For those engaged in the maintenance and repair of outdoor power equipment, comprehending the layout of engine components is essential. This knowledge not only aids in effective troubleshooting but also ensures that each part functions harmoniously within the larger system.

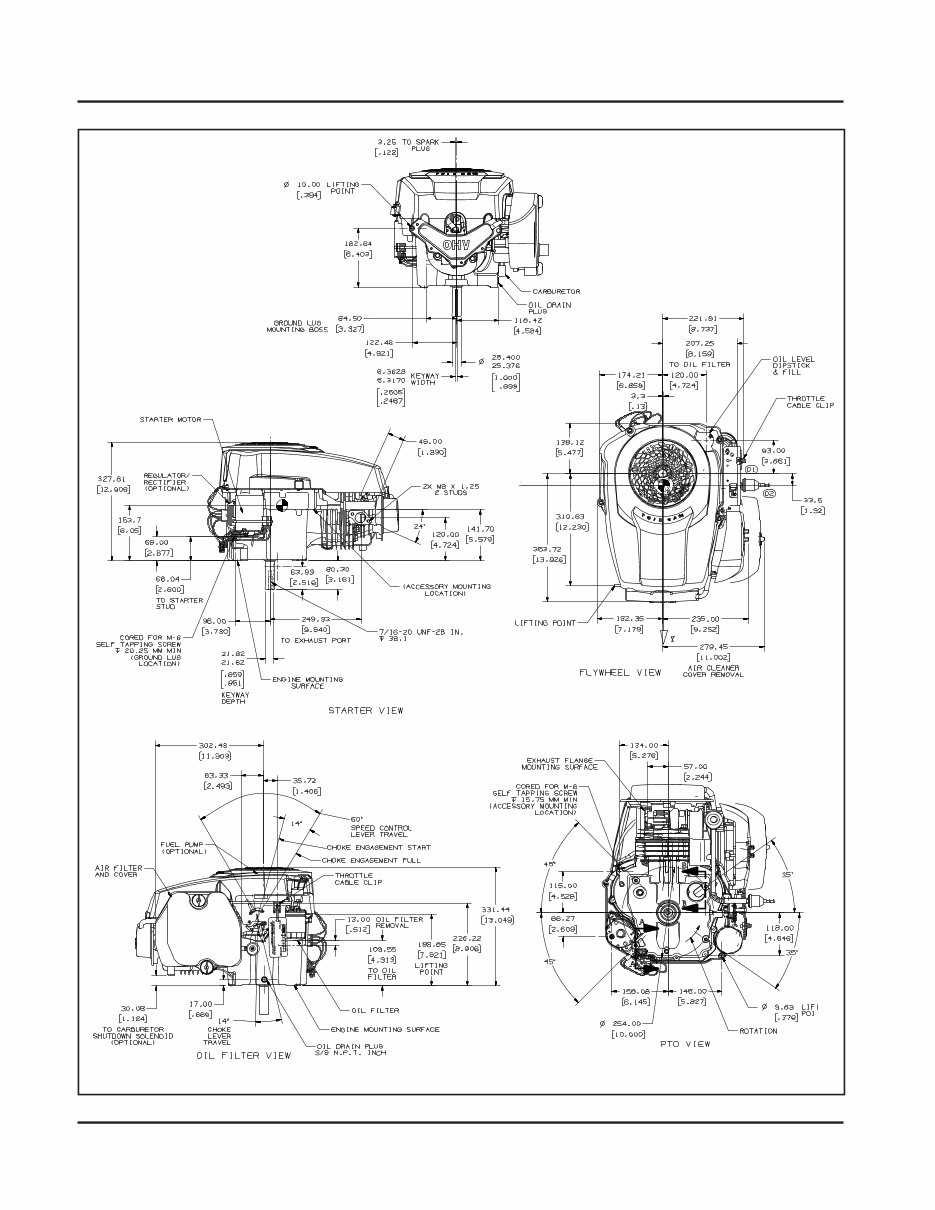

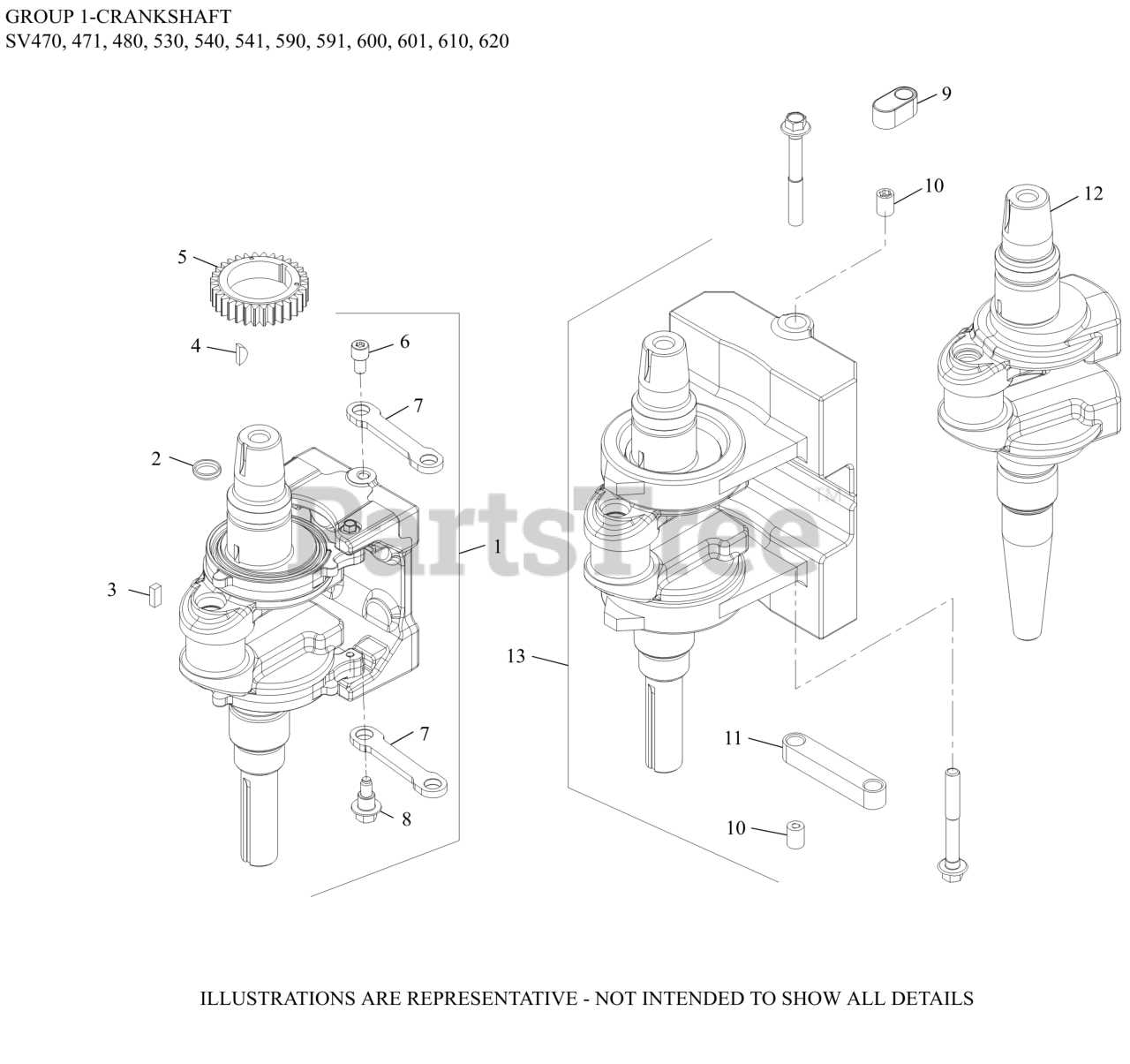

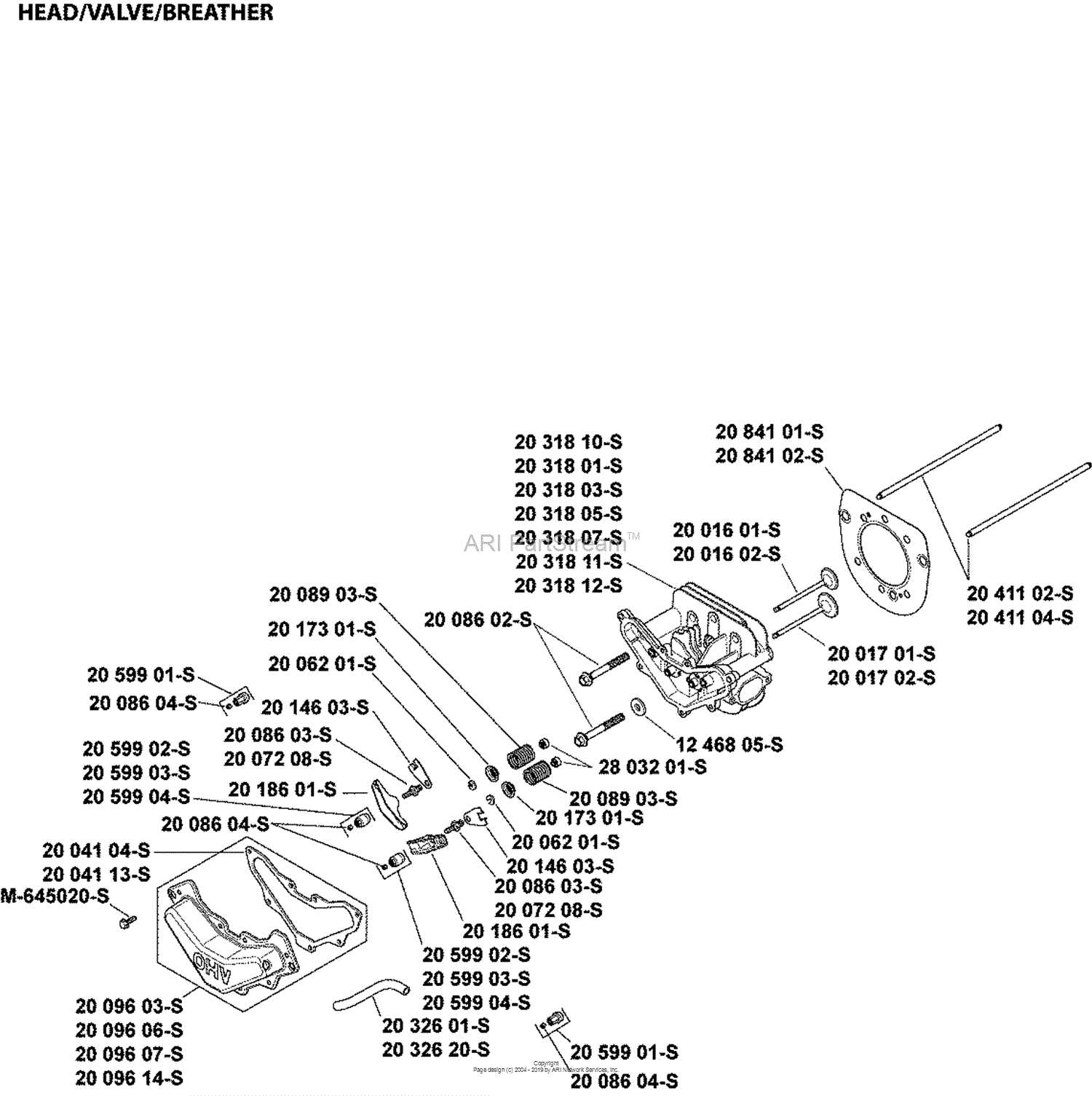

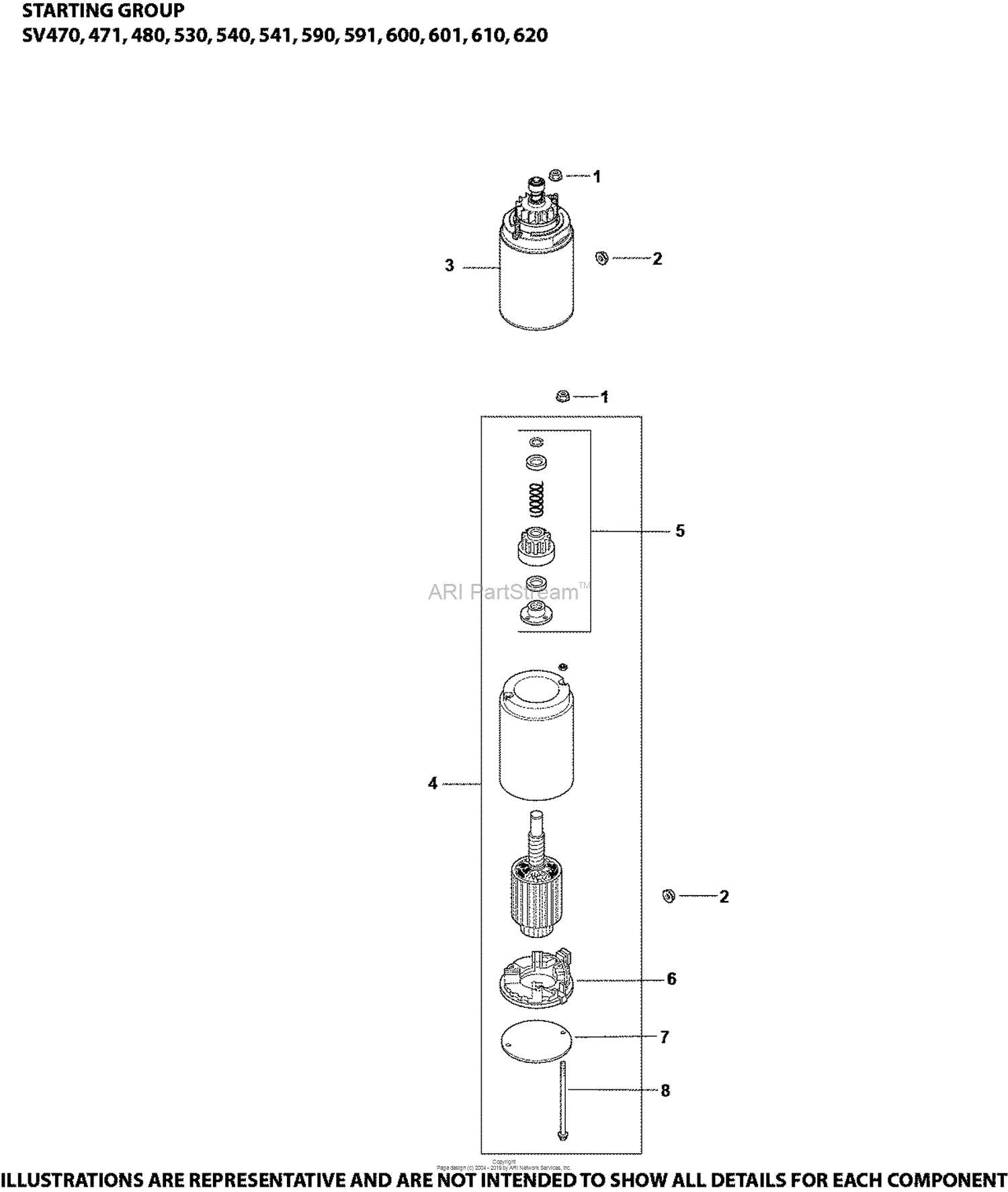

Visual representations of these layouts serve as invaluable tools, allowing technicians to pinpoint specific elements swiftly. With a clear understanding, one can delve deeper into the functionality and replacement of each section, enhancing overall performance.

