The internal structure of a kitchen waste processing system can seem complex at first glance. However, by exploring the various elements that make up this device, it becomes easier to understand how it functions effectively to manage food waste. Each element plays a vital role in ensuring that the system operates smoothly and efficiently, preventing common issues like clogs or malfunctions.

In this guide, we will explore the essential mechanisms that allow the system to break down and dispose of waste, focusing on the layout and configuration of its internal sections. By delving into the different sections, you will gain a clearer picture of how the system processes waste and how you can maintain it for optimal performance.

Whether you’re troubleshooting or looking to upgrade specific elements, having a clear understanding of the internal layout and functionality will empower you to make informed decisions. This knowledge not only helps in maintaining the system but also assists in identifying potential areas for improvement or repair.

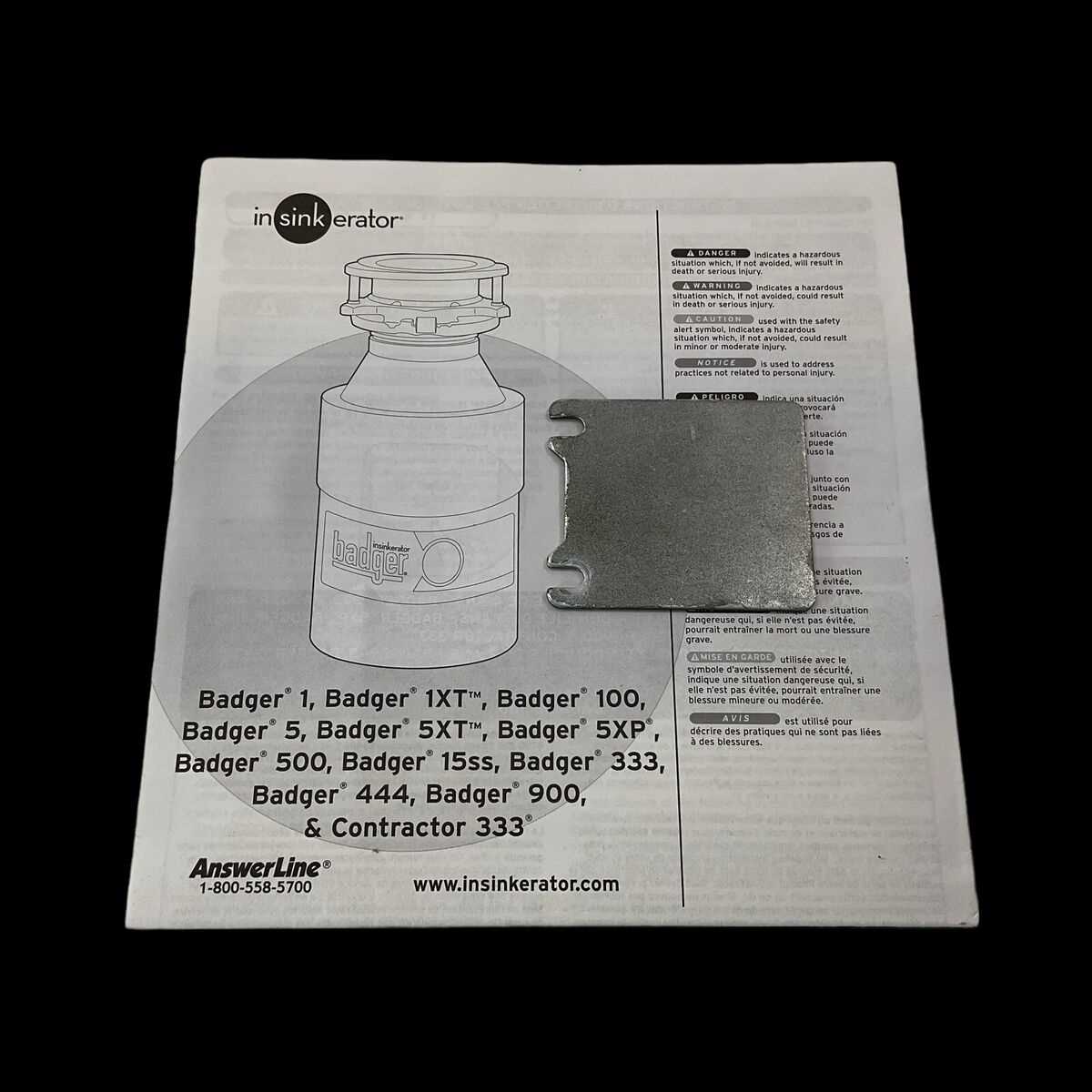

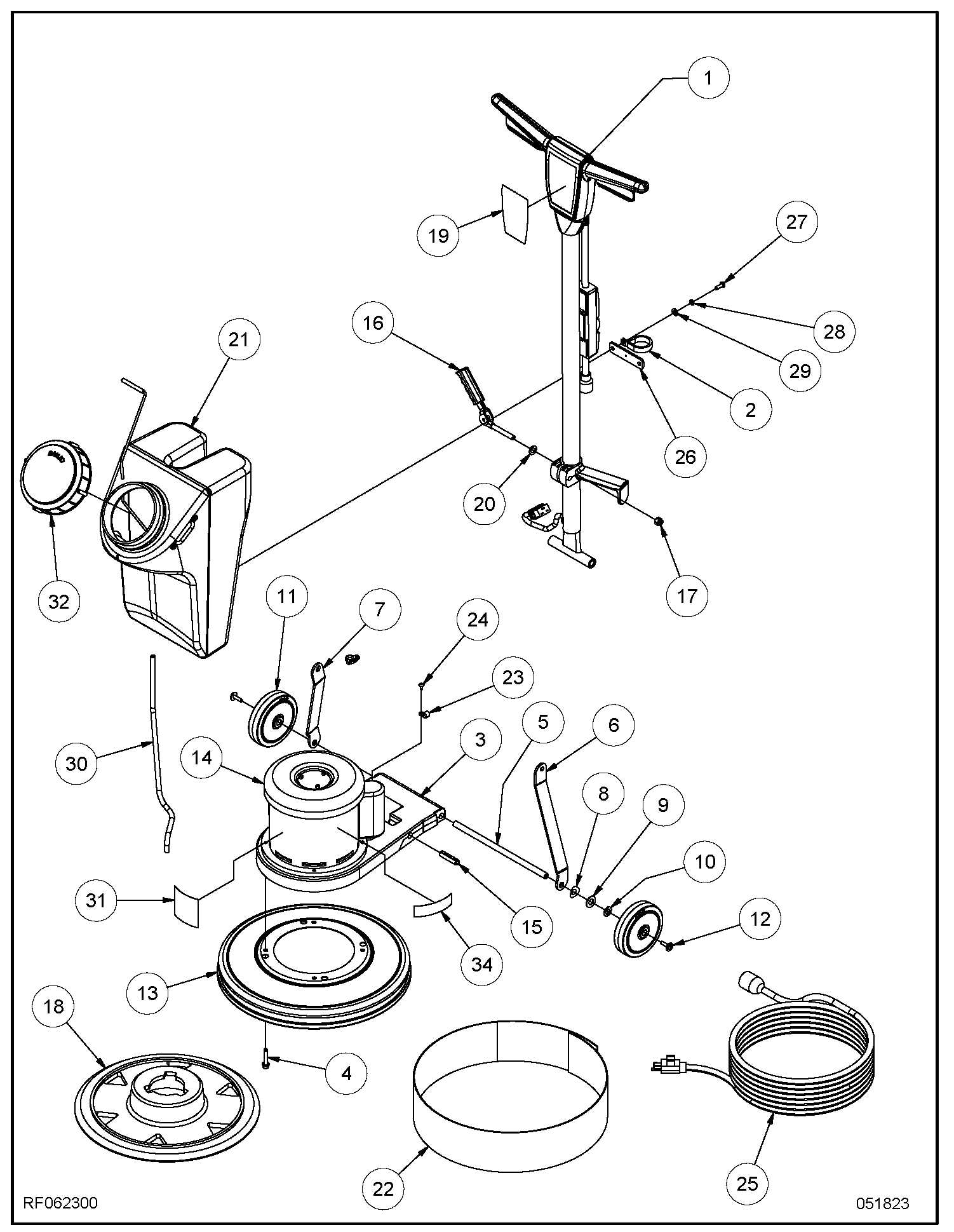

Overview of Insinkerator Pro 333 Components

