When it comes to maintaining outdoor tools, having a clear visual guide to the essential elements is invaluable. These illustrations serve as a map to better navigate the internal workings and ensure each piece is in proper condition. Whether you’re handling a small repair or a full overhaul, knowing where each element belongs can save both time and effort.

Diagrams of various machinery are especially useful for those who prefer doing repairs themselves. These visual breakdowns help users quickly identify the necessary elements and ensure proper reassembly. With the right knowledge, even complex machinery becomes manageable.

Furthermore, keeping these visual guides on hand can help in sourcing the correct replacements, ensuring long-term durability and proper functioning. Correct identification is the first step toward ensuring the continued performance of your equipment.

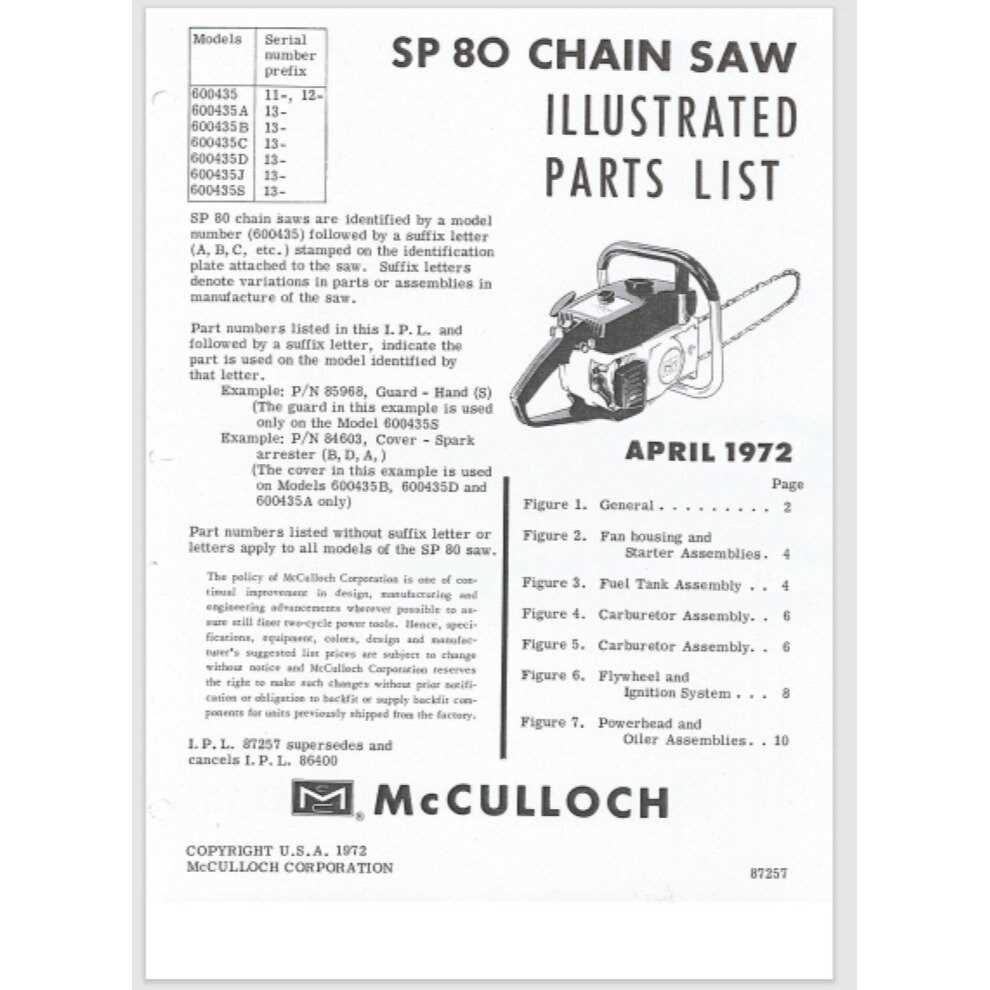

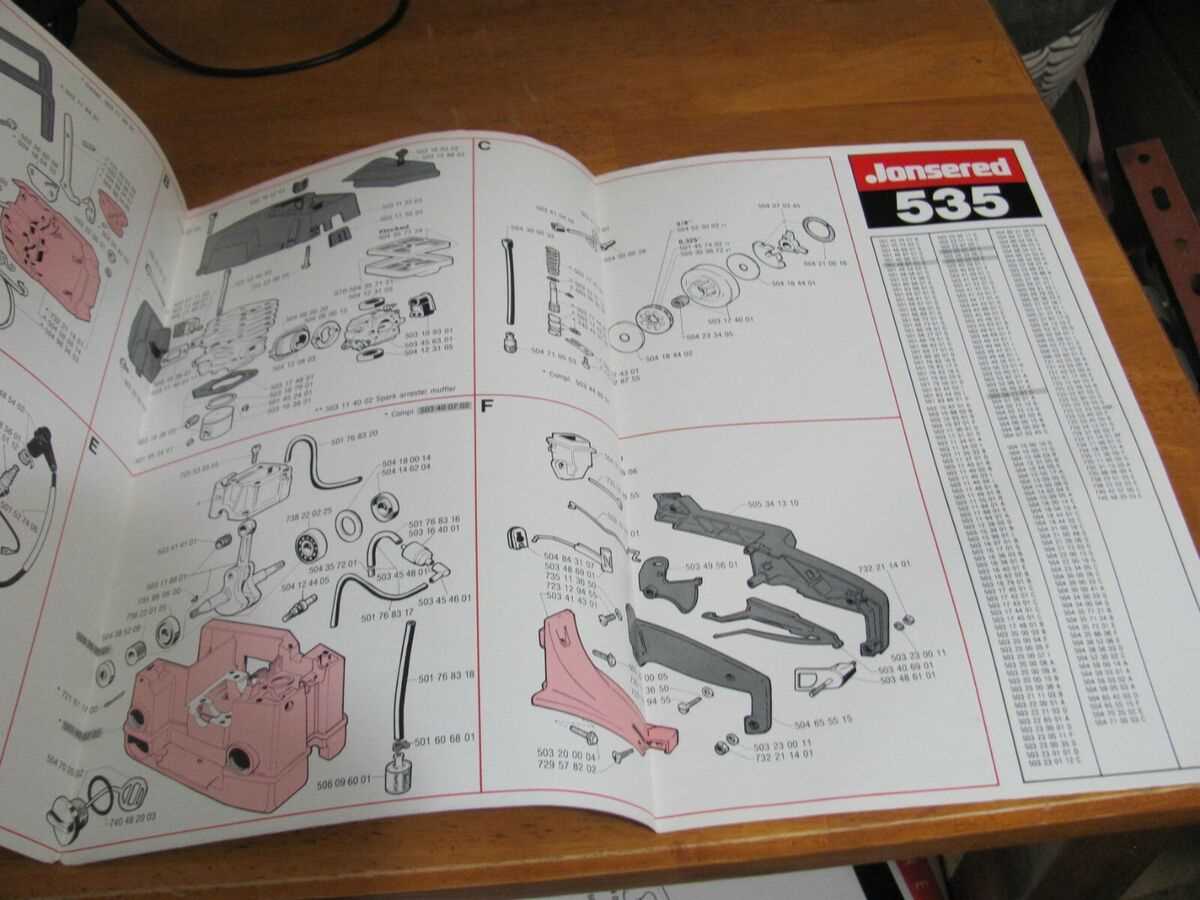

Overview of Jonsered 535 Chainsaw Components

The chainsaw is a complex tool composed of multiple interconnected elements designed to ensure efficiency, power, and safety during operation. Understanding the key components is essential for proper maintenance and performance optimization. This guide provides a detailed look into the main structural and functional elements, highlighting their roles and importance.

Engine Unit: At the core of the machine lies the motor, which converts fuel into mechanical energy. This component is responsible for driving the entire system and requires regular attention to maintain smooth operation.

Cutting Mechanism: The cutting blade is designed to handle tough materials. It operates at high speeds, and its sharp teeth allow precise and efficient cutting, making it one of the most critical components of the machine.

Fuel and Oil Systems: These are crucial for providing the necessary lubrication and energy supply. The fuel system powers the motor, while the oil system ensures that the cutting mechanism operates without excessive friction or wear.

Handle and Safety Features: These are designed to offer comfort and control, allowing the operator to maintain a steady grip and prevent accidents. Advanced safety mechanisms, such as chain brakes and throttle locks, are integrated to enhance user protection.

Proper maintenance and understanding of each component ensure the longevity and reliability of the equipment, keeping it running smoothly and safely for a long time.

