Understanding the inner workings of any high-performance appliance requires a clear and organized view of its key mechanisms. By exploring the layout of different elements, users can gain insight into how various sections interact to ensure optimal functionality. This structured approach offers a deeper appreciation for the engineering and precision behind such advanced technology.

The detailed visual layout helps users navigate the intricate system, allowing them to easily locate specific components. This makes it simpler to identify potential areas for maintenance or replacement. Whether you’re performing routine upkeep or addressing specific issues, having a well-organized view of all internal systems is essential for efficiency.

With a clear focus on clarity and precision, this guide offers a valuable resource for anyone looking to enhance their understanding of this technology. The detailed exploration of the internal elements ensures that users can maintain, repair, or optimize their equipment with confidence.

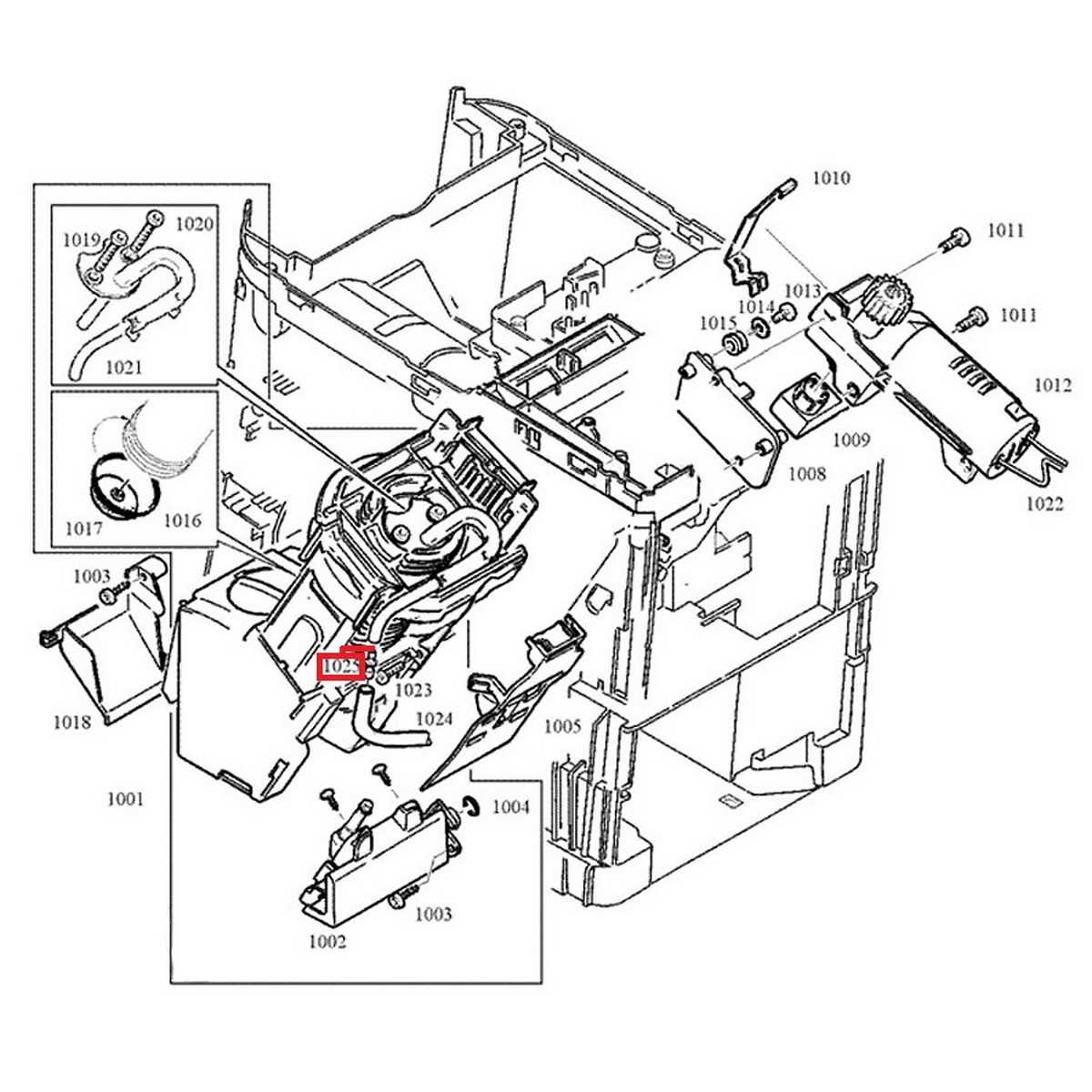

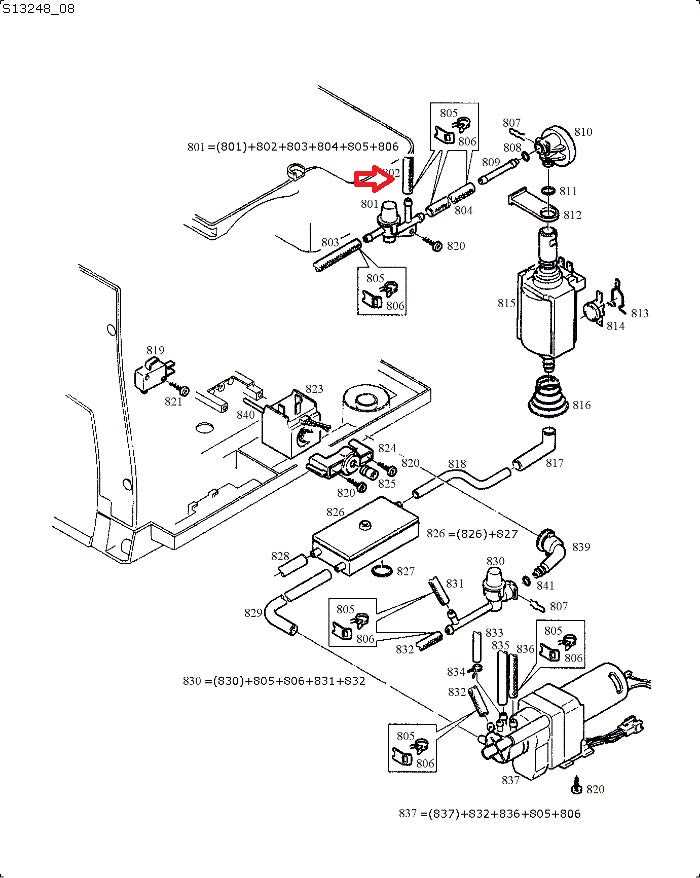

Jura Z5 Internal Component Overview

The inner structure of this machine consists of various crucial elements that work together to deliver optimal performance. These components are precisely engineered to ensure smooth operation and long-lasting functionality. Understanding the layout and function of these internal elements can help users maintain the equipment effectively, enhancing its overall longevity.

Key mechanical elements include various systems responsible for water flow, temperature regulation, and pressure control. Each of these plays a vital role in ensuring that the device operates efficiently and

Main Functional Elements of Jura Z5

The machine is designed with a range of essential features that ensure optimal performance and user convenience. Each component plays a critical role in creating a seamless coffee-making experience, from precise brewing functions to intuitive controls. The interplay of these elements guarantees high-quality results in every cup.

Brewing Unit

The brewing unit is the core of the system, responsible for preparing beverages by perfectly balancing water temperature and pressure. This unit works in coordination with other components to deliver consistently great results.

User Interface

The user interface allows for easy customization of beverage settings, providing intuitive control over the entire process. The layout ensures quick access to all functions, enabling users to effortlessly select their desired preferences.

Exploring the Grinder Mechanism

The grinder mechanism plays a critical role in preparing finely ground coffee for brewing. This component ensures that the coffee beans are processed to the ideal texture, allowing for optimal extraction during brewing. Understanding how this intricate system operates helps to maintain the consistency of flavor and aroma in each cup.

