Exploring the intricate layout of engine components is essential for anyone looking to maintain or repair small machinery. A comprehensive overview not only aids in identifying parts but also enhances the overall efficiency of the engine.

When delving into these schematics, users can uncover the ultimate arrangement of various elements that contribute to the engine’s functionality. Recognizing each component’s role ensures that maintenance tasks are performed effectively and accurately.

By familiarizing oneself with these visual aids, both novice and experienced mechanics can navigate through repairs with confidence. An organized representation simplifies troubleshooting, leading to improved performance and longevity of the machinery.

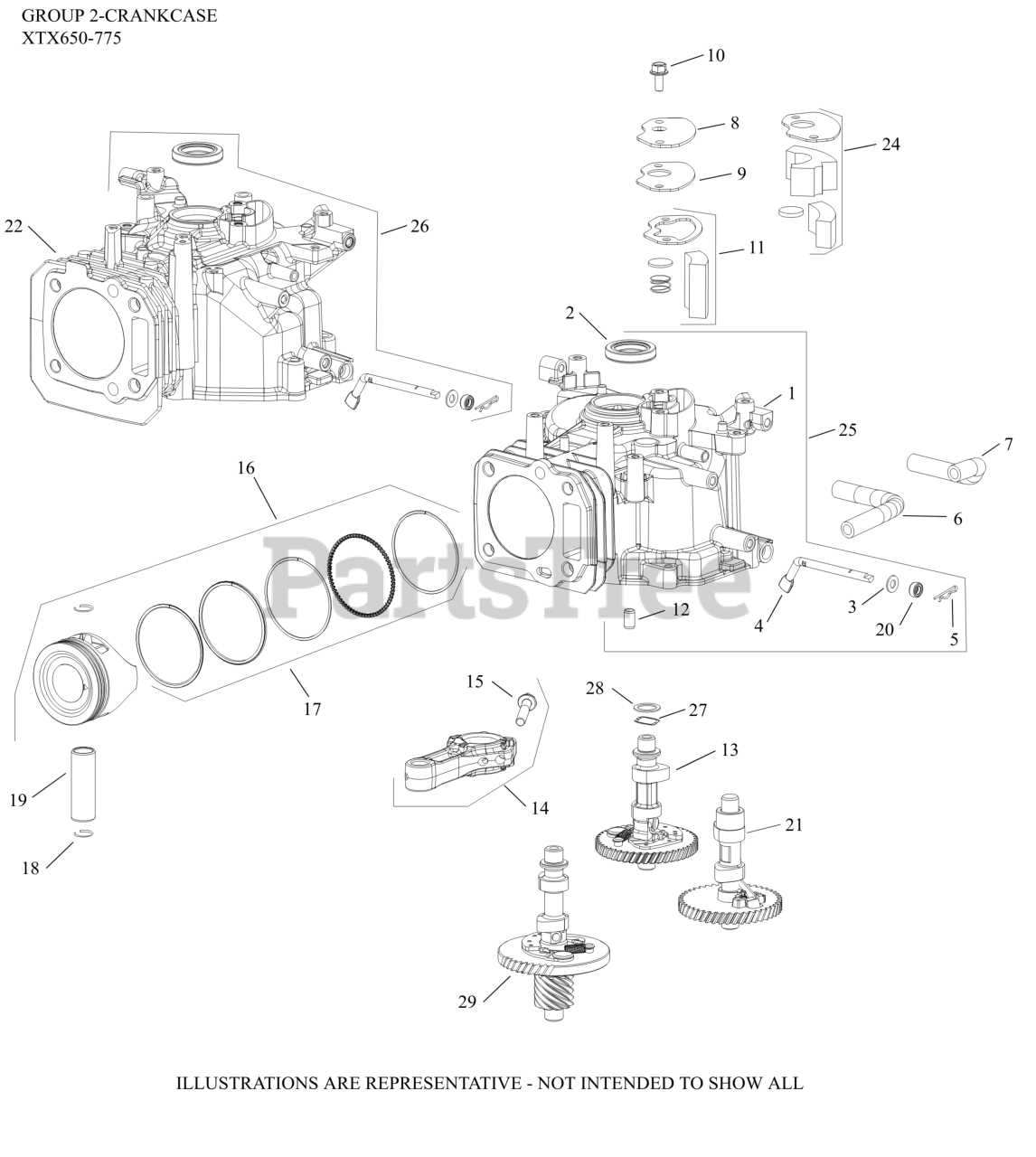

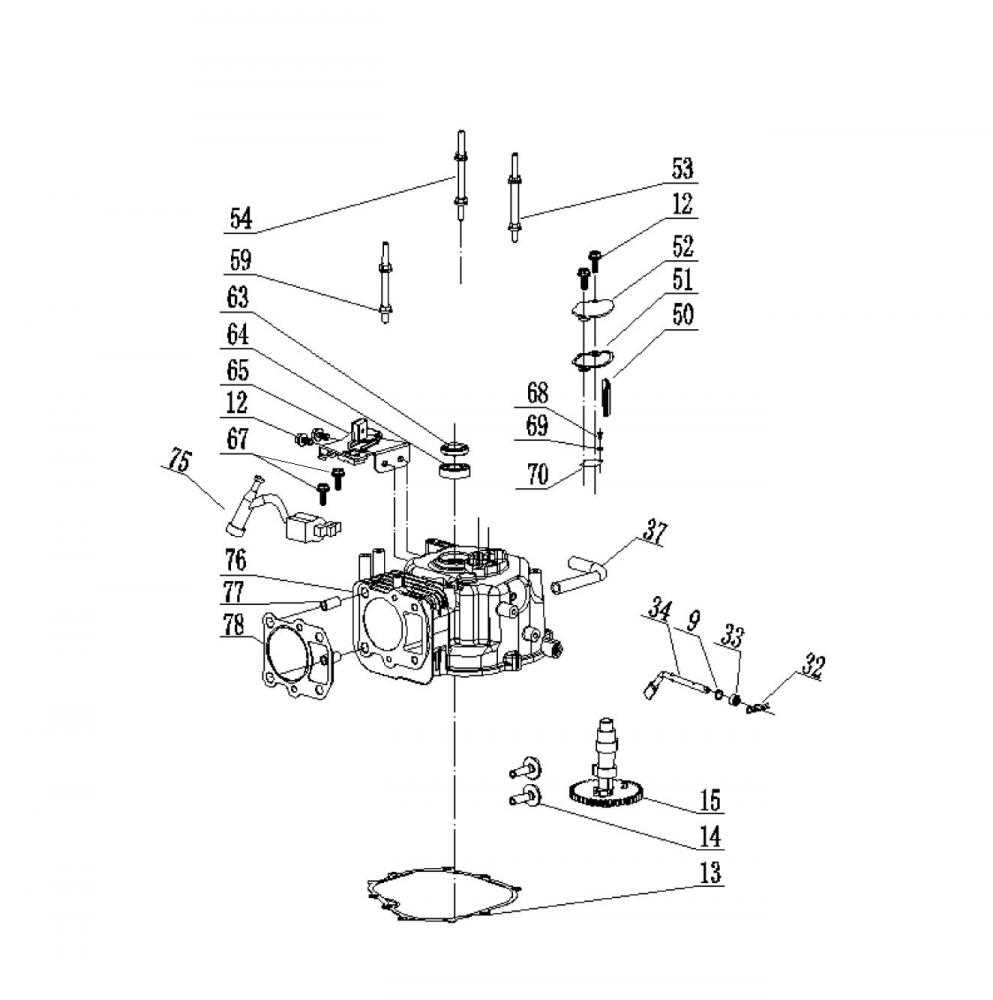

