The functionality of any engine is largely determined by the intricate arrangement of its components. Each element plays a vital role in ensuring optimal performance and reliability. This section aims to shed light on the various elements found within a specific engine system, providing clarity on their organization and interconnections.

To fully grasp the operation of these mechanisms, it is essential to explore the various units that comprise the assembly. By examining the structural relationships and positions of each part, one can gain a deeper appreciation of how they collectively contribute to the engine’s efficiency. Whether you are troubleshooting issues or simply seeking to enhance your understanding, familiarity with these layouts is invaluable.

Through detailed exploration, this resource will equip readers with the necessary knowledge to navigate the complexities of engine construction. Understanding the arrangement of components not only aids in maintenance and repair but also empowers users to make informed decisions regarding upgrades and modifications.

Kohler Command Pro Overview

This section provides a comprehensive look at a powerful line of small engines designed for high performance and reliability. Engineered for a variety of applications, these units are favored for their durability and efficiency in demanding environments.

Key Features: The engines are equipped with advanced technologies that enhance fuel efficiency and reduce emissions. Their robust construction ensures long-lasting operation, making them ideal for both commercial and residential use.

Applications: These engines are widely utilized in lawn care, landscaping, and other outdoor equipment, providing the necessary power to tackle challenging tasks effortlessly.

Overall, this series of engines stands out in the market for its combination of innovation and dependability, catering to the needs of users who seek performance without compromise.

