The functioning of any printing mechanism relies on a variety of integral components, each playing a crucial role in delivering high-quality outputs. From the mechanisms that facilitate ink flow to those that ensure precise image reproduction, the efficiency of the device is a result of the harmonious interaction between these elements.

In-depth knowledge of these individual elements can significantly enhance one’s ability to troubleshoot issues and maintain optimal performance. Recognizing how each component contributes to the overall process enables users to make informed decisions regarding repairs or upgrades.

Furthermore, a clear comprehension of these functionalities not only aids in resolving technical problems but also empowers users to maximize their device’s potential. Engaging with the intricate workings of the system fosters a greater appreciation for the technology involved in creating vibrant and precise printed materials.

To fully grasp the mechanics behind the devices that produce high-quality images and text, it’s essential to explore their components and how they work together. Each element plays a crucial role in ensuring smooth operation and optimal output. Understanding these functionalities can enhance one’s ability to troubleshoot and maintain the equipment effectively.

Key Components

Several vital elements contribute to the overall functionality of these devices:

- Ink Cartridges: Responsible for holding and delivering the ink to the print head.

- Print Head: This component transfers the ink onto the paper, utilizing tiny nozzles for precision.

- Paper Feed Mechanism: Ensures the correct alignment and movement of the paper during the printing process.

- Control Circuitry: Manages the operations and interactions between various components.

- Housing: Protects internal components and provides a structure for the device.

How Components Work Together

The coordination between these components is crucial for producing high-quality outputs:

- The control circuitry activates the print head based on the user’s command.

- Ink is drawn from the cartridges to the print head, where it is precisely ejected onto the media.

- The paper feed mechanism advances the media, ensuring each section is printed accurately.

- Finally, the housing keeps all components safe from external factors that could disrupt their functions.

Recognizing the significance of each element and their interactions can lead to better maintenance practices and an improved understanding of how to resolve common issues.

