In any intricate system, it’s essential to know how individual elements connect and work together. Whether you’re dealing with a mechanical setup or a more complex infrastructure, having a clear view of the internal layout is crucial for maintenance and troubleshooting. This section offers a closer look at the detailed structure of a specific assembly, helping to identify key components that ensure optimal functionality.

Exploring core elements often involves breaking down the assembly into smaller units, making it easier to understand their individual roles. By focusing on these critical sections, you’ll be better equipped to maintain performance and address any potential issues that may arise.

It’s important to recognize that each component plays a vital role in the overall operation. Proper identification of these elements ensures that you can not only keep the system running smoothly but also make informed decisions about upgrades or replacements as needed.

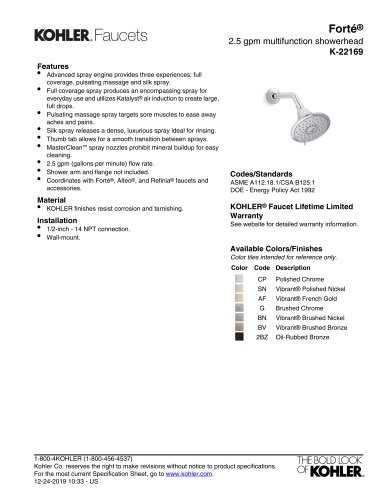

Exploring Kohler A112 18.1 Components

Understanding the individual elements of this model can help ensure smooth functionality and proper maintenance. Each component plays a specific role in the overall system, working together to deliver consistent performance. In this section, we’ll take a closer look at the key elements that make up the system and how they contribute to its operation.

- Water Flow Controller: This part is responsible for regulating the flow of water, ensuring an efficient and stable operation.

- Sealing Mechanism: Proper sealing is crucial for preventing leaks and maintaining pressure within the system.

- Connector Fittings: These ensure all parts are securely linked, promoting a seamless interaction between each section.

- Mounting Hardware: These elements are designed to support the overall structure, providing stability and durability over time.

- Adjustment Valves: These allow for precise control over various

Understanding the Structure of Kohler A112 18.1

The design of this model revolves around an intricate assembly of various components, each contributing to the overall functionality and performance. Recognizing the arrangement of these elements can assist in comprehending how the system works as a whole, making it easier to maintain and optimize over time.

Main Elements Overview

The key elements of the system include a variety of interconnected mechanisms, all working together to ensure efficient operation. Each part plays a critical role in ensuring that the flow and distribution of resources are smooth and reliable. Understanding how these elements interact is essential for anyone looking to perform adjustments or repairs.

Component Interaction

The components within this system are structured to interact seamlessly, allowing for a balanced flow between each section. Below is a basic overview of how these parts are organized, highlighting their connections and dependencies.

Component Function Key Features of Kohler A112 18.1 Model

This particular model is known for its reliability and practical design, making it a popular choice for various installations. Its thoughtful construction ensures a smooth operation while maintaining a high standard of performance. Users appreciate its durability, as well as the ease of maintenance, which contributes to its long-lasting functionality.

Durability and Build Quality

One of the standout aspects of this unit is its sturdy construction. Built with quality materials, it is designed to withstand frequent use without compromising its efficiency. The robust design ensures that it remains functional even in challenging conditions, providing consistent operation over time.

Efficient Water Flow and Functionality

Another key feature is its ability to manage water flow effectively, contributing to both convenience and energy efficiency. The model’s internal components work together seamlessly to ensure an optimal experience, minimizing potential disruptions in performance. Its reliable mechanisms also help in reducing water wastage, promoting sustainability.

Materials Used in Kohler A112 18.1

When discussing the construction of modern fixtures, it’s essential to understand the variety of elements that contribute to their durability and functionality. Different components in these units are crafted from distinct substances, each chosen for its specific properties, ensuring long-term performance and resistance to wear.

Metals for Structural Integrity

The core structure of the device is often reinforced with sturdy metals. These materials are selected for their ability to withstand pressure, maintain their shape, and resist corrosion over time. Strong alloys are typically used to ensure that critical sections remain reliable even under constant use.

