Visual guides and schematics are helpful tools in this process, offering a detailed view of how everything is interconnected and providing clarity on where each element is located within the system.

Understanding the Components of Ingersoll Rand Machines

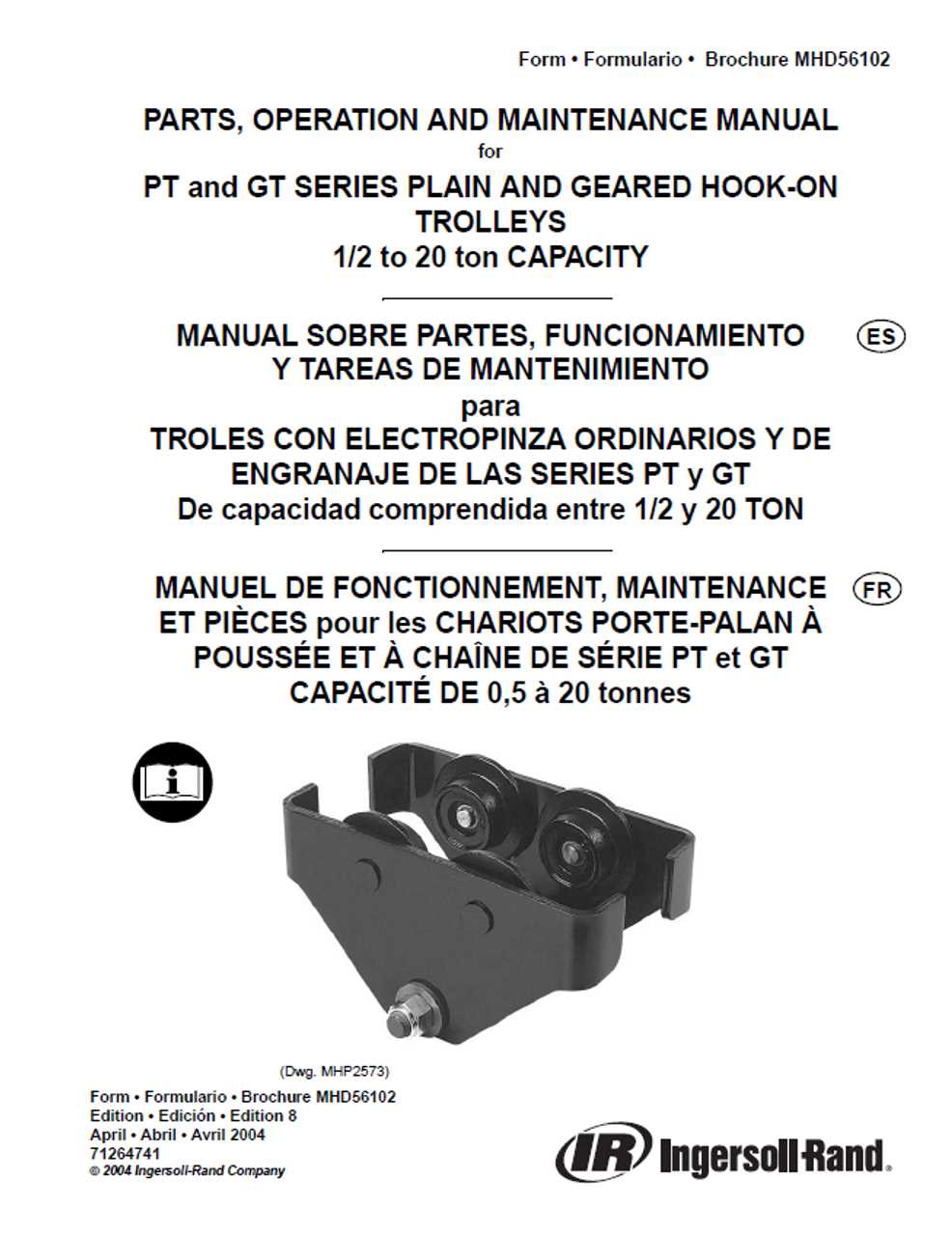

When examining the structure of industrial equipment, it is essential to recognize the various elements that contribute to their efficient operation. These machines rely on an intricate system of interconnected parts, each playing a vital role in delivering performance and durability. From the power source to the intricate mechanisms driving the processes, understanding these components is key to maintaining and optimizing the equipment.

