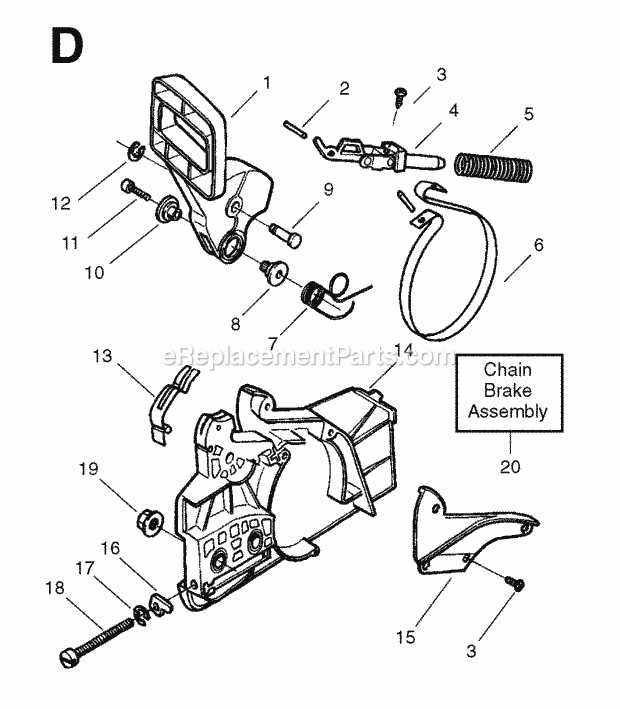

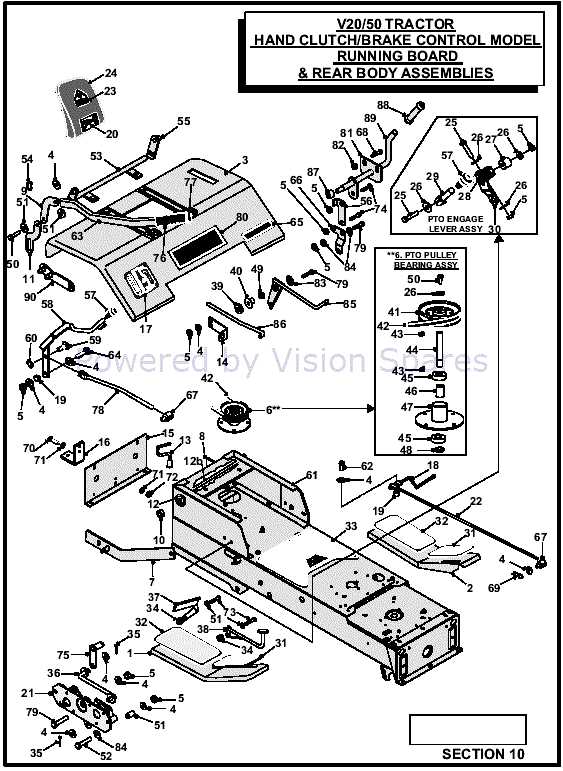

Understanding how individual elements come together to create a seamless mechanism is essential for both maintenance and repair. Blueprints that showcase the inner structure of machinery allow users to easily navigate its assembly and identify essential elements for smooth operation.

Detailed visual references help enthusiasts and technicians alike by providing clear insight into the internal configuration of complex equipment. These resources serve as valuable tools, offering a step-by-step breakdown of the layout and connections between smaller elements.

Whether you’re troubleshooting an issue or planning routine maintenance, comprehensive structural maps ensure that every

