Understanding the structure of an engine and how its various components interact is crucial for maintaining optimal performance and ensuring a long lifespan. Whether you’re performing regular maintenance or troubleshooting a specific issue, having a clear view of the internal and external elements can greatly simplify the task.

Identifying the essential elements within the engine assembly enables smoother repair processes and helps prevent potential issues from escalating. Knowing the layout of each element, along with its function and placement, provides a solid foundation for anyone looking to perform effective maintenance or upgrades.

In this guide, you’ll find a detailed exploration of the different sections, including the mechanical connections and functional areas that contribute to the overall performance. This knowledge is not only valuable for repairs but also for understanding how to maximize efficiency and ensure reliability over time.

Kohler SV720 Parts Diagram Guide

Understanding the layout of various components in a complex engine can simplify maintenance and repairs. A visual representation helps identify individual elements, making it easier to locate specific items and understand how they connect within the system. This guide aims to provide a clear overview for users seeking to improve their understanding and streamline their tasks.

Component Overview

Each mechanical unit features several interconnected elements, including moving parts, fasteners, and support structures. The arrangement ensures smooth operation, with every section playing a crucial role in performance. Familiarity with this setup can assist in troubleshooting and identifying which area may require attention.

Maintenance Tips

Regular upkeep and careful inspection can significantly extend the life of your equipment. Checking the alignment and condition of various elements can prevent minor issues from escalating into major problems. Make sure to follow recommended practices for cleaning and replacing worn-out sections to maintain optimal functionality.

Understanding Kohler SV720 Engine Layout

The structure of this engine model reveals a thoughtfully designed arrangement aimed at optimizing performance and maintenance. The configuration ensures all components are easily accessible, facilitating straightforward servicing and efficient cooling. Each element is strategically positioned to contribute to the system’s overall stability and functionality.

Cylinder positioning plays a key role in balancing the unit, while the placement of other components enhances airflow and reduces potential overheating. The layout includes areas dedicated to crucial elements such as the fuel delivery system and ignition controls, all arranged for seamless operation.

Additionally, the positioning of maintenance points, such as the oil filter and air intake, is carefully considered to enable easy reach, allowing for quicker inspections and replacements. This arrangement helps in maintaining consistent performance over time, ensuring reliability in various operating conditions.

Key Components of Kohler SV720

The engine is made up of various crucial elements that work together to ensure reliable performance and efficiency. Understanding these essential parts can help in maintaining and troubleshooting the system, ensuring smooth operation and longevity. Below, we’ll explore the main elements that contribute to the engine’s functionality.