Understanding the key elements of this appliance is essential for ensuring its efficient operation. The internal and external features work together to provide smooth functionality, making it a reliable addition to any kitchen. Each component plays a specific role in the overall system, contributing to its robust performance and durability.

Primary Mechanisms: The core parts are responsible for the appliance’s main function, effectively managing the waste disposal process. These mechanisms ensure seamless operation while minimizing disruptions during usage.

Supporting Elements: Alongside the main mechanisms, auxiliary components assist in enhancing efficiency. They provide structural support and contribute to noise reduction, safety, and overall system longevity.

Maintenance Aspects: Proper upkeep of each part is crucial for the long-term functionality of the appliance. Regular inspections and care will help prevent wear and tear, ensuring smooth performance over time.

Understanding Key Functional Parts

In any complex system, individual components play crucial roles in ensuring smooth operation and functionality. By recognizing the importance of each element, you can gain a better understanding of how the entire setup works in unison. This section delves into the main elements that are essential for maintaining efficiency and longevity.

Motor Unit – The motor is at the heart of the system, providing the necessary power for the mechanism. Its performance and durability are vital to the overall operation. Regular maintenance and proper usage can greatly extend its life span.

Grinding Chamber – This part is responsible for breaking down materials efficiently. It operates under heavy conditions and requires durable construction to handle various tasks without frequent repairs.

Sealing Mechanism – A robust sealing system is crucial to prevent leaks and maintain a stable operation environment. Ensuring that the seal remains intact is critical for both safety and performance.

Drainage System – Proper flow of liquids is key to preventing clogs and ensuring smooth operation. A well-designed drainage setup supports the efficiency of the entire mechanism and reduces the chances of malfunction.

Understanding these components will help in identifying potential issues and ensuring that the system remains in optimal working condition over time.