Grinding precision is crucial for achieving the right balance between coarseness and fineness, directly affecting the taste and strength of the beverage. The grinder’s components work in harmony to deliver uniform grounds, which is key to the brewing process.

Regular maintenance of the grinding system ensures long-lasting performance and prevents any disruptions in functionality. Learning about the operation and care of the grinder helps enhance the overall efficiency of the coffee-making process.

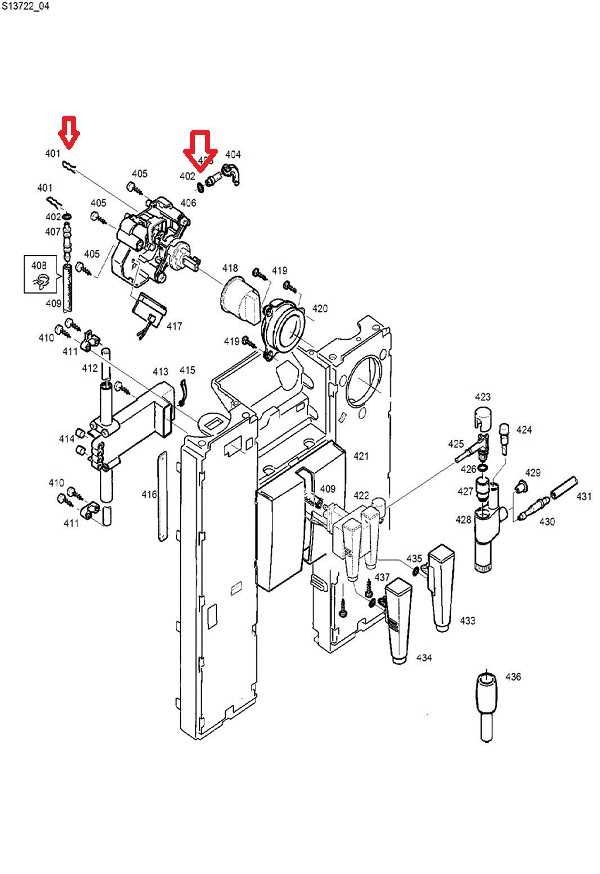

Brewing Unit Configuration and Parts

The brewing mechanism is a key component in any coffee machine, responsible for extracting flavors and creating the perfect beverage. This section provides an overview of the structure and function of the brewing system, highlighting its various elements that work together to ensure an optimal coffee experience.

Main Components of the Brewing Unit

- Brewing Chamber: The area where ground coffee is compressed and water is forced through to extract flavor.

- Water Inlet: Directs water into the brewing chamber, regulating temperature and pressure for precise extraction.

- Pressure Valve: Ensures that the correct amount of pressure is applied during the brewing process, controlling the flow of water.

- Outlet Spout: Guides the freshly brewed coffee into the cup, maintaining a smooth and consistent flow.

