The intricate arrangement of mechanical elements is crucial for the optimal performance of complex machinery. A thorough comprehension of how each component interacts within a system can significantly enhance operational efficiency and reliability. By delving into the structural blueprint of these assemblies, users can better diagnose issues, perform maintenance, and implement improvements.

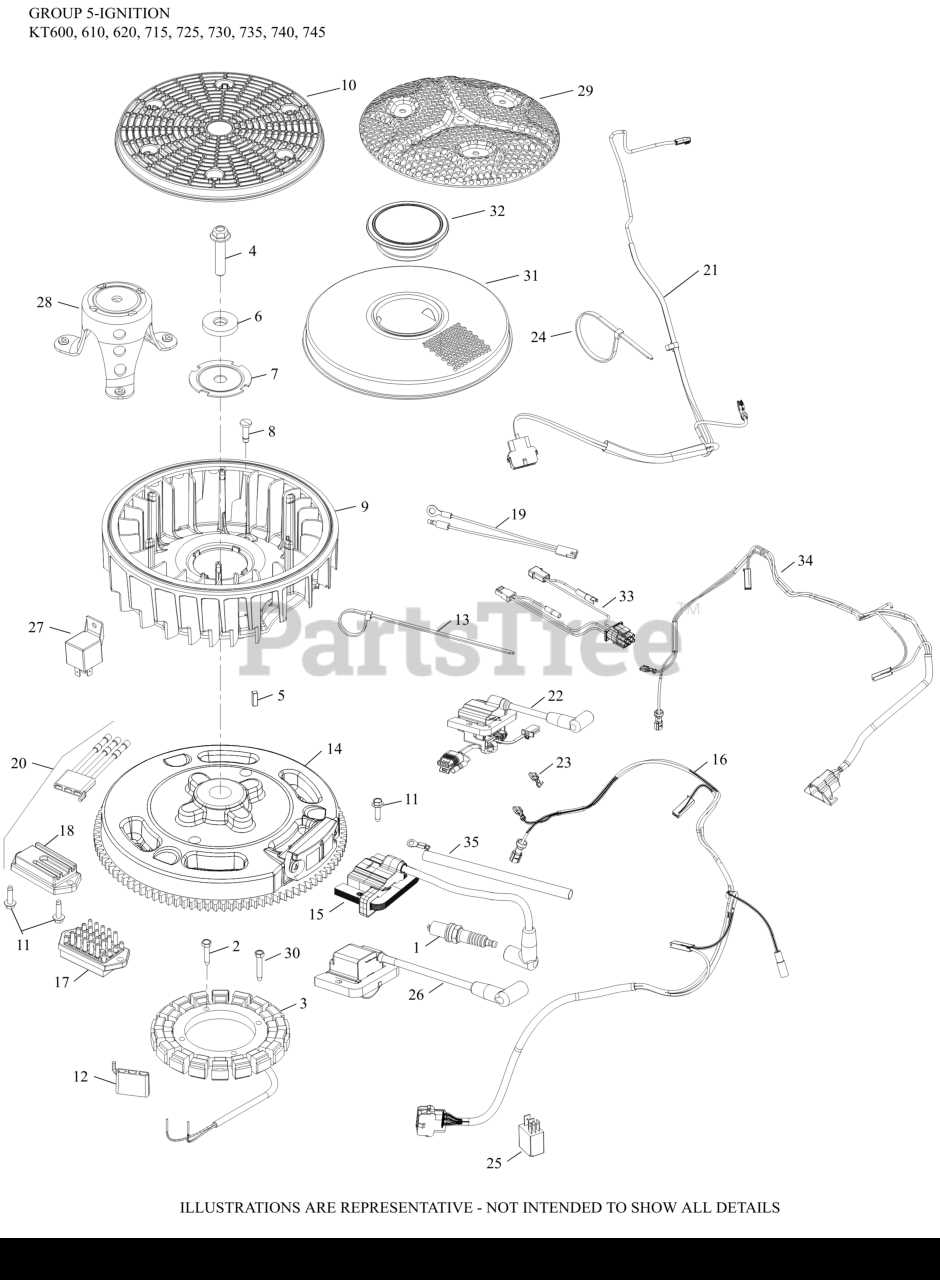

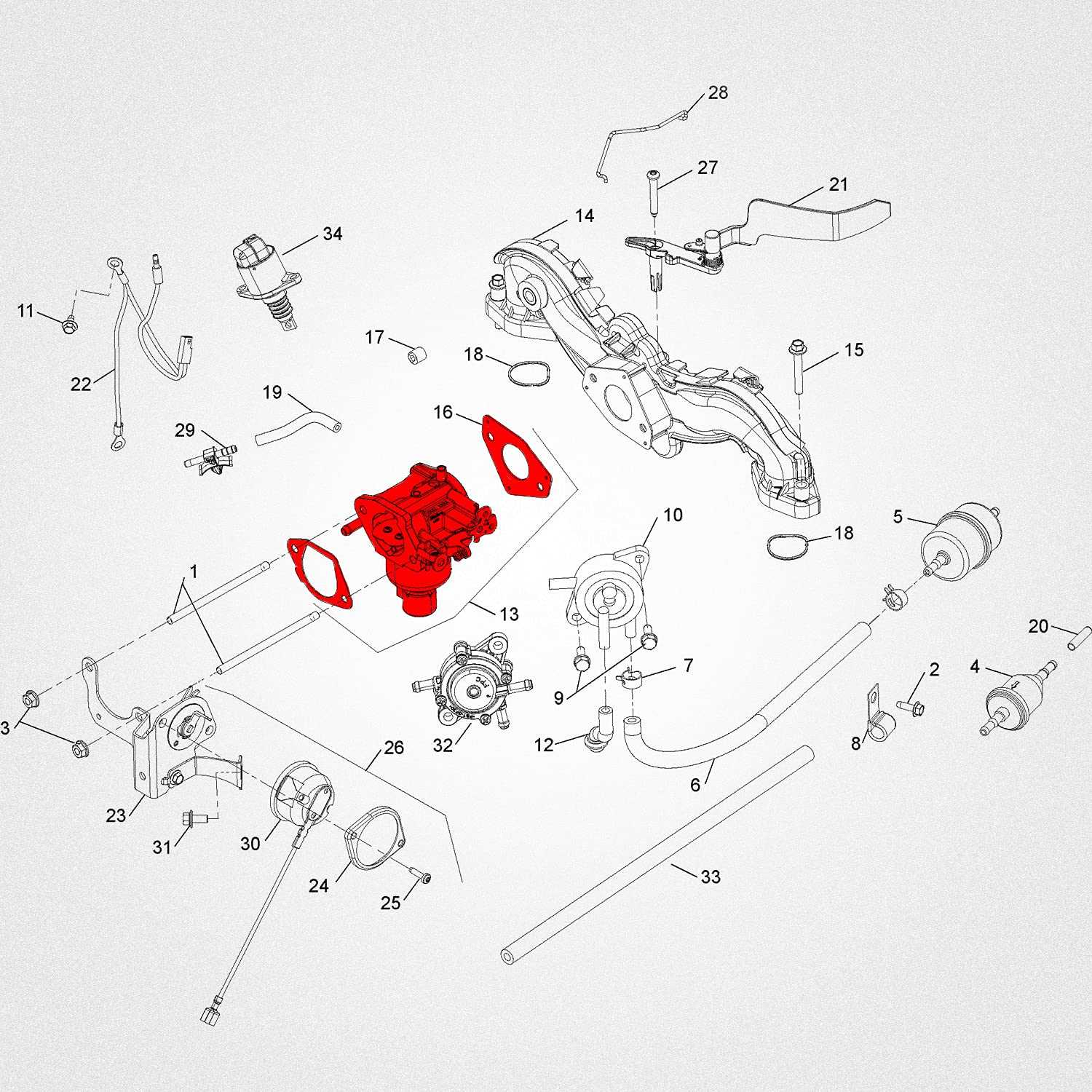

In this exploration, we will navigate through the detailed schematics that illustrate the relationships and placements of various constituents in a specific model. Each section of the schematic provides valuable insights, allowing technicians and enthusiasts alike to grasp the overall architecture and functionality. Understanding these visual representations not only aids in repairs but also fosters a deeper appreciation for the engineering behind the machinery.

As we proceed, we will uncover the significance of each part’s positioning and role within the larger framework. Grasping these connections enables effective troubleshooting and paves the way for informed upgrades. Emphasizing clarity and coherence, this discussion aims to illuminate the nuances of component configurations, ensuring that readers leave with a comprehensive understanding of the subject.

Understanding the Kt730 Components

Grasping the various elements of a complex mechanical system is crucial for both maintenance and optimal performance. Each individual component plays a significant role in the overall functionality, and understanding their interactions can lead to more efficient operation and troubleshooting. This section delves into the essential features and roles of these components, providing insights that can enhance user knowledge and facilitate effective management.

Key Elements and Their Functions

The assembly consists of several vital units, each designed to fulfill specific tasks. For instance, the engine unit generates power necessary for operation, while the transmission components manage the transfer of that power to the wheels. Additionally, the electrical system is responsible for regulating various functions, from ignition to lighting, ensuring that everything operates smoothly and reliably.

Interconnections and Maintenance Considerations

Understanding how these elements interact is as important as knowing their individual functions. Regular inspection and timely maintenance of these components can prevent unexpected failures and extend the lifespan of the entire system. It is advisable to consult technical manuals and resources to gain a deeper comprehension of these interconnections, ensuring that all elements work in harmony for optimal performance.

