In the realm of agricultural machinery, comprehending the intricate interplay of various elements is essential for optimal functionality. Each component serves a unique purpose, contributing to the overall efficiency and performance of the equipment. A detailed exploration of these individual parts can illuminate their roles and interconnections.

Maintenance and repair become significantly easier with a clear understanding of how each piece fits into the larger system. Knowing the specifications and arrangements helps operators make informed decisions, ultimately enhancing the longevity of their machinery. Visual representations of these components can serve as invaluable tools for both novice users and seasoned professionals.

By delving into the specifics of each segment, one can gain insights into best practices for upkeep and troubleshooting. This knowledge is not just beneficial for repairs; it also empowers users to maximize the capabilities of their equipment, ensuring it operates at its peak performance.

Understanding Kioti CK25 Components

The functionality and performance of a compact utility machine rely on the intricate design and arrangement of its various elements. A comprehensive understanding of these components is essential for efficient operation and maintenance. Each part plays a pivotal role in the overall mechanism, contributing to the machine’s reliability and effectiveness in various tasks.

Identifying and comprehending the function of each component can enhance troubleshooting skills and facilitate better care practices. Below is a summary table highlighting key elements and their respective functions within the machine.

| Component | Function |

|---|---|

| Engine | Generates power for operation. |

| Transmission | Transfers power from the engine to the wheels. |

| Hydraulic System | Operates attachments and implements. |

| Chassis | Provides structural support and stability. |

| Wheels | Facilitates movement across various terrains. |

| Control Panel | Allows operator to manage functions and settings. |

By familiarizing oneself with these components, operators can ensure better performance and longevity of their machinery, leading to enhanced productivity in their tasks.

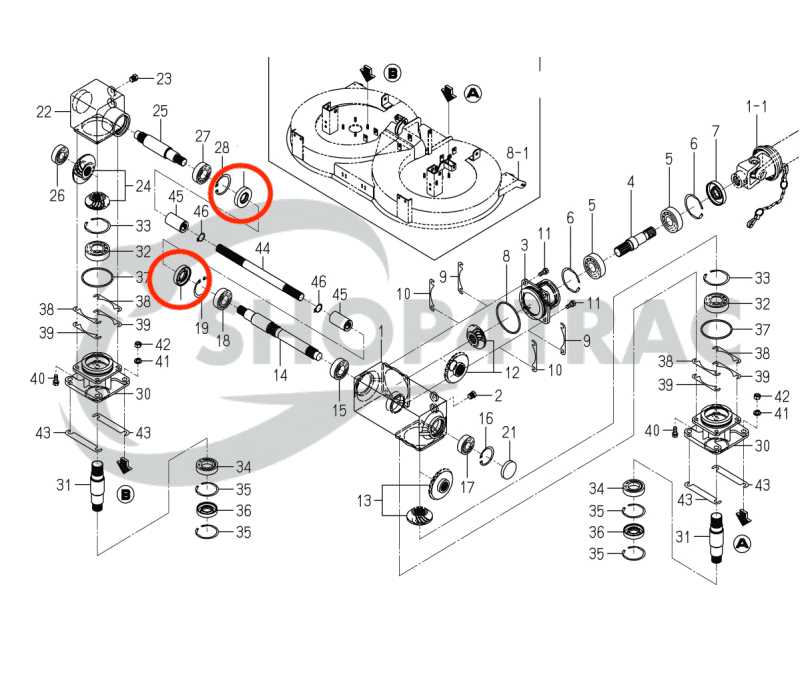

Importance of Parts Diagrams

Understanding the layout of components within machinery is crucial for effective maintenance and repair. Visual representations of these elements provide users with a comprehensive overview, facilitating the identification of each individual piece and its function. This clarity enhances the overall efficiency of any restoration efforts.

Accessibility to such visual aids allows technicians and enthusiasts to quickly locate necessary items, streamlining the process of assembly and disassembly. When confronted with a malfunction, having a clear reference can drastically reduce the time spent troubleshooting issues.

Moreover, these illustrations serve as a valuable educational resource. Newcomers can familiarize themselves with the equipment’s design, enhancing their understanding of how various parts interact. This foundational knowledge is essential for anyone aiming to develop their skills in machinery upkeep.

In summary, utilizing comprehensive visual guides promotes not only efficiency and accuracy but also fosters a deeper connection with the mechanical systems in question. The benefits extend to both experienced professionals and novices alike, ultimately contributing to better performance and longevity of the equipment.