Non-Metal Components for Flexibility

In addition to metals, flexible and lightweight substances are incorporated into various parts. These materials help ensure smooth operation while reducing the risk of damage due to bending or external impact. Such substances are also used in areas where elasticity is needed to absorb motion or vibration.

Common Replacement Parts for Kohler A112 18.1

When it comes to maintaining the efficiency of your fixture, certain components may need to be replaced over time to ensure proper function. These elements are designed to wear out after extended use, and keeping them in good condition helps avoid more costly repairs down the line.

- Valves: These are critical for controlling the water flow, and they can wear down with use, requiring replacement to prevent leaks or inefficiency.

- Seals and Gaskets: Over time, rubber or silicone seals can degrade, leading to water leakage. Replacing these is essential to keep the fixture watertight.

- Handles: Daily use can lead to wear and tear on handles, which might become loose or difficult to operate. A simple swap can restore ease of use.

- Sprayers and Aerators: These attachments may clog or wear out, affecting water pressure

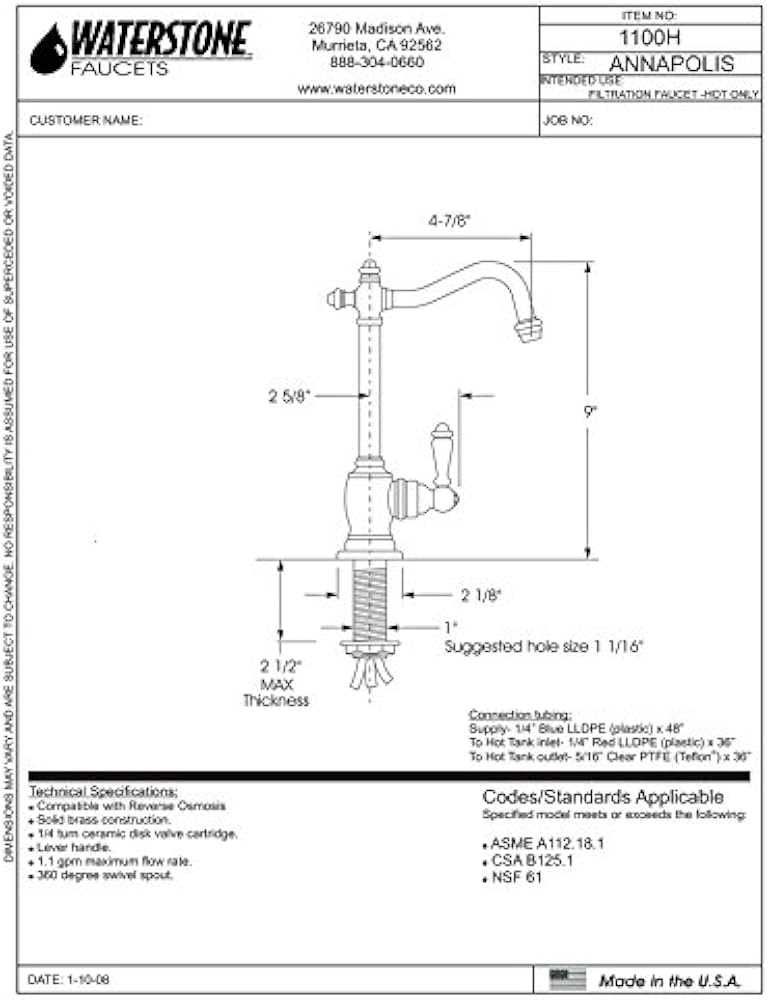