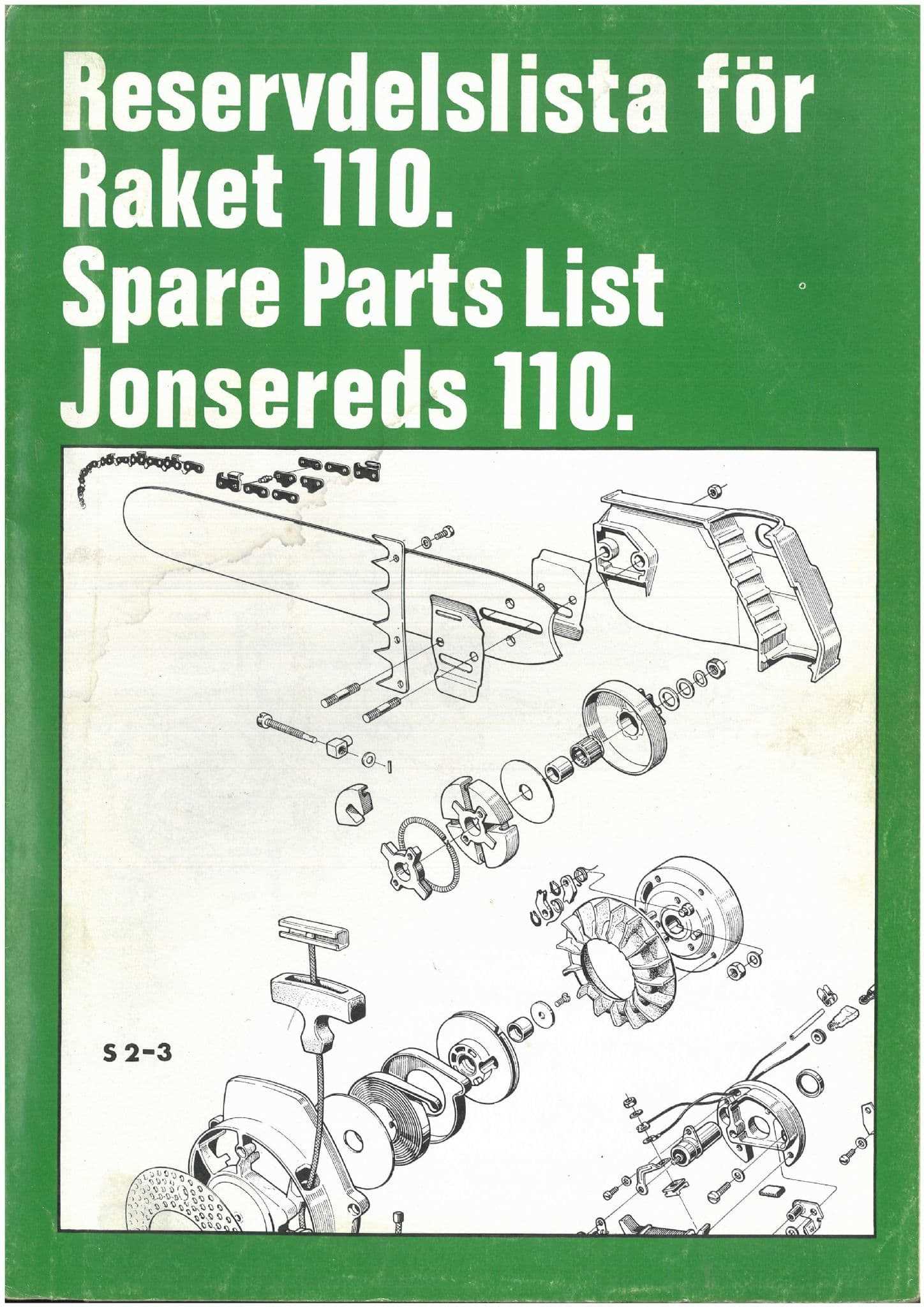

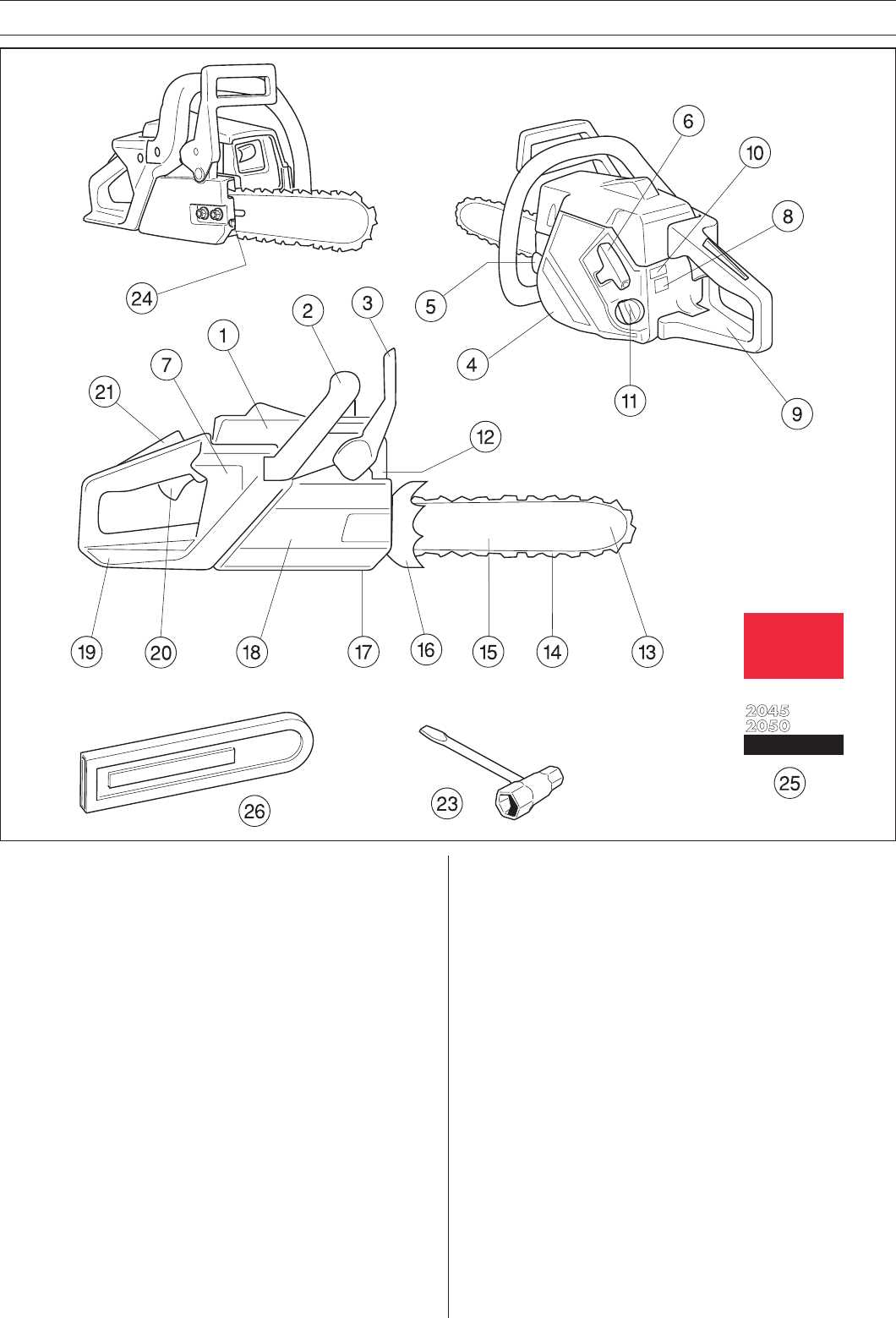

Jonsered 2050 Parts Diagram

Understanding the internal structure and components of machinery is essential for maintaining peak performance. A detailed illustration helps users identify individual elements and their placement, ensuring correct assembly and smooth operation.

Visual references are especially valuable during repairs and maintenance. They guide users in locating specific components, such as connectors, fasteners, and moving parts, reducing errors during reassembly.

An organized layout showing the interconnection of elements also aids in troubleshooting. Spotting potential issues,