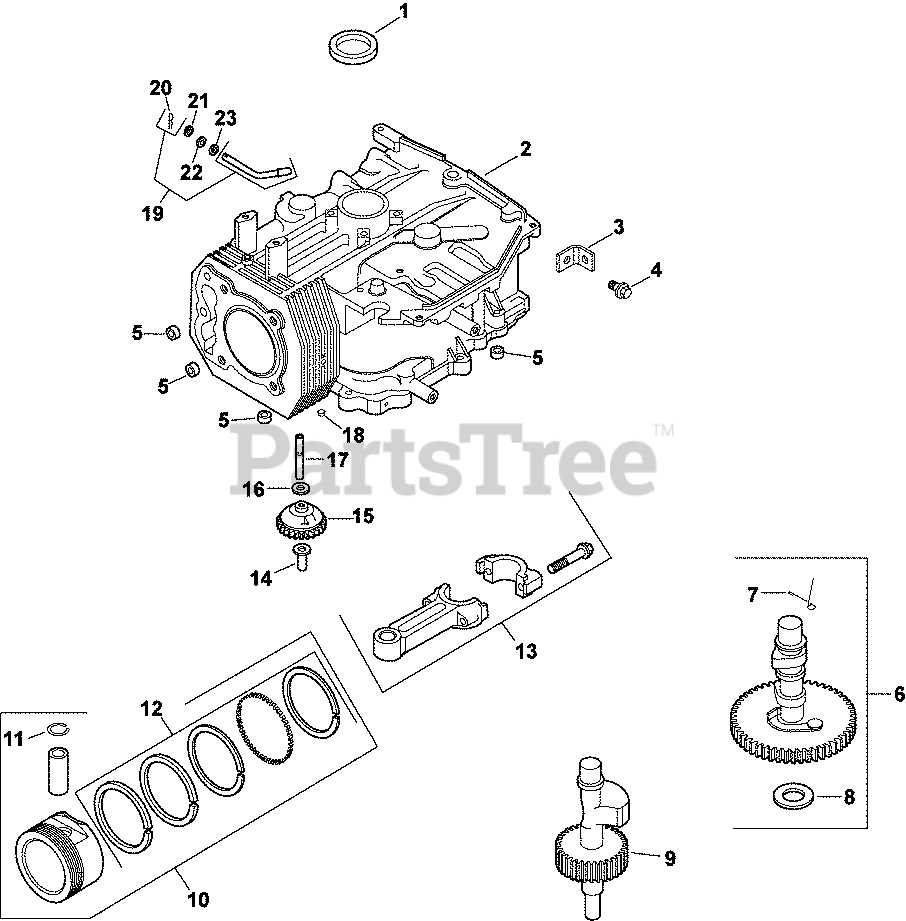

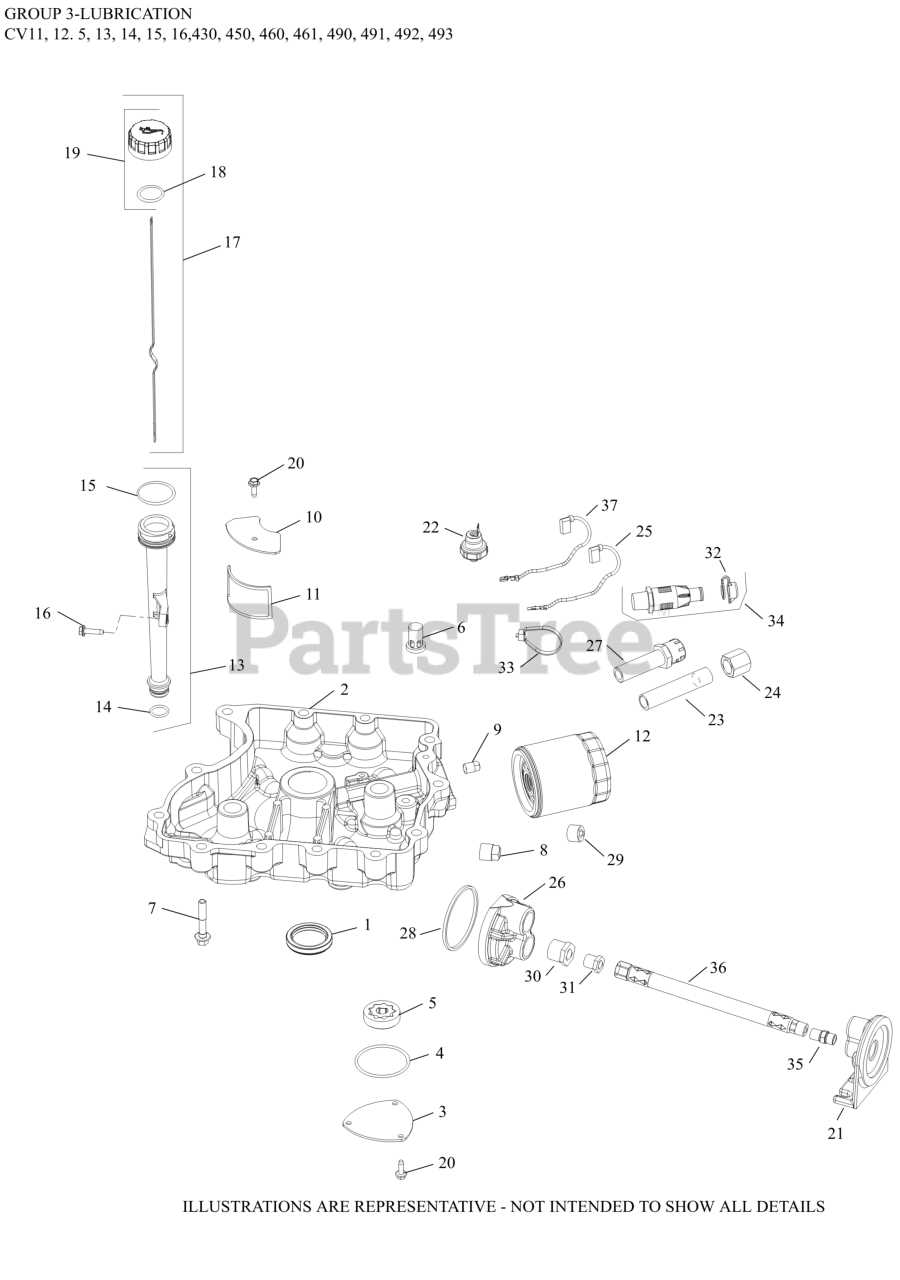

Key Components of the Engine

The internal combustion engine consists of various essential elements that work together to generate power efficiently. Understanding these components is crucial for proper maintenance and performance optimization. Each part plays a significant role in the overall function, contributing to the engine’s reliability and effectiveness.

Piston: The piston is a moving part that compresses the fuel-air mixture within the cylinder. It converts the pressure from combustion into mechanical energy, driving the crankshaft.

Crankshaft: This component transforms the linear motion of the piston into rotational motion, which ultimately powers the vehicle or equipment. Its design and material affect the engine’s performance and durability.

Cylinder Head: Located on top of the engine block, the cylinder head houses the combustion chambers, valves, and spark plugs. It plays a vital role in controlling the flow of air and fuel, ensuring efficient combustion.

Valves: These components regulate the intake and exhaust of gases in and out of the combustion chamber. Proper timing and functioning of the valves are critical for optimal engine performance.

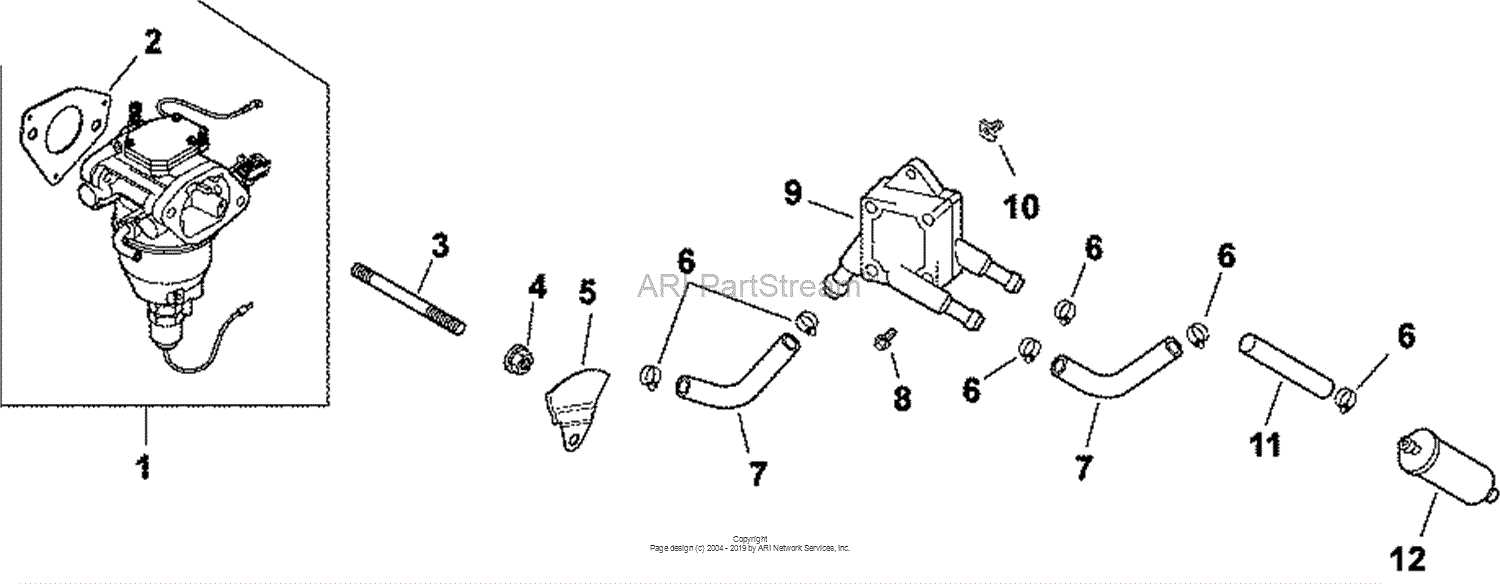

Fuel System: The fuel system delivers the necessary fuel to the engine for combustion. It includes components like fuel injectors or carburetors, ensuring a precise mixture of air and fuel for efficient operation.

Cooling System: This system maintains the engine’s temperature within an optimal range, preventing overheating. It typically consists of a radiator, water pump, and cooling passages in the engine block.

