Understanding the structure and function of individual elements within mechanical systems can greatly enhance maintenance and repair efficiency. By familiarizing yourself with the layout and role of specific components, you can ensure smooth operation and extend the lifespan of your equipment.

This section provides a comprehensive breakdown of crucial elements, highlighting their placement and interaction within the overall system. By following this guide, you will gain valuable insights into the intricate assembly of the equipment, helping you address potential issues more effectively.

Explore the relationship between various elements, identifying how they work together to maintain optimal performance. This detailed look will assist in diagnosing and resolving common issues that may arise during regular use.

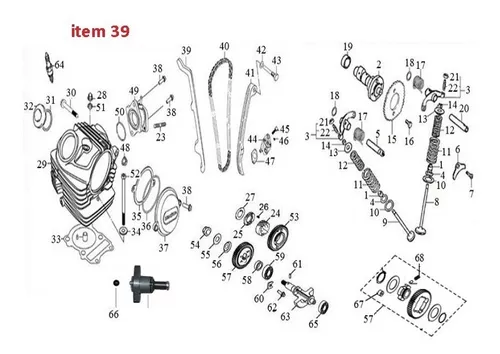

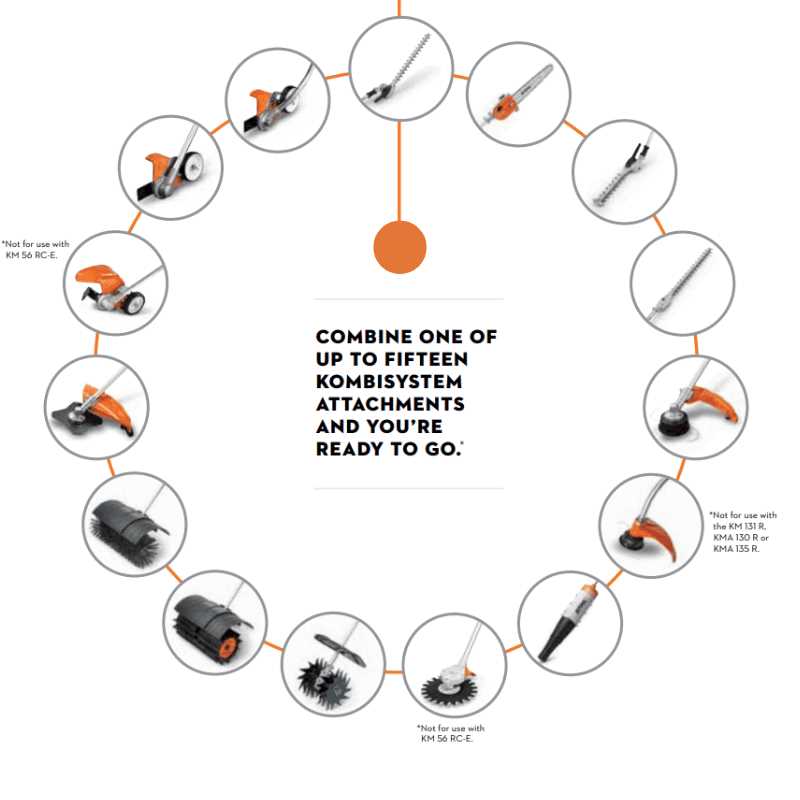

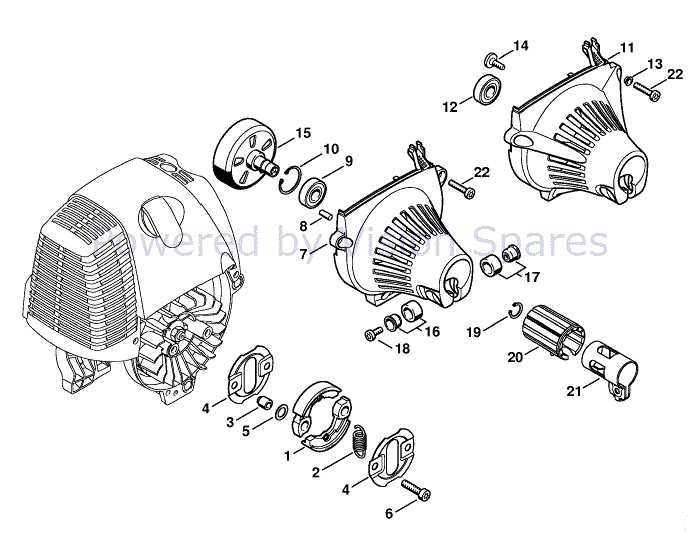

Km111r Parts Diagram Overview

This section provides an insight into the various elements and components that make up the specific model, focusing on how they interact and function together. The breakdown offers a clear understanding of the internal structure and how each piece is essential to the overall operation.