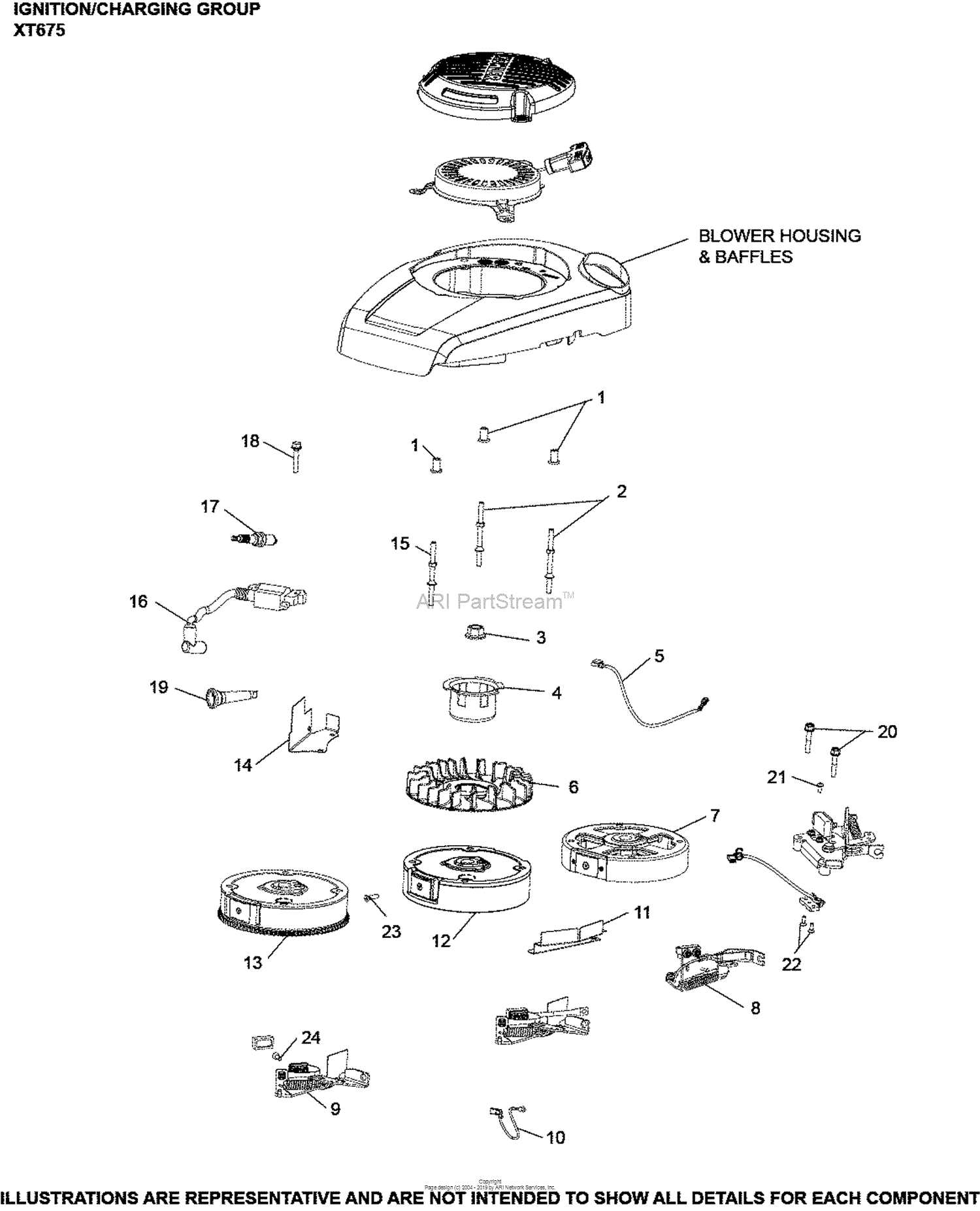

Understanding Kohler XT675 Engine Design

This section explores the intricate design of a well-known small engine model, focusing on its various components and their functions. By examining the structure and mechanisms, one gains insight into the efficiency and performance that define this engine type.

| Component | Description |

|---|---|

| Cylinder | Houses the combustion process, converting fuel into mechanical energy. |

| Piston | Moves up and down within the cylinder, creating compression for ignition. |

| Crankshaft | Transforms the linear motion of the piston into rotational motion. |

| Valves | Control the intake of air-fuel mixture and exhaust of combustion gases. |

| Ignition System | Ensures reliable starting and optimal combustion through spark generation. |

Each component plays a vital role in the overall functionality, highlighting the thoughtful engineering behind this specific engine model. Understanding these elements can lead to improved maintenance and performance optimization.

Key Components of the XT675 Engine

Understanding the essential elements of a small engine can enhance its performance and longevity. Each part plays a vital role in ensuring efficient operation and reliability, making knowledge of these components crucial for maintenance and repair.

1. Cylinder Assembly

The cylinder assembly is fundamental, housing the combustion process. It comprises the cylinder, piston, and rings, all working in harmony to generate power. A well-functioning assembly ensures optimal compression and fuel efficiency.