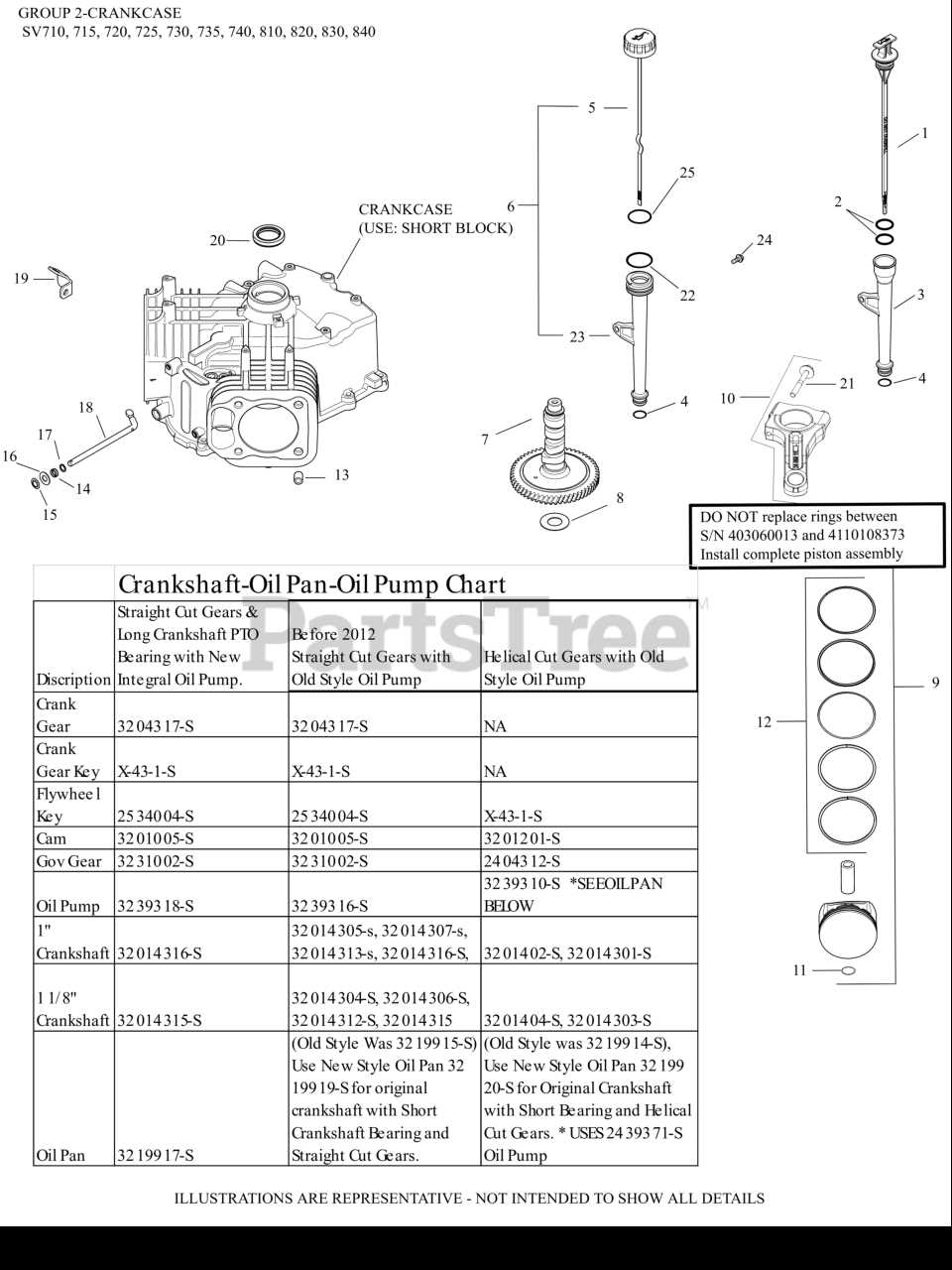

Main Structural Elements

Several structural components form the foundation, including the cylinder block and the crankcase. These parts provide stability and house the moving elements of the engine, allowing the various mechanical operations to occur seamlessly. Their design ensures durability and resistance to wear, even under demanding conditions.

Functional Moving Parts

Key moving elements include the piston, connecting rod, and crankshaft, which convert combustion energy into rotational motion. Additionally, the camshaft, paired with the valve system, manages the intake and exhaust cycles, optimizing airflow. These dynamic compone