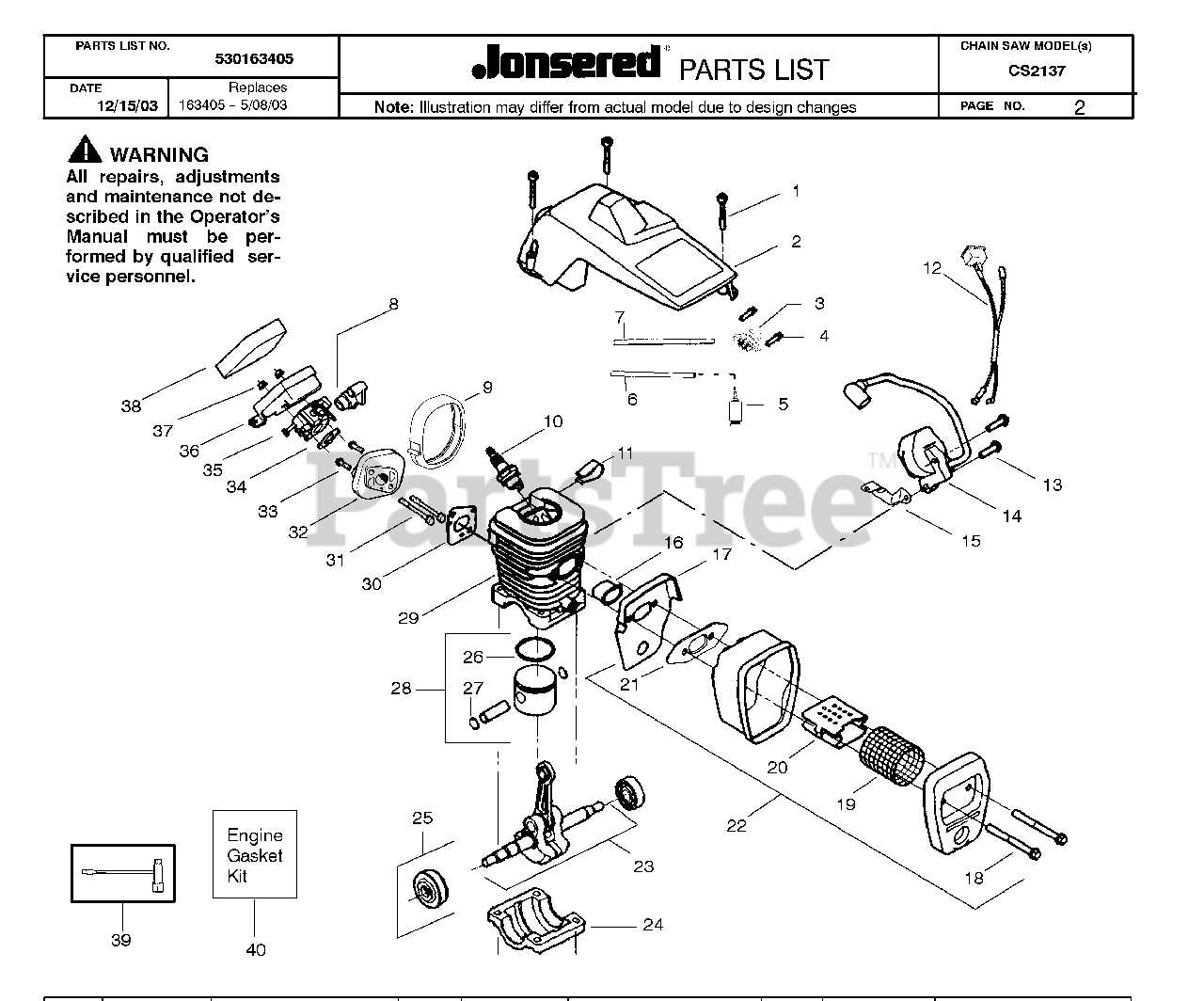

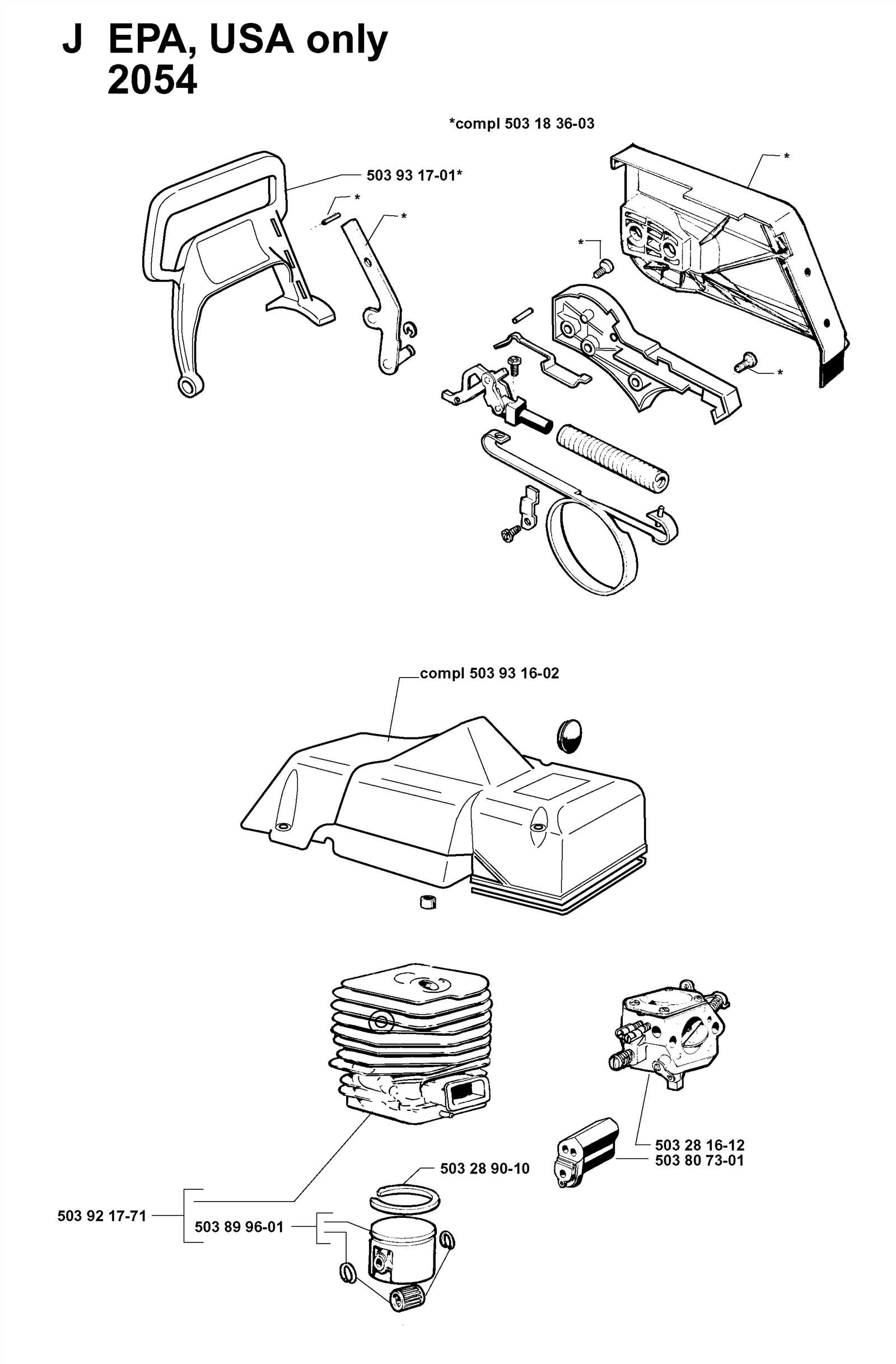

Engine Components Breakdown

An engine relies on a range of interconnected components to function effectively, each playing a critical role in maintaining performance and durability. Understanding these elements helps in troubleshooting issues, conducting maintenance, and ensuring smooth operation over time.

Cylinder and Piston Assembly

The cylinder houses the piston, which moves up and down to generate power. The interaction between the two must be precise to prevent compression loss and ensure efficient fuel combustion. Regular inspections are essential to detect signs of wear or scoring on these parts.