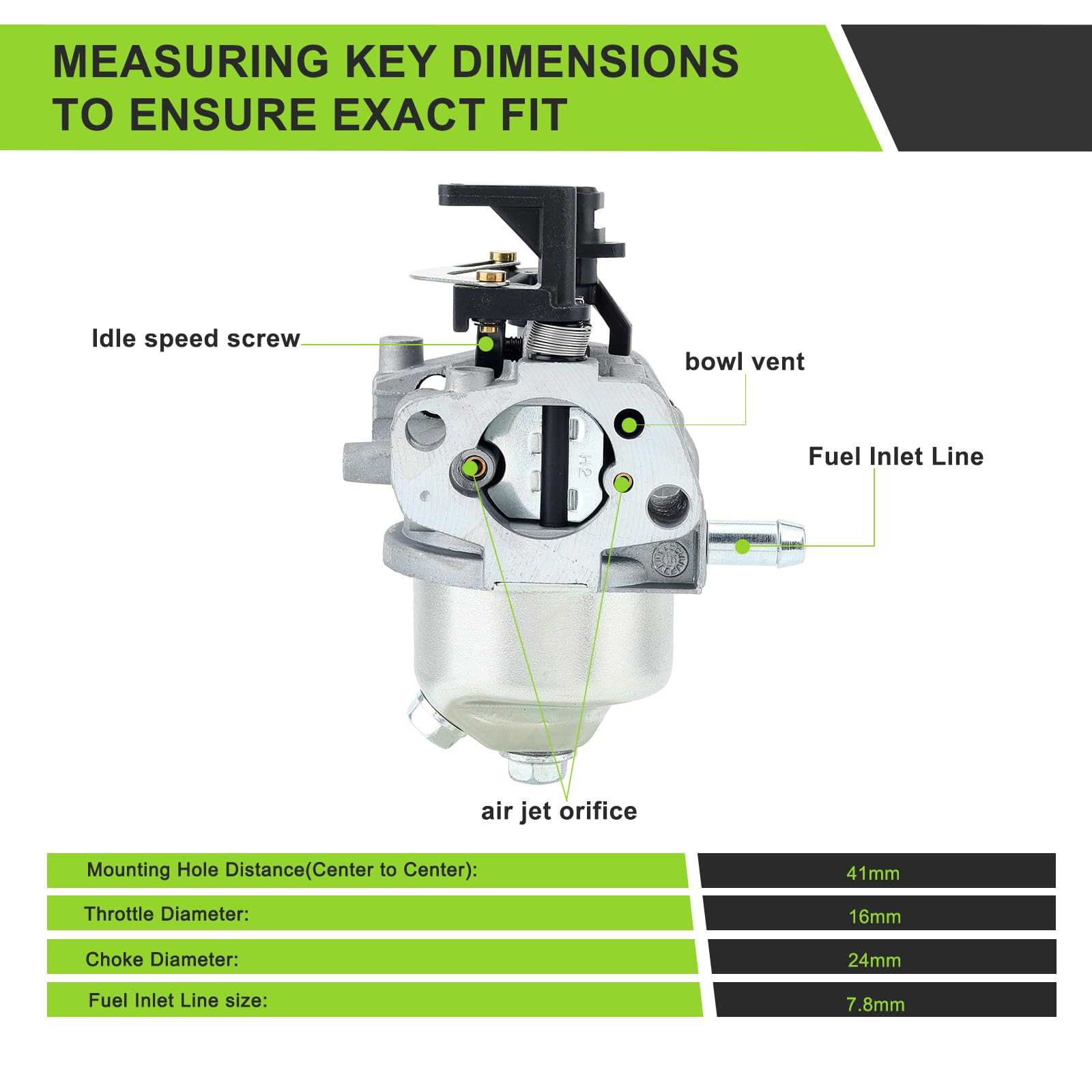

2. Fuel System

This system includes the carburetor and fuel lines, responsible for mixing air and fuel. Proper calibration is essential for effective engine performance. Any issues here can lead to poor starting or power loss, highlighting its importance.