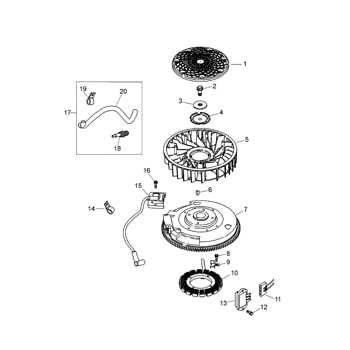

Exploded View of Kohler SV720

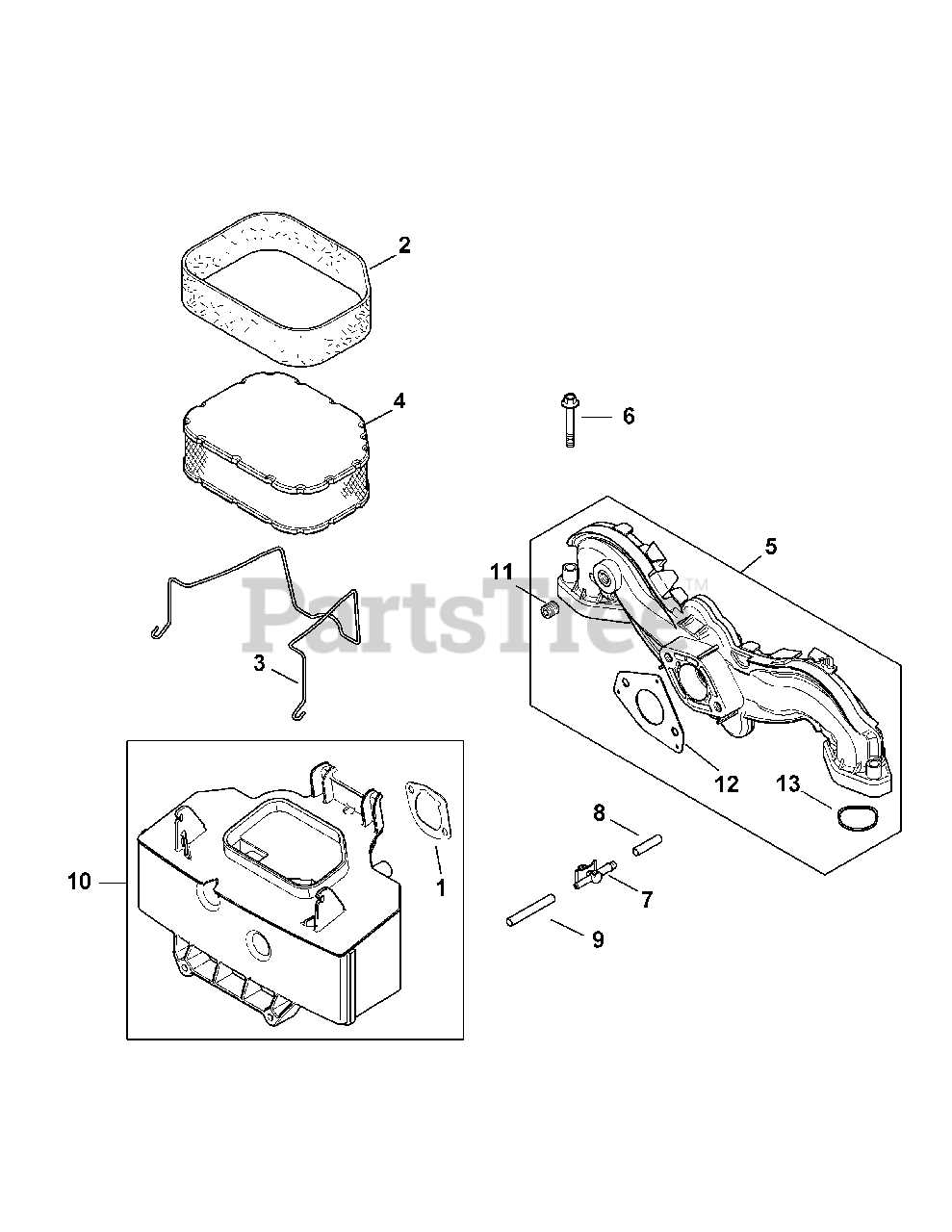

An exploded view provides a detailed representation of the internal components and their arrangement within a machine, giving a visual breakdown of each element’s placement. This approach helps in understanding the assembly and disassembly process, making maintenance and repairs more straightforward. By visualizing each section separately, users can easily identify the specific areas that require attention or replacement.

Main Sections and Components

- Engine Block: The central section, housing crucial internal mechanisms and providing structural support.

- Cylinder Head: Contains valves and supports various smaller elements involved in combustion.

- Exhaust and Intake Systems: Includes pathways for air-fuel mixture intake and exhaust gas expulsion, along with relevant connecting components.

Benefits of Using an Exploded View

- Facilitates quick identification of individual elements, improving troubleshooting efficiency.

- Assists in proper reassembly by showing the exact order and positioning of parts.

- Regularly check and replace the oil to maintain lubrication and reduce wear.

- Inspect the air filter periodically; a clean filter promotes better airflow and performance.

- Examine the spark plugs for signs of wear or deposits; replacing them can improve ignition.

- Keep the cooling system clean and free of debris to prevent overheating.

- Check fuel lines and connections for leaks or damage, ensuring safe operation.

- Follow the manufacturer’s service schedule for any additional specific maintenance tasks.

- Difficulty starting the engine

- Inefficient fuel consumption

- Unusual noises during operation

- Overheating due to inadequate cooling

- Clogged air filters affecting airflow

- Worn spark plugs leading to misfires

- Degraded fuel lines causing leaks

- Oil contamination affecting lubrication

- Material Quality: The durability of materials directly affects overall performance. High-quality materials resist wear and tear, contributing to a longer lifespan.

- Specifications: Each component has specific measurements and capabilities. Ensuring these align with the engine’s requirements is vital for optimal operation.

- Manufacturer Guidelines: Adhering to recommendations from the manufacturer can help avoid compatibility issues and ensure reliable performance.

- Type of Usage: Understanding how the machine will be utilized can guide the selection of components that enhance performance for specific tasks.

