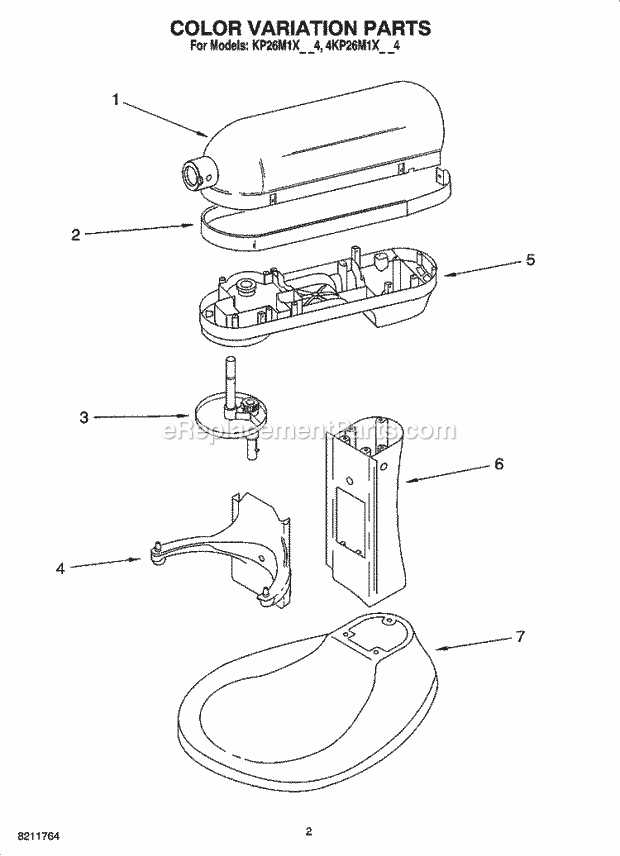

Exploring the Motor Housing Design

The motor housing is a crucial component that ensures the overall stability and performance of any kitchen appliance. It plays a significant role in protecting internal mechanisms while providing a secure framework for the engine’s operation. Understanding the structure and materials used in its design can help in maintaining the appliance’s longevity and efficiency.

Typically, the housing serves as a protective shell, guarding the motor against external elements such as dust and moisture. It also helps in noise reduction, ensuring a quieter performance during operation. The layout and material choice are optimized to withstand heat and wear over time, keeping the appliance running smoothly for extended periods.

Another key aspect of motor housing design is ensuring proper ventilation. Without adequate airflow, the motor could overheat, leading to potential damage. The placement of vents and the use of heat-resistant materials help to regulate temperature and ensure consistent performance, even during prolonged use.