Power Unit: At the core of every industrial machine is a robust energy source. This component ensures the necessary force is supplied to initiate and sustain the equipment’s functions.

Control Mechanism: Managing the flow of power and coordinating the different sections of the machine requires a sophisticated control system. This feature ensures that all operations run smoothly and safely, adjusting performance as needed.

Processing Systems: These are the parts responsible for carrying out the machine’s primary tasks. They convert the supplied power into meaningful work, whether it’s compressing air, generating torque, or moving heavy loads.

Safety Features: Integral to every machine, these components are designed to protect both the equipment and the operator. They ensure that the system operates within safe limits and reacts to potential issues effectively.

How to Read Ingersoll Rand Schematics

Understanding technical blueprints is crucial when it comes to maintaining or repairing mechanical systems. These schematics provide a detailed visual representation of how various components interact with each other, making it easier to diagnose issues or assemble parts. Below are steps to help you navigate these detailed drawings effectively.

- Identify the legend: Look for the legend or key on the diagram, which explains the symbols used. This is essential for interpreting what each part represents.

- Trace the flow: Follow the lines and arrows, which indicate the direction of air, fluid, or power flow through the system. This helps in understanding how the system operates.

- Focus on component labels: Components are often labeled with codes or numbers. Cross-reference these labels with the accompanying manual to get more information about each part’s function.

- Understand connections: Pay attention to how different elements are connected. This will give you insight into the assembly process or areas where problems might arise.

- Break it down:

Commonly Used Parts in Air Compressors

Air compressors are essential devices in many industries, ensuring the smooth operation of various tools and machinery. The efficiency and longevity of these machines depend on several components, each playing a critical role in maintaining pressure and airflow. Understanding the function of key elements in these devices can help ensure their proper maintenance and performance.

Pumps are the core of the compressor, responsible for the generation of compressed air. A well-maintained pump ensures consistent air output and pressure levels, making it one of the most vital parts of the system.

Filters are essential for keeping the air intake clean, preventing dust, dirt, and other particles from entering the system. This helps in maintaining optimal performance and protecting the internal mechanisms from damage.

The valves regulate the airflow and pressure, ensuring the proper distribution of compressed air. They are crucial for maintaining balance within the system, preventing over-pressurization and ensuring safe operation.

Belt drives are often used to transfer power from the motor to the pump. A properly functioning belt drive ensures smooth and efficient operation, while a worn-out one can lead to a decrease in performance and potential breakdowns.

Other important elements include cooling systems, which prevent

Exploring Diagrams of Ingersoll Rand Systems

Understanding the structure of complex mechanical systems often begins with visual representations that outline key components and their connections. These illustrations provide a clear overview of how different elements work together, ensuring efficient operation and maintenance. Such representations are vital for both technicians and operators, offering an intuitive way to grasp the function and placement of various parts within the equipment.

Importance of Visual References

When dealing with advanced machinery, having access to detailed visuals helps to simplify troubleshooting and assembly tasks. Whether for repair or preventive maintenance, these illustrations offer insights into the layout and interaction of the system’s critical elements. By following the images, professionals can quickly identify and address potential issues, ensuring smooth and uninterrupted performance.

Understanding the Components’ Interactions

Each component in these systems plays a unique role, and the way they are interconnected impacts the overall functionality. Visual aids highlight these relationships, making it easier to follow the operational flow. This is crucial for ensuring that every part functions in harmony, contributing to the system’s reliability and longevity.

Maintenance Tips for Ingersoll Rand Equipment

Proper maintenance of industrial equipment is crucial for its long-term performance and efficiency. Regular checks, timely repairs, and preventive care ensure the machinery operates at peak capacity, reducing the likelihood of breakdowns and costly downtime. Following best practices in upkeep not only extends the lifespan of the equipment but also maintains its optimal functionality.

