The inner workings of a high-quality manufacturing device are essential for achieving precise outcomes in woodworking and metalworking. A thorough grasp of the various components is crucial for both effective operation and maintenance. This section aims to provide an insightful overview of these vital elements, enhancing your overall experience with the equipment.

By exploring the intricate details of each segment, users can appreciate the engineering behind their machinery. Understanding how these components interact not only aids in troubleshooting but also promotes informed upgrades and repairs. The goal is to delve into the specifics, providing clarity and empowering operators to achieve the ultimate performance from their tools.

Whether you’re a novice or a seasoned professional, recognizing the significance of each element fosters confidence in your abilities. An informed user is better equipped to handle challenges, ensuring longevity and efficiency in every task. Let’s embark on this journey to uncover the fundamental building blocks of your device.

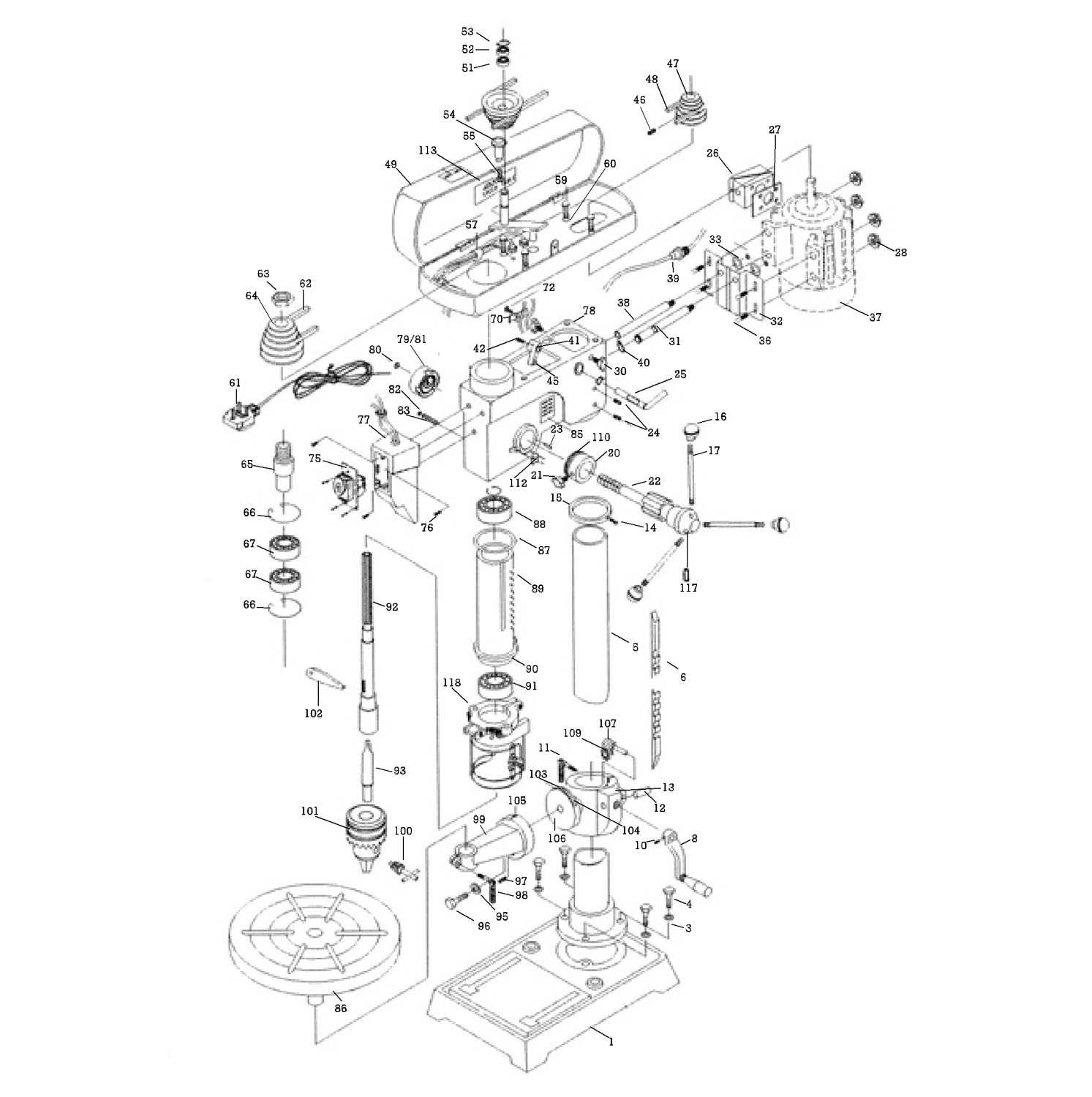

Understanding Jet Drill Press Components

This section aims to explore the essential elements that make up a high-quality tool designed for precision work. By breaking down these key components, users can gain insights into their functionality and how they contribute to overall performance.