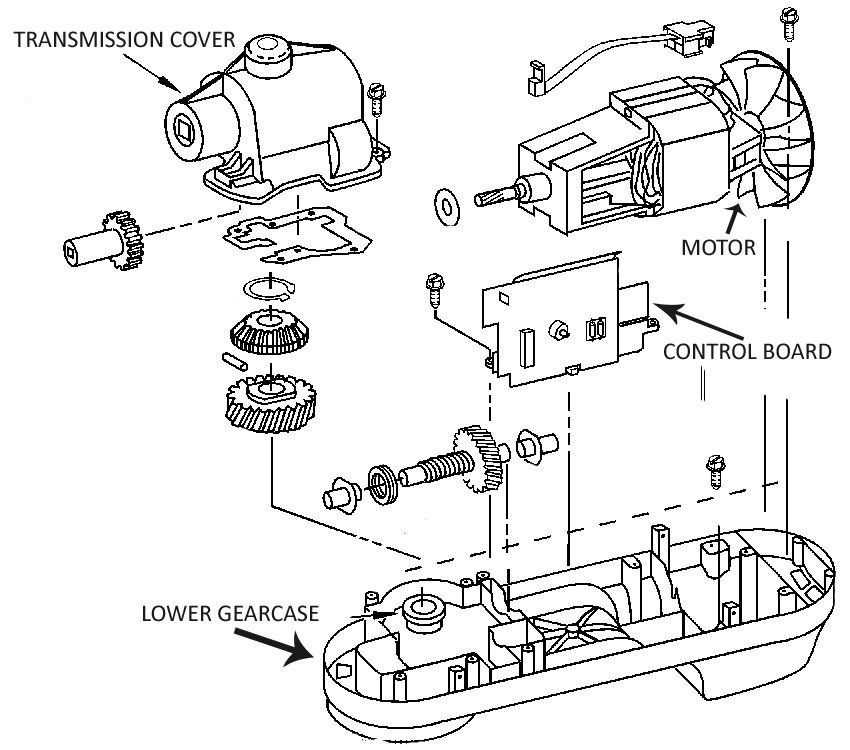

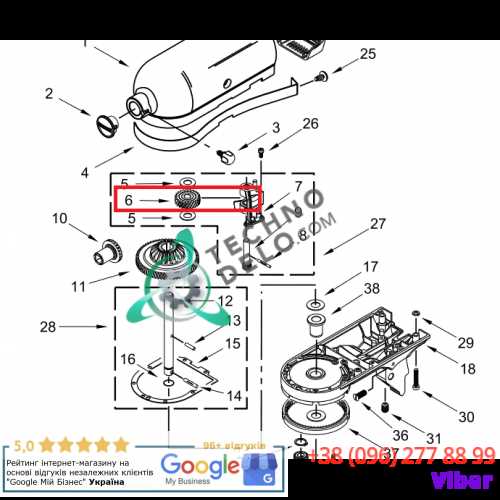

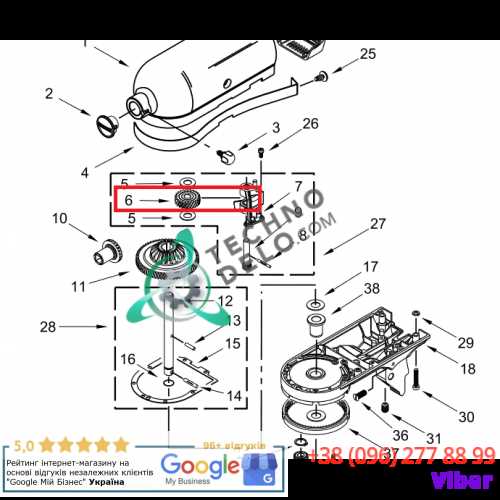

Breakdown of the Planetary Gear System

The planetary gear system is a vital component in many modern appliances, known for its efficiency in delivering rotational power. This system consists of multiple gears working in unison to provide smooth and balanced motion, crucial for various applications. Understanding its structure can help in recognizing how torque is distributed and transferred efficiently.

Main Components of the Planetary Gear System

At the core of this mechanism, we find the central sun gear that drives the other elements. Surrounding it are the planet gears, which rotate around the sun gear and are held in place by a rotating carrier. This arrangement allows for an even distribution of force and smooth operation.

How the Gear System Functions

The planet gears are in constant engagement with both the sun gear and the outer ring gear, creating a balanced and powerful movement.