Ultimately, grasping the intricacies of these diagrams fosters a more profound appreciation for the machinery, leading to informed decisions during repairs and upgrades. This understanding empowers users to maintain their equipment effectively, prolonging its lifespan.

Kohler SV540 Overview

This section provides an in-depth look at a specific engine model renowned for its performance and reliability in various applications. Designed with efficiency in mind, it combines robust engineering with innovative features to meet the needs of users across different sectors.

Power and Performance: This engine excels in delivering high torque and consistent power output, making it ideal for demanding tasks. Its design ensures optimal fuel efficiency while maintaining excellent performance under load.

Durability and Maintenance: Built to withstand harsh conditions, the unit incorporates advanced materials and technology that enhance its longevity. Routine maintenance is simplified, promoting ease of care and reducing downtime.

Applications: Commonly utilized in outdoor power equipment, this engine serves a wide range of applications, from lawn mowers to generators, providing dependable operation and versatility for users.

Conclusion: Overall, this engine model stands out in its category, representing a blend of power, efficiency, and resilience, making it a preferred choice for many professionals and enthusiasts alike.

Key Features of SV540 Engine

The engine in question is designed to deliver exceptional performance and reliability, making it a preferred choice for various applications. With advanced engineering and innovative technology, this power unit stands out for its efficiency and durability, catering to the needs of both professionals and enthusiasts.

Performance and Efficiency

This powerhouse boasts impressive output, ensuring that tasks are completed swiftly and effectively. The fuel consumption is optimized, allowing for extended operation without frequent refueling. Low emissions are a hallmark, contributing to a more environmentally friendly performance while adhering to regulatory standards.