Functionality and Maintenance Tips

The brewing system operates by combining heated water

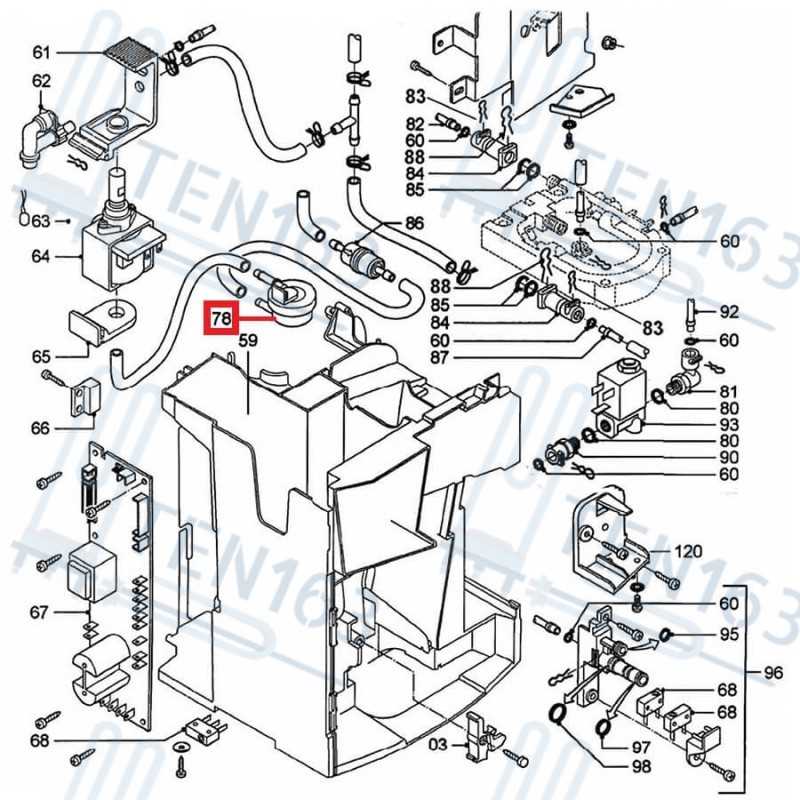

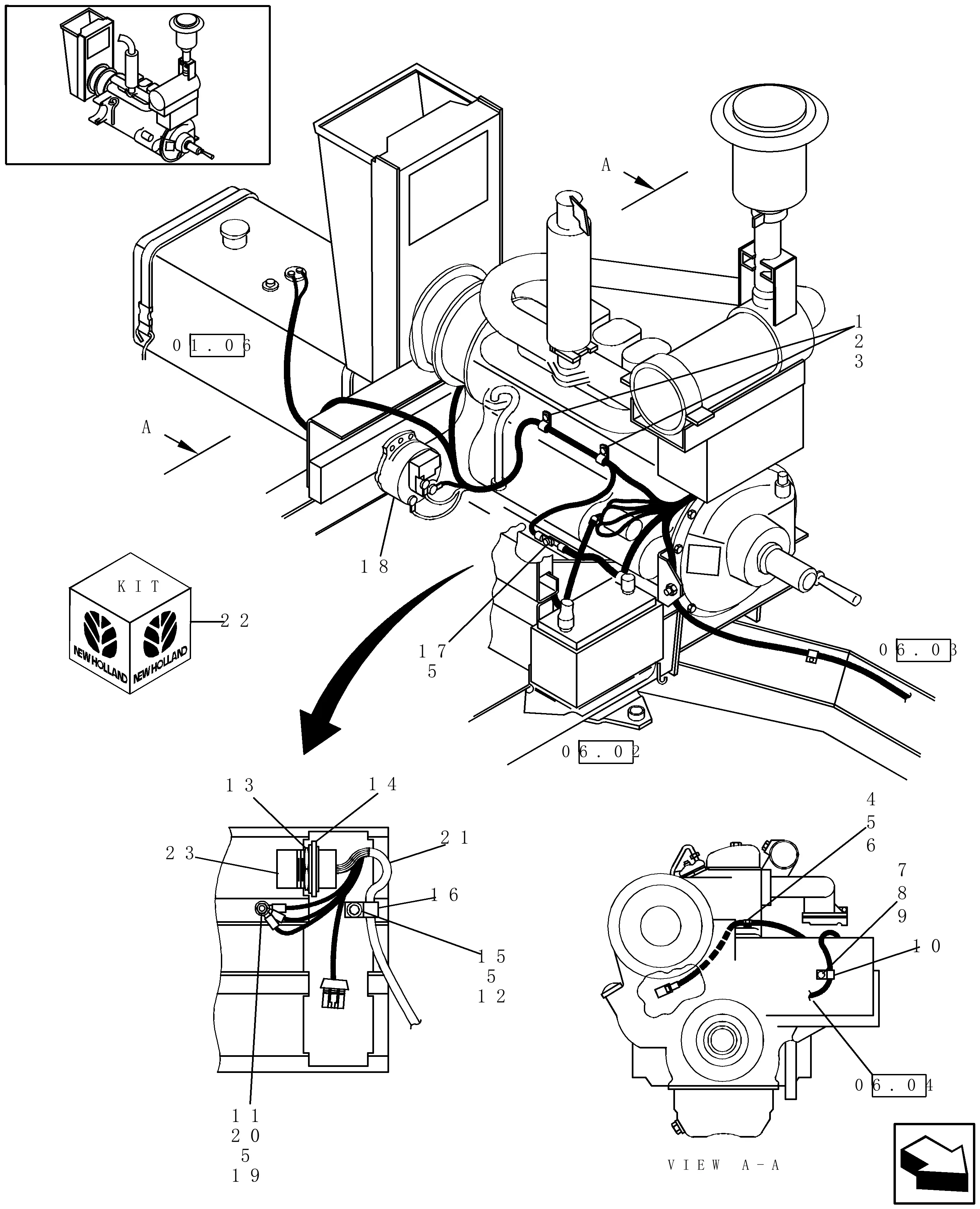

Water Flow System Breakdown

The water flow system is a crucial component that ensures smooth operation by directing water through various internal channels. Understanding its structure and functionality helps maintain the machine’s efficiency and detect any issues that might arise during use. This section provides an overview of how the water moves through the internal system, including key functional elements that regulate flow and pressure.

Main Components of the Flow System

- Pump: Responsible for generating the necessary pressure to move water through the system.

- Water Reservoir: Holds the water, feeding it into the internal pathways when needed.

- Tubes and Valves: These elements guide the water through different sections, controlling the flow direction and volume.