- Explores the main components and their roles.

- Details the key sections and their placement within the system.

- Clarifies the assembly and disassembly process for easy maintenance.

By studying the structural layout, users can efficiently troubleshoot issues and ensure smooth operation by understanding the critical connections between each segment.

Essential Components Breakdown

This section provides a detailed look at the crucial elements that ensure the proper functioning of the device. Understanding these individual components can help in troubleshooting, maintenance, and overall system optimization.

| Component | Description |

|---|---|

| Engine Assembly | The heart of the system, responsible for converting energy into motion, driving the entire operation forward. |

| Transmission Unit | Transfers the generated power to the appropriate mechanical parts, ensuring smooth functionality. |

| Fuel System | Regulates and delivers the necessary fuel to the engine, maintaining optimal performance levels. |

| Cooling Mechanism | Prevents overheating by circulating coolant and managing temperature within the system. |

| Control Interface | Allows for user interaction, offering control over the various functions and settings. |

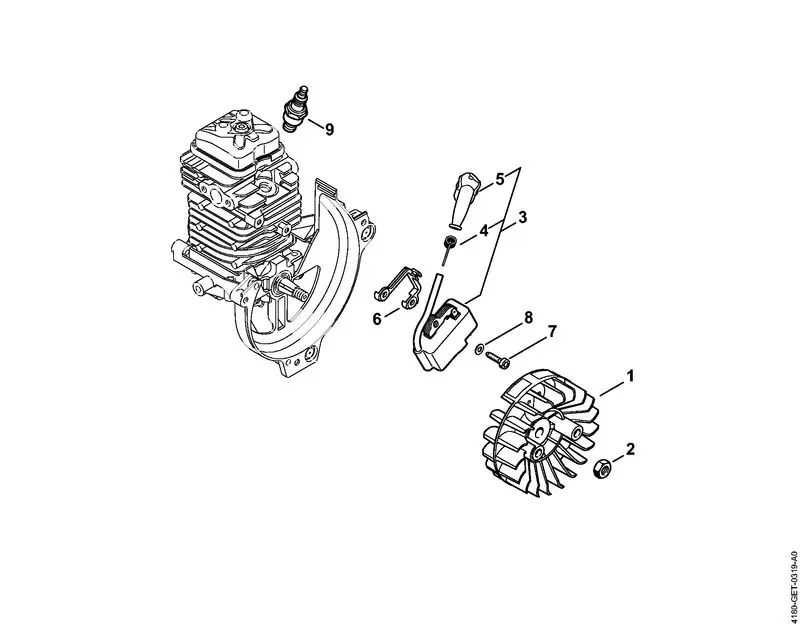

Key Engine Parts and Functions

Every engine is a complex system of components that work together to ensure efficient performance. Each element has a specific role, and when combined, they create the power necessary to drive a machine forward. Understanding how these components interact is essential for anyone interested in engine mechanics.

Main Components of the Engine

The core of any engine includes essential elements like cylinders, which house the combustion process. The piston moves up and down inside the cylinder, compressing fuel and air to create energy. This motion is then transferred to the crankshaft, converting linear motion into rotational energy that powers the engine.

Additional Functional Elements

Supporting the engine’s core functions are systems like the cooling system, which maintains optimal operating temperatures, and the lubrication system that reduces friction between moving parts. Each of these systems plays a vital role in ensuring the engine runs smoothly and efficiently under various conditions.