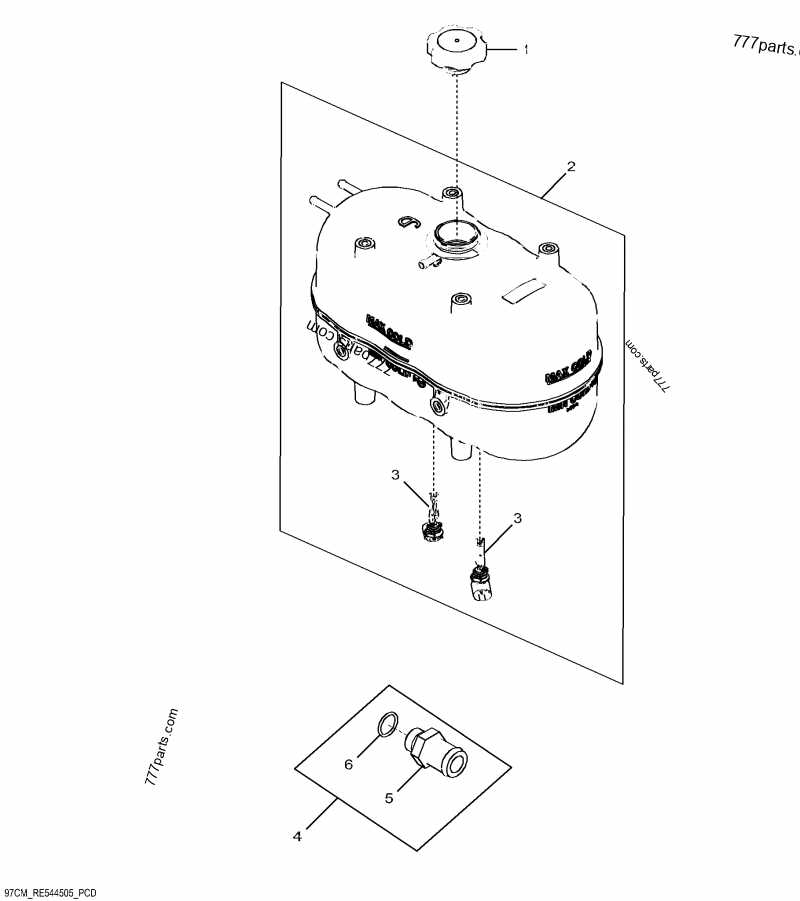

Identifying Key Drive Mechanisms

The functionality of any mechanical device heavily depends on the efficiency and structure of its drive system. Understanding the essential components that transmit power within a machine is crucial for maintaining smooth operation. Each mechanism plays a specific role in transferring motion, and recognizing these elements helps in diagnosing potential issues or improving overall performance.

Main Power Transmission Components

At the core of the drive system, the main components responsible for power transmission include gears, belts, and pulleys. These elements work together to convert motor energy into rotational movement. Proper alignment and tension are vital for ensuring efficient power flow and preventing wear and tear on the system.

Supporting Mechanisms and Adjustments

In addition to the primary elements, supporting parts such as tensioners and couplings ensure the smooth transfer of motion. Regular adjustment and inspection of these components

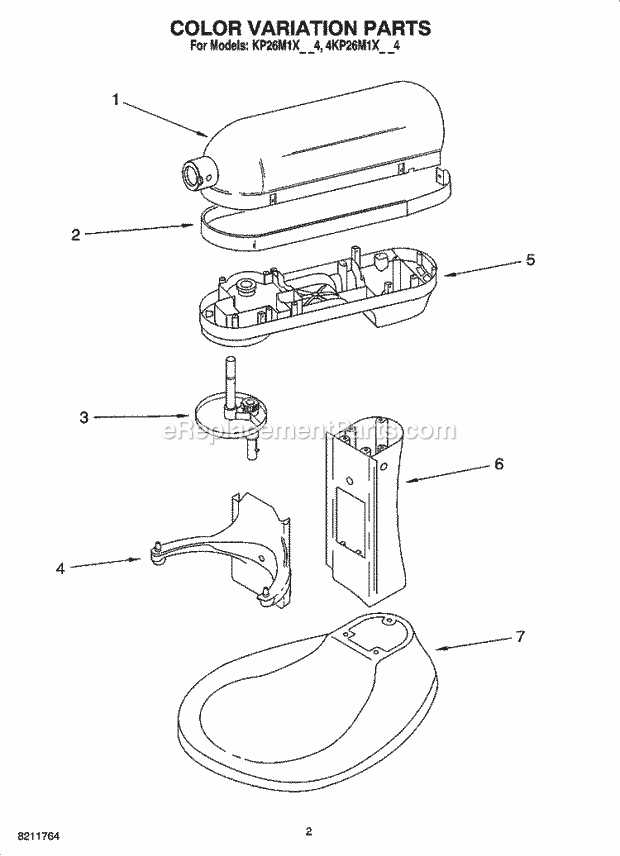

Attachments and Their Connection Points

The versatility of kitchen machines largely depends on the various attachments designed to enhance their functionality. Understanding how these accessories connect and interact with the main unit is crucial for achieving optimal results in food preparation. Each attachment has specific points where it can be securely attached, allowing for a seamless integration of tools and tasks.

Common attachments include:

- Mixing Bowls: Essential for combining ingredients, these bowls often have specific fittings that ensure stability during operation.

- Whisks: Ideal for aerating mixtures, whisks typically connect to a drive shaft, enabling efficient whipping and beating.

- Dough Hooks: Designed for kneading, dough hooks attach securely to the machine, allowing for thorough mixing of heavy batters.

- Food Grinders: These attachments fit into dedicated openings, providing a convenient way to prepare meats and vegetables.

- Juicers: Often connecting to a spout or outlet, juicers allow for quick extraction of juice from fruits and vegetables.

Each of these accessories not only expands the capabilities of the machine but also requires a clear understanding of how they connect and function together. Familiarizing oneself with these points ensures smooth operation and enhances the overall cooking experience.