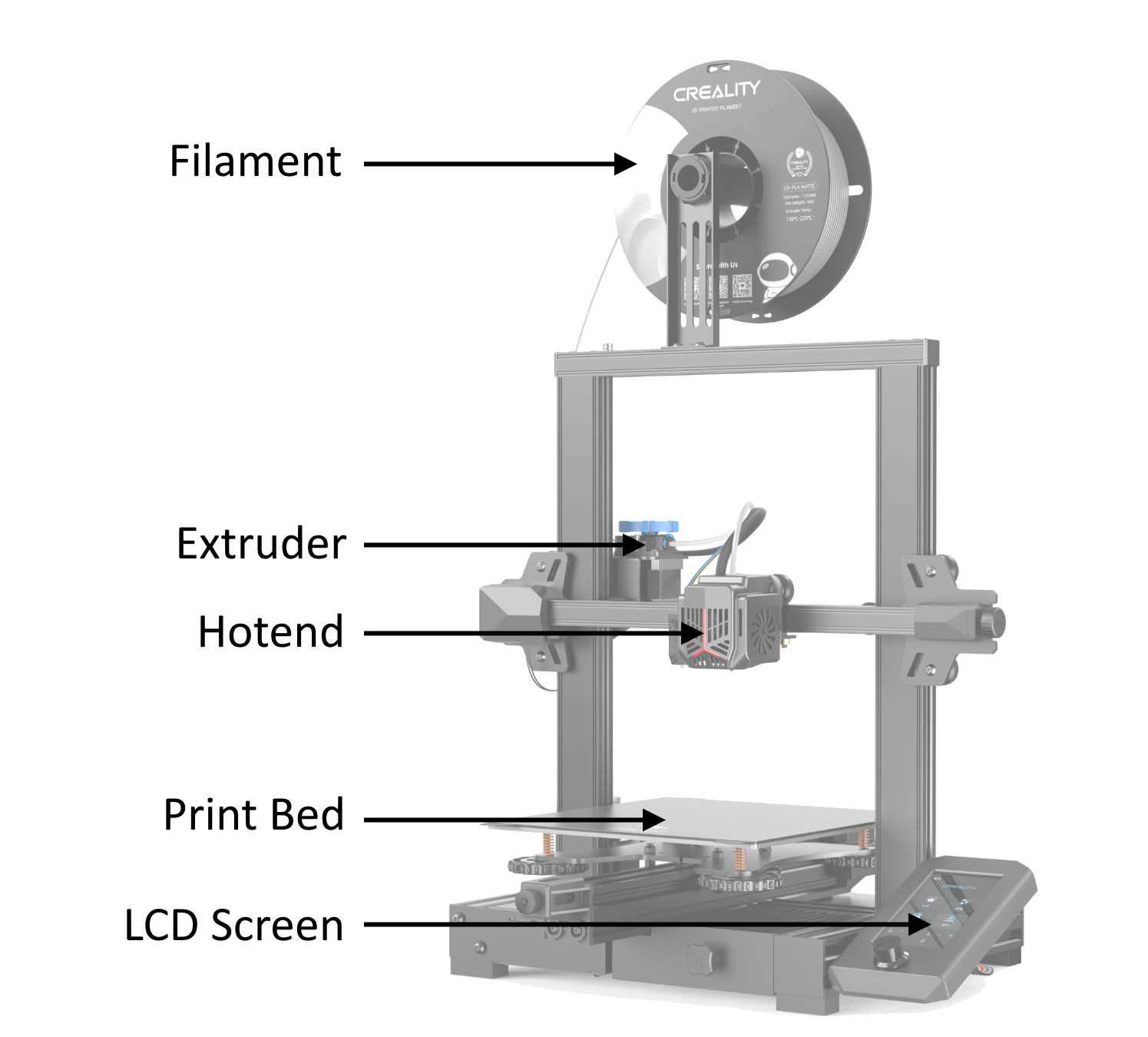

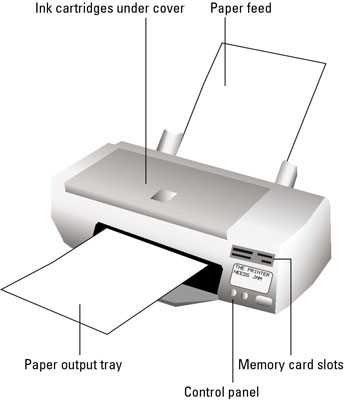

Components of an Inkjet Printer

Modern printing devices consist of various elements that work harmoniously to produce high-quality images and text. Understanding these components is essential for maintaining and troubleshooting these machines effectively.

1. Print Head: The print head is a crucial component responsible for transferring ink onto the paper. It contains tiny nozzles that spray microscopic droplets of ink, creating vibrant and detailed outputs.

2. Ink Cartridges: These containers hold the ink used during the printing process. Different cartridges can contain various colors, allowing for a wide range of hues and shades in the final print.

3. Paper Feed Mechanism: This mechanism guides the media through the device, ensuring it is properly aligned for accurate printing. It typically consists of rollers that grip and move the sheets smoothly.

4. Control Circuit Board: This electronic board coordinates the operation of the device, interpreting commands from the user and managing the functions of other components to ensure seamless performance.

5. Output Tray: The output tray collects printed documents as they emerge from the device. It is designed to accommodate various paper sizes and ensure that the prints are handled gently.

6. Maintenance Station: This area houses mechanisms for cleaning and maintaining the print head, preventing clogs and ensuring consistent print quality over time.

Role of Print Heads Explained

The function of print heads is crucial in the process of transferring images and text onto various surfaces. These components serve as the primary mechanism for delivering the fluid medium onto the target area with precision. Understanding how they operate can greatly enhance the overall quality of the output and ensure that the results meet the desired standards.

Print heads are equipped with nozzles that eject the liquid in fine droplets, enabling intricate designs and sharp text. This operation is controlled by electrical signals that dictate the timing and quantity of the fluid released. The effectiveness of the head directly impacts factors such as resolution, speed, and color vibrancy.

| Function | Description |

|---|---|

| Fluid Delivery | Responsible for depositing the liquid onto the medium in precise patterns. |

| Control Mechanism | Operates through electrical signals to manage droplet size and release timing. |

| Quality Assurance | Affects resolution and clarity of printed materials by maintaining nozzle cleanliness and function. |

In summary, the effectiveness of print heads is essential for achieving high-quality results in various applications. Their ability to deliver liquid accurately and consistently is key to producing vibrant and clear outputs.