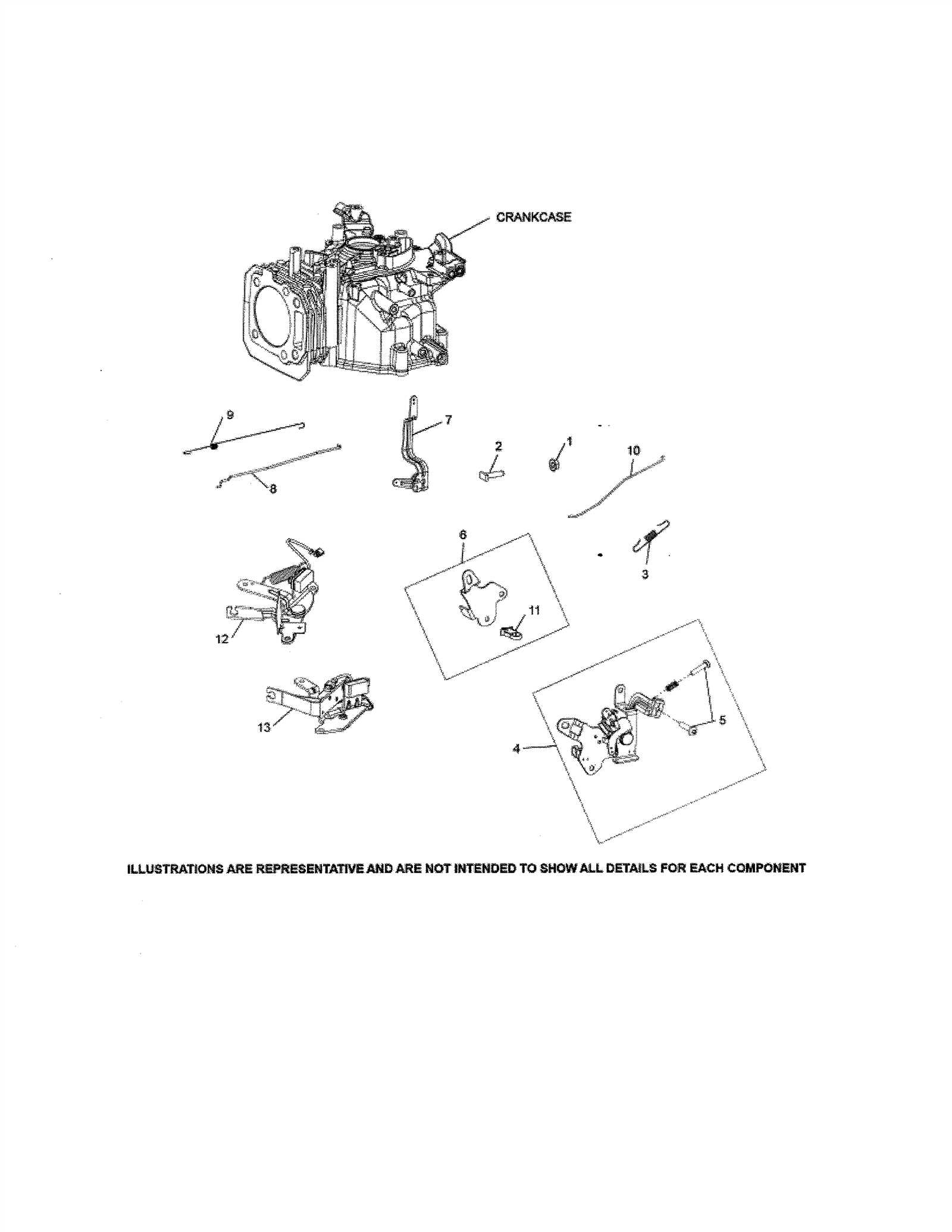

How to Read Parts Diagrams

Understanding visual schematics is essential for efficient maintenance and repair tasks. These illustrations serve as guides, helping you identify individual components and their relationships within a system. Familiarity with these visuals can significantly enhance your troubleshooting and assembly processes.

To effectively interpret these illustrations, consider the following steps:

| Step | Description |

|---|---|

| 1 | Identify the overall layout to grasp the general structure. |

| 2 | Look for labels and numbers that indicate specific items. |

| 3 | Refer to the accompanying list to find detailed descriptions. |

| 4 | Pay attention to any notes regarding assembly or disassembly. |

| 5 | Cross-reference with your equipment to ensure accuracy. |

By following these steps, you can enhance your ability to utilize these resources effectively, leading to smoother repairs and a better understanding of your machinery.

Common Issues with Kohler XT675 Parts

When dealing with small engine components, various challenges can arise that affect performance and efficiency. Understanding these common problems can help in maintaining optimal functionality and prolonging the lifespan of the machinery.