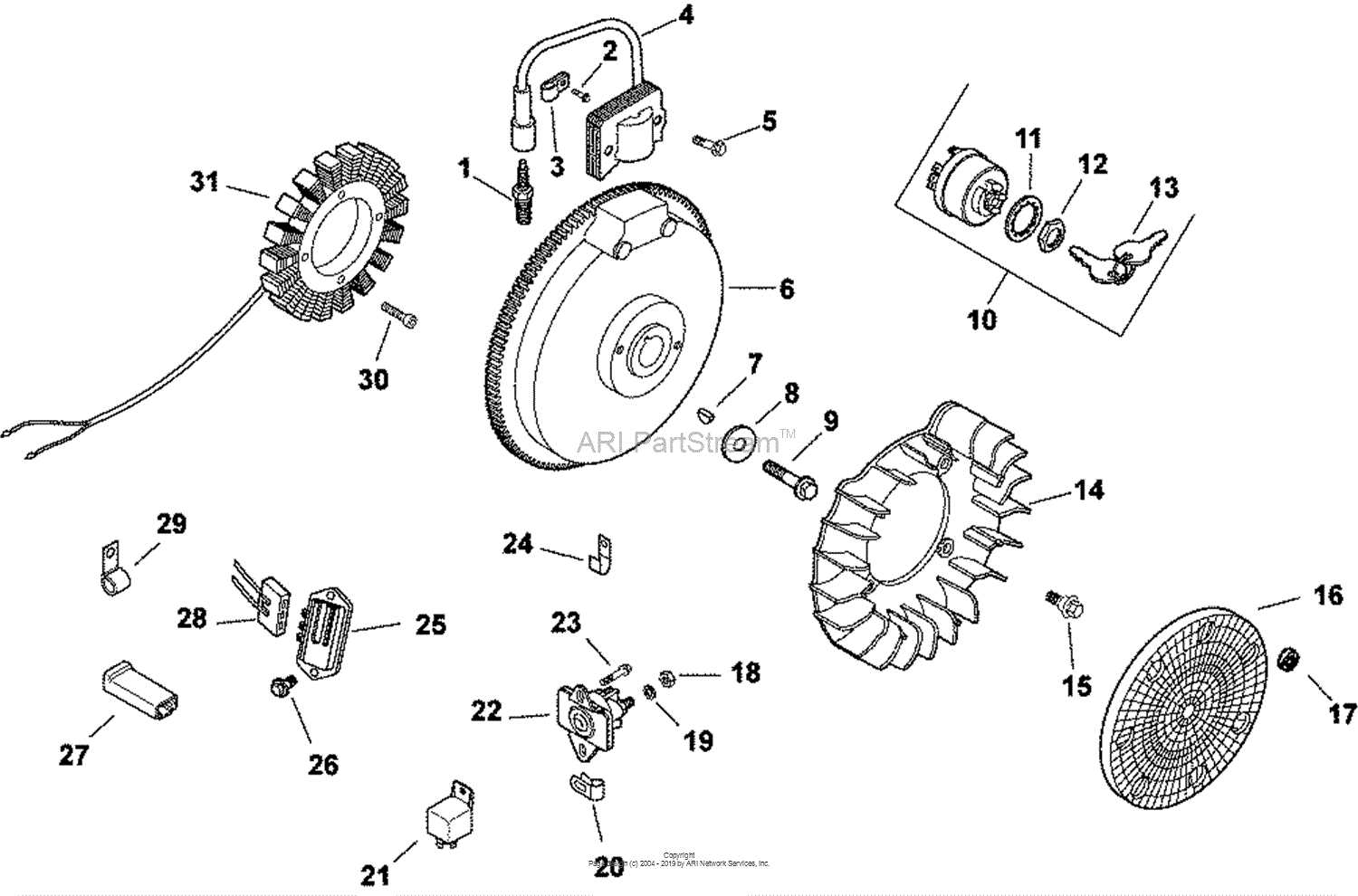

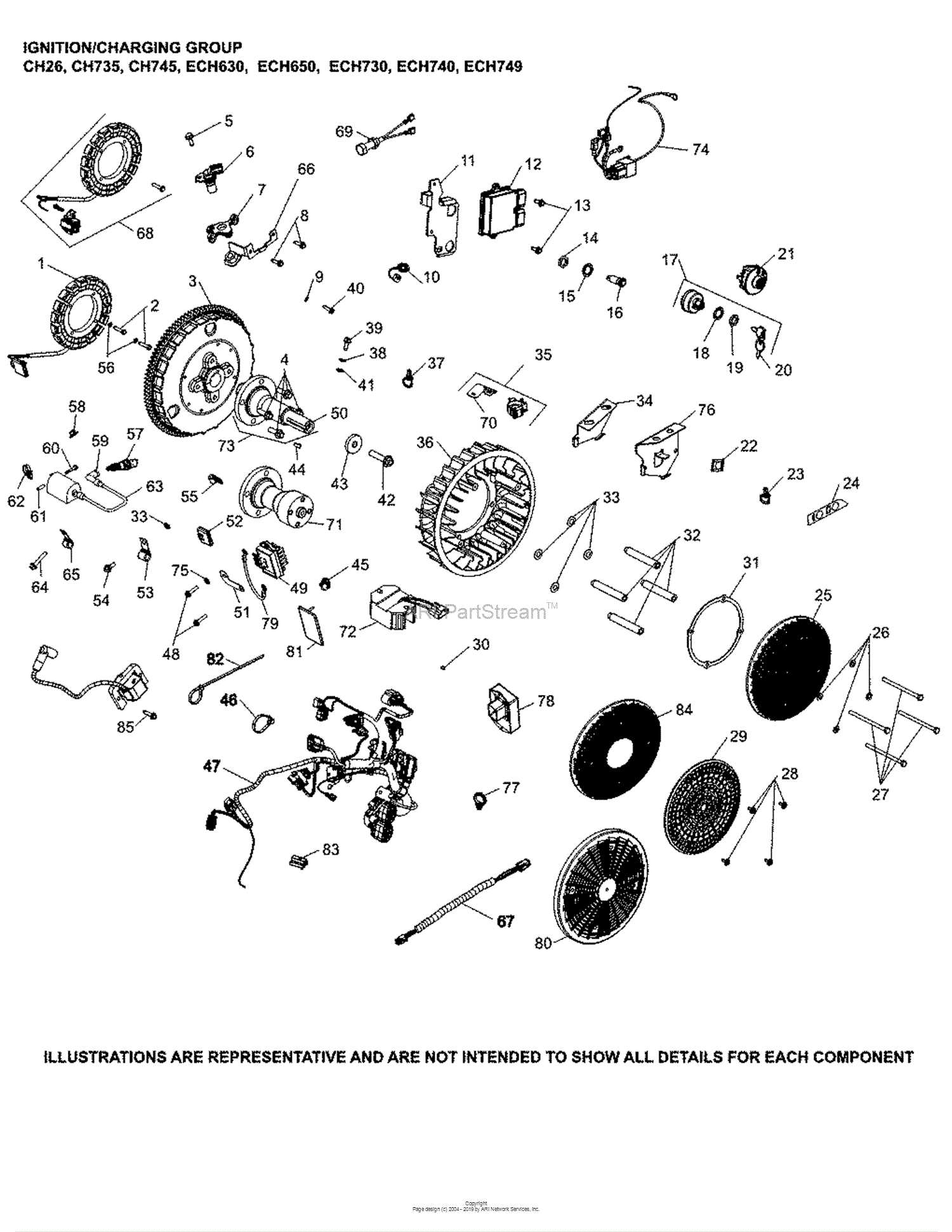

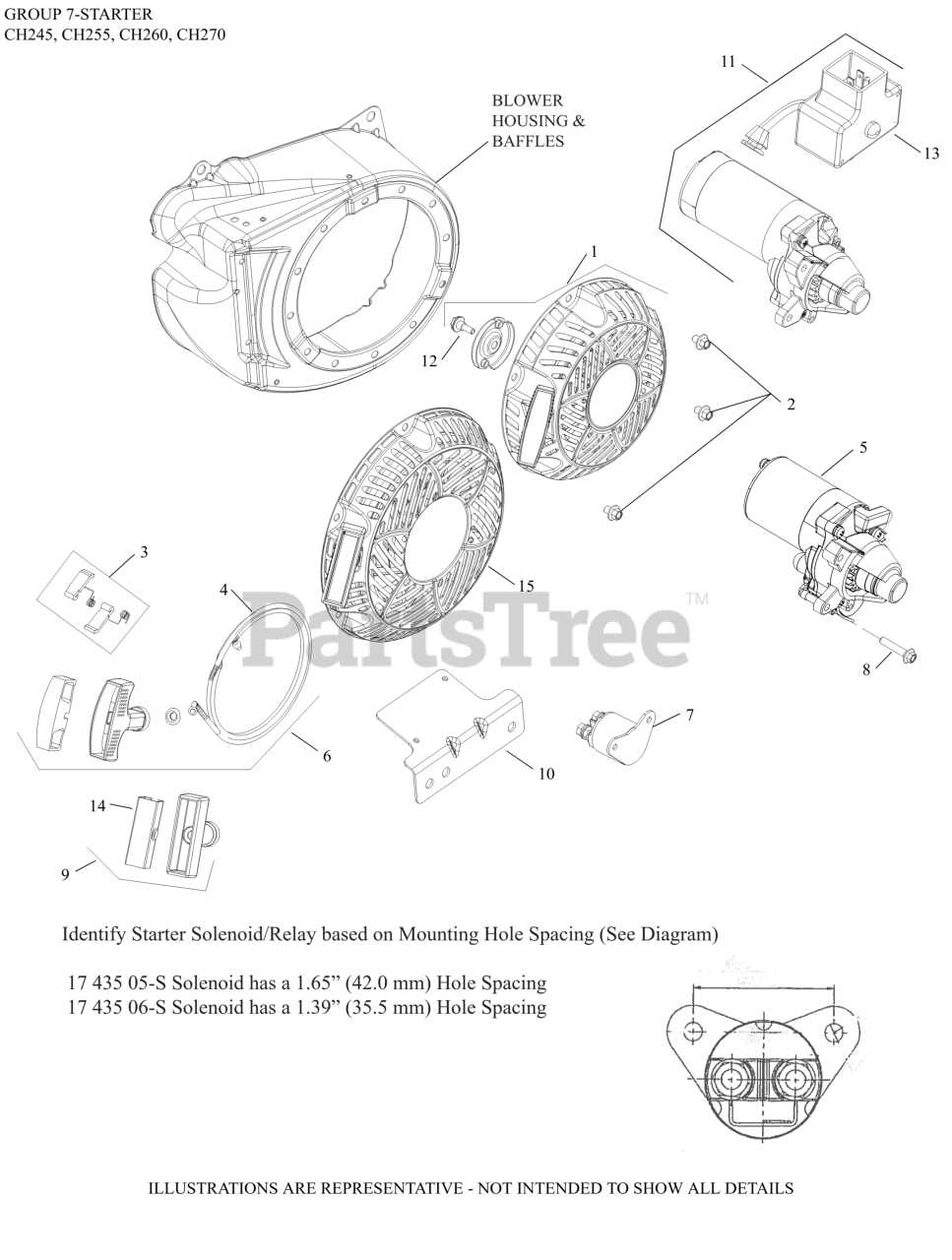

Ignition System: The ignition system is responsible for igniting the fuel-air mixture within the combustion chamber. It includes components such as spark plugs and ignition coils, which are essential for starting the engine and maintaining its operation.