Key Areas to Focus On

Maintaining heavy-duty tools involves paying attention to several critical areas. Regular lubrication, checking fluid levels, inspecting components, and monitoring system performance are all essential to keep everything running smoothly. Below are some key points to include in your maintenance routine.

Maintenance Task Recommended Frequency Lubricate moving parts Weekly Inspect filters and replace if necessary Monthly Key Components in Pneumatic Systems

Pneumatic systems play a crucial role in various industrial applications by utilizing compressed air to power tools and machinery. Understanding the fundamental elements of these systems is essential for optimizing performance and ensuring reliability. This section outlines the primary components that contribute to the effective functioning of pneumatic setups.

- Compressor: This device compresses air and stores it in a reservoir, providing the necessary pressure for the entire system.

- Reservoir: A storage tank that holds compressed air until it is needed for operation, helping to maintain consistent pressure levels.

- Actuator: Often in the form of cylinders, actuators convert the energy from compressed air into mechanical motion, enabling various tasks.

- Valves: These control the flow and direction of air within the system, allowing for precise control over the operation of actuators.

- Pipes and Fittings: Essential for the transportation of compressed air, these components connect different parts of the system and ensure efficient airflow.

- Filters: Filters remove contaminants from the compressed air, protecting the system and prolonging the life of components.

- Regulators: These devices manage air pressure, ensuring that it remains within specified limits for optimal performance.

By familiarizing oneself with these key components, one can enhance the efficiency and effectiveness of pneumatic systems, ultimately leading to improved productivity and reduced operational costs.

Where to Find Ingersoll Rand Spare Parts

Locating replacement components for your equipment can be crucial for maintaining optimal performance and ensuring longevity. Various sources provide access to these necessary items, making it easier for users to find what they need efficiently.

Authorized Dealers and Distributors

One of the most reliable options is to seek out authorized dealers and distributors. These entities often have direct connections with manufacturers, ensuring the authenticity and quality of the components. They typically offer a comprehensive range of products and can assist customers in identifying the specific items required for their machinery.

Online Marketplaces

Another convenient avenue is through online marketplaces. Websites dedicated to industrial supplies often feature a wide array of offerings, from common components to specialized items. When utilizing these platforms, it’s essential to verify the credibility of the seller to avoid counterfeit products. Additionally, many websites allow users to compare prices and read reviews, helping to make informed purchasing decisions.

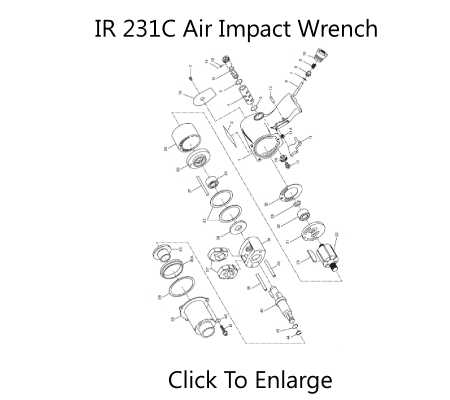

Visual Guide to Ingersoll Rand Parts

This section serves as a comprehensive overview of the various components that play crucial roles in the operation of machinery. Understanding these elements is essential for maintenance and repair, enabling users to identify each part’s function and importance. By familiarizing oneself with the intricacies of these units, one can ensure optimal performance and longevity of the equipment.

Component Description Function Compressor A mechanical device that increases the pressure of air or gas. Provides the necessary pressure for operation. Motor An engine that converts electrical energy into mechanical energy. Powers the compressor and other attached components. Filter A device that removes contaminants from air or fluid. Ensures clean operation by preventing dirt and debris from entering the system. Valve A device that regulates the flow of fluid or gas. Controls the pressure and direction of the air within the system. Receiver Tank A storage vessel for compressed air. Holds compressed air until it is needed for operation. Identifying Critical Elements in Compressors