Frequent Problems Encountered

Several typical issues can arise with engine components, often leading to operational difficulties. These problems can stem from wear and tear, improper maintenance, or manufacturing defects. Recognizing these concerns early on can save time and resources in repairs.

| Issue | Description | Possible Solutions |

|---|---|---|

| Starting Difficulties | Engines may struggle to start due to fuel delivery problems or ignition failures. | Check fuel lines, replace spark plugs, and ensure battery health. |

| Overheating | Excess heat can cause severe damage if not addressed promptly, often linked to cooling system failures. | Inspect cooling fins, clean air intakes, and check coolant levels. |

| Excessive Vibration | Unusual vibrations can indicate misalignment or imbalance in moving parts. | Tighten loose components and inspect for damaged or worn parts. |

| Fuel Leaks | Leaks can result from degraded seals or damaged fuel lines, leading to safety hazards. | Replace faulty seals and inspect fuel lines for cracks. |

Preventive Measures

Regular maintenance is essential for preventing these issues. Scheduling routine checks and following manufacturer guidelines can significantly reduce the likelihood of encountering serious problems. Keeping an eye on wear indicators and replacing components as needed will contribute to smoother operation and enhanced reliability.

Finding Replacement Parts Online

Locating components for machinery can be a straightforward process with the right approach. The internet offers a plethora of resources to help individuals identify and procure the necessary items efficiently. With a bit of research and knowledge about the specific equipment, one can navigate various platforms to find suitable options.

Start by using specific keywords related to the equipment model and its specifications. This targeted search can lead to various retailers and forums where enthusiasts share insights and recommendations. Additionally, many manufacturers provide online catalogs that can aid in identifying the exact items needed.

Once you have identified potential suppliers, compare prices and availability. Online marketplaces often feature customer reviews, which can help gauge the reliability of the sellers. Ensuring the authenticity of the components is crucial, so seek out authorized distributors or well-reviewed shops.

Finally, consider joining online communities or forums dedicated to the equipment in question. Engaging with fellow users can provide valuable tips on sourcing and maintaining components. With the right resources and community support, finding what you need can become a seamless experience.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and optimal performance of your equipment. By following a few straightforward practices, you can significantly extend its lifespan and maintain efficiency. Consistent care not only prevents issues but also promotes smoother operation, saving time and costs in the long run.

1. Routine Inspections: Conducting frequent checks for wear and tear is crucial. Look for signs of damage, corrosion, or any unusual sounds during operation. Early detection of potential problems can prevent more significant repairs down the line.

2. Cleanliness: Keeping your machinery clean is vital. Debris and dirt can cause components to function poorly. Regularly remove any buildup to ensure all parts operate smoothly and efficiently.

3. Lubrication: Proper lubrication reduces friction and prevents wear. Use the recommended lubricants for various components, and be sure to follow the manufacturer’s guidelines regarding frequency and application methods.

4. Fuel Quality: Use high-quality fuel to avoid contamination and buildup in the system. Poor fuel quality can lead to clogs and operational issues, ultimately affecting performance.

5. Storage Conditions: When not in use, store your equipment in a dry and sheltered location. Protecting it from harsh weather conditions can prevent rust and other forms of damage.

6. Follow the Manual: Always refer to the user manual for specific maintenance recommendations. Each model may have unique requirements, and adhering to these guidelines will ensure that your machinery remains in peak condition.

By integrating these practices into your routine, you can enhance the reliability and longevity of your equipment, making it a valuable asset for years to come.

Tools Required for Repairs

When undertaking maintenance or repair tasks on small engines, having the right tools is essential for achieving optimal results. A well-equipped toolkit not only streamlines the process but also ensures that each component is handled with care, minimizing the risk of damage.

Essential Tools

First and foremost, a reliable set of wrenches and screwdrivers is crucial. These instruments allow for the easy removal and installation of various components. Additionally, a socket set can enhance your efficiency, particularly in tight spaces where leverage is limited.

Additional Equipment

Incorporating a multimeter for electrical diagnostics can be invaluable, allowing for accurate troubleshooting of ignition and electrical systems. Furthermore, a fuel line cutter and a torque wrench will ensure that connections are secure and meet manufacturer specifications.

Identifying Genuine Kohler Parts

When it comes to maintaining equipment, ensuring the use of authentic components is crucial for optimal performance and longevity. Recognizing the real items from counterfeits can be a challenge, but understanding specific indicators can greatly assist in this process. This section will outline key aspects to look for when verifying the authenticity of your components.