How Ink Cartridges Work

Understanding the functionality of ink containers is essential for anyone using modern printing devices. These essential components play a crucial role in the printing process, ensuring that the desired images and texts are transferred accurately onto various surfaces. The mechanism behind their operation involves a combination of technology and chemistry that allows for precise color reproduction and efficient usage.

Mechanism of Dispersion

The process begins when a signal is sent from the device to the ink container. This initiates the release of ink through tiny nozzles. The technology behind this involves thermal or piezoelectric methods that control the movement of the liquid. As the ink is expelled, it forms droplets that land on the medium, creating the intended visual output. This controlled release ensures that colors blend effectively, providing sharp and vibrant results.

Maintenance and Performance

Proper maintenance of these liquid reservoirs is vital for optimal performance. Regularly checking the levels and replacing them when necessary prevents issues such as clogging and uneven output. Additionally, using high-quality ink can enhance the longevity of the devices, ensuring that they deliver consistently excellent results over time.

Importance of Paper Feed Mechanism

The mechanism responsible for feeding media into a printing device plays a crucial role in ensuring smooth and accurate operation. This system is vital for maintaining consistent performance and preventing common issues that can disrupt workflow. Understanding its significance helps in recognizing how it influences overall functionality and output quality.

Consistent Media Handling

The reliability of the feed mechanism directly affects the handling of various media types. It ensures that sheets are fed correctly, preventing jams and misalignments that could lead to wasted resources and time. An efficient system allows for a seamless transition between different media sizes and types, enhancing productivity.

Impact on Print Quality

Accurate alignment and consistent movement of media are essential for achieving high-quality results. A well-functioning feed mechanism ensures that the media is positioned precisely during the printing process, minimizing the risk of blurriness or misprints. This precision is vital for professional-quality outputs, making the mechanism an indispensable component in any printing operation.