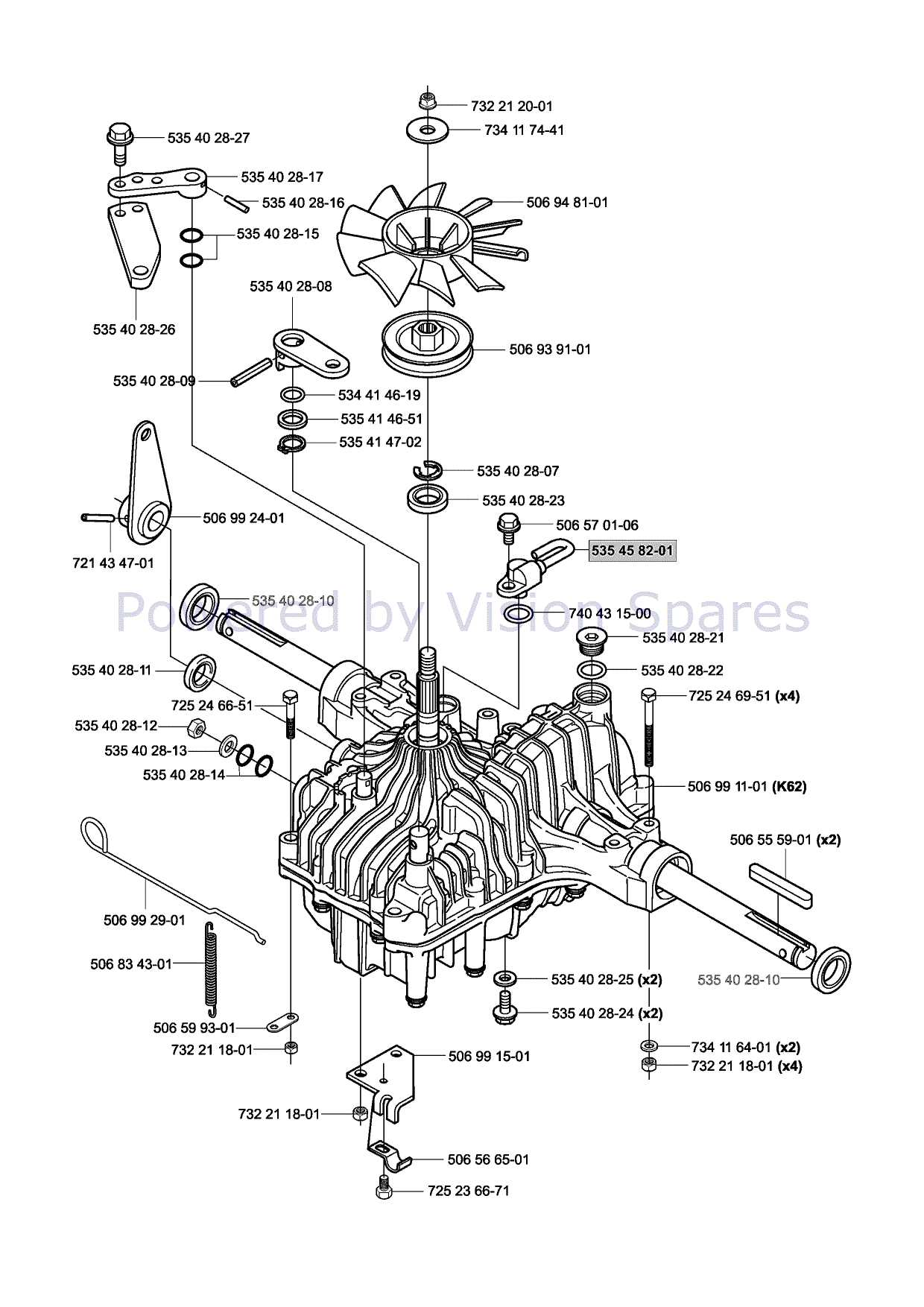

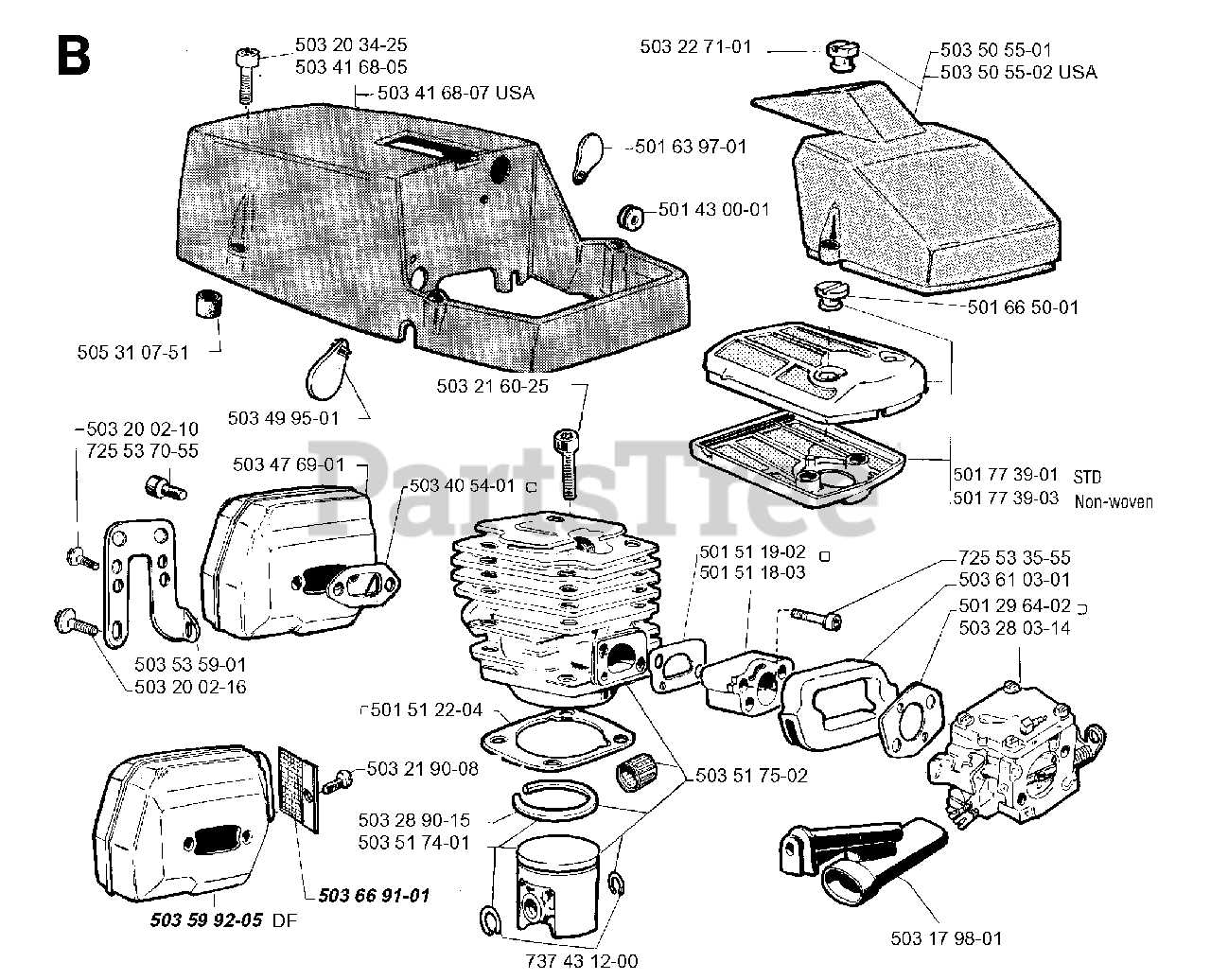

Detailed Breakdown of the Jonsered 535 Engine Parts

The internal structure of this powerful chainsaw features a range of essential mechanical elements that work together to deliver optimal performance. Understanding the individual components of the engine is crucial for maintenance, repair, and enhancing the lifespan of the machine. Below, we will explore the key elements that ensure smooth operation and reliability.

- Cylinder Assembly: This core part houses the combustion process, where fuel is ignited to drive the engine. It must be well-maintained to prevent wear and tear from affecting performance.

- Piston and Rings: The piston, combined with rings, ensures efficient movement within the cylinder, converting combustion energy into mechanical motion. Regular inspection helps maintain compression and power output.

- Crankshaft: The crankshaft is responsible for converting the linear motion of the piston into rotational force, which drives the chain and other systems.

- Carburetor: This component mixes air and fuel in the correct proportions to ensure the engine runs smoothly under various conditions. Proper tuning is essential for efficiency.

- Ignition System: Comprising the flywheel and spark plug, this system initiates the combustion process by delivering the necessary spark at the right moment.