Flow Control Mechanism

Once water is pumped from the reservoir, it

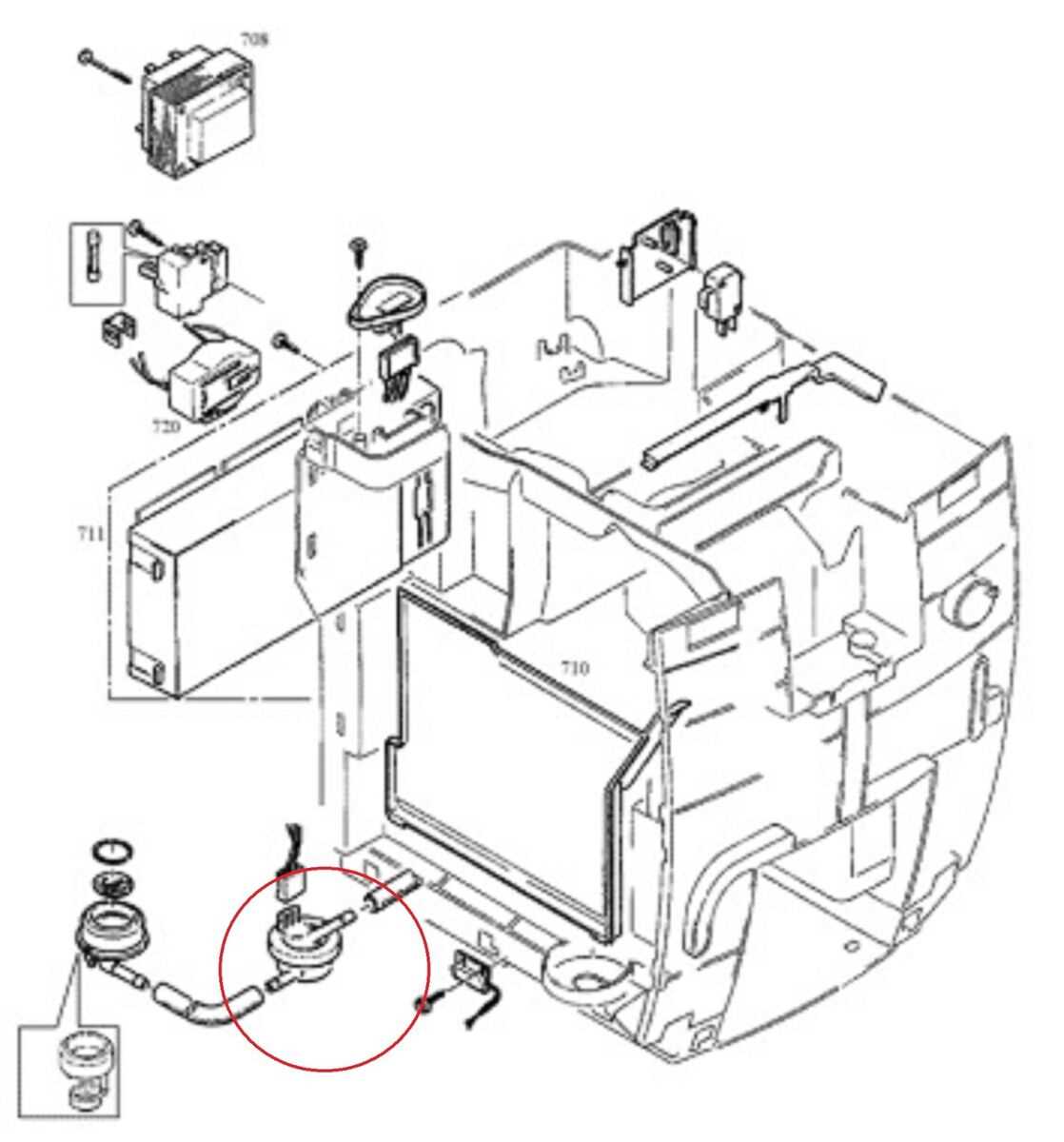

Cleaning Mechanism Components

The cleaning system is designed to ensure efficient maintenance and hygiene, playing a crucial role in the overall performance of the equipment. Understanding the elements that comprise this system can help extend the life of your appliance and ensure optimal operation.

Key Components of the Cleaning System

- Cleaning Unit: Responsible for distributing cleaning agents and ensuring that all internal areas are thoroughly cleaned, preventing buildup and blockages.

- Rinse Valve: Controls the flow of water used during the rinse cycle, ensuring that all cleaning agents are properly flushed out after each use.

- Waste Container: Collects waste materials and used cleaning solutions, making the disposal process easy and hygienic.

Maintenance of Cleaning Components

- Regular Inspection: Check for any signs of wear

Milk Frothing System Overview

The milk frothing system is an essential feature in many modern coffee machines, designed to create rich, velvety foam for a variety of specialty beverages. This system ensures that milk is heated and aerated to the perfect consistency, enhancing the flavor and texture of drinks like cappuccinos and lattes.

How it works: The frothing process typically involves drawing milk through a steam nozzle or frother, where it is combined with hot air to produce a smooth, creamy foam. The efficiency of this process depends on the temperature control and steam pressure within the device.

Maintenance and cleaning of the frothing system are crucial to ensure consistent performance. Regular care prevents buildup and guarantees that the machine delivers high-quality foam every time, while also extending the lifespan of the frother components.

Thermal Systems and Heating Parts

Effective thermal systems are crucial for maintaining consistent temperature control. The heating elements within these systems ensure optimal performance by regulating the heat required for various processes. Understanding how these components function together is key to maximizing operational efficiency and longevity.

Key Components

Thermal systems rely on several interconnected elements, including heating modules and temperature sensors. These parts work in tandem to deliver the right amount of heat when needed. Proper maintenance of these components ensures smooth operation and prevents overheating.

Maintenance Tips

Regular inspection of the thermal system’s heating modules helps prevent failures. Cleaning and occasional part replacement can extend the system’s life and enhance its efficiency. Following recommended maintenance schedules is essential for keeping the heating elements in top condition.