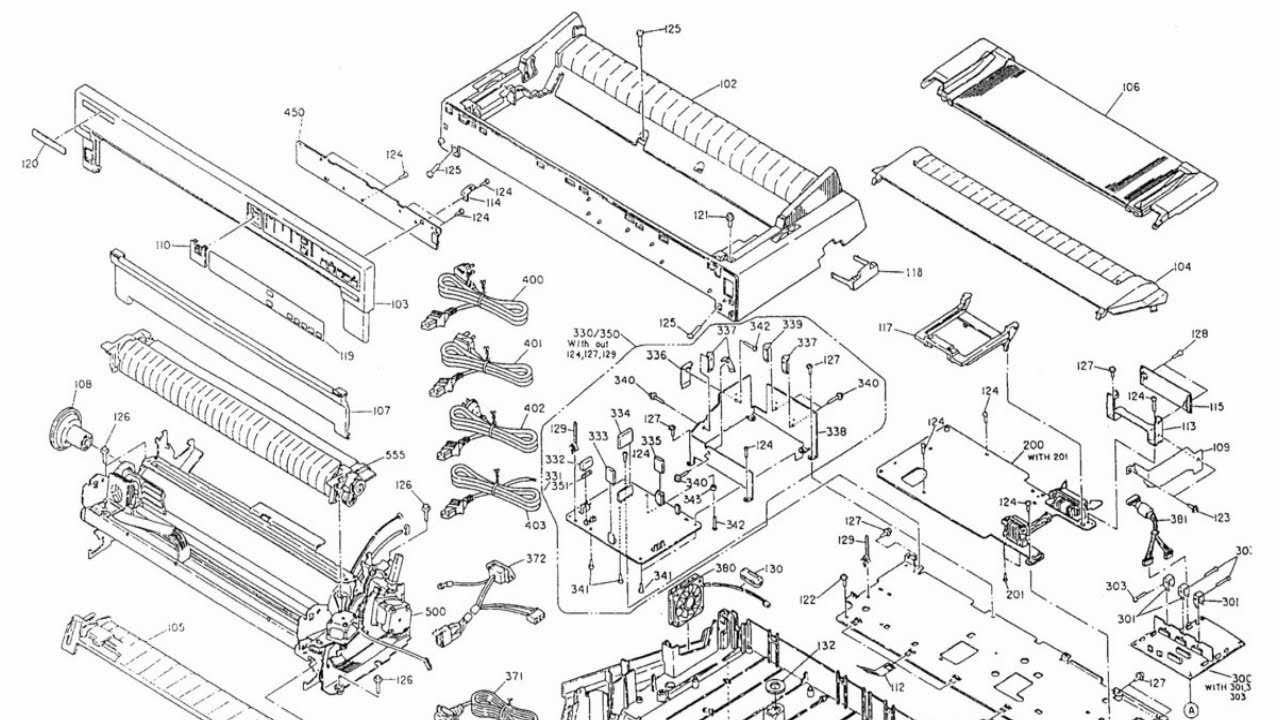

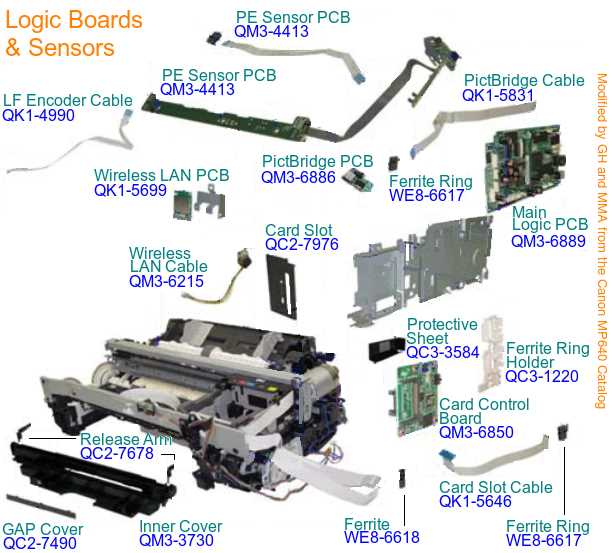

Analyzing the Control Circuit Board

The control circuit board serves as the brain of any electronic device, orchestrating various functions and ensuring seamless operation. This section delves into the intricacies of this essential component, examining its structure, functions, and significance in the overall system.

Structure and Components

The control circuit board is comprised of several key elements that work in harmony to facilitate communication between different parts. Understanding these components is crucial for troubleshooting and enhancing performance. The main elements include:

- Microcontroller: The core unit that executes commands and processes data.

- Resistors: Components that regulate current flow, ensuring the stability of the circuit.

- Capacitors: Devices that store and release electrical energy, playing a crucial role in signal processing.

- Connectors: Interfaces that allow communication with external devices or circuits.

Functions and Importance

The control circuit board plays several vital roles in the functionality of the device:

- Signal Processing: It interprets signals from various sensors and components, converting them into actionable commands.

- Data Management: The board manages data transmission, ensuring that information is accurately relayed between components.

- Power Distribution: It efficiently distributes power to different parts, maintaining optimal performance.

- Diagnostic Capabilities: Integrated diagnostic features allow for troubleshooting and maintenance, enhancing longevity.

Understanding the control circuit board is crucial for anyone involved in the maintenance or enhancement of electronic devices. Its design and functionality directly influence the overall efficiency and reliability of the system.