- Exhaust System: Responsible for expelling gases produced during combustion, the exhaust must remain unobstructed to prevent loss of power and overheating.

Regular checks and maintenance of these critical elements will ensure the engine operates efficiently, reducing the likelihood of breakdowns and extending the overall lifespan of the machine.

Understanding the Fuel System in Jonsered 535

The fuel system plays a crucial role in ensuring efficient performance by delivering the necessary fuel mixture to the engine. A well-functioning setup is key to maintaining optimal combustion and power output, especially in demanding environments. Understanding how each component interacts and supports the overall operation can help in diagnosing issues and performing regular maintenance.

Main Components of the Fuel Delivery Mechanism

The primary elements of the system include the carburetor, fuel lines, and the fuel filter. The carburetor is responsible for mixing air and fuel in precise proportions to meet the engine’s needs. Fuel lines carry the mixture from the tank to the carburetor, while the filter prevents debris from entering, ensuring clean fuel flow.

Common Issues and Maintenance Tips

Regular maintenance of these components is essential to avoid potential problems. Over time, fuel filters can become clogged, leading to poor performance or even engine failure. Cracked fuel lines may cause leaks, reducing the efficiency of the system. Cleaning or replacing parts as needed ensures smooth operation and extends the lifespan of the engine.

Guide to Replacing Chain Assembly

Replacing the chain on a chainsaw is an essential part of its maintenance. A well-maintained chain ensures efficient cutting and prolongs the lifespan of the tool. Whether you’re dealing with a worn-out chain or simply upgrading for better performance, following the correct steps for replacement is crucial for both safety and optimal operation.

Step-by-Step Process for Chain Replacement

- First, ensure the tool is completely powered off and placed on a stable surface.

- Use the appropriate tool to remove the side cover, exposing the guide bar and chain.

- Carefully release the tensioner to loosen the current chain. Slide the chain off the guide bar and sprocket.

- Place the new chain around the sprocket, ensuring the teeth face the correct cutting direction.

- Reattach the guide bar and ensure the chain fits snugly within the groove.

- Adjust the tensioner to provide the correct tightness for smooth operation, but avoid overtightening.

- Replace the side cover and securely tighten all screws.

Tips for Chain Maintenance

- Regularly check the tension of the chain to avoid slippage or damage.

- Ensure proper lubrication to reduce friction and wear during operation.

- Inspect the guide bar for signs of uneven wear and replace if necessary.