Main Elements

- Motor: The powerhouse that drives the mechanism.

- Column: The sturdy vertical structure providing stability.

- Table: The adjustable surface that supports materials during operation.

- Head: Houses the cutting tool and its mechanisms.

Additional Features

- Spindle: Responsible for the rotation of the tool.

- Belt Drive: Transfers power from the motor to the spindle.

- Depth Stop: Ensures precise control over the depth of the cut.

Understanding these components not only enhances operational efficiency but also aids in maintenance and troubleshooting. Delve deeper into each element for a comprehensive grasp of their ultimate significance in tool performance.

Importance of Accurate Parts Identification

Correct identification of components is essential for maintaining efficiency and longevity in machinery. When each element is recognized accurately, it ensures seamless operation and minimizes the risk of errors during assembly or repair.

Benefits of Precise Identification

- Enhances overall performance

- Reduces downtime

- Facilitates easier maintenance

Consequences of Misidentification

- Increased risk of damage

- Higher repair costs

- Compromised safety standards

Ultimately, investing time in accurate component recognition pays off in reliability and functionality, leading to better outcomes in operations.

Common Issues with Drill Press Parts

Understanding frequent challenges associated with machinery components can significantly enhance performance and longevity. Identifying and addressing these common problems ensures a smoother operation and prevents costly repairs.

Wear and Tear

Over time, components may experience deterioration due to consistent use. Lubrication is crucial; inadequate maintenance can lead to friction and eventual failure. Regular inspections help identify these issues early.

Alignment Problems

Misalignment can cause inaccuracies in operation, affecting the quality of work. Proper calibration and adjustment are essential to maintain precision. Users should regularly check settings to ensure optimal functioning.

How to Maintain Your Jet Drill Press

Proper upkeep of your equipment ensures longevity and optimal performance. Regular maintenance can prevent issues and enhance precision, allowing you to achieve your best work consistently.

Regular Inspection

- Check for any loose or damaged components.

- Inspect the motor and belts for wear and tear.

- Ensure all moving parts are properly lubricated.

Cleaning Routine

- Dust and debris should be cleared after each use.

- Use a soft cloth to wipe down surfaces.

- Clean the interior to prevent buildup that may affect performance.