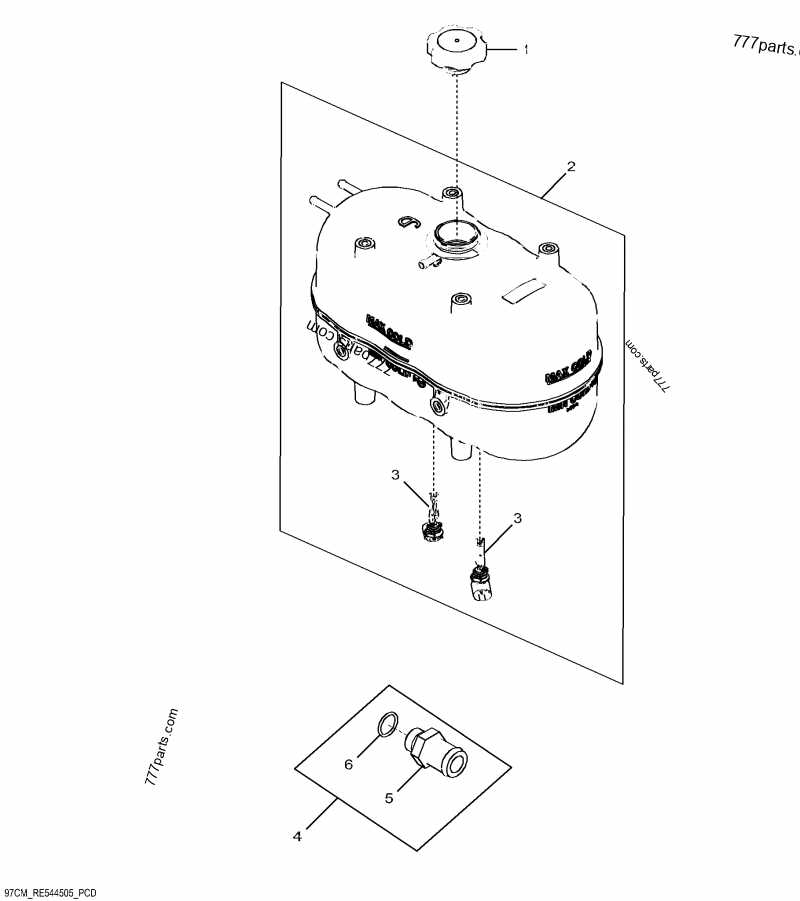

Exploring the Bowl Lift Assembly

The bowl lift assembly is a crucial component in certain kitchen mixers, designed to facilitate the lifting and lowering of the mixing bowl with ease. This mechanism not only enhances the user experience but also contributes to the overall functionality of the appliance. By allowing for quick adjustments, it ensures that ingredients can be mixed thoroughly without unnecessary hassle.

This assembly typically consists of several essential parts, including the lift lever, bowl support, and various connecting mechanisms. Understanding how these elements work together can provide valuable insights into the efficient operation of the mixer. When the lever is engaged, it raises the bowl to the desired height, enabling seamless access to the mixing attachments. Conversely, lowering the bowl allows for easy removal and cleaning.

Maintenance of the bowl lift assembly is vital for the longevity of the appliance. Regularly checking for wear and tear in the components can prevent potential issues that may arise from prolonged use. Proper care will ensure that the lifting mechanism functions smoothly, allowing for a hassle-free cooking experience.

Internal Wiring and Electrical Layout

The internal wiring and electrical configuration of a kitchen appliance play a crucial role in its functionality and safety. Understanding how these components interact helps in diagnosing issues and performing maintenance effectively. Proper knowledge of the electrical layout can also assist in making modifications or upgrades as needed.

Wiring Components and Connections

Each appliance consists of various wiring components, including switches, motors, and circuit boards, which are interconnected to facilitate seamless operation. The wiring harness serves as a central pathway for electrical flow, connecting the main power supply to individual components. Identifying the specific connections is essential for troubleshooting any electrical malfunctions.

Safety Considerations

When working with the electrical layout, safety is paramount. Ensuring that all connections are secure and properly insulated minimizes the risk of short circuits and electrical hazards. Regular inspections of the wiring can prevent potential failures and ensure that the appliance operates efficiently over time.

How the Control Panel Functions

The control interface of a kitchen appliance plays a vital role in ensuring smooth operation and user convenience. This panel allows users to easily navigate various settings, providing an intuitive experience for adjusting features such as speed, mixing time, and other essential functions.