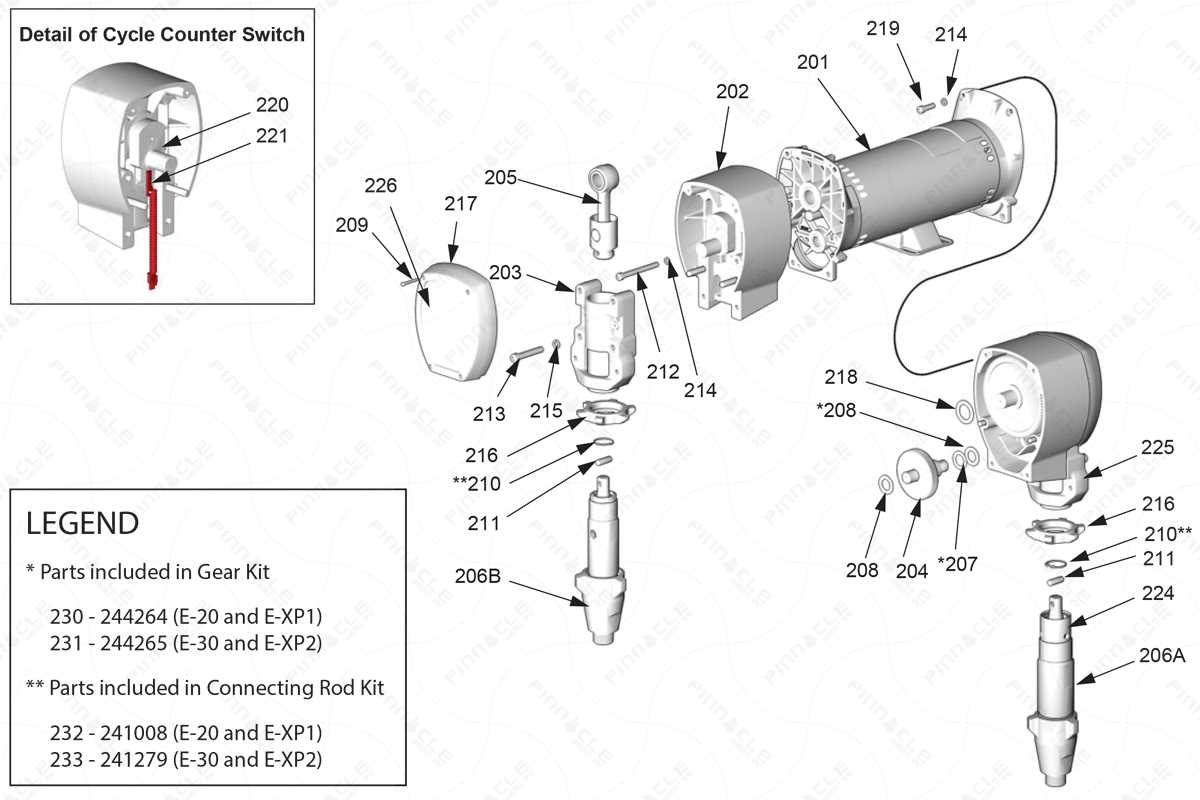

Exploring Motor and Grinding Mechanism

The internal components responsible for smooth and efficient food waste disposal are primarily the motor and the grinding unit. Understanding how these two systems work together provides insight into the overall performance and durability of the machine. By analyzing the mechanics, it becomes easier to see how the combination of power and precision contributes to effective waste breakdown.

Motor Efficiency and Power Delivery

The motor is designed to deliver consistent power, ensuring that even tougher materials are processed with ease. Its energy-efficient design not only reduces electrical consumption but also helps maintain long-term reliability. This section explores how the motor converts electrical energy into mechanical motion, directly influencing the unit’s grinding capability.

Grinding Mechanism Precision

The grinding mechanism plays a crucial role in reducing food waste into fine particles. Utilizing centrifugal force and sharp components, this system ensures that materials are broken down effectively without clogging or jamming. The precision of the grinding process is enhanced by the strategic arrangement of its elements, designed to handle various types of waste with minimal noise and vibration.