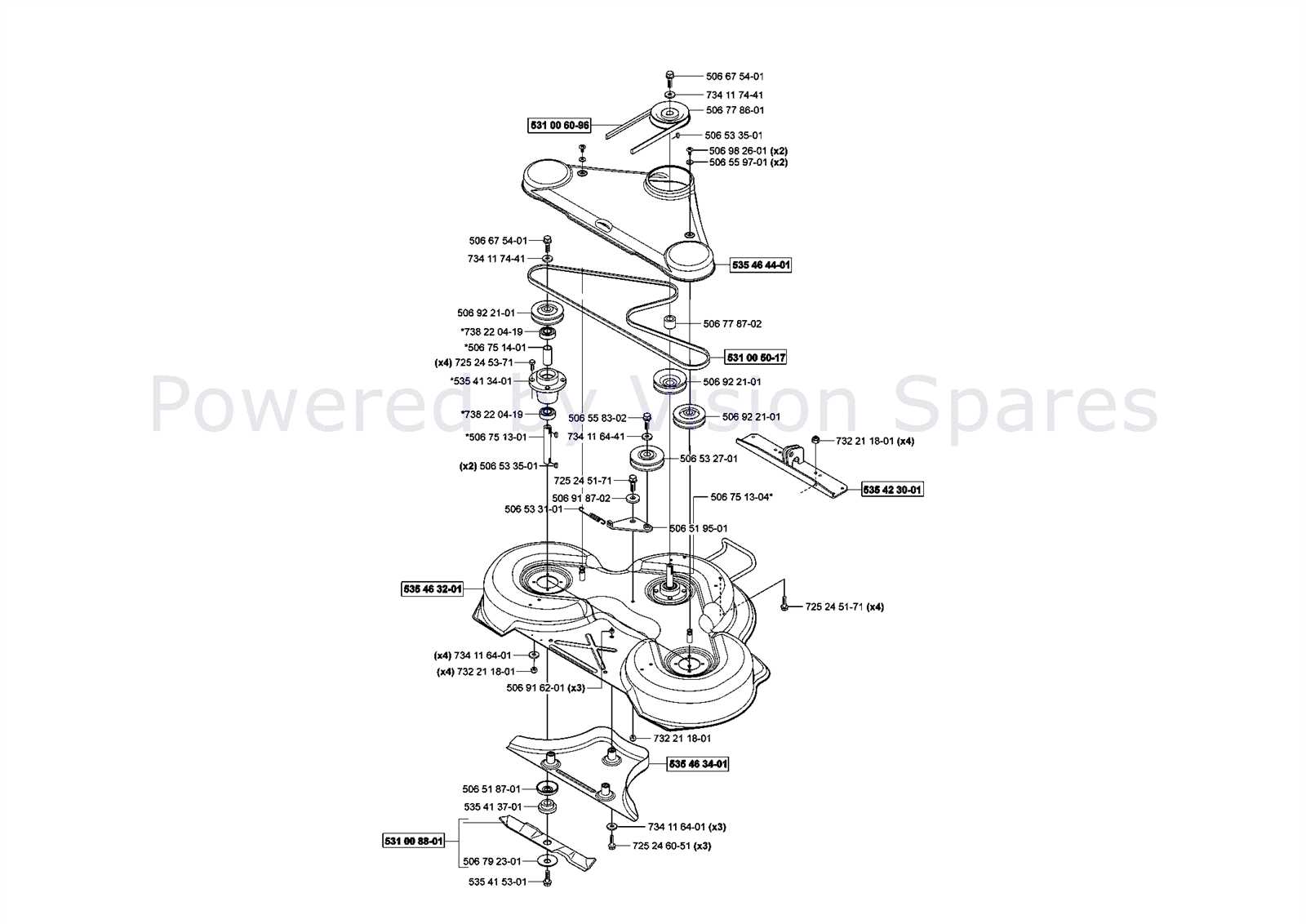

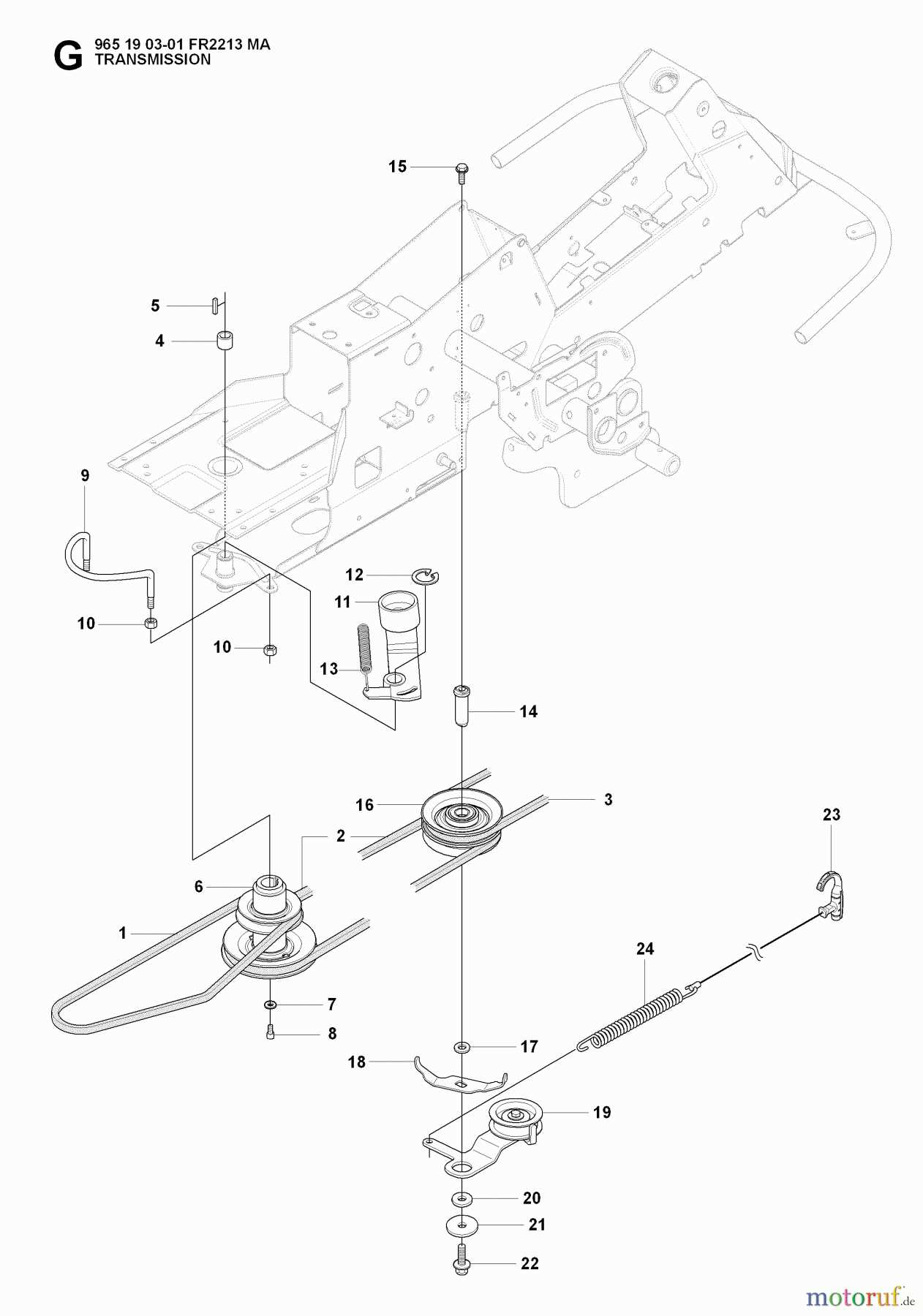

Clutch and Drive Mechanism Explained

The clutch and drive system is essential for transferring power from the engine to the cutting components, ensuring smooth operation and control. This section provides an overview of how these components work together to manage engine power and deliver it efficiently to the cutting chain. Understanding this mechanism is key to maintaining optimal performance and preventing wear on critical parts.

Clutch Functionality: The clutch engages and disengages based on engine speed, allowing the cutting tool to spin when necessary and remain idle when not in use. This automatic regulation helps prevent damage by controlling the transfer of power at the correct moments.

Drive System: Once the clutch is engaged, the drive system takes over, sending energy through the chain or belt to the cutting tool. Proper alignment and tension in this system are crucial for reliable operation and long-term durability of the tool.

Regular maintenance of both systems is essential to avoid unnecessary breakdowns. Proper lubrication, tension adjustments, and part replacements will ensure that the tool performs efficiently under various operating conditions.

Maintenance of the Air Filter on Jonsered 535

Proper upkeep of the air filtration system is crucial for ensuring optimal performance and longevity of your equipment. Regular maintenance not only enhances efficiency but also helps prevent engine wear and tear. This section provides essential guidance on how to care for the air filter effectively.

Importance of a Clean Air Filter

A clean air filter plays a vital role in protecting the engine by preventing dirt and debris from entering. Here are some key benefits:

- Improved airflow and engine performance

- Better fuel efficiency

- Reduced risk of engine damage