Each button and dial on the control panel is designed with a specific purpose in mind. For instance, the speed settings enable users to select the appropriate intensity for different tasks, from gentle stirring to vigorous mixing. The presence of indicator lights can also assist in tracking the operational status of the device, ensuring that users are informed throughout the process.

Moreover, modern interfaces often include digital displays, enhancing usability by offering clear feedback on the selected settings. This helps prevent mistakes and allows for precise adjustments, ultimately leading to improved results in food preparation. In summary, the functionality of the control panel is integral to the overall performance and user satisfaction of the appliance.

Details of the Speed Control Lever

The speed control lever is a vital component in many culinary devices, allowing users to adjust the mixing speed with precision. Understanding its structure and functionality is essential for efficient operation and maintenance of the equipment.

Functionality of the Speed Control Lever

This lever plays a crucial role in regulating the motor speed, enabling a range of mixing options from slow stirring to high-speed whipping. Proper use enhances the versatility of the appliance, making it suitable for various culinary tasks.

Common Issues and Maintenance

- Wear and Tear: Over time, the lever may experience degradation, affecting its responsiveness.

- Calibration: It is essential to ensure that the lever is correctly calibrated for accurate speed adjustments.

- Cleaning: Regular cleaning can prevent buildup that may interfere with the lever’s operation.

Routine checks and maintenance can help extend the life of the speed control lever and ensure optimal performance of the device.

Seals, Bearings, and Their Importance

Seals and bearings play a crucial role in the efficient operation of various mechanical devices. They are essential components that ensure smooth movement and prevent the ingress of contaminants. These elements work together to reduce friction, maintain alignment, and enhance the overall functionality of equipment.

Seals are designed to protect internal mechanisms from dust, dirt, and moisture, thereby prolonging the lifespan of the machinery. They create a barrier that prevents leakage of lubricants, which is vital for maintaining optimal performance. Without effective seals, machines can suffer from increased wear and tear, leading to premature failure.

Bearings, on the other hand, facilitate rotational or linear movement by supporting loads and reducing friction between moving parts. They enable smooth operation, ensuring that components can function effectively without excessive resistance. High-quality bearings are essential for minimizing energy loss and enhancing the overall efficiency of the system.

In summary, both seals and bearings are integral to the durability and efficiency of machinery. Regular inspection and timely replacement of these components can prevent costly repairs and ensure reliable performance in various applications.

Maintenance of the Beater Shaft

The beater shaft is a crucial component in stand mixers, ensuring efficient mixing and blending of various ingredients. Regular upkeep of this element can enhance the performance and longevity of the appliance. It is essential to follow proper maintenance practices to prevent wear and tear, which can lead to operational issues.

Cleaning the beater shaft after each use is vital. Food particles can accumulate, leading to contamination or malfunction. Use a damp cloth to wipe down the shaft and ensure it is free from residue. For a more thorough cleaning, disassemble the mixing attachment and wash it with warm, soapy water.

Lubrication is also key to maintaining smooth operation. Periodically, apply a food-safe lubricant to the shaft where it meets the motor housing. This helps reduce friction and wear, allowing for smoother mixing action. Ensure that you do not over-lubricate, as excess grease can attract dirt and debris.

Additionally, regular inspections of the beater shaft can identify potential issues before they become major problems. Check for signs of wear, such as scoring or bending, and replace the shaft if necessary. By staying proactive with maintenance, you can ensure optimal performance and extend the lifespan of your mixing appliance.

Troubleshooting Common Component Issues

When dealing with various appliances, it’s essential to identify and resolve common issues related to their components. Many problems can arise from wear and tear, improper usage, or lack of maintenance. Understanding how to diagnose these issues can help ensure optimal performance and longevity of your device.

Identifying Symptoms

Recognizing the signs of malfunction is the first step in troubleshooting. Here are some typical symptoms you might encounter:

- Unusual noises during operation

- Failure to start or intermittent operation

- Inconsistent performance or reduced efficiency

- Visible wear or damage to parts

Common Issues and Solutions

Below are some prevalent problems and their possible solutions:

- Motor Problems:

- Check the power supply and ensure connections are secure.

- Inspect the motor for any signs of overheating or damage.

- Belt Wear:

- Examine the belt for fraying or cracking.

- Replace the belt if it shows significant wear.

- Electrical Issues:

- Inspect fuses and circuit breakers for any faults.

- Test switches and wiring for continuity.

By systematically checking these components, you can effectively address common issues and restore functionality to your appliance.