Durability and Maintenance

Constructed with robust materials, this engine is built to withstand rigorous use and harsh conditions. Easy maintenance features simplify servicing, allowing users to keep their machinery in top condition with minimal effort. This reliability translates into lower downtime and increased productivity over time.

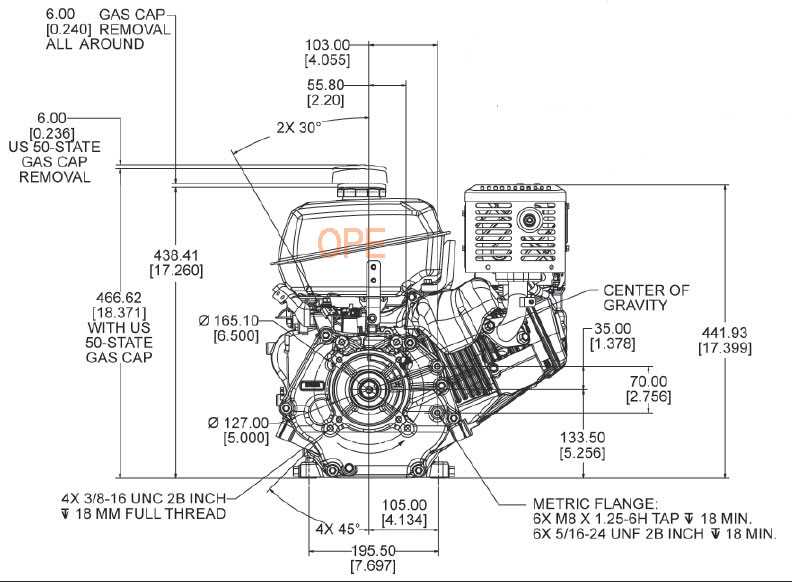

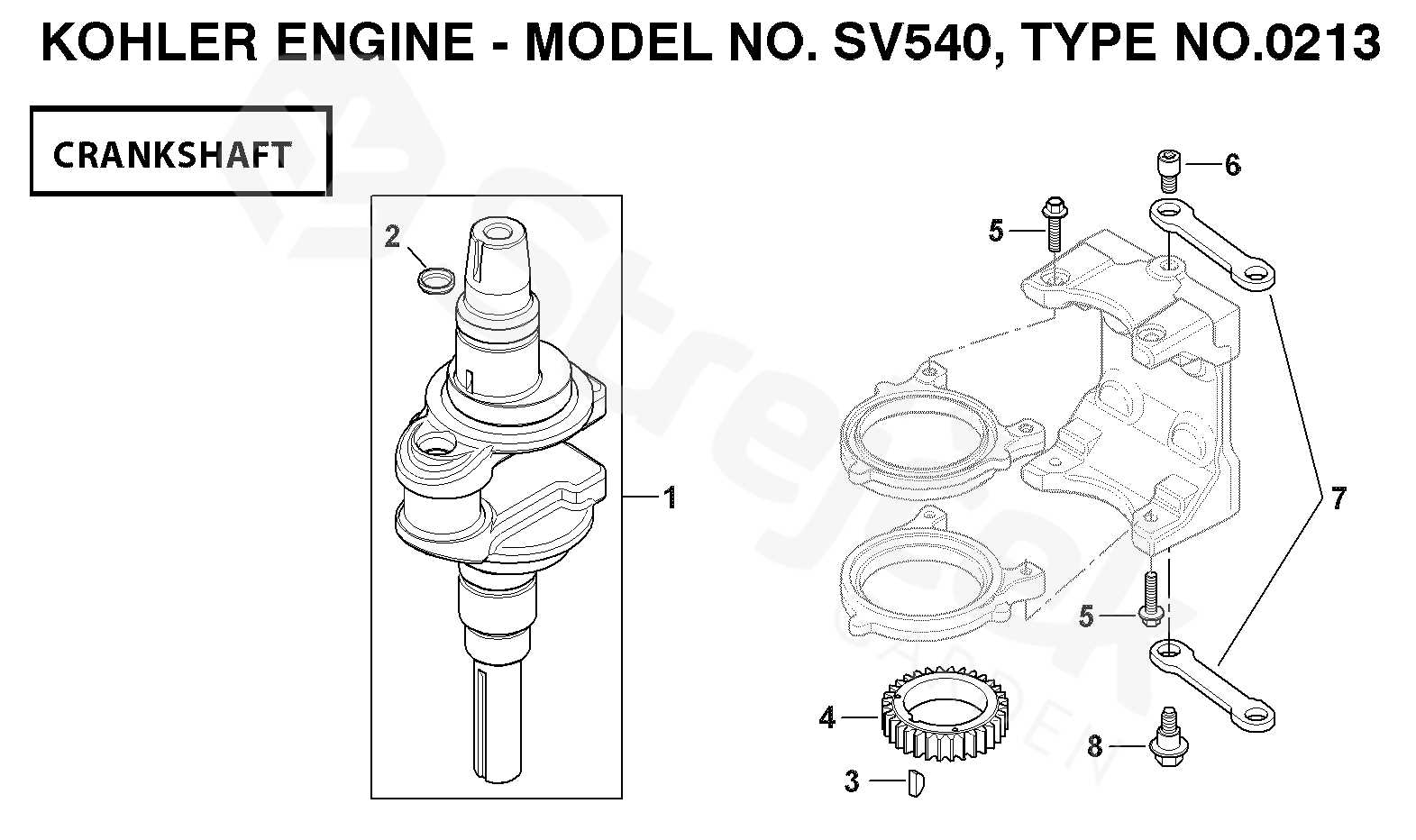

Understanding Parts Diagram Importance

Comprehending the significance of technical illustrations is essential for anyone engaged in maintenance or repair tasks. These visual representations serve as a crucial guide, enabling users to identify individual components and their relationships within complex machinery. By providing a clear overview, such illustrations facilitate efficient troubleshooting and ensure that necessary replacements are accurately selected.

One of the primary benefits of utilizing these visual tools is the enhancement of user knowledge. They break down intricate systems into understandable sections, allowing even those with limited experience to grasp the overall function of each element. This understanding leads to improved decision-making when it comes to repairs and replacements.

Furthermore, these visuals contribute significantly to time management. By clearly indicating where specific elements are located and how they fit together, they minimize the guesswork often involved in repairs. This efficiency not only saves time but also reduces the risk of errors, ultimately leading to more successful maintenance outcomes.

Common Components in Kohler SV540

Understanding the essential elements of a small engine is crucial for effective maintenance and repair. These components work together to ensure optimal performance and reliability. Below, we explore the primary elements found in these types of engines.

Key Elements

- Fuel System

- Air Intake

- Ignition System

- Cooling Mechanism

- Lubrication System

Fuel System Components

- Carburetor: Regulates air-fuel mixture for combustion.

- Fuel Pump: Delivers fuel from the tank to the engine.