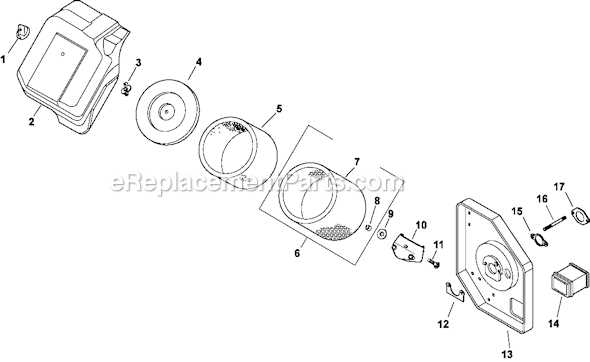

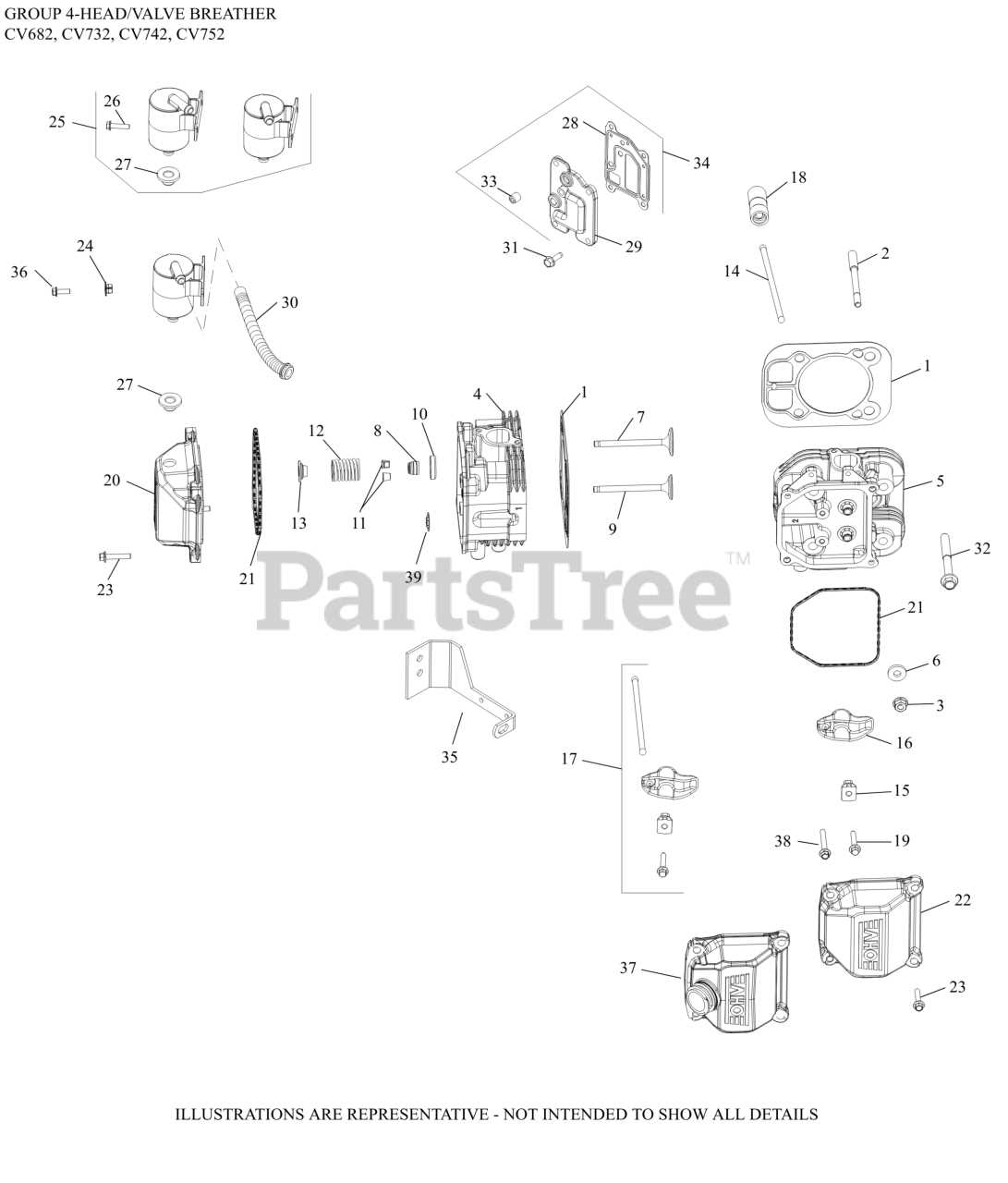

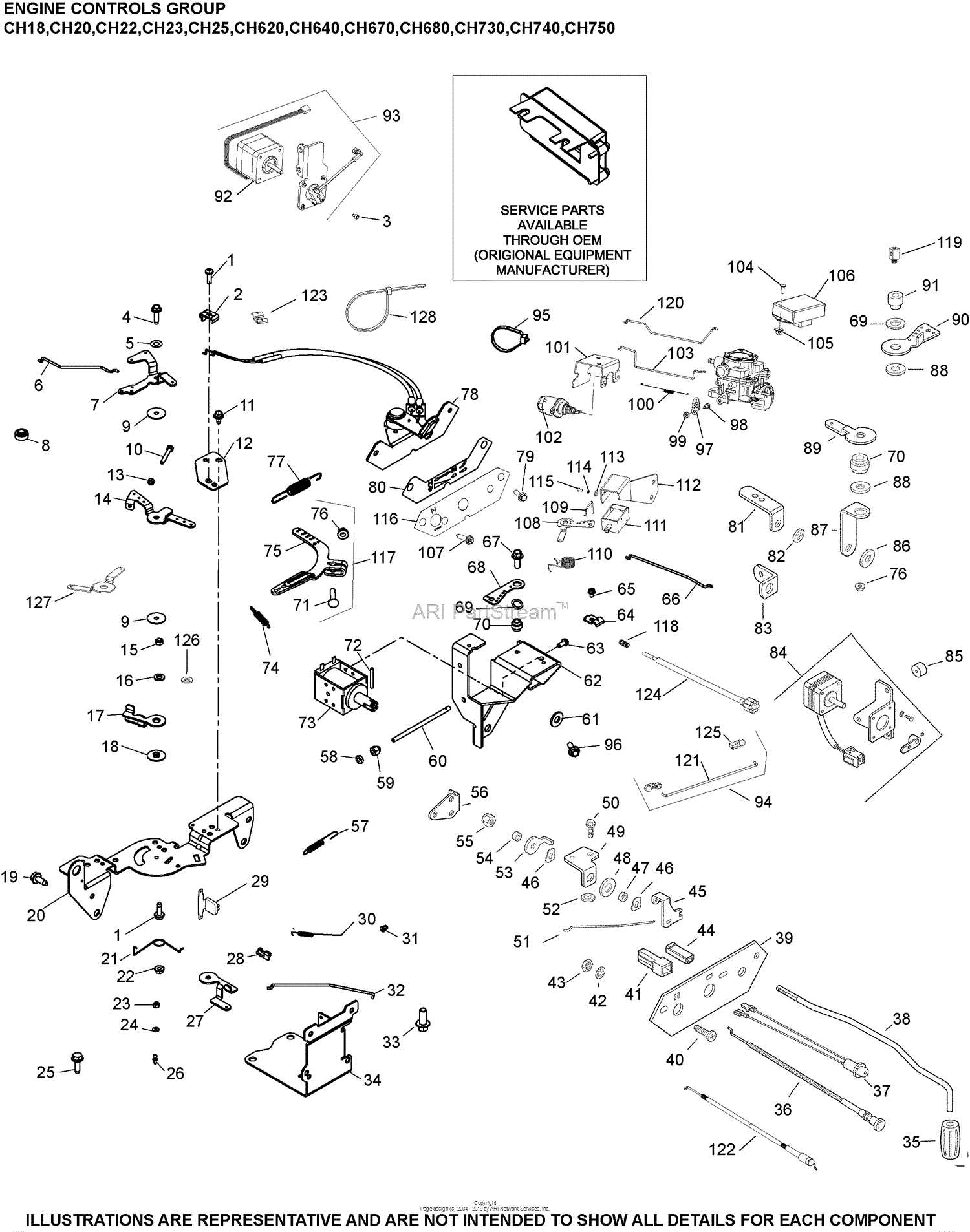

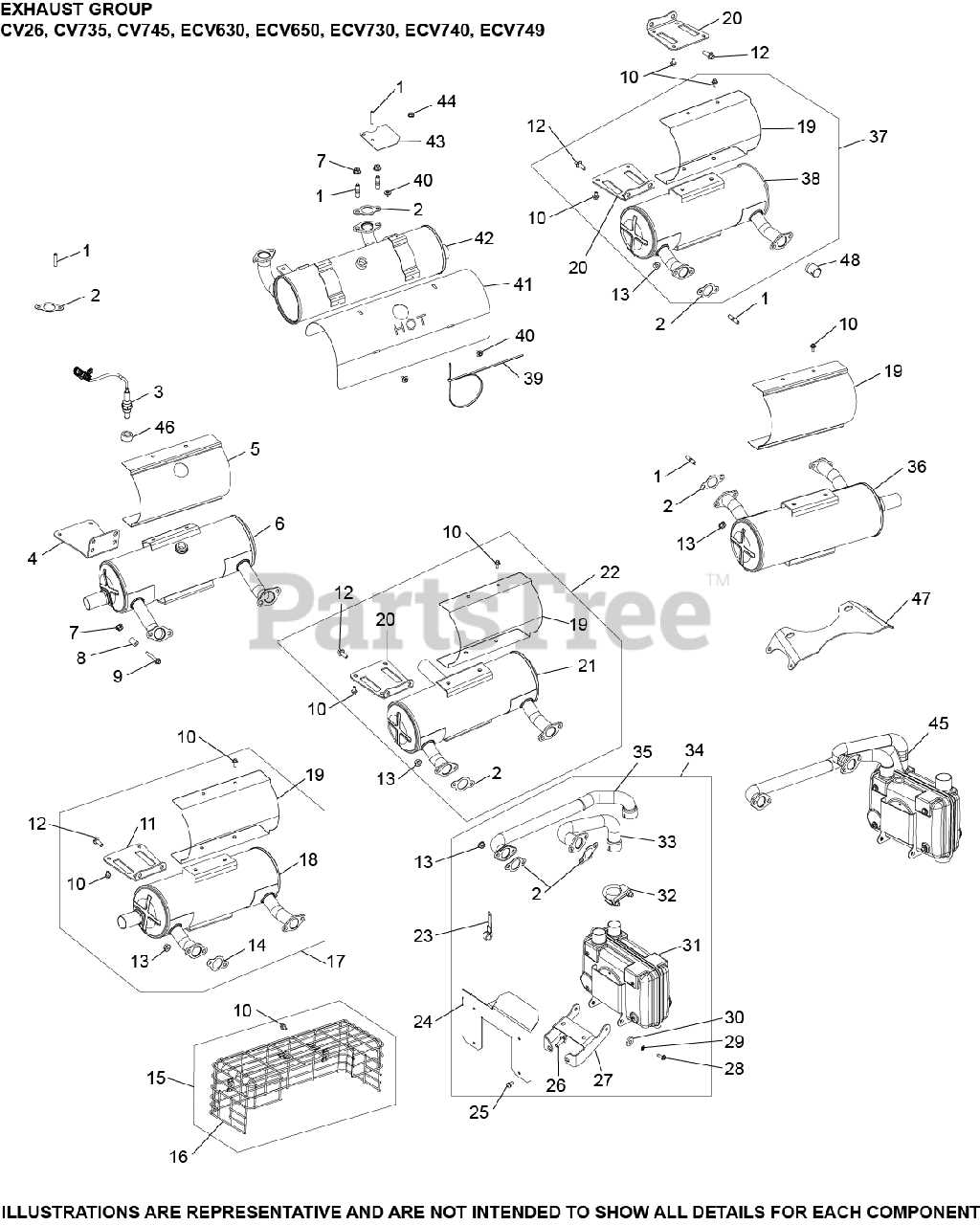

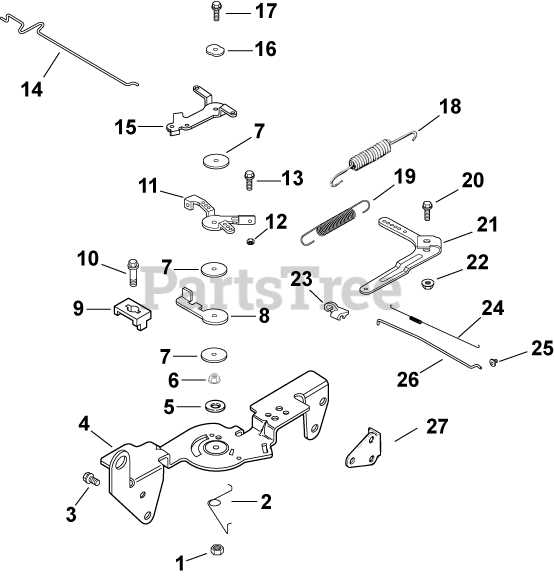

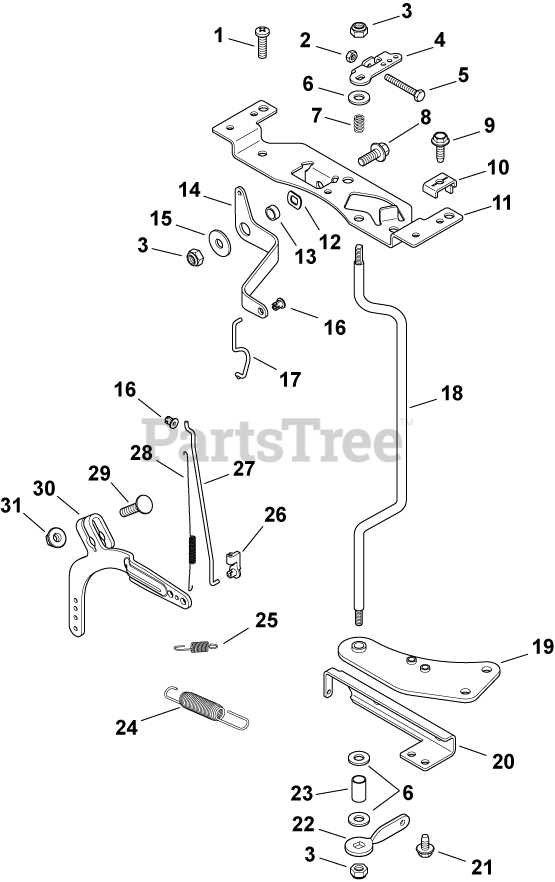

Understanding the Parts Diagram

This section provides insight into the visual representation of components within a specific system, allowing users to identify and comprehend the various elements and their functions. Such illustrations serve as valuable tools for maintenance, repairs, and modifications.

Recognizing the layout and relationships between different components is crucial for effective troubleshooting and enhancement. Familiarity with this visual guide can lead to improved efficiency and reduced downtime during service activities.

- Identification: Each component is labeled clearly, facilitating easy recognition and reference.

- Functionality: Understanding how parts interact helps in diagnosing issues and planning repairs.

- Assembly: Diagrams often include assembly sequences, guiding users on how to properly install or replace components.

By studying the schematic illustration, individuals can enhance their expertise and ensure their equipment operates at optimal levels. A comprehensive grasp of these visuals fosters confidence in performing tasks related to maintenance and upgrades.

Maintenance Tips for Longevity

Ensuring the prolonged lifespan of your equipment requires diligent care and regular upkeep. Implementing effective maintenance practices not only enhances performance but also prevents costly repairs and downtime. Following a systematic approach to servicing can significantly extend the operational life of your machinery.

Regular Inspections