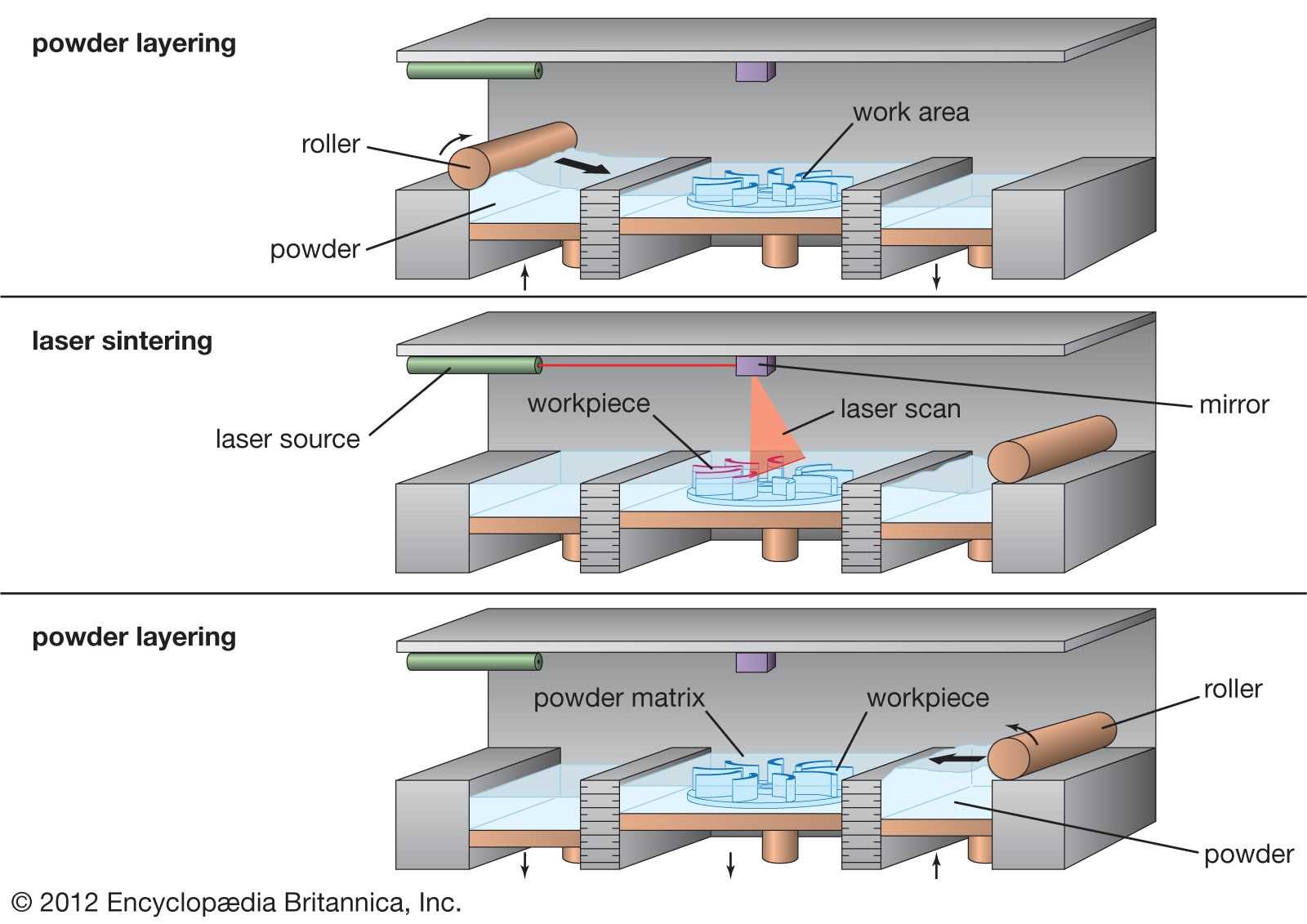

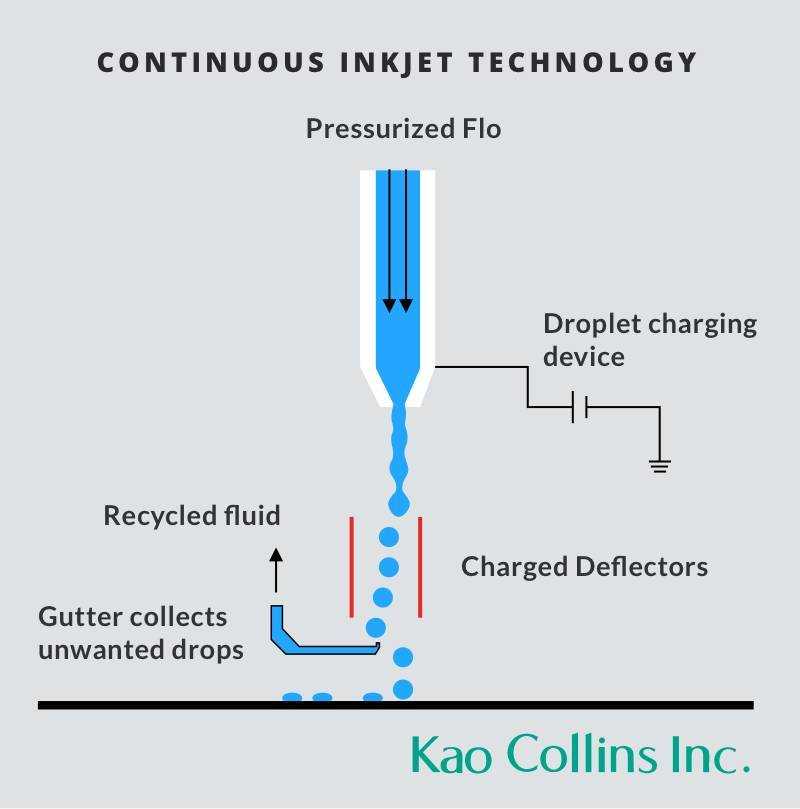

Overview of the Ink Delivery System

The ink delivery system is a crucial component in devices that utilize liquid colorants for producing images and text. This system is responsible for transporting the fluid from the reservoirs to the print head, ensuring a consistent and precise flow during operation. Understanding the various elements involved in this process helps users appreciate the technology behind high-quality output.

Key Components

- Ink Cartridges: These containers hold the liquid colorant and come in various capacities and formulations to meet different printing needs.

- Hoses and Tubing: Flexible conduits that connect the cartridges to the print head, facilitating the movement of the liquid.

- Print Head: A vital part that ejects the fluid onto the media in tiny droplets, creating the desired image or text.

- Pump Mechanism: This component generates the necessary pressure to draw the fluid from the cartridges to the print head.

Functionality

The functionality of the ink delivery system relies on precise control and coordination among its components. Here’s how it works:

- The liquid is drawn from the cartridges through the pump mechanism.

- The fluid travels through hoses to the print head.

- Upon activation, the print head ejects the liquid in a controlled manner onto the surface being printed.

- The system continuously monitors the fluid levels and adjusts the flow to ensure optimal performance.