Maintenance Steps

Follow these steps to maintain the air filtration system:

- Inspection: Regularly check the air filter for dirt and damage. Replace if necessary.

- Cleaning: If the filter is reusable, clean it with compressed air or a suitable cleaner.

- Replacement: Change the filter according to the manufacturer’s recommendations or if it’s visibly dirty.

- Installation: Ensure the new or cleaned filter is properly installed, sealing it against dirt ingress.

By following these maintenance tips, you can ensure that the air filter remains effective, contributing to the overall health and performance of your equipment.

Exploring the Ignition System on Jonsered 535

The ignition system plays a crucial role in the performance and reliability of outdoor power equipment. Understanding its components and functionality can significantly enhance maintenance practices and troubleshooting efforts. This section delves into the various elements of the ignition mechanism, providing insights into their operations and importance.

Key components of the ignition assembly include:

- Ignition Coil: This component transforms the battery’s low voltage into a high voltage, necessary for creating a spark at the spark plug.

- Spark Plug: A vital element that ignites the air-fuel mixture, ensuring the engine runs smoothly.

- Flywheel Magnet: Responsible for generating the magnetic field that powers the ignition coil.

- Control Module: Manages the timing and intensity of the spark, optimizing engine performance.

Each of these parts works in tandem to ensure the engine starts effectively and operates efficiently. Regular checks and maintenance of these components can prevent common ignition issues such as hard starting or misfiring.

To maintain optimal performance, consider the following tips:

- Inspect the ignition coil for signs of wear or damage.