Conducting routine evaluations is crucial for identifying potential issues before they escalate. Look for signs of wear, leaks, or unusual sounds. Performing these checks frequently allows for timely interventions, ensuring that minor problems do not develop into major repairs.

Fluid Management

Maintaining appropriate fluid levels is essential for optimal performance. Regularly check oil and coolant levels, and replace fluids according to the manufacturer’s recommendations. Clean filters and replace them when necessary to ensure efficient operation. Proper fluid management contributes to a smoother running system and prevents overheating or mechanical failures.

Common Issues and Solutions

In any mechanical system, users may encounter various challenges that can affect performance and efficiency. Understanding these issues and their potential solutions is crucial for maintaining optimal operation and extending the lifespan of the equipment. Below are some frequently observed problems along with suggested remedies.

- Starting Difficulties:

Many users experience trouble starting the engine. This can be due to fuel delivery issues or electrical failures.

- Check the fuel level and ensure it is fresh and uncontaminated.

- Inspect the battery and connections for any corrosion or loose wiring.

- Examine the ignition system components for wear and tear.

- Overheating:

Excessive heat can lead to significant damage if not addressed promptly. Common causes include coolant leaks and blockages.

- Verify the coolant levels and top off if necessary.

- Inspect hoses for leaks or cracks.

- Clean any debris obstructing airflow around the cooling system.

- Unusual Noises:

Strange sounds during operation can indicate mechanical problems. These noises might signal wear in moving parts or insufficient lubrication.

- Listen for grinding or knocking sounds and check the oil levels.

- Inspect the components for loose or damaged parts.