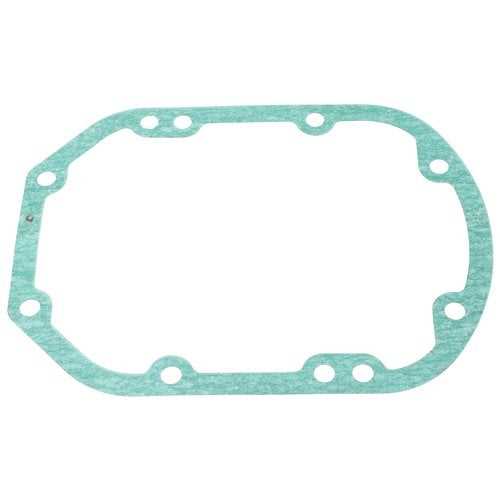

Common Issues with CK25 Parts

When dealing with specific machinery, various components may encounter recurring problems that can affect performance and longevity. Understanding these common challenges is essential for effective maintenance and operation.

- Wear and Tear: Regular use can lead to deterioration, especially in high-stress areas.

- Overheating: Insufficient cooling can cause critical components to malfunction.

- Fluid Leaks: Seals and gaskets may degrade, resulting in leaks that impact functionality.

Addressing these issues promptly can enhance the overall efficiency and durability of the equipment.

- Regular inspections to identify early signs of trouble.

- Timely replacement of worn-out components.

- Proper lubrication and cooling maintenance.

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repair of machinery. Such illustrations provide valuable insights into the arrangement and interrelation of various elements, enabling users to identify and procure the correct items for their needs.

Key Elements to Focus On

- Labels: Each part is typically labeled with a unique identifier, which aids in recognizing specific components.

- Numbers: Numerical references correspond to a list that outlines each item’s specifications and availability.

- Lines and Arrows: These indicate connections and relationships between different components, showing how they fit together.

Steps for Effective Interpretation

- Start by reviewing the overall layout to gain a sense of the entire assembly.

- Locate the identifiers for each component to understand their function and position.

- Cross-reference the labels with the accompanying list to gather detailed information about each item.

- Pay attention to any notes or legends that clarify specific details or offer additional context.

By following these steps, you can enhance your ability to interpret visual representations, facilitating smoother repairs and maintenance processes.

Essential Tools for Maintenance

Regular upkeep of machinery is crucial for ensuring longevity and optimal performance. A well-equipped toolbox can make all the difference in effectively handling repairs and routine checks. Here are some indispensable instruments that every operator should have on hand to facilitate smooth maintenance tasks.

Basic Hand Tools

Having a set of reliable hand tools is fundamental for any maintenance activity. These tools allow for quick adjustments and minor repairs, making them essential in any situation.

| Tool | Purpose |

|---|---|

| Wrenches | Used for tightening or loosening nuts and bolts. |

| Screwdrivers | Essential for fastening or removing screws. |

| Pliers | Helpful for gripping, twisting, or cutting wires. |

Specialized Equipment

In addition to basic tools, some specialized equipment is necessary for more complex maintenance tasks. These instruments provide greater precision and efficiency.

| Tool | Purpose |

|---|---|

| Multimeter | Used for measuring electrical properties and diagnosing issues. |

| Grease Gun | Facilitates the lubrication of moving parts to reduce wear. |

| Torque Wrench | Ensures fasteners are tightened to the correct specifications. |

Where to Find Replacement Parts

Locating components for machinery maintenance can be a crucial task for ensuring optimal performance. Understanding the best sources can simplify the process and save time.

- Authorized Dealers: Visit local dealerships that specialize in the brand; they often carry genuine components and can provide expert advice.

- Online Retailers: Explore various e-commerce platforms that focus on agricultural and industrial equipment. Many websites offer extensive catalogs.

- Aftermarket Suppliers: Consider companies that produce compatible alternatives. These can be cost-effective options without sacrificing quality.

- Salvage Yards: Check out salvage operations that may have used parts available. This can be a treasure trove for budget-conscious repairs.

By exploring these avenues, you can ensure your equipment remains functional and efficient.

Benefits of Genuine Kioti Parts

Utilizing authentic components for your machinery offers numerous advantages that enhance performance and longevity. These specially designed elements ensure compatibility and reliability, leading to smoother operation and reduced maintenance issues.

Quality Assurance

- Manufactured to meet strict standards.

- Durability that withstands rigorous conditions.

- Consistent performance over time.

Warranty Protection

- Maintains warranty coverage for your equipment.

- Minimizes risk of damage due to inferior alternatives.

- Provides peace of mind with trusted solutions.