Key Indicators of Authentic Components

Genuine items often exhibit distinct features that differentiate them from imitations. These characteristics include high-quality materials, precise manufacturing details, and clear branding. Observing these traits can help you make informed decisions and avoid potential issues that may arise from using inferior substitutes.

Tips for Verification

Here are some essential tips for ensuring you are purchasing authentic components:

| Indicator | Description |

|---|---|

| Branding | Check for proper logos and trademarks on the product. |

| Packaging | Authentic items usually come in professional packaging with clear labeling. |

| Material Quality | Examine the materials; genuine products feel sturdy and durable. |

| Price | Be cautious of prices that are significantly lower than market value. |

| Authorized Dealers | Purchase from reputable sellers to ensure authenticity. |

By following these guidelines, you can enhance your ability to distinguish between authentic and counterfeit items, ultimately leading to better maintenance and performance of your equipment.

Step-by-Step Repair Guide

When it comes to fixing your equipment, having a structured approach can make all the difference. This guide will walk you through the essential steps to ensure a successful repair process, helping you to restore functionality efficiently and effectively.

Gathering Necessary Tools and Materials

Before diving into the repair, it’s crucial to assemble all the required tools and components. Make a list of everything you’ll need, such as wrenches, screwdrivers, and replacement elements. Having everything ready at hand will minimize interruptions and streamline the workflow.

Step-by-Step Process

Start by turning off the power and disconnecting any fuel sources. This step is vital for your safety. Next, carefully disassemble the unit, taking note of each component’s position and orientation. Document the process with photos if necessary. After removal, inspect each part for wear or damage, replacing any that do not meet quality standards. Reassemble the equipment in reverse order, ensuring all connections are secure. Finally, conduct a thorough test to confirm that everything is functioning as intended.

By following these steps diligently, you can achieve a successful repair and prolong the life of your machinery.

How to Assemble XT675 Components

Assembling the various elements of an engine requires careful attention to detail and a systematic approach. Understanding the relationship between each part is essential for achieving optimal performance. This guide will provide a step-by-step method to ensure that all components fit together seamlessly.

Begin by laying out all the necessary elements on a clean surface. This will allow you to easily identify and access each component during the assembly process. Make sure to refer to the manufacturer’s specifications to understand the correct order of assembly and the required tools.

Start with the base components, securing them firmly in place. Follow this by attaching any intermediate parts, ensuring that all connections are snug and aligned properly. It’s crucial to check for any misalignments, as these can lead to performance issues down the line.

Once the main assembly is complete, proceed to the installation of additional accessories. Double-check that each element is properly fitted and that no screws or bolts are loose. After everything is securely attached, perform a final inspection to confirm that all components are in their designated positions.

Finally, take a moment to clean the area and dispose of any excess materials responsibly. With the assembly complete, your engine will be ready for operation, delivering reliable performance when called upon.

Upgrading Your Kohler Engine

Enhancing the performance of your small engine can significantly improve efficiency and longevity. By focusing on key components, you can elevate its capabilities and ensure it meets your specific needs. This guide will explore essential upgrades that can transform your machinery into a powerhouse.

| Component | Benefits |

|---|---|

| Air Filter | Improves airflow, enhances combustion, and boosts power. |

| Spark Plug | Ensures better ignition, leading to more efficient fuel use. |

| Carburetor | Optimizes fuel mixture for improved performance and responsiveness. |

| Exhaust System | Reduces back pressure, enhancing overall engine output. |

Implementing these upgrades will not only enhance functionality but also extend the lifespan of your engine. Each component plays a crucial role in achieving the ultimate performance, so consider each modification carefully.

Resources for Kohler Engine Owners

Maintaining and servicing small engines requires access to a variety of reliable tools and information. Whether you are a seasoned mechanic or a novice enthusiast, having the right resources can enhance your understanding and ensure optimal performance. This section will provide a compilation of valuable references and tools that can assist in the upkeep and repair of your engine.

Online forums and communities are excellent for sharing experiences, tips, and advice. Many enthusiasts offer insights into troubleshooting common issues, making these platforms invaluable for learning and problem-solving. Additionally, manufacturer websites often host technical documents and user manuals, which can guide you through maintenance tasks and parts identification.

Furthermore, consider investing in specialized repair guides that delve deeper into specific models, offering detailed instructions and illustrations. Local workshops or dealers can also be great resources, providing expert advice and quality replacement components. Utilizing these resources will equip you to handle challenges effectively and prolong the life of your equipment.