- Fuel Filter: Cleans fuel before it reaches the engine.

Each of these components plays a vital role in ensuring the engine operates smoothly, demonstrating the importance of regular checks and maintenance for longevity.

Where to Find Parts Diagrams

Locating visual guides for mechanical components is essential for effective maintenance and repair. These resources provide valuable insights into the structure and assembly of machinery, helping users identify necessary elements easily.

- Manufacturer Websites: Most manufacturers offer downloadable resources directly on their sites, ensuring accuracy and reliability.

- Online Retailers: Many e-commerce platforms feature detailed illustrations alongside product listings, making it easy to find what you need.

- Forums and Community Groups: Enthusiast communities often share valuable links and documents, enhancing collaborative knowledge.

- Technical Manuals: Comprehensive guides often include detailed visuals; check for downloadable versions or physical copies.

Utilizing these resources can significantly streamline your repair process and enhance your understanding of the equipment’s components.

Maintenance Tips for SV540 Engine

Proper upkeep of your engine is essential for ensuring optimal performance and longevity. Regular maintenance helps prevent breakdowns and costly repairs while enhancing efficiency. By following a structured maintenance routine, you can keep your machinery running smoothly and extend its lifespan.

Begin with regular oil changes, as clean oil is vital for lubricating engine components and minimizing wear. Check the manufacturer’s guidelines for recommended intervals and oil type. Additionally, inspect and replace the air filter as needed to maintain proper airflow and prevent dirt from entering the engine.

Fuel quality is equally important; using clean, high-quality fuel will improve performance and reduce the risk of clogs. Regularly inspect fuel lines for any signs of wear or leaks. It’s also beneficial to keep the cooling system in check. Ensure that coolant levels are adequate and look for any signs of corrosion or blockage.