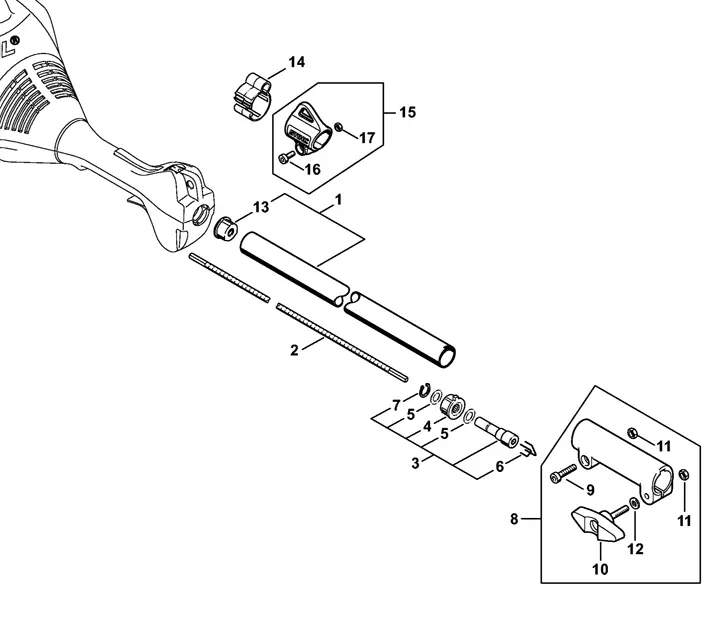

Detailed View of the Control System

The control mechanism is an essential component that ensures the proper functioning and coordination of various elements. Understanding its structure allows for efficient management and maintenance of the equipment. This section provides a clear breakdown of the components that make up the system responsible for regulation and control.

| Component | Description | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Controller Unit | This unit is responsible for managing input signals and ensuring that they are processed correctly to activate other functions. | ||||||||||||

| Wiring System | A network of connections that transmits signals between various parts of the control mechanism. | ||||||||||||

| Control Panel | The interface where manu

Fuel System Components and LayoutThe fuel system ensures the smooth delivery of fuel to the engine, maintaining its performance and efficiency. Its design includes various key elements that work together to provide a consistent fuel flow, crucial for proper engine operation.

Understanding the Exhaust System StructureThe exhaust system plays a crucial role in directing gases produced by the engine away from the vehicle while minimizing harmful emissions. It ensures that the vehicle operates efficiently and complies with environmental standards. This system consists of multiple components that work together to manage the flow of gases, reduce noise, and control emissions. Each section of the exhaust system contributes to these functions, starting from the manifold, where gases exit the engine, to the muffler, which dampens the sound. The precise arrangement of these elements ensures smooth and safe operation, preventing harmful gases from accumulating and affecting performance. Wiring and Electrical ConnectionsProper wiring and electrical connections are essential for ensuring smooth and safe operation of any mechanical or electrical system. Careful attention to detail during installation can prevent potential hazards and malfunctions. Installation Guidelines

When setting up electrical components, it is important to follow all provided instructions. Ensure that each wire is connected to the correct terminal and that insulation is intact to avoid short circuits. Additionally, double-check the polarity and voltage requirements of each component. Safety ConsiderationsAlways disconnect the power source before beginning any work on electrical systems. Use appropriate tools designed for electrical tasks and wear protective gear, such as insulated gloves, to reduce the risk of injury. It is also advisable to consult a certified technician for complex connections. Mechanical Parts Assembly and InteractionThe assembly of mechanical components is a fundamental aspect of engineering, ensuring that various elements function cohesively within a system. This section delves into the relationships and connections between different elements, highlighting how their interaction contributes to overall performance. Understanding how these components integrate is essential for effective design and troubleshooting. The following points outline key aspects of mechanical assembly:

Each of these factors plays a significant role in the overall functionality of mechanical assemblies. Analyzing their interactions allows for improvements in efficiency and reliability, leading to better performance in applications. Maintenance Tips for Critical Sections

Ensuring the longevity and optimal performance of your equipment involves regular attention to essential components. Proper upkeep not only enhances efficiency but also minimizes the risk of unexpected failures. Regular Inspection: Conduct routine examinations of key areas to identify wear and tear early. Look for signs of damage, corrosion, or loose fittings, as these can lead to larger issues if left unaddressed. Lubrication: Apply appropriate lubricants to moving parts to reduce friction and wear. Ensure that you use the recommended type of lubricant for each specific area to maintain effectiveness. Cleaning: Keep critical sections free from dust and debris. Regular cleaning helps prevent buildup that can impede performance and cause overheating. Replace Worn Components: Do not delay in replacing parts that show signs of significant wear. Using components beyond their service life can lead to failures that affect the overall functionality of your equipment. Consult the Manual: Always refer to the manufacturer’s guidelines for specific maintenance schedules and procedures. Following these recommendations can help you maintain optimal performance. Exploded View of Internal MechanismsThe intricate assembly of internal components plays a crucial role in the functionality and efficiency of machinery. Understanding the arrangement and interaction of these elements can provide valuable insights into their operation and maintenance. Key Components and Their Functions

