The world of airbrushing is intricate and fascinating, filled with various elements that contribute to its functionality. Each component plays a vital role in achieving precision and control, making it essential for artists and hobbyists alike to familiarize themselves with these parts. A comprehensive understanding of how these pieces interact can significantly enhance the overall experience and outcomes of your creative projects.

In this section, we will explore the essential elements of an airbrush system. By examining the individual components and their relationships, users can better grasp how to maintain their tools and troubleshoot any potential issues. Knowledge of these elements not only aids in effective usage but also empowers users to customize their equipment to suit their artistic needs.

Whether you are a seasoned professional or a newcomer to this art form, having access to a detailed overview of the various elements will undoubtedly improve your skills and understanding. Emphasizing the importance of each part fosters a deeper appreciation for the craft and encourages better practices in airbrush maintenance and application.

Proper upkeep is essential for ensuring the durability and optimal performance of your equipment. By following a few key practices, you can significantly extend its lifespan and maintain its functionality over time.

- Regular Cleaning: After each use, clean the components thoroughly to prevent the buildup of residue and ensure smooth operation.

- Inspect Seals and Gaskets: Periodically check for wear and tear on seals and gaskets, replacing them as needed to avoid leaks and maintain efficiency.

- Use Quality Supplies: Always opt for high-quality materials compatible with your device to prevent damage and ensure consistent performance.

- Store Properly: When not in use, store the equipment in a dry, dust-free environment to protect it from environmental factors that could lead to deterioration.

- Avoid Overuse: Give your device breaks during use to prevent overheating and excessive wear, allowing for better overall function.

By adhering to these maintenance guidelines, you can ensure that your equipment remains reliable and effective for years to come.

Common Issues and Solutions

This section addresses frequent problems that users may encounter with their equipment, along with effective solutions to enhance performance and longevity.

-

Inconsistent Spray Pattern:

This issue often arises from blockages or incorrect nozzle sizes. To resolve this, clean the nozzle thoroughly and ensure the appropriate size is used for your specific tasks.

-

Air Leaks:

Leaks can lead to reduced efficiency and compromised output quality. Check all connections and seals for any wear and tear, and replace any faulty components.

-

Clogging:

Material build-up can cause interruptions in the flow. Regular cleaning of the internal components and using proper maintenance techniques can help prevent this problem.

-

Inadequate Pressure:

If the pressure is too low, it may result in poor application. Verify the air compressor settings and adjust them to match the requirements of your tasks.

-

Uneven Finish:

Variations in the applied finish may occur due to improper technique or inconsistent material viscosity. Practice consistent motion and mix materials according to manufacturer guidelines.

Replacement Parts Availability

Access to essential components is crucial for maintaining the functionality and longevity of airbrush equipment. Users often seek reliable sources for acquiring these necessary elements, ensuring their tools remain in optimal condition.

Where to Find Components

Several avenues can be explored when looking for replacement components:

- Authorized retailers that specialize in airbrush supplies

- Online marketplaces featuring a wide selection of products

- Local craft stores that carry airbrush accessories

- Manufacturer websites offering direct sales

Considerations When Purchasing

When acquiring components, keep the following in mind:

- Ensure compatibility with your specific airbrush model

- Check for warranty options to protect your investment

- Look for customer reviews to assess product quality

- Compare prices across different vendors for the best deal

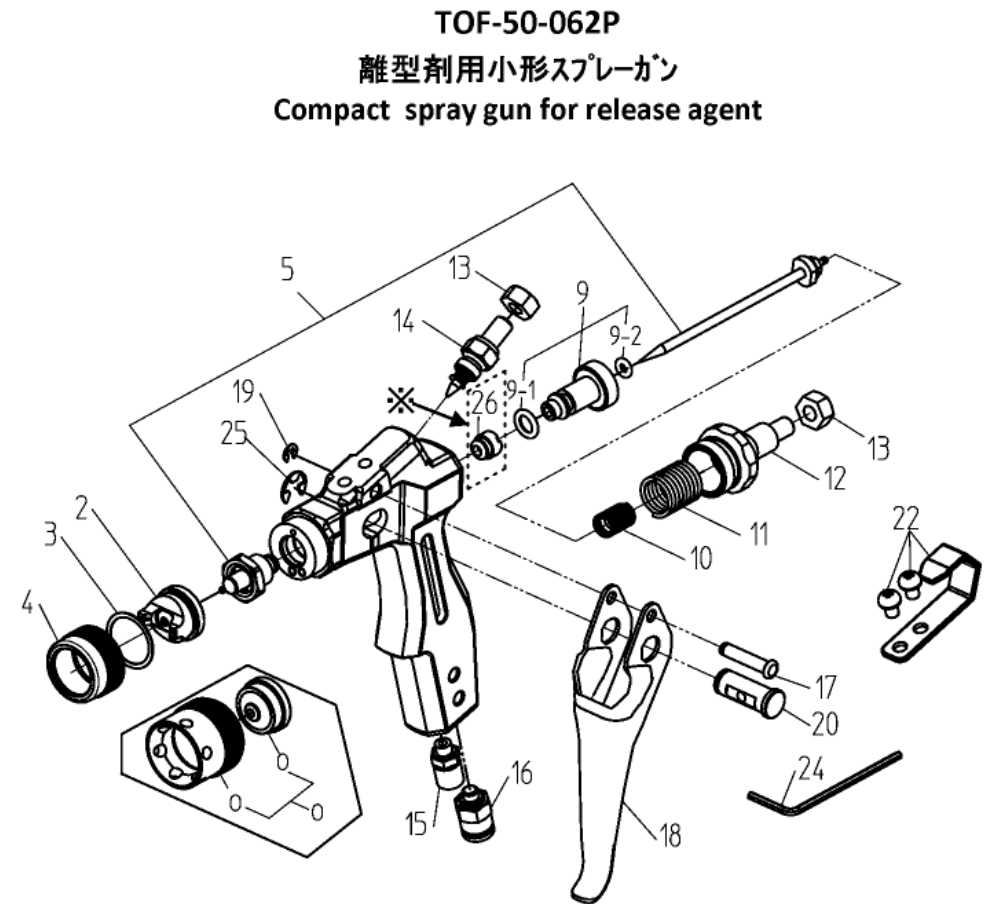

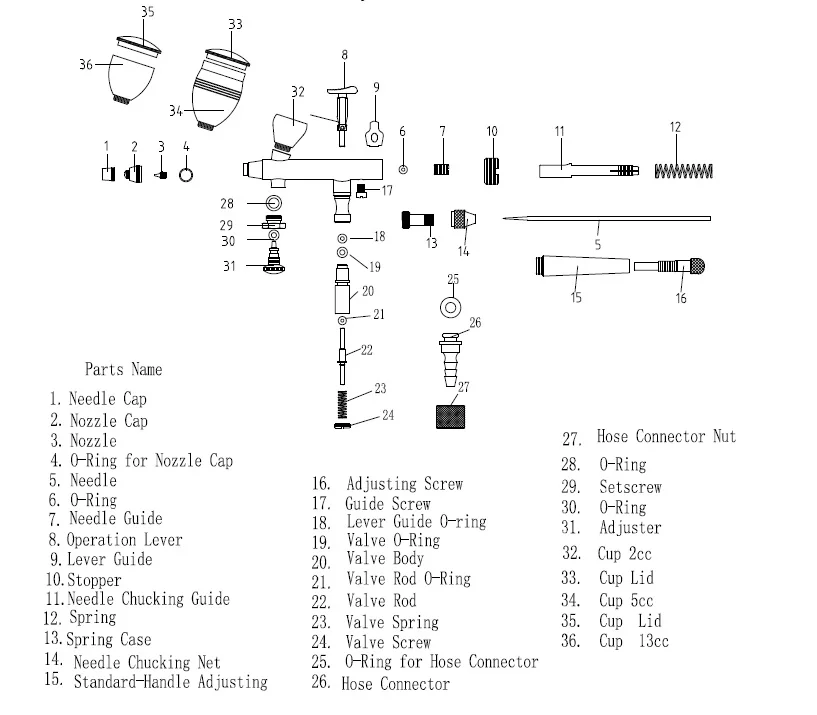

Step-by-Step Disassembly Guide

This section provides a comprehensive walkthrough for disassembling a specific model of an airbrush tool. Understanding the process is essential for maintenance and troubleshooting, ensuring that each component can be accessed and serviced appropriately.