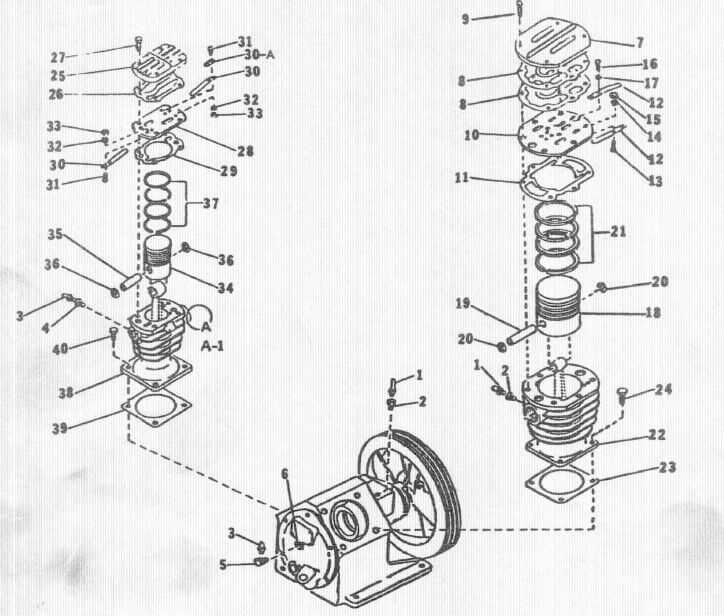

Understanding the essential components of compressors is vital for ensuring their optimal performance and longevity. Recognizing these crucial elements allows operators to make informed decisions regarding maintenance and troubleshooting, ultimately leading to increased efficiency and reduced downtime.

Key Components to Consider

Several components play a pivotal role in the functionality of a compressor. Among them, the piston and cylinder work in tandem to compress air, while the valves regulate airflow and maintain pressure. Additionally, the crankshaft provides the necessary rotational motion, making it an indispensable part of the mechanism.

Maintenance and Troubleshooting Insights

Regular inspection and maintenance of these critical components can prevent significant operational issues. Identifying wear or damage early can save resources and ensure the system operates efficiently. Understanding how each part interacts helps in troubleshooting and enhancing overall performance.

Replacing Parts in Ingersoll Rand Models

When it comes to maintaining machinery, understanding the process of swapping out components is essential for ensuring optimal functionality and longevity. Each model requires specific attention to detail, making it crucial for operators to familiarize themselves with the respective assembly and available replacements. By following proper procedures, users can enhance the performance and efficiency of their equipment.

Identifying Necessary Components

Before undertaking any replacement task, it is vital to accurately determine which components need attention. Regular inspection can reveal wear or damage, prompting the need for immediate action. Utilizing a comprehensive reference can assist in pinpointing the exact elements that require replacement, allowing for a smooth transition during the process.

Steps for Efficient Replacement

To ensure a successful swap, follow these steps:

- Gather Tools: Ensure you have the necessary tools and replacements on hand.

- Power Down Equipment: Always shut off the machinery and disconnect power sources to prevent accidents.

- Carefully Remove Old Components: Take your time to avoid damaging surrounding areas.

- Install New Components: Position the new elements correctly and secure them as per the guidelines.

- Test the Equipment: Once everything is reassembled, power up the machinery to ensure proper function.

By adhering to these steps, operators can effectively manage the replacement of essential components, ultimately leading to improved performance and reduced downtime.

Upgrading Your Ingersoll Rand Equipment

Enhancing your machinery can significantly improve performance and efficiency. Whether you are looking to boost productivity or reduce operational costs, investing in upgrades can make a notable difference. This section will explore key aspects to consider when modernizing your equipment and the benefits it can bring to your operations.

Identifying Key Components for Upgrade

One of the first steps in the enhancement process is to pinpoint which components require attention. Assess the current state of your machinery and determine areas that may benefit from improvement. This could involve upgrading specific parts or replacing outdated systems to ensure optimal functioning. Investing in advanced technology can lead to better efficiency and longevity of your equipment.

Benefits of Modernization

Upgrading your machinery can result in various advantages. Improved energy efficiency can lead to significant cost savings over time. Additionally, newer components often come with enhanced features that can boost overall performance. Moreover, modernized equipment can also enhance safety standards, reducing the risk of accidents and ensuring a safer working environment. Embracing these improvements not only enhances productivity but also contributes to a sustainable future.