- Consider using a higher-grade lubricant to improve performance.

- Power Loss:

A reduction in power output can hinder productivity. This issue may stem from several factors, including fuel supply problems or air filter blockages.

- Examine the air filter and replace it if it is dirty or clogged.

- Check fuel lines for obstructions or leaks.

- Ensure the spark plugs are functioning correctly and replace them if necessary.

Ordering Replacement Parts Easily

Acquiring new components for machinery can be a straightforward task when you have the right approach. Efficiently navigating the purchasing process is crucial for maintaining the functionality of your equipment. Understanding where to look and how to communicate your needs can save both time and effort.

When seeking new elements, it’s essential to start with a clear list of the required items. Having specific details about the items, including model numbers and descriptions, will streamline the ordering process. This helps in avoiding delays or misunderstandings with suppliers.

Additionally, leveraging online resources can enhance your experience. Many websites offer comprehensive catalogs, allowing you to browse through available options and compare prices. Here are some tips to keep in mind:

| Tip | Description |

|---|---|

| Check Compatibility | Ensure the components you are ordering are compatible with your equipment model. |

| Use Reliable Suppliers | Select well-reviewed suppliers to ensure quality and timely delivery of your items. |

| Read Reviews | Look for customer feedback on the components to gauge their reliability and performance. |

| Keep Records | Maintain a log of all purchases for future reference and warranty purposes. |

By following these guidelines, you can enhance your ordering experience and ensure that your machinery remains in optimal condition.