Lastly, routine inspections of the ignition system, including spark plugs and wires, can prevent starting issues. Clean or replace these components as necessary to ensure reliable ignition. By adhering to these maintenance tips, you can enjoy a well-functioning engine for years to come.

Identifying Specific Parts Easily

Locating individual components within a complex assembly can often be a challenging task. However, with the right approach and resources, the process becomes significantly more manageable. Understanding the layout and having access to a clear visual reference can greatly enhance your ability to pinpoint the necessary elements with confidence.

Utilizing Visual References

Accessing well-structured illustrations or guides allows for quicker identification. These resources often provide labeled sections that simplify the process of finding what you need. Visual aids serve as invaluable tools, especially when dealing with intricate machinery.

Familiarity with Component Functions

Gaining a basic understanding of how different components interact is essential. Knowing the role each part plays can help narrow down your search effectively. This knowledge not only saves time but also enhances overall efficiency in maintenance or repairs.

How to Use the Diagram Effectively

Understanding a visual representation of components can significantly enhance your ability to maintain and repair machinery. By familiarizing yourself with these illustrations, you can streamline your troubleshooting process and ensure efficient reassembly of parts. Here are some tips on how to make the most of these resources.

1. Familiarize Yourself with the Layout

Before diving into the specifics, take some time to understand the overall structure. This will help you identify key sections and locate relevant components quickly. Consider the following:

- Identify the main sections and their functions.

- Look for legends or keys that explain symbols and terminology.

- Note any color codes that may indicate specific categories of parts.

2. Follow a Step-by-Step Approach

When using the visual guide for repairs or assembly, a systematic approach is essential. Here’s a suggested workflow:

- Gather all necessary tools and replacement components.

- Refer to the illustration to identify the part you need to replace or inspect.

- Follow the indicated connections and placements carefully.

- As you work, cross-reference the visual guide with your actual assembly to ensure accuracy.

By adopting these strategies, you can effectively utilize these visual resources to enhance your repair and maintenance tasks, leading to more successful outcomes and improved machinery performance.

Common Issues and Solutions

When dealing with small engine machinery, various complications may arise that can hinder performance. Understanding these frequent problems and their corresponding solutions is essential for maintaining efficiency and prolonging the life of the equipment. Below are some common challenges faced by users and practical steps to address them.

Engine Performance Problems

One of the most prevalent issues is inadequate engine performance, which can manifest as rough idling or poor acceleration. This can be caused by a number of factors, including fuel quality, air filter conditions, or ignition system malfunctions.

| Issue | Possible Cause | Solution |

|---|---|---|

| Poor acceleration | Clogged air filter | Replace or clean the air filter |

| Rough idling | Old fuel or fuel contamination | Drain and replace fuel with fresh quality fuel |

| Hard starting | Faulty spark plug | Inspect and replace spark plug as needed |

Overheating Issues

Another significant concern is overheating, which can lead to severe damage if not addressed promptly. This often results from insufficient cooling, low oil levels, or blockages in the cooling system.

| Issue | Possible Cause | Solution |

|---|---|---|

| Overheating | Low oil level | Check and refill oil to the recommended level |

| Engine shuts down | Blocked cooling fins | Clean cooling fins and ensure proper airflow |

| Unusual noises | Insufficient lubrication | Verify oil quality and quantity; replace if necessary |

Replacing SV540 Parts: Best Practices

Maintaining machinery involves careful attention to its components. When it comes time to swap out worn or damaged elements, following best practices ensures efficiency and longevity. Understanding the process can significantly reduce the risk of errors and enhance performance.

Here are some essential tips for successful replacement:

- Consult the Manual: Always refer to the manufacturer’s manual for specific instructions and specifications. This will provide guidance on compatible replacements and installation techniques.

- Gather Tools: Before starting, ensure you have all necessary tools on hand. Commonly required items include wrenches, screwdrivers, and pliers.

- Work in a Clean Environment: A tidy workspace minimizes the chance of losing small components and reduces contamination risks during installation.

- Take Photos: Document the original setup with photographs. This can serve as a valuable reference when reassembling parts.

- Check for Wear: Examine surrounding components for signs of wear or damage. Addressing these issues during the replacement process can prevent future problems.

Following these guidelines will enhance the effectiveness of your replacement efforts and contribute to the overall reliability of the machinery.