- Better compatibility with existing machinery

- Consistent performance levels under various conditions

- Reduction in wear and tear, leading to a longer lifespan

- Fewer breakdowns and repairs due to superior quality

- Extended equipment lifespan, delaying replacement costs

- Improved fuel efficiency and lower operational costs

Identifying Critical Engine Parts

Understanding the key components of an engine is essential for proper maintenance and troubleshooting. Each element plays a crucial role in the engine’s overall performance and efficiency, working together to ensure smooth operation. Recognizing these vital components helps in diagnosing issues and carrying out necessary repairs effectively.

The following table provides an overview of some essential engine elements and their functions:

| Component | Description | |||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cylinder Head | Houses the combustion chamber and controls air and fuel flow, affecting compression and power output. | |||||||||||||||||||||||

| Crankshaft | Converts the up-and-down motion of the pistons into rotational energy, driving the engine’s movement. | |||||||||||||||||||||||

| Piston | Moves within the

Maintenance Tips for Kohler SV720

Proper upkeep of your engine is essential for ensuring its longevity and optimal performance. Regular maintenance not only enhances efficiency but also prevents potential issues that may arise from neglect. Here are some essential recommendations to keep your engine running smoothly. By adhering to these guidelines, you can ensure that your engine remains in top condition, providing reliable power and efficiency for your needs. Replacing Worn-out SV720 PartsMaintenance of outdoor power equipment is crucial for optimal performance and longevity. Over time, components may experience wear, leading to decreased efficiency or functionality. Timely replacement of these items can ensure your machinery operates smoothly and effectively. Identifying worn components is the first step in the replacement process. Regular inspections can help pinpoint areas that may require attention. Common signs of wear include unusual noises, decreased power output, and visible damage. Once you have identified the necessary replacements, sourcing quality items is essential for ensuring reliable operation.

Once you have procured the necessary components, follow manufacturer guidelines for installation to ensure proper fit and function. Using the right tools and techniques can greatly enhance the replacement process, allowing for a smoother experience. Regular maintenance and timely replacements will keep your equipment running at its best. Common Issues with Kohler SV720Understanding the frequent challenges that arise with small engines can help users maintain optimal performance. Various factors can contribute to operational difficulties, and being aware of these issues can aid in prevention and resolution. Engine Performance ProblemsOne of the primary concerns is related to engine performance. Users may experience: Maintenance-Related ComplicationsNeglecting regular maintenance can lead to a range of complications, including: Finding the Right Parts Diagram

Locating the appropriate illustration for components can significantly enhance the efficiency of repairs and maintenance. A detailed representation not only aids in understanding the assembly but also facilitates the identification of specific elements necessary for successful troubleshooting. This ensures that individuals can perform their tasks with confidence and accuracy. Understanding Component Layouts

To effectively navigate through the various components, it is essential to comprehend how different elements interact within the assembly. Each illustration provides a unique perspective on the arrangement, allowing for better insight into the operational mechanics. Familiarizing oneself with these layouts can streamline the repair process. Utilizing Resources for Accurate InformationMany resources are available to access comprehensive representations of components. Websites, manuals, and technical publications often provide valuable information that can assist in finding the right illustration. Engaging with these resources ensures that you have the most reliable data at your fingertips, ultimately leading to more efficient maintenance practices.

Engine Performance and Parts CompatibilityOptimal functioning of a motor relies heavily on the synergy between its components. Understanding how different elements interact can lead to enhanced efficiency and longevity. Selecting compatible components is crucial for maintaining peak performance levels, allowing the machine to operate smoothly under various conditions. When considering upgrades or replacements, various factors must be taken into account to ensure that all parts work harmoniously. Here are some essential aspects to keep in mind: Compatibility is not just about fitting parts together; it also encompasses the collective interaction of components during operation. A well-matched assembly contributes significantly to the machine’s overall efficiency and effectiveness, making it essential to choose wisely. Benefits of Using Genuine Kohler PartsUtilizing authentic components offers numerous advantages that enhance both performance and longevity. These elements are specifically engineered to meet the highest standards, ensuring optimal functionality and reliability in your equipment. Choosing original pieces over generic alternatives can significantly impact the overall experience and maintenance of machinery. Enhanced PerformanceOne of the key benefits of opting for original components is the enhanced efficiency they provide. Genuine elements are designed to work seamlessly with the rest of the system, resulting in improved performance. This ensures: Long-Term Cost SavingsWhile the initial investment in authentic components may seem higher, the long-term financial benefits are substantial. Authentic components can save you money in several ways: |