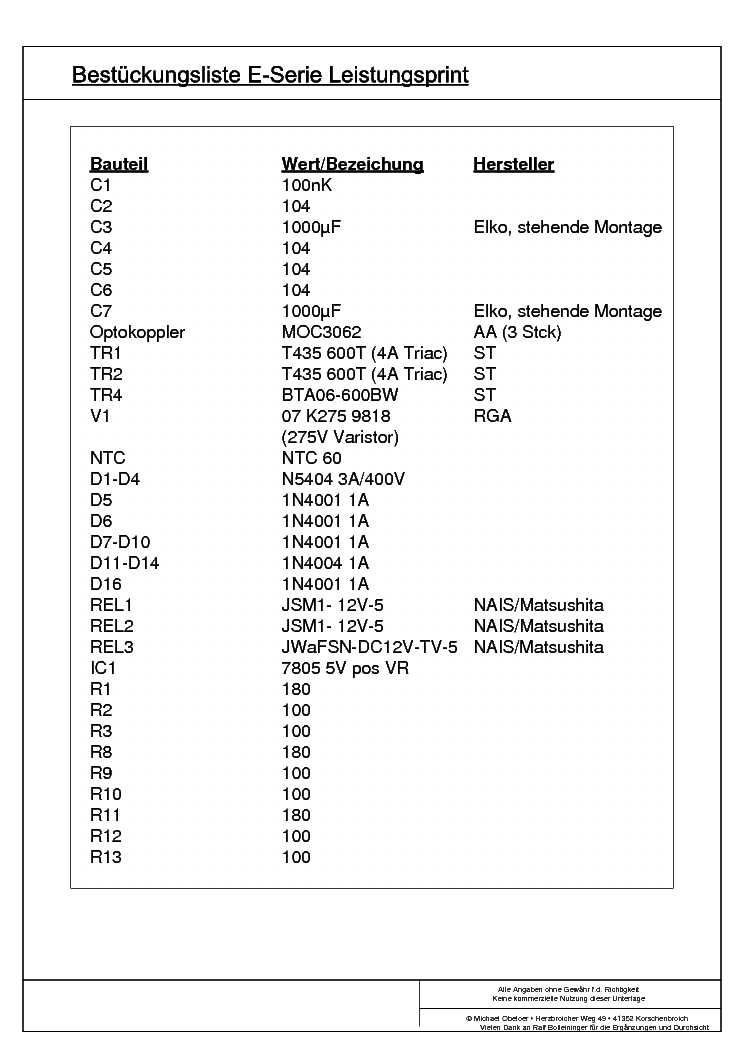

Component Function Maintenance Frequency Electronic Control Board Elements

The electronic control board serves as the brain of the device, orchestrating various functionalities through an intricate network of components. This assembly is pivotal in managing operations, ensuring that every function is executed seamlessly and efficiently.

Key components of the control board include microcontrollers, which process information and execute commands, as well as sensors that monitor performance parameters. Additionally, relays play a crucial role in controlling power distribution to various parts of the system, allowing for precise management of energy consumption.

Moreover, integrated circuits are essential for facilitating communication between different elements, ensuring that signals are transmitted accurately. Capacitors and resistors also contribute to the overall stability and functionality of the control board, enabling smooth operation under varying conditions.

Understanding these elements is vital for troubleshooting and maintenance, as each component interacts to maintain the operational integrity of the device. A comprehensive knowledge of these elements allows for effective diagnostics and potential upgrades to enhance performance.

Nozzle Structure

The nozzle is a critical component in coffee machines, playing a vital role in the brewing process. It is designed to deliver water and steam precisely, ensuring optimal extraction of flavors from the coffee grounds. Understanding the intricacies of its construction helps in appreciating its functionality and the quality of beverages produced.

The design typically consists of several key elements that contribute to its performance. The nozzle body serves as the main structure, providing stability and support. It often features multiple openings that facilitate the controlled release of water and steam, allowing for customized brewing parameters.

Another important aspect is the filtering mechanism, which ensures that only the finest particles pass through, preventing clogging and maintaining the integrity of the coffee. The seals within the nozzle are essential for preventing leaks, ensuring that pressure is maintained during the brewing cycle.

In summary, the structure of the nozzle is intricately designed to enhance the brewing experience. Each element works in harmony to deliver a perfect cup, reflecting the precision engineering behind high-quality coffee machines.