Ignition and Fuel Systems

A reliable ignition system sparks

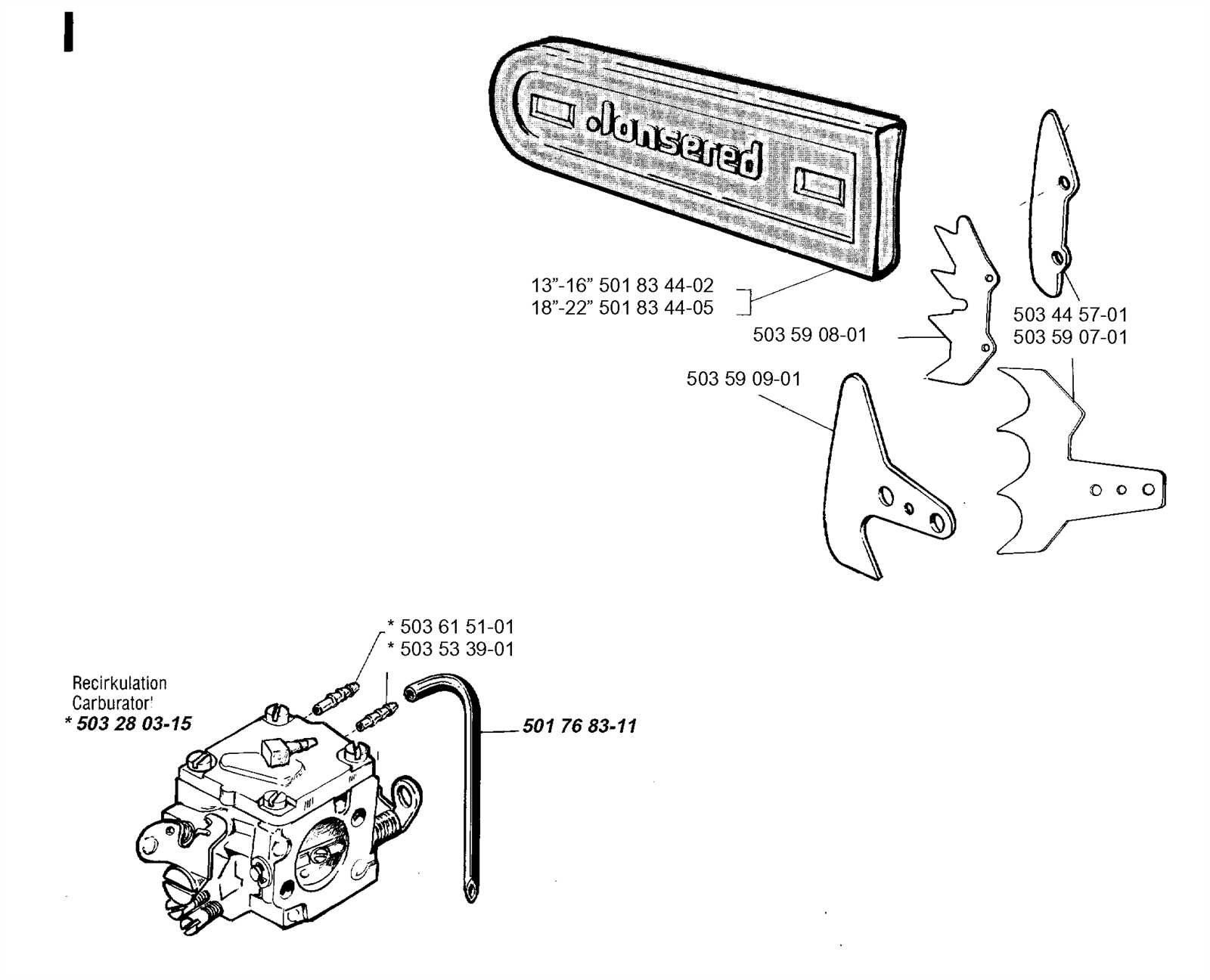

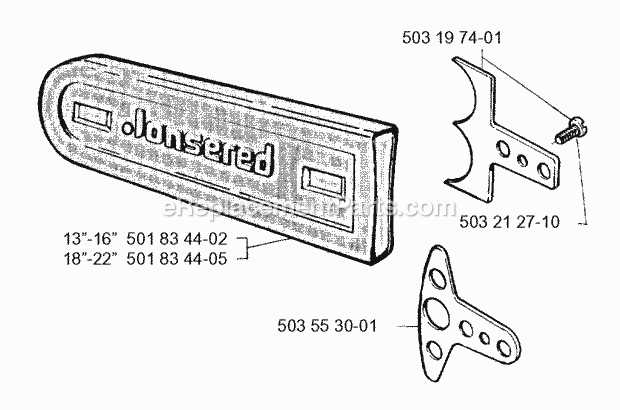

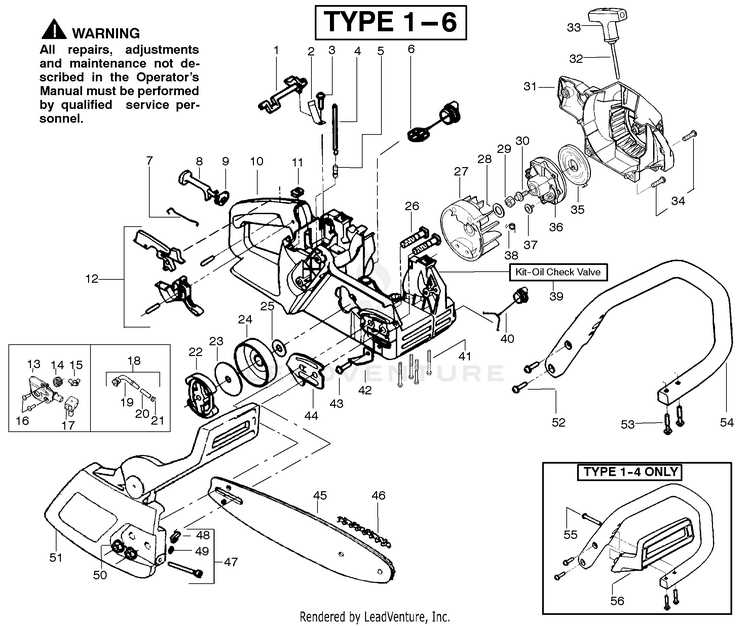

Chainsaw Chain and Bar Setup

Proper alignment and maintenance of the chain and bar are essential for smooth and efficient operation of any chainsaw. Ensuring the right fit between these components not only enhances performance but also extends the lifespan of the tool. Understanding how to correctly assemble and maintain them helps prevent wear and ensures safe usage.

| Component | Description | Maintenance Tips | ||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Chain | A series of interconnected links designed to cut through wood efficiently. | Keep the chain sharp and properly tensioned to avoid slippage. | ||||||||||||||||||||||||||||||||||||

| Bar | The metal guide that holds the chain in place during operation. | Clean the bar regularly and check for wear on the rails