Assembly Overview

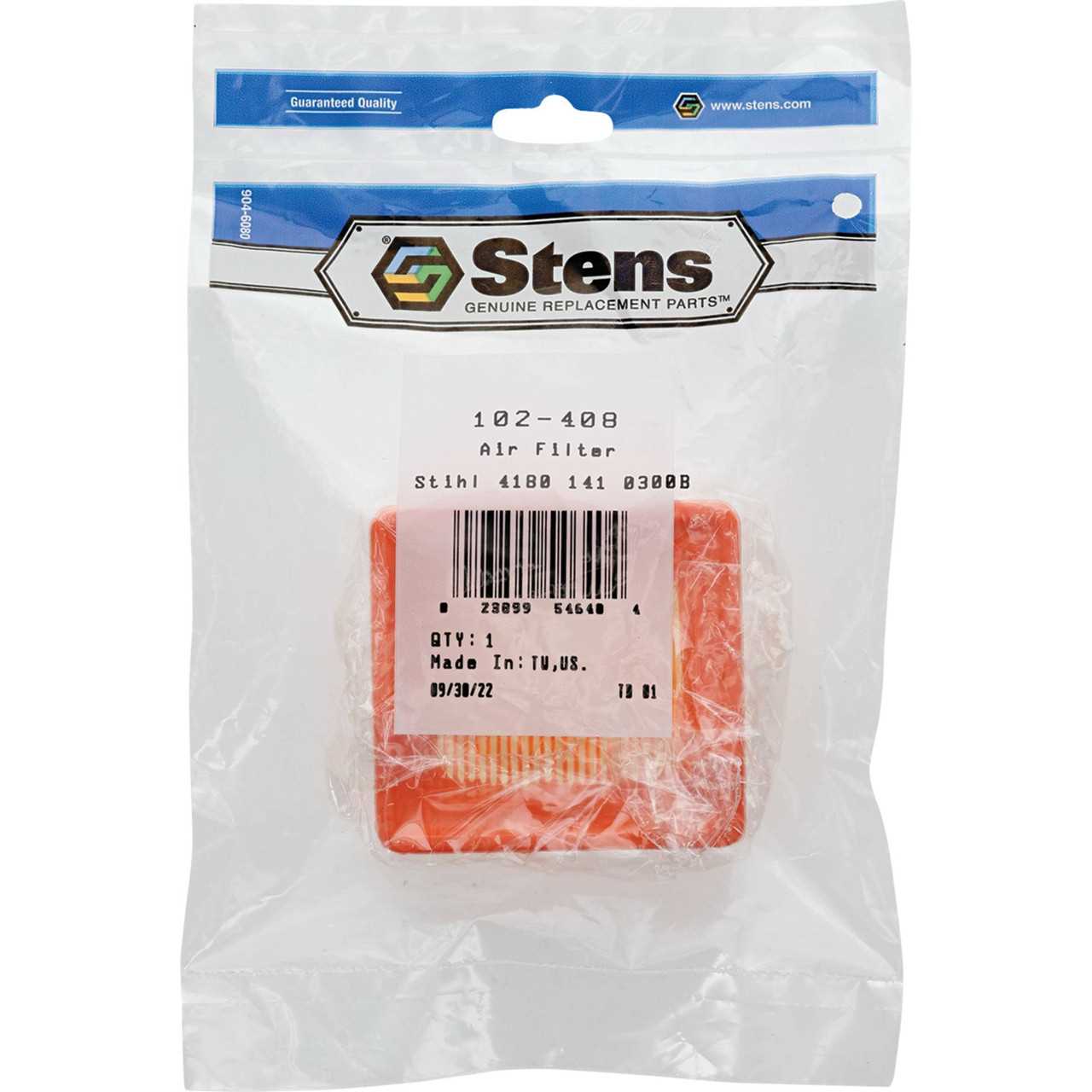

Common Replacement Parts and SpecificationsWhen maintaining machinery, understanding the various components that may require periodic substitution is essential. This section outlines frequently replaced items along with their specifications to ensure optimal performance and longevity. Frequently Replaced Components

Specifications OverviewHere are some key specifications for common replacement items:

|