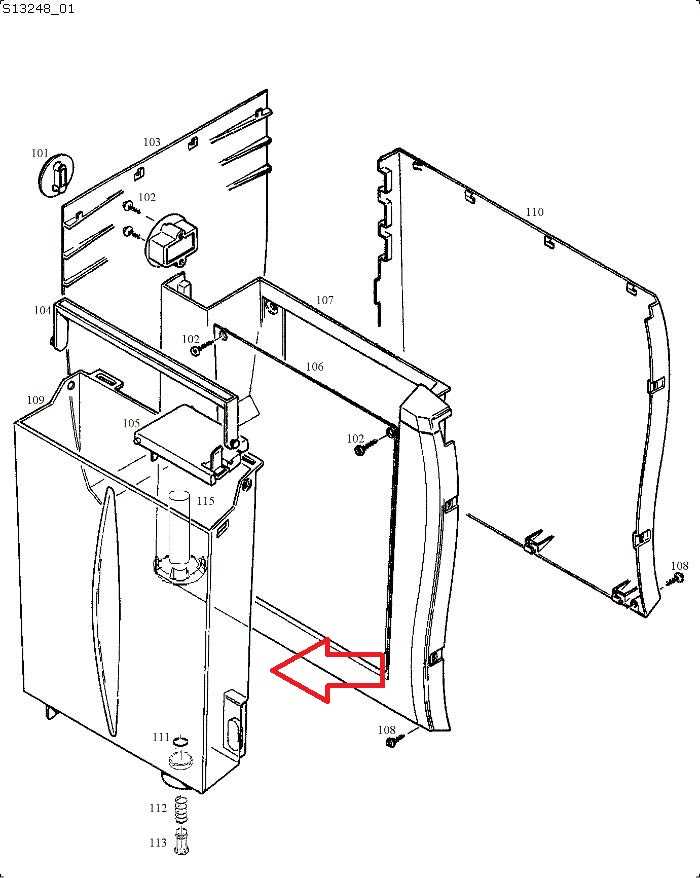

Commonly Replaced Parts of Jura Z5

Maintaining a high-quality brewing appliance often requires replacing certain components to ensure optimal performance and longevity. Understanding which elements are frequently updated can help users keep their devices running smoothly. Below are some of the most commonly exchanged components found in these sophisticated coffee machines.

Essential Components

Several key elements are vital for the effective operation of the brewing equipment. These parts may wear out over time due to regular use, and replacing them can significantly enhance the overall experience.

Component Function Water Filter Purifies the water used for brewing, ensuring better taste and quality. Brewing Unit Responsible for the extraction of coffee, this unit can accumulate residues and may require replacement. Seal Gasket Prevents leaks by ensuring a tight fit between moving parts, critical for maintaining pressure. Milk Frother Enhances the preparation of milk-based drinks, requiring periodic replacement to maintain performance. Signs of Wear

Identifying when these components need to be updated can prevent further damage and maintain functionality. Common indicators include decreased brewing efficiency, unusual noises during operation, or leaks in the system.

Maintenance Tips for Internal Parts

Regular upkeep of internal components is essential for optimal performance and longevity. Ensuring that each element is properly maintained can prevent common issues and enhance the overall functionality of the equipment. This section provides key strategies to help maintain the internal mechanisms effectively.

Routine Cleaning

Periodic cleaning is vital to remove dust, debris, and residue that can accumulate over time. Utilize a soft, damp cloth to wipe down surfaces, ensuring that no moisture seeps into sensitive areas. Consider using a vacuum with a brush attachment for hard-to-reach spots, which helps maintain cleanliness without damaging delicate components.

Lubrication and Inspection

Proper lubrication of moving parts is crucial to reduce friction and wear. Apply suitable lubricants sparingly to avoid buildup, and make sure to follow the manufacturer’s recommendations. Additionally, conduct regular inspections to identify any signs of wear or damage. Prompt attention to minor issues can prevent more significant problems down the line.