Aftermarket vs. Original Components

When it comes to machinery maintenance, the choice between replacement components can significantly impact performance and longevity. Two primary options are widely discussed: components produced by the original manufacturer and those created by third-party suppliers. Each option has its own set of advantages and drawbacks, influencing the decision-making process for users.

Original components are designed specifically for the equipment, ensuring a perfect fit and compatibility. These parts often come with a guarantee of quality, as they are manufactured under strict standards. However, they tend to be more expensive and may not always be readily available, depending on the model.

On the other hand, aftermarket alternatives can provide cost-effective solutions. They often come with a variety of options, allowing users to select based on budget and specific needs. While some aftermarket components are of high quality and can perform just as well as their original counterparts, there can be variability in manufacturing standards. It is essential to research and choose reputable brands to avoid potential issues.

Ultimately, the decision hinges on individual preferences, budget considerations, and the specific requirements of the machinery in question. Weighing the pros and cons of each option can lead to a more informed choice, ensuring optimal performance and durability.

Maintenance Tips for CK25 Owners

Proper upkeep is essential for maximizing the lifespan and efficiency of your machinery. Regular maintenance not only ensures optimal performance but also prevents costly repairs down the line. Adhering to a systematic approach can significantly enhance your equipment’s reliability.

Regular Checks

- Inspect fluids regularly: oil, coolant, and hydraulic fluid.

- Check air filters and replace them as needed.

- Monitor tire pressure and tread wear.

Scheduled Servicing

- Follow the manufacturer’s service schedule for routine maintenance.

- Keep an eye on belts and hoses for signs of wear or damage.

- Ensure all safety features are functioning properly.

Identifying Parts via Diagrams

Understanding the components of machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools, helping users recognize and differentiate various elements within a system. By utilizing these illustrations, one can easily locate specific components, enhancing both efficiency and accuracy during servicing tasks.

| Component Name | Description | Common Issues |

|---|---|---|

| Engine Block | The main structure housing the engine components. | Overheating, cracks. |

| Hydraulic Pump | Device that generates hydraulic pressure for operation. | Leakage, loss of pressure. |

| Transmission Assembly | Transmits power from the engine to the wheels. | Slipping, grinding noises. |

Cost Considerations for Repairs

When addressing maintenance needs for machinery, it is essential to evaluate the financial implications associated with repairs. Understanding these costs can help owners make informed decisions, ensuring that their investments are protected and that operations remain efficient. Various factors come into play, including the type of repair, availability of components, and labor expenses.

| Factor | Description | Impact on Cost |

|---|---|---|

| Type of Repair | Major repairs typically involve significant parts replacement, while minor fixes may require less intensive work. | Higher for major repairs due to part costs and complexity. |

| Component Availability | The ease of sourcing components can affect repair time and expenses. | Limited availability can lead to increased costs due to shipping or emergency orders. |

| Labor Rates | Skilled technicians may charge higher rates, but their expertise can result in quicker, more effective repairs. | Higher labor costs can increase total repair expenses. |

| Preventive Maintenance | Regular upkeep can prevent costly breakdowns and extend equipment lifespan. | Lower overall costs when maintenance is performed consistently. |

By taking these factors into account, machinery owners can better prepare for potential repair costs, optimizing their maintenance strategies and ultimately enhancing their operational efficiency.

Frequently Asked Questions

This section addresses common inquiries regarding components and their organization in various machinery. Understanding these aspects can enhance maintenance and repair processes, ensuring optimal performance.

What should I do if I can’t find a specific component?

If a certain item is elusive, consider checking online resources or contacting local dealers for assistance. They often have comprehensive inventories and can guide you through the search process.

How can I ensure I’m selecting the right component for my equipment?

It’s crucial to verify compatibility by consulting the user manual or manufacturer’s guidelines. This practice will help you make informed decisions and avoid unnecessary issues.

Expert Recommendations for CK25 Care

Proper maintenance is crucial for the longevity and performance of your machinery. Following expert advice can help ensure optimal functioning and prevent unexpected issues. This section offers essential tips to keep your equipment in peak condition, enabling you to achieve the best results.

| Maintenance Task | Frequency | Recommendations |

|---|---|---|

| Fluid Checks | Weekly | Inspect oil, coolant, and hydraulic fluids; top off as needed. |

| Filter Replacement | Every 100 hours | Replace air and fuel filters to maintain efficiency. |

| Tire Inspection | Monthly | Check tire pressure and tread; rotate as necessary. |

| Battery Maintenance | Every 6 months | Clean terminals and check charge levels. |

Regular adherence to these practices will significantly enhance the reliability and durability of your equipment, ensuring it performs at its ultimate best for years to come.