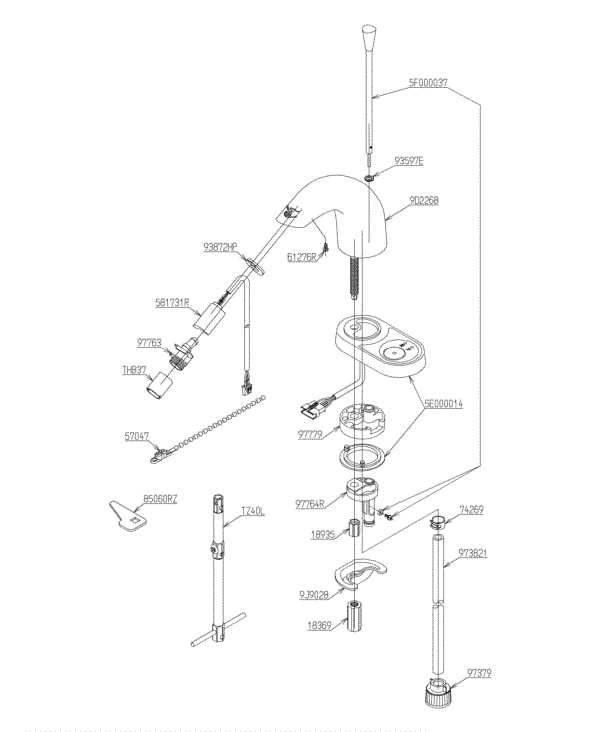

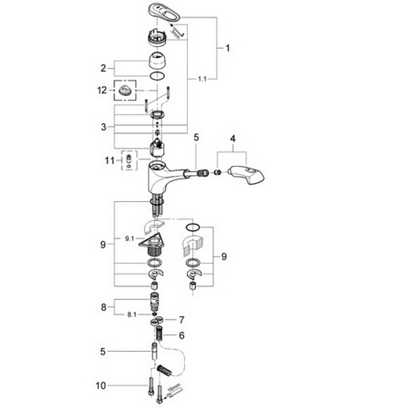

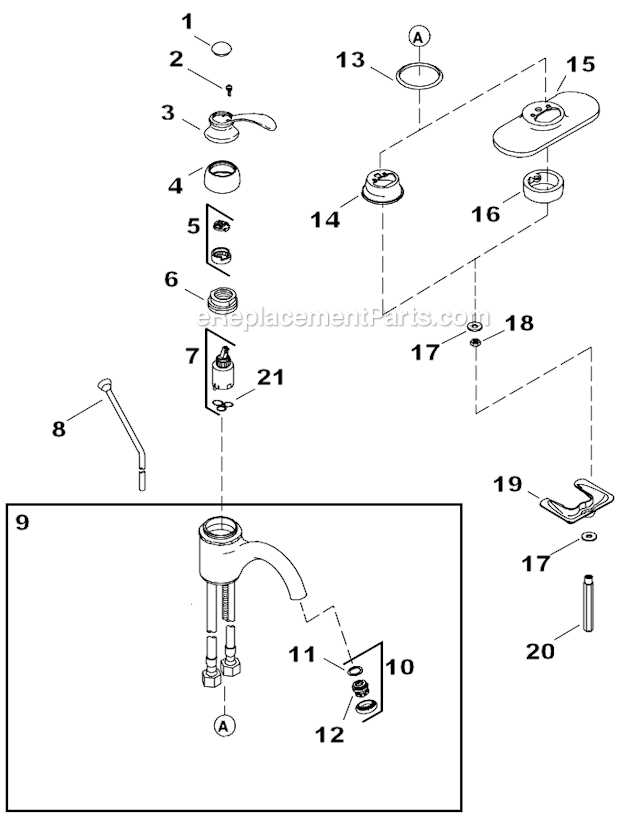

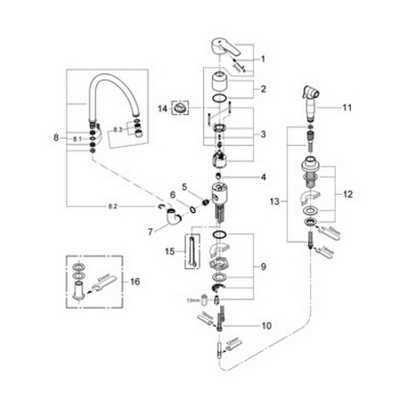

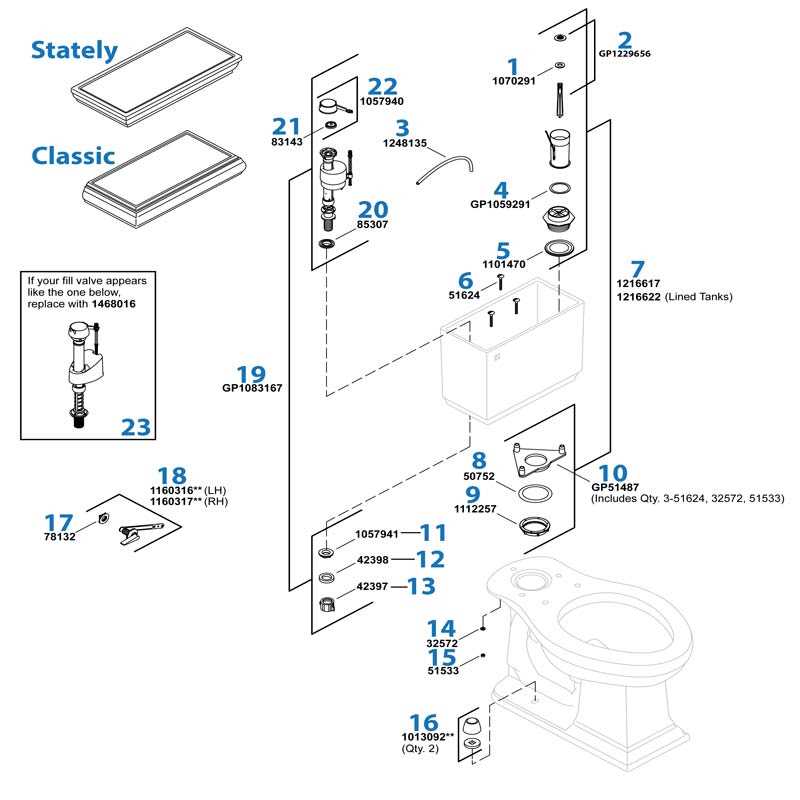

Identifying Essential Components in the Diagram

Understanding the key elements within an assembly layout is crucial for effective maintenance and repair. Each component serves a specific purpose, contributing to the overall functionality of the system. By familiarizing yourself with these elements, you can enhance your ability to troubleshoot and optimize performance.

To facilitate this process, consider the following critical components typically found in such schematics:

- Housing: The outer casing that protects internal elements.

- Valves: Mechanisms controlling fluid flow and pressure within the system.

- Seals: Elements that prevent leaks by providing a tight fit between components.

- Connectors: Parts that join different sections, ensuring a seamless operation.

- Filters: Devices that remove impurities from the fluid, safeguarding the integrity of the system.

By recognizing these essential parts, you will be better equipped to interpret assembly layouts, ensuring that you can effectively manage repairs and maintenance tasks.

Troubleshooting Common Issues with Kohler A112 18.1

Addressing typical challenges encountered with plumbing fixtures can enhance their functionality and longevity. Identifying the root cause of malfunctions is essential for effective resolution. Below are common problems and their potential solutions.

-

Low Water Pressure:

If the water flow seems weak, check for clogs in the aerator or cartridge. Clean these components to restore optimal pressure.

-

Leakage:

Leaks may occur at connections or seals. Inspect all joints and replace worn washers or gaskets to eliminate dripping.

-

No Hot Water:

Ensure that the hot water supply is functioning. Check the mixing valve and replace if necessary.

-

Strange Noises:

Unusual sounds during operation can indicate air in the lines or a loose component. Bleed the system to remove air and tighten any loose parts.

-

Inconsistent Temperature:

If the temperature fluctuates, verify the thermostat settings and inspect for any issues with the temperature control mechanism.

Regular maintenance and timely troubleshooting can significantly reduce the risk of major repairs. It is advisable to consult a professional if problems persist after attempting these fixes.