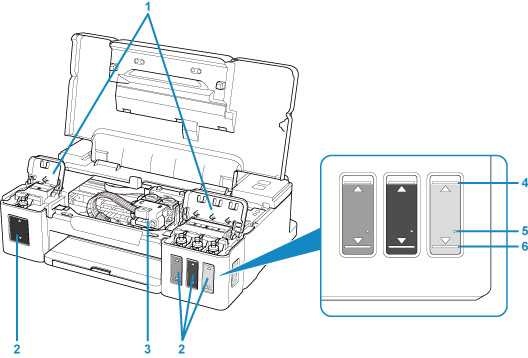

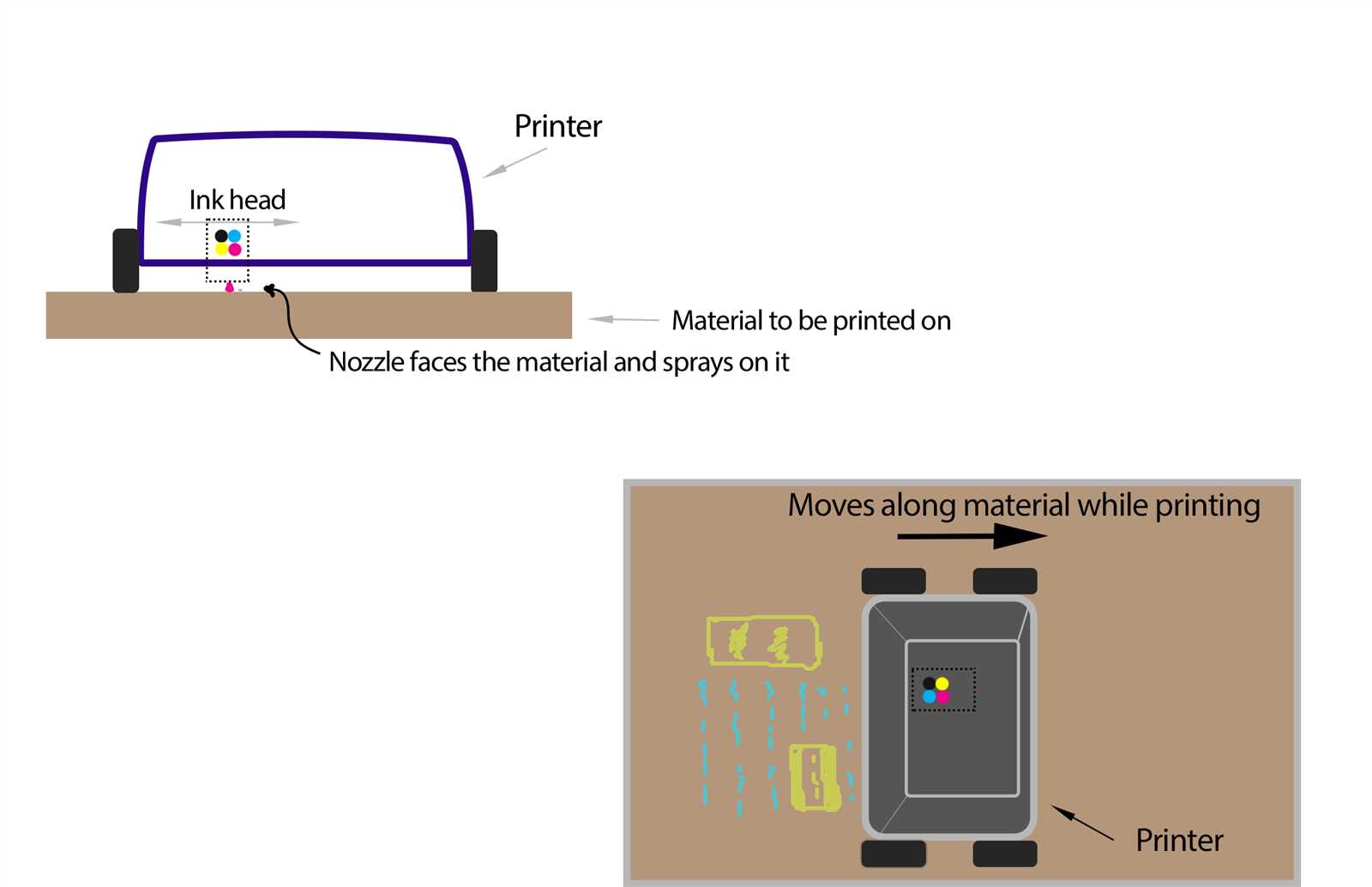

Exploring the Print Head Assembly

The print head assembly is a crucial component in the world of digital imaging, responsible for transferring ink onto various surfaces. This assembly plays a pivotal role in achieving high-quality output, making it essential to understand its structure and function.

This section delves into the various elements that comprise the print head assembly, detailing their roles and significance in the overall operation. Here are some key components:

- Nozzle: The tiny openings through which ink is ejected, determining the precision and quality of the printed image.

- Ink Cartridges: These hold the ink and feed it to the nozzles, playing a vital role in maintaining consistent ink flow.

- Head Driver: This electronic component controls the movement of the print head, ensuring that it operates smoothly and accurately.

- Wiper Blade: Used to clean the nozzles and prevent clogs, ensuring optimal performance during each cycle.

- Temperature Sensor: Monitors the heat levels within the assembly, crucial for maintaining ink fluidity and preventing damage.

Understanding these components is essential for troubleshooting issues and ensuring the longevity of the print head assembly. Regular maintenance and awareness of how each element contributes to the overall function can enhance performance and reduce operational failures.

Understanding the Print Roller Function

The print roller plays a crucial role in the functioning of various document reproduction devices. This component ensures that the medium is properly fed through the machine, allowing for accurate and efficient transfer of ink onto the surface. Understanding how this element operates is essential for grasping the overall printing process.

Here are the key functions of the print roller:

- Media Handling: The roller helps in guiding the material smoothly through the device, preventing jams and ensuring a steady flow.

- Pressure Application: It applies the necessary pressure to facilitate the transfer of ink, ensuring that the print is clear and well-defined.

- Alignment: Proper alignment of the media is crucial for accurate reproduction; the roller assists in keeping the material correctly positioned during the printing process.