- Replace the spark plug regularly to avoid misfires.

- Ensure the flywheel magnet is clean and free from debris.

- Check the connections and wiring for any signs of corrosion or fraying.

By understanding and caring for the ignition system, users can significantly extend the life of their equipment and improve its reliability during operation.

Jonsered 535 Carburetor: Adjustment and Replacement Tips

The carburetor plays a crucial role in the performance of any small engine, ensuring the right mix of air and fuel for efficient combustion. Proper tuning and timely replacement of this component can significantly enhance the functionality and longevity of your machine. This section provides valuable insights into adjusting and replacing the carburetor to keep your equipment running smoothly.

Adjustment: To achieve optimal performance, regular adjustments are necessary. Start by inspecting the air filter; a clean filter promotes better airflow. Next, locate the adjustment screws–usually labeled as the idle and mixture screws. Turn the idle screw clockwise to increase the engine speed or counterclockwise to decrease it. For the mixture screw, a good starting point is to set it at 1.5 turns out from the seated position, then fine-tune based on engine response. Always listen for a steady engine sound while making these adjustments.

Replacement: If the carburetor shows signs of wear or damage, replacement may be the best option. Begin by disconnecting the fuel line and removing the mounting screws that secure the carburetor to the engine. Carefully detach any linkages connected to the throttle and choke. When installing the new unit, ensure all gaskets are intact to prevent leaks. Reconnect the fuel line and adjust the new carburetor according to the previous guidelines to ensure proper operation.

Maintenance: Regular maintenance is key to prolonging the life of the carburetor. Clean it periodically to prevent the buildup of dirt and debris, which can hinder performance. Use carburetor cleaner and a soft brush to gently remove any deposits. Additionally, always use fresh fuel mixed at the recommended ratio to prevent clogging and ensure smooth operation.

Exhaust System and Muffler Parts for Jonsered 535

The exhaust system plays a crucial role in the overall performance and efficiency of small engines. It is responsible for directing exhaust gases away from the engine, minimizing noise, and ensuring optimal operation. Understanding the components involved in this system can aid in maintenance and repairs, enhancing the longevity and functionality of the equipment.

Key Components of the Exhaust System

The primary components of the exhaust assembly include the exhaust manifold, which collects gases from the engine cylinders, and the muffler, designed to reduce noise levels. Additionally, the exhaust pipe is essential for directing these gases away from the engine. Each element must be in good condition to prevent leaks and ensure proper function.

Muffler Functionality and Maintenance

The muffler is critical in controlling engine noise and can significantly influence the performance of the machine. Regular inspection for rust, damage, or blockages is vital. If the muffler is not functioning optimally, it may lead to increased noise levels or reduced engine efficiency. Replacing worn-out components promptly ensures that the engine operates smoothly and quietly.

Troubleshooting Common Issues with Jonsered 535 Parts

When working with outdoor equipment, it’s not uncommon to encounter various challenges that can hinder performance. Understanding how to diagnose and resolve these issues can greatly enhance the efficiency and longevity of your machine. This section focuses on typical problems users face and provides helpful insights on how to address them effectively.

1. Engine Fails to Start: One of the most common issues is a failure to start the engine. This can result from a drained battery, stale fuel, or a clogged air filter. Check the battery for adequate charge, replace any old fuel, and ensure the air intake is clear to improve the chances of ignition.

2. Poor Cutting Performance: If the cutting tool struggles to perform effectively, inspect the sharpness of the blade. Dull blades can significantly reduce cutting efficiency. Additionally, examine the tension and alignment of the cutting components to ensure they are properly configured.

3. Overheating: Overheating can lead to severe damage if not addressed promptly. Regularly clean any debris from the cooling vents and ensure the lubrication system is functioning correctly. Insufficient oil levels can contribute to excessive heat, so always check and maintain appropriate fluid levels.

4. Excessive Vibration: Unusual vibrations during operation can indicate imbalances or loose components. Inspect the equipment for any loose screws or worn-out parts. Tightening connections and replacing damaged elements can restore stability and comfort during use.

5. Fuel Leaks: Fuel leaks pose safety risks and can indicate a failing fuel line or a loose connection. Check all fuel lines for signs of wear and replace any compromised sections. Ensure that all fittings are secure to prevent further leaks.

By regularly maintaining your equipment and promptly addressing these issues, you can ensure reliable performance and extend its lifespan.