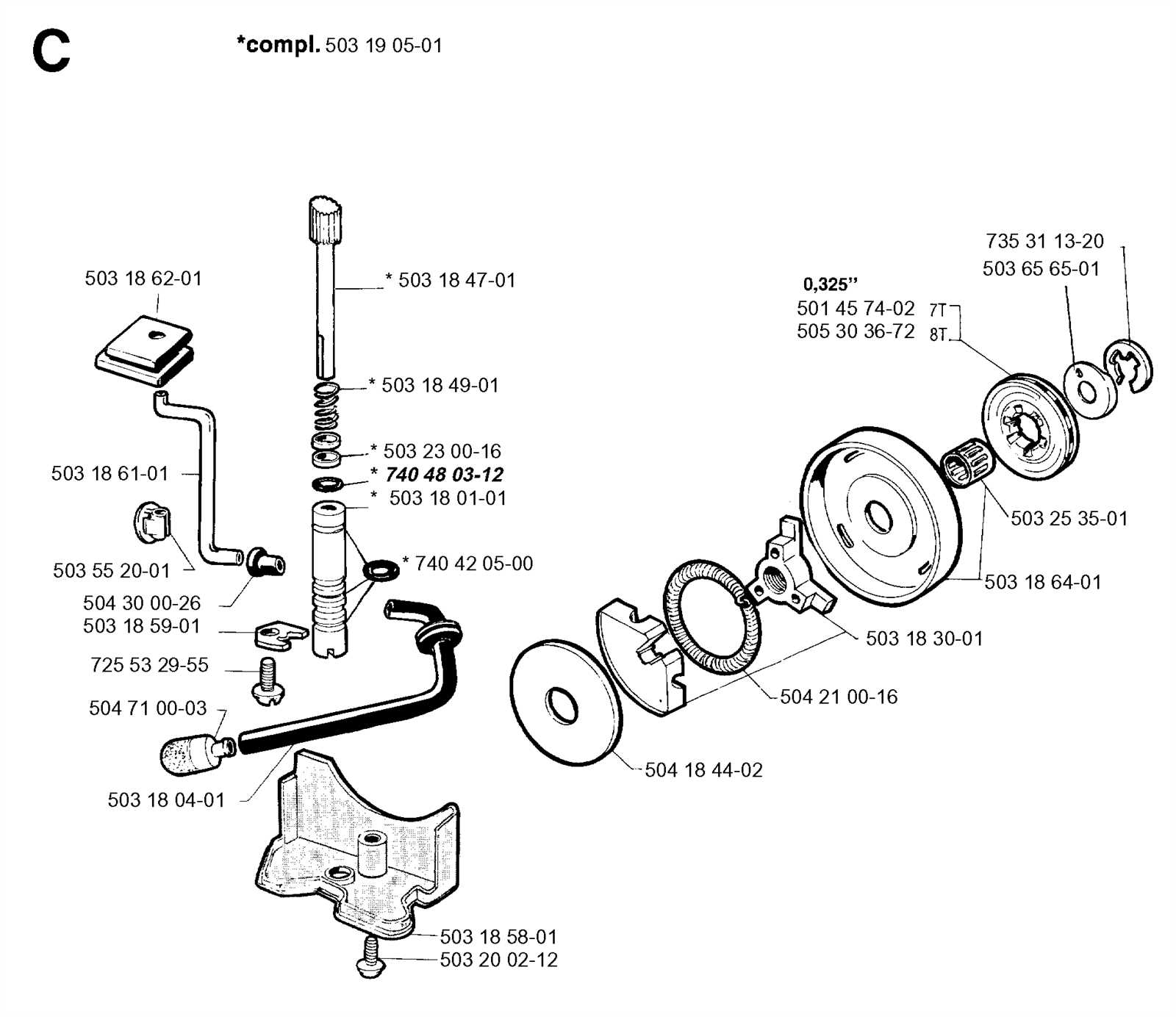

Fuel and Oil System OverviewThe fuel and lubrication systems are essential components ensuring the smooth operation and longevity of small engines. Their primary function is to deliver the correct mixture of fuel and oil to the motor, maintaining performance under various conditions. Proper maintenance of these systems can prevent common mechanical issues and extend the engine’s lifespan.

Each of these components plays a vital role in ensuring that the handle assembly functions effectively while providing comfort and safety during operation. Clutch Mechanism and Drive System

The clutch mechanism plays a vital role in the functioning of various machinery, enabling the effective transfer of power from the engine to the drive system. This component ensures that the system operates smoothly by allowing the operator to engage or disengage power transmission as needed. Key elements of the clutch mechanism include:

The drive system, in conjunction with the clutch, is responsible for the overall movement and functionality of the machinery. It comprises several crucial components:

Understanding the clutch mechanism and drive system’s intricacies is essential for maintenance and troubleshooting, ensuring optimal performance of the equipment. Starter Assembly ComponentsThe starter assembly is crucial for initiating the operation of various machinery. Understanding its components can enhance maintenance and troubleshooting efforts. Each part plays a vital role in ensuring the smooth engagement and disengagement of the engine, contributing to overall performance and reliability. Key elements of the starter assembly typically include the starter motor, which converts electrical energy into mechanical motion, and the flywheel, which allows the motor to engage with the engine. Additionally, the ignition switch serves as the primary control mechanism, enabling the operator to activate the system easily. Other important parts are the solenoid, responsible for the electrical connection, and the starter gear, which interacts directly with the flywheel. Proper inspection and maintenance of these components are essential to ensure optimal functionality and prevent potential failures. Regular checks can help identify wear or damage early, enabling timely replacements and prolonging the lifespan of the machinery. Muffler and Exhaust Layout