Overall, the print roller is integral to achieving high-quality results in document reproduction. Regular maintenance and understanding its function can significantly enhance performance and longevity.

Insights into the Maintenance Station

The maintenance station plays a crucial role in ensuring optimal performance and longevity of your device. It is designed to handle various tasks related to cleaning and maintaining vital components, thereby enhancing overall efficiency. Understanding its functions can greatly aid in achieving better print quality and reducing downtime.

Key Functions of the Maintenance Station

One of the primary responsibilities of the maintenance station is to keep the print heads clean. It employs specific mechanisms to remove dried ink and debris, which can impede performance. Regular cleaning not only prevents clogs but also ensures that the colors remain vibrant and accurate.

Importance of Regular Maintenance

Consistent upkeep of the maintenance station is essential for sustaining print quality. Neglecting this aspect can lead to increased wear on other components and potential malfunctions. Implementing a routine check can help identify any issues early, preventing costly repairs and ensuring a smooth printing experience.

Examining the Output Tray Design

The output tray plays a crucial role in the overall functionality of a device that produces documents and images. This component is responsible for receiving and collecting finished materials, ensuring that they are neatly organized and easily accessible. A well-thought-out design can significantly enhance user experience and efficiency.

One of the primary considerations in the output tray’s design is its capacity. A larger tray allows for more sheets to be stored, reducing the need for frequent emptying. Additionally, the shape and structure of the tray must facilitate smooth handling of the output, preventing jams or misalignment as the materials are ejected. Durability is also essential; materials used in construction should withstand the wear and tear associated with continuous use.

Moreover, an effective output tray design often includes features such as adjustable extensions or dividers to accommodate different sizes of paper. These adjustments provide versatility, catering to a range of printing needs. Overall, a thoughtful approach to the output tray design can greatly impact the efficiency and satisfaction of users.

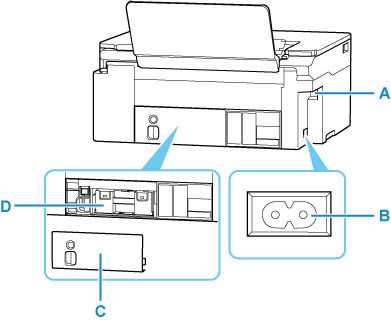

Identifying the Power Supply Unit

The power supply unit plays a crucial role in ensuring that electronic devices function properly. It converts alternating current (AC) from the wall outlet into the direct current (DC) required for internal components. Understanding its features and functions is essential for troubleshooting and maintenance.

Key Characteristics of the Power Supply Unit

This unit typically consists of several key elements that contribute to its operation. Familiarizing oneself with these components can aid in diagnosing issues and performing repairs effectively.

| Component | Description |

|---|---|

| Transformer | Steps down the voltage from the outlet to a usable level. |

| Rectifier | Converts AC to DC voltage. |

| Capacitor | Stores energy and smooths out voltage fluctuations. |

| Regulator | Maintains a constant output voltage despite variations in input voltage. |

Importance of Proper Identification

Accurately identifying the power supply unit is vital for ensuring compatibility with other components. It helps in selecting the right replacement parts and can significantly affect the overall performance of the device.

Connecting the Interface Ports

Establishing a connection through various interface ports is crucial for ensuring effective communication between devices. These ports serve as the gateways for data transfer and control signals, enabling seamless interaction and functionality. Properly connecting these interfaces is essential for optimal performance and reliability.

When setting up the connections, it is important to identify the specific types of ports available, such as USB, Ethernet, and parallel connections. Each port type has its unique characteristics and compatibility requirements. Make sure to use the appropriate cables and connectors that match the designated interfaces to avoid connectivity issues.

Before proceeding, verify that all devices are powered off to prevent any electrical damage. Carefully align the connectors with the ports and insert them gently until they are securely in place. Once all connections are made, power on the devices and check for any indicators that confirm successful communication.

In cases where multiple devices are connected, ensuring the correct configuration in the settings is vital. This may involve selecting the proper interface from a menu or installing necessary drivers for smooth operation. Regular maintenance and checks can help in identifying potential issues with the connections, ensuring that the system remains functional and efficient.