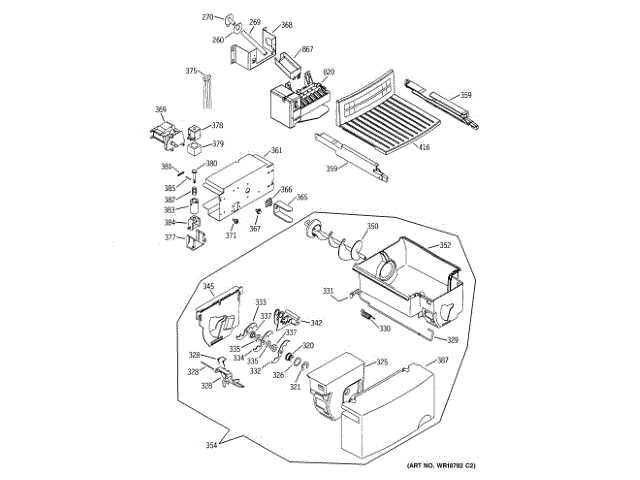

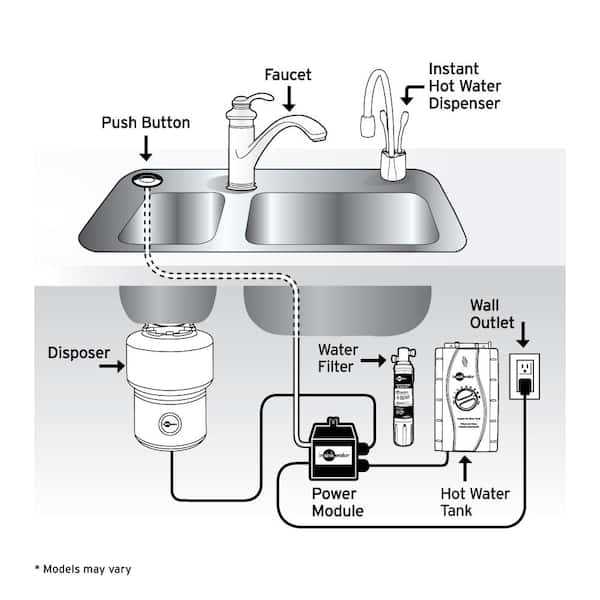

Drain Assembly and Its Role

The drain assembly plays a crucial function in ensuring the efficient flow of wastewater from the sink. Properly designed and installed, it helps to manage the exit of water and waste, directing them into the plumbing system. Without a well-functioning drainage setup, the system could experience blockages or water flow issues, leading to potential damage.

Main Components of the Drain System

- Flange: This part connects the sink to the drainage system, ensuring a watertight seal.

- Gasket: Positioned between the flange and the sink, it prevents water from leaking around the edges.

- Tailpiece: The section that directs water from the sink basin into the main drainage pipe.

- Slip nuts and washers: Used to secure the tailpiece and other parts, allowing easy disassembly for maintenance.

Importance of Proper Maintenance

Keeping the drain assembly in good condition is vital for the overall health of your kitchen’s plumbing. Regular inspections and cleaning can prevent buildup and clogs. Additionally, checking for wear and replacing parts as needed will help avoid costly repairs in the long term.

Examining the Mounting System

The mounting mechanism plays a crucial role in ensuring the stability and security of various kitchen fixtures. It is designed to provide a reliable attachment, reducing vibration and preventing loosening over time. Understanding how the system is structured helps in both installation and maintenance, ensuring long-term functionality.

- Component Alignment: Proper alignment of components guarantees a secure fit, minimizing the risk of unwanted movement during operation.

- Fastening Methods: Various fasteners are used to hold the system in place, requiring precision to ensure stability and reduce wear over time.

- Vibration Dampening: Integrated features often include elements that reduce vibration, contributing to quieter performance and prolonged durability.

In this section, we will break down the essential elements of the mounting system, offering tips on how to ensure a smooth installation and long-lasting performance.

Replacement Options for Worn Parts

When components of a waste disposal unit show signs of wear or malfunction, it’s crucial to explore suitable alternatives to ensure optimal performance. Timely replacement can prevent further damage and enhance the unit’s efficiency. This section outlines various options available for those looking to substitute deteriorated elements with reliable replacements.

Several factors should be considered when selecting replacement components, such as compatibility, durability, and cost-effectiveness. Below is a table summarizing common alternatives and their respective features:

| Component Type | Replacement Option | Benefits |

|---|---|---|

| Motor | Universal Motor | High efficiency and long lifespan. |

| Seals | Silicone Seals | Resistant to wear and temperature variations. |

| Impeller | Stainless Steel Impeller | Corrosion-resistant and robust performance. |

| Power Cord | Heavy-Duty Power Cord | Enhanced durability and safety features. |

In conclusion, selecting the right replacements can significantly improve the functionality of the unit while ensuring longevity. Always verify compatibility and quality when opting for new components.

Common Issues with Component Wear

Understanding the typical challenges associated with component degradation is essential for maintaining optimal performance in various devices. Over time, wear and tear can lead to several common problems, affecting both functionality and efficiency. Identifying these issues early can prevent further damage and ensure reliable operation.

Frequent Signs of Wear

As components age, certain indicators become apparent. These may include unusual noises, leaks, or reduced efficiency. Vibrations can also signal an imbalance, often resulting from worn parts. Regular inspections can help detect these signs before they escalate into more significant issues.

Impact on Overall Performance

Worn components can have a detrimental effect on overall system performance. Efficiency declines when parts do not function as intended, leading to increased energy consumption and operational costs. Moreover, neglecting minor wear can result in complete system failure, necessitating costly repairs or replacements.