Preparation

- Gather necessary tools, including a small screwdriver and cleaning supplies.

- Find a well-lit workspace to easily see all components.

- Organize a small container to keep screws and small parts safe.

Disassembly Steps

- Begin by removing the nozzle carefully, twisting it counterclockwise.

- Next, detach the needle cap to gain access to the needle.

- Pull out the needle gently; ensure it doesn’t bend or break.

- Unscrew the main body from the grip, taking care not to lose any seals or small parts.

- Finally, separate the trigger mechanism from the assembly for a thorough cleaning.

Follow these steps methodically to ensure a successful disassembly. Remember to take notes or pictures if necessary to aid in reassembly.

Reassembly: Best Practices

Successfully putting together a device after maintenance or repair requires attention to detail and a systematic approach. Following a few key guidelines can enhance the reassembly process, ensuring all components are correctly positioned and function as intended.

Begin by organizing all pieces in a designated area to avoid misplacement. Using a clean, well-lit workspace can greatly aid in visibility and precision. It is also beneficial to refer to any available visual aids or instructions that outline the assembly sequence.

Take your time to inspect each element for wear or damage before reinserting it. When reattaching parts, apply gentle pressure and ensure a snug fit without forcing them together. This will help maintain the integrity of the components and prevent potential issues during operation.

Once reassembly is complete, conduct a thorough check to confirm that everything is securely in place. Testing the device under its intended operating conditions can also help identify any problems that may arise, allowing for timely adjustments.

Essential Tools for Repairs

When it comes to performing maintenance on intricate devices, having the right instruments is crucial. These essential tools facilitate efficient repairs, ensuring that each component functions optimally. Familiarity with the necessary equipment not only streamlines the repair process but also enhances the overall longevity of the equipment.

Basic Repair Instruments

Basic instruments such as precision screwdrivers, pliers, and wrenches form the foundation of any repair toolkit. These items are indispensable for accessing internal mechanisms and making adjustments or replacements. Additionally, a reliable set of tweezers is beneficial for handling small parts with care.

Advanced Repair Equipment

For more complex repairs, specialized tools like a magnifying glass or a soldering iron may be required. A magnifying glass allows for close inspection of minute details, while a soldering iron is essential for reassembling electrical connections. Having these advanced tools on hand can make a significant difference in the effectiveness and efficiency of repairs.

Upgrades for Enhanced Performance

Improving the efficiency and functionality of your airbrush can significantly enhance your overall experience. By integrating advanced components and making thoughtful modifications, users can achieve superior results in their artistic endeavors. This section will explore various upgrades that can elevate performance, ensuring smoother operation and better outcomes.

Key Upgrades to Consider

- Nozzle Replacement: Opt for a high-quality nozzle to improve paint flow and achieve finer detail.

- Needle Upgrade: A more responsive needle can provide better control over paint application.

- Pressure Regulator: Installing a regulator allows for precise control of air pressure, resulting in consistent spray patterns.

Maintenance Tips for Optimal Performance

- Regularly clean all components to prevent clogging and ensure optimal function.

- Lubricate moving parts as needed to maintain smooth operation.

- Inspect seals and gaskets for wear, replacing them promptly to avoid air leaks.

User Experiences and Feedback

This section delves into the various impressions and insights shared by users regarding their interactions with a particular airbrush model. Feedback from users can offer valuable perspectives on performance, usability, and maintenance, contributing to a more comprehensive understanding of the product.

Many individuals highlight the smooth operation and precision of the device, making it suitable for both novice and experienced artists. Users appreciate the ergonomic design, which enhances comfort during extended use, and they often mention the ease of cleaning as a significant advantage. Furthermore, several testimonials emphasize the versatility of the tool, noting its effectiveness in a range of applications, from intricate detailing to broader coverage.

However, some users have expressed concerns regarding the learning curve associated with mastering the airbrush technique. A few have pointed out that achieving optimal results requires practice and patience. Overall, the shared experiences paint a balanced picture, showcasing the strengths and potential challenges of using this airbrush.