The configuration of the silencer and exhaust system plays a crucial role in the overall performance of the engine. Properly designed layouts enhance efficiency and reduce noise, ensuring a smoother operation. Understanding the arrangement of these components is essential for effective maintenance and troubleshooting. The exhaust system typically consists of several key elements:

Each of these parts contributes to the system’s efficiency and functionality. Regular inspections can help identify potential issues before they escalate, promoting longevity and optimal performance. Replacement Part Identification

Identifying the correct components for maintenance and repair tasks is essential for ensuring the optimal performance of your equipment. This process involves recognizing various elements and their specifications, which can aid in sourcing suitable replacements efficiently. To facilitate the identification of necessary components, consider the following guidelines:

By following these steps, you can streamline the process of locating appropriate substitutes, ensuring that your machinery operates smoothly and effectively. Troubleshooting Common Part Issues

When working with machinery, identifying and resolving frequent component-related problems is essential for maintaining optimal performance. Various factors can contribute to malfunctions, ranging from wear and tear to improper assembly. Understanding these common issues can help users effectively diagnose and rectify them, ensuring the equipment operates smoothly. Identifying Symptoms

Recognizing the signs of potential failures is the first step in troubleshooting. Common indicators may include unusual noises, decreased efficiency, or visible damage to components. Users should pay attention to these symptoms to determine which areas require inspection. Common Issues and Solutions

|