Benefits of Genuine Kohler Parts

Using authentic components for your equipment ensures optimal performance and longevity. These original items are specifically designed to fit perfectly and function effectively with your machinery, providing a seamless experience for users.

Quality Assurance: Authentic replacements undergo rigorous testing and quality control, guaranteeing that they meet the manufacturer’s high standards. This reliability minimizes the risk of failure and enhances overall efficiency.

Enhanced Performance: Genuine items are crafted with precision, ensuring that they work harmoniously with your equipment. This compatibility leads to improved operation, reduced wear and tear, and enhanced productivity over time.

Warranty Protection: Utilizing original components often maintains the validity of your warranty. Manufacturers typically require the use of their genuine items for repairs and replacements to uphold warranty claims, providing you with peace of mind.

Availability of Support: When using authentic components, you have access to the manufacturer’s support and resources. This includes detailed information, installation guidance, and customer service, ensuring that you can address any issues that arise efficiently.

Cost-Effectiveness: While the initial investment in authentic items may seem higher, the long-term benefits often outweigh the costs. Enhanced durability and performance can lead to lower maintenance expenses and prolonged equipment lifespan.

Visual Identification of Parts

Recognizing components in a mechanical assembly can significantly enhance maintenance and repair efficiency. Understanding the appearance and arrangement of various elements aids users in identifying issues promptly and selecting the appropriate replacements. This section focuses on the visual characteristics that differentiate individual elements within the system, enabling more effective diagnostics and servicing.

Component Overview

Each element plays a crucial role in the overall functionality of the machinery. The unique shapes, colors, and materials can often provide insights into their specific functions. For instance, metallic components may indicate strength and durability, while plastic parts might signify lightweight designs. Familiarity with these visual cues is essential for effective troubleshooting.

Labeling and Markings

Labels and markings are often utilized to provide additional information about components. These identifiers can include part numbers, manufacturer details, and safety warnings. Paying close attention to these labels can facilitate accurate identification, ensuring that replacements are compatible and meet the necessary specifications.

Using the Diagram for Repairs

Utilizing a visual representation of components can significantly enhance the repair process. It provides a comprehensive overview of the various elements involved, allowing users to easily identify each piece and understand its function. This clarity is essential when diagnosing issues or replacing specific components.

Identifying Components

When attempting to fix an engine, having a clear view of its structure is invaluable. A well-detailed illustration aids in pinpointing the exact location of each element, ensuring that no part goes overlooked. This accuracy can prevent potential mistakes that may arise during reassembly.

Streamlining the Repair Process

Having access to a detailed schematic allows for a more organized approach to maintenance. By following the layout, users can systematically address each component, reducing the likelihood of confusion. This methodical technique not only saves time but also enhances overall efficiency.

| Component | Function | Replacement Tip |

|---|---|---|

| Fuel Filter | Removes impurities from fuel | Check for clogs regularly |

| Spark Plug | Ignites fuel mixture | Replace every season |

| Oil Seal | Prevents leakage | Inspect for wear and tear |

Comparing Different Command Pro Models

This section provides an overview of various models from a renowned engine manufacturer, highlighting their unique features and specifications. By examining the differences and similarities among these engines, users can make informed decisions based on their specific needs and applications.

Several models stand out in the lineup, each designed for different operational requirements. Here are some key aspects to consider:

- Engine Size: Variations in engine displacement can significantly impact performance and efficiency.

- Power Output: Different models deliver varying horsepower levels, catering to a range of tasks.

- Fuel Type: Options include gasoline and diesel, influencing operating costs and suitability for specific applications.

- Cooling System: Some engines feature air cooling, while others utilize liquid cooling for improved thermal management.

- Weight: Consideration of weight is essential for portability and ease of installation.

When comparing these engines, it’s also important to look at:

- Durability: Material quality and design play a crucial role in the longevity of the engine.

- Maintenance Requirements: Understanding the maintenance intervals and ease of access to components can save time and costs.

- Application Suitability: Certain engines are tailored for specific tasks, such as lawn care, construction, or agricultural use.

By analyzing these factors, users can determine which model best fits their operational needs, ensuring optimal performance and efficiency in various applications.

FAQs About Kohler Command Pro

This section addresses common inquiries related to the engine series designed for durability and performance. Here, you’ll find essential information and answers to frequently asked questions, helping users better understand their equipment and enhance its functionality.

What types of applications are suitable for this engine series?

This engine series is versatile and can be utilized in various applications, including landscaping equipment, construction tools, and agricultural machinery. Its robust design ensures reliable operation in demanding environments.

How can I maintain optimal performance?

To ensure longevity and efficiency, regular maintenance is crucial. This includes routine oil changes, air filter replacements, and checking spark plugs. Following the manufacturer’s maintenance schedule will help keep your engine running smoothly.

Resources for Further Assistance

When tackling maintenance and repair tasks, accessing reliable information can significantly enhance the process. Numerous resources are available to support individuals seeking detailed guidance on various engine components and their functionality.

Online Forums and Communities: Engaging with online groups dedicated to engine enthusiasts can provide valuable insights. Participants often share their experiences, troubleshooting tips, and detailed advice on specific issues.

Manufacturer Websites: Official websites often offer comprehensive manuals and technical specifications. These resources can help users understand the assembly and operation of different engine systems.

Video Tutorials: Platforms like YouTube feature numerous instructional videos that visually demonstrate repair techniques and maintenance procedures. These can be especially beneficial for visual learners looking to grasp complex tasks.

Local Repair Shops: Consulting with professionals in nearby workshops can provide hands-on assistance and expert advice. Many mechanics are willing to share their knowledge and offer personalized tips for particular models.

Books and Guides: Printed manuals and guides are excellent resources for in-depth information. They typically cover a wide range of topics, including diagnostics, repair methods, and preventive maintenance strategies.

By leveraging these resources, users can enhance their understanding and effectively address their equipment needs.