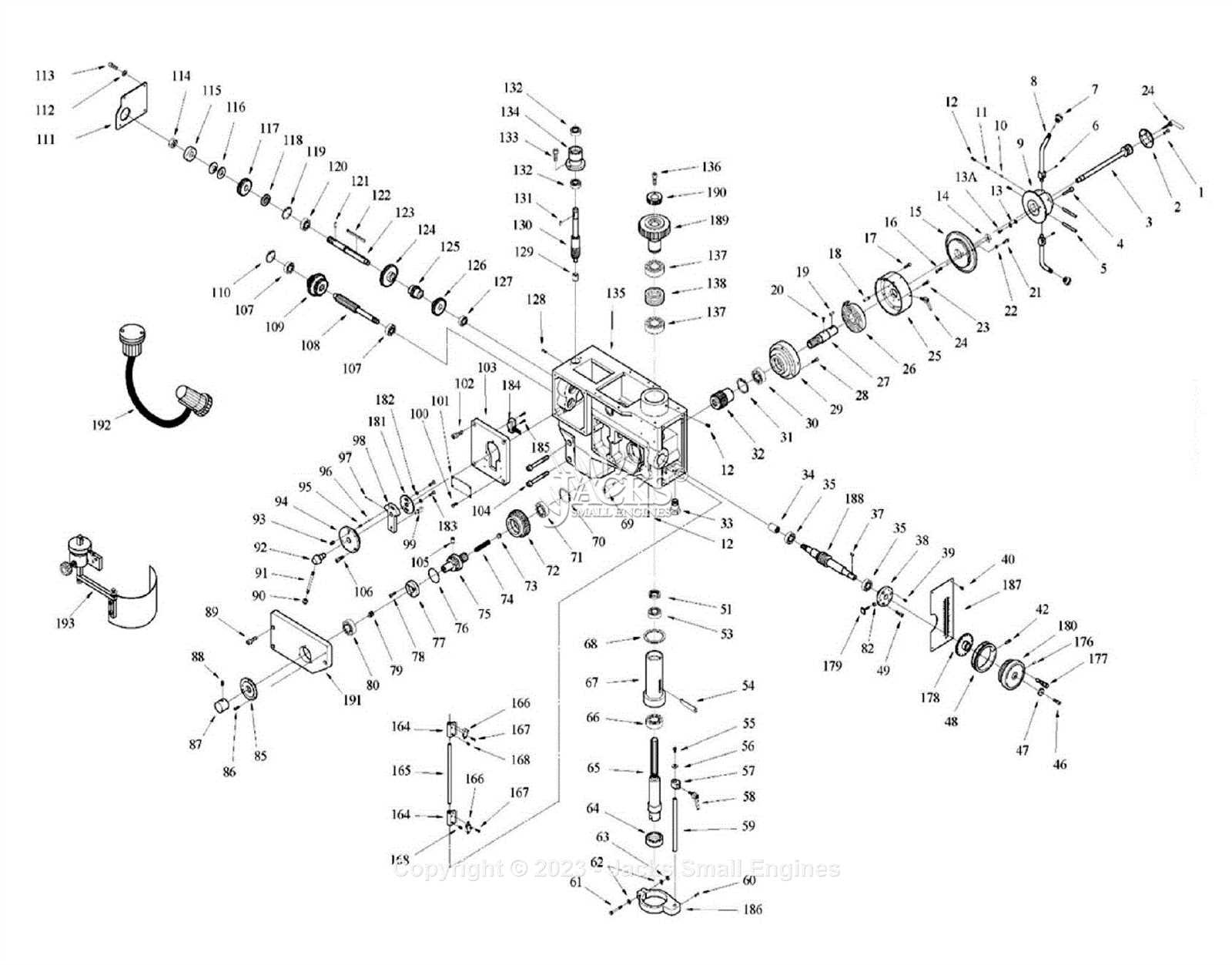

Essential Tools for Repairing Parts

When it comes to restoring machinery, having the right instruments at your disposal can make all the difference. A well-equipped toolkit not only enhances efficiency but also ensures accuracy during repairs. Understanding which tools are essential allows for a smoother workflow and better outcomes.

Key Instruments

- Wrenches

- Screwdrivers

- Pliers

- Socket Sets

- Measuring Tools

Additional Supplies

- Lubricants

- Cleaning Solutions

- Safety Gear

- Replacement Components

- Fasteners

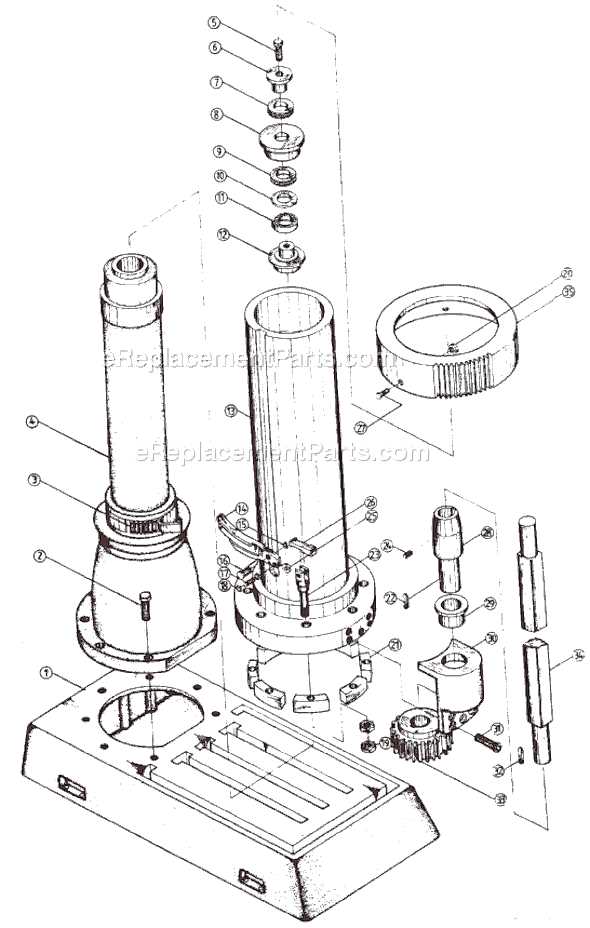

Upgrading Components for Better Performance

Enhancing the effectiveness of your machine can significantly elevate its overall functionality. By investing in high-quality components, users can experience smoother operations, increased precision, and extended lifespan of their equipment. This approach not only optimizes performance but also contributes to a more enjoyable experience in crafting and production tasks.