Installation Tips for Specific Parts

When setting up components for your waste disposal system, it’s essential to follow proper guidelines to ensure optimal functionality and longevity. Here are some key considerations to keep in mind while installing various elements.

Proper Alignment and Positioning

Ensuring that each component is aligned correctly is crucial for efficient operation. Follow these tips:

- Check the manufacturer’s specifications for alignment instructions.

- Use a level tool to ensure that the unit is properly positioned.

- Secure all connections to prevent any movement that could disrupt functionality.

Sealing and Insulation

Effective sealing is vital to prevent leaks and maintain performance. Consider the following:

- Apply the recommended sealant around joints to create a watertight seal.

- Ensure insulation is intact and properly fitted to minimize energy loss.

- Inspect gaskets regularly and replace them if they show signs of wear.

Maintenance of Moving Elements

Regular upkeep of dynamic components is crucial for ensuring optimal performance and longevity. These elements play a vital role in the overall functionality of the system, and neglecting them can lead to decreased efficiency or potential failure. Establishing a routine maintenance schedule is essential to address wear and tear, preventing costly repairs or replacements.

Inspection of moving parts should be conducted periodically to identify any signs of wear, misalignment, or damage. Look for unusual noises or vibrations, which may indicate an underlying issue. Lubrication is also key; using appropriate lubricants can minimize friction and prolong the life of these components. Always refer to manufacturer recommendations for specific products and frequencies.

Moreover, keeping the surrounding area clean is vital. Accumulation of debris can hinder the performance of moving parts, leading to obstructions or overheating. Ensure that all pathways and openings remain clear, promoting smooth operation.

By implementing these maintenance practices, you can enhance the reliability and efficiency of your system, ensuring that it operates at its best for years to come.

Electrical Connections and Safety Considerations

Proper management of electrical connections is essential for ensuring the effective and safe operation of any appliance. This section will explore important aspects related to wiring, grounding, and safety measures that should be adhered to during installation and maintenance procedures.

Wiring Guidelines

Adhering to specific wiring protocols is crucial to guarantee optimal performance and minimize hazards. Key recommendations include:

- Ensure compatibility between the electrical supply and the device requirements.

- Utilize appropriate gauge wires to handle the device’s load efficiently.

- Follow local electrical codes and regulations to maintain compliance.

Safety Precautions

To prevent accidents and ensure user safety, consider the following precautions:

- Always disconnect power before performing any installation or maintenance work.

- Verify that all connections are secure and free from corrosion.

- Utilize ground fault circuit interrupters (GFCIs) where necessary to protect against electrical shock.

- Consult a professional electrician if there are uncertainties about the installation process.

Compatibility with Other Models

This section explores the compatibility of a specific food waste disposal unit with various other units in its brand lineup. Understanding how these units interact can assist users in making informed decisions regarding upgrades, replacements, or expansions of their existing systems.

Interchangeable Components

Many disposal units share similar components, allowing users to interchange parts among different models. This compatibility can simplify repairs and maintenance, as well as potentially reduce costs by utilizing existing components rather than purchasing new ones.

Upgrading Options

When considering an upgrade, it’s important to know which models can seamlessly integrate with current systems. Some newer versions may offer enhanced features while still being compatible with older units. Users are encouraged to check compatibility charts or consult manufacturer guidelines to ensure smooth transitions.

Where to Find Spare Parts

Locating replacement components for your kitchen appliance can be essential for maintaining its functionality and ensuring longevity. Here are several avenues to explore when searching for these crucial items:

- Authorized Retailers: Many manufacturers have a network of approved sellers that offer genuine replacements.

- Online Marketplaces: Websites such as Amazon, eBay, and specialized appliance parts stores often stock a variety of components suitable for various models.

- Local Hardware Stores: Check with nearby home improvement or plumbing supply stores, as they may carry compatible items or be able to order them for you.

- Manufacturer’s Website: Visiting the official site can provide valuable resources, including parts catalogs and direct purchasing options.

- Repair Shops: Professional repair services may have access to components or can guide you on where to find them.

Before making a purchase, ensure you verify compatibility with your specific model to avoid any mismatches.