Optimizing Performance with Proper Maintenance

Ensuring the peak efficiency of your equipment requires a commitment to regular upkeep and attention to detail. A well-maintained system operates smoothly, reducing the likelihood of unexpected breakdowns and enhancing overall functionality. Implementing a consistent maintenance schedule can significantly extend the lifespan of your machinery while promoting optimal performance.

Here are some essential maintenance practices to consider:

- Regular Inspections: Frequently check all components for signs of wear or damage. Identifying issues early can prevent more extensive repairs later.

- Cleanliness: Keep the machinery clean to avoid the buildup of debris and dirt, which can hinder operation and lead to inefficiencies.

- Lubrication: Ensure that all moving parts are adequately lubricated to reduce friction and wear, thus enhancing performance and efficiency.

- Filter Replacement: Replace air and fuel filters regularly to maintain optimal flow and prevent contaminants from affecting the system’s operation.

- Fluid Checks: Monitor oil and coolant levels to ensure they are within recommended limits, as proper fluid levels are critical for effective functioning.

Incorporating these practices into your routine will not only optimize performance but also contribute to a more reliable and efficient operation. Prioritizing maintenance is an investment that pays off through improved productivity and reduced downtime.

Comparing Different Kohler Models and Parts

When examining various models of plumbing fixtures, it’s essential to consider the differences in components and features. Each design may offer unique specifications that cater to specific needs and preferences. By understanding these distinctions, users can make informed choices about which model best suits their requirements, ensuring optimal functionality and reliability.

Key Features Across Models

Different models often come with a variety of enhancements that improve performance. These can include variations in water flow efficiency, durability of materials, and ease of installation. By analyzing these key attributes, one can identify which models excel in particular areas, such as energy conservation or maintenance simplicity.

Compatibility and Upgrades

Compatibility between components is crucial when considering replacements or upgrades. Some models share similar features that allow for interchangeable elements, while others may require specific components designed exclusively for that design. This can impact both the ease of finding replacements and the overall cost of maintenance. Understanding these compatibility factors can significantly aid in making the right selection.

How to Read Kohler A112 18.1 Diagrams

Understanding technical illustrations related to mechanical systems can greatly enhance your ability to maintain and troubleshoot equipment. These visual guides provide a detailed overview of various components and their interconnections, allowing users to identify parts and understand their functions effectively. By familiarizing yourself with the conventions used in these representations, you can streamline repairs and replacements.

When approaching these illustrations, start by noting the key symbols and labels employed. Each symbol typically represents a specific element, while lines indicate relationships or connections between them. It is crucial to refer to the legend or key that accompanies the illustration, as this will provide clarity on what each symbol signifies.

Symbol Description ⚙️ Represents gears or rotating components. Indicates screws or fasteners used in assembly. Denotes electrical connections or wiring. Shows measurement lines for dimensions. Additionally, pay attention to the arrangement of components. Understanding the flow and placement can provide insight into the operational process of the system. Look for groupings that suggest functionality and consider how each element contributes to the overall mechanism.

Finally, practice interpreting these illustrations with actual examples. The more you engage with different representations, the more intuitive reading them will become. With time and experience, navigating these visuals will enhance your understanding and capability in working with various mechanical systems.

Installation Tips for Kohler A112 18.1

Ensuring a smooth setup for your plumbing fixture requires careful attention to detail. Proper installation not only enhances functionality but also prolongs the lifespan of the unit. Below are essential tips to guide you through the process, making it efficient and straightforward.

Preparation is Key

Before beginning, gather all necessary tools and components. This includes wrenches, screwdrivers, and any additional fittings required. Having everything at hand will minimize disruptions during the process. Additionally, review the provided manual to familiarize yourself with the specific requirements for installation, which can prevent common mistakes.

Follow Proper Sealing Techniques

When connecting various elements, use appropriate sealing methods to prevent leaks. Utilize plumber’s tape on threaded connections for added security. Ensure that all joints are tightened adequately but avoid over-tightening, which could lead to damage. Regularly check for any signs of leaks after installation, as early detection can save you from costly repairs.