Choosing Superior Materials

Upgrading to premium materials can drastically improve durability and efficiency. High-grade bearings and pulleys reduce friction, leading to less wear and tear. Additionally, selecting robust housings can protect internal mechanisms from environmental factors, ensuring longevity.

Integrating Advanced Technology

Incorporating modern technology can elevate performance to new heights. Features like variable speed controls and digital displays offer enhanced versatility and accuracy, allowing for tailored adjustments during use. These upgrades can transform standard operations into seamless, efficient workflows.

Exploring Safety Features in Drill Presses

Ensuring user safety is paramount when working with machinery designed for precision tasks. Various mechanisms are integrated into these devices to minimize risks and enhance operational security. Understanding these features is essential for both novice and experienced users.

Emergency Stop Mechanisms

One of the ultimate safety features includes emergency stop buttons that immediately halt operations. These buttons are strategically placed for quick access, allowing users to respond swiftly in critical situations. Incorporating such mechanisms significantly reduces the chance of accidents.

Protective Shields and Guards

Another vital component is the presence of protective shields and guards that cover moving parts. These barriers not only prevent accidental contact with rotating elements but also safeguard against debris. Users are encouraged to regularly check these components to ensure they are intact and functional.

Comparing Jet Drill Press Models

This section explores the various models available in the realm of precision boring equipment, focusing on their unique features, specifications, and intended applications. Understanding these differences is crucial for users seeking to make informed choices based on their specific needs.

Key Features to Consider

When evaluating different models, it’s essential to assess factors such as power capacity, speed settings, and build quality. Higher power options may provide better performance for tougher materials, while variable speed settings offer versatility for various tasks.

Target Audience and Applications

Each model caters to different user needs, from hobbyists to professionals. Lightweight options are ideal for casual users, whereas heavy-duty variants are designed for industrial applications, ensuring optimal performance under demanding conditions.

Replacing Worn Out Parts Effectively

Ensuring optimal functionality of machinery often requires addressing components that have degraded over time. Recognizing the signs of wear and taking proactive measures can enhance performance and extend the lifespan of your equipment.

Identifying Signs of Wear

- Unusual noises during operation

- Inconsistent performance or results

- Visible damage or corrosion on components

- Difficulty in moving parts smoothly

Steps for Effective Replacement

- Consult the manufacturer’s guidelines for specific instructions.

- Gather necessary tools and replacement components.

- Carefully disassemble the affected areas.

- Replace old components with new ones, ensuring proper alignment.

- Reassemble and test the machinery to verify functionality.

Assembly Tips for DIY Enthusiasts

Building your own tools can be an exciting venture that enhances both your skills and workspace. To ensure a smooth assembly process, it’s crucial to approach the task with careful planning and attention to detail. This section provides practical advice that will help you navigate the assembly with confidence.

1. Organize Your Workspace: Start by creating a clean and well-lit area for your project. Gather all necessary components and tools before you begin. This will prevent unnecessary interruptions and keep your focus sharp.

2. Read the Instructions Thoroughly: Take the time to review the assembly manual from start to finish. Familiarize yourself with the terminology and layout, as this will aid in understanding how each component fits together.

3. Use Quality Tools: Employing the right tools not only makes the process easier but also ensures a more precise assembly. Invest in reliable equipment that can handle the specifications of your project.

4. Take Your Time: Rushing through the assembly can lead to mistakes. Allocate sufficient time to complete the project, allowing for breaks when needed. Patience will pay off in the long run.

5. Seek Assistance if Needed: If you encounter challenges during assembly, don’t hesitate to ask for help. Collaborating with a friend or seeking advice from experienced individuals can provide valuable insights.

6. Test for Stability: After assembling, check the stability and alignment of your creation. Make any necessary adjustments before putting it to use, ensuring that it operates safely and efficiently.

By following these guidelines, you can enhance your assembly experience and create a functional tool that meets your needs. Embrace the process, and enjoy the satisfaction that comes from building something with your own hands.

Where to Find Replacement Parts Online

When equipment malfunctions, sourcing the right components becomes crucial for restoration. The internet offers a plethora of platforms to locate high-quality replacements, ensuring your machinery operates efficiently once more.

Official Manufacturer Websites

Many manufacturers maintain official websites where users can browse and purchase authentic components directly. This guarantees compatibility and often provides helpful resources for installation.

Third-Party Retailers

Numerous online retailers specialize in tools and machinery accessories. Websites like Amazon or specialized tool shops often feature user reviews, aiding in the selection of the right items. Be sure to verify compatibility before purchasing.