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the intricate assemblies of machinery. They serve as essential tools for technicians and engineers, providing clarity and facilitating efficient maintenance and repair processes. By offering a detailed overview of individual elements and their interactions, these illustrations enhance the ability to troubleshoot issues and ensure optimal functionality.

Facilitating Communication

These visual aids promote effective communication among team members, allowing for a shared understanding of complex systems. When everyone can reference the same detailed images, it minimizes confusion and streamlines collaborative efforts. Clear depictions of each component enable quick identification of parts that require attention, thereby enhancing overall productivity.

Enhancing Learning and Training

For those new to a particular machine or system, these representations serve as valuable educational resources. They simplify the learning curve by breaking down complicated structures into manageable segments. This approach not only aids in comprehension but also fosters confidence in handling repairs and maintenance, ultimately leading to a more skilled workforce.

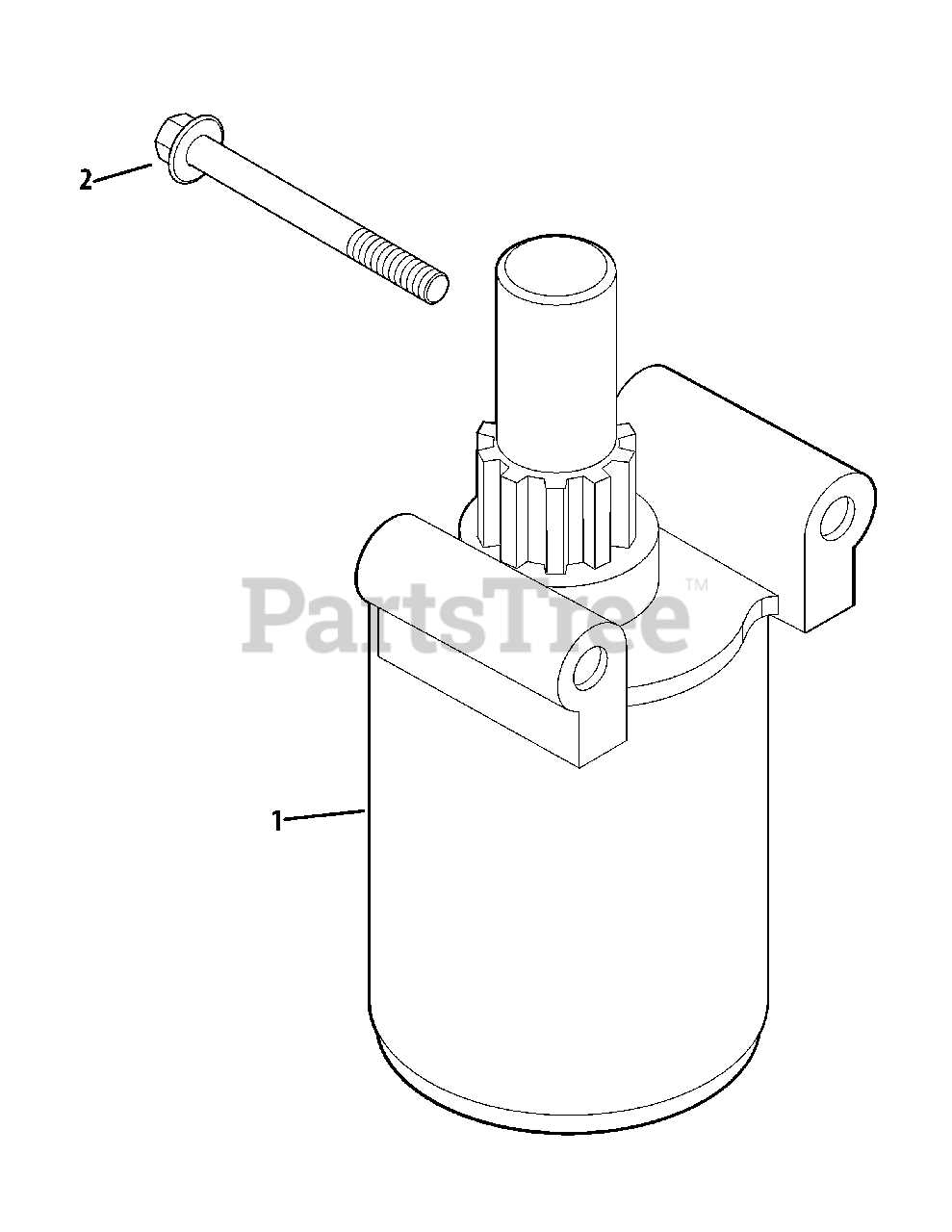

Identifying Kt730 Main Parts

Understanding the key components of a complex machine is essential for effective maintenance and troubleshooting. This section aims to outline the primary elements that contribute to the functionality and performance of the equipment. Recognizing these crucial parts will help in identifying potential issues and ensuring the longevity of the unit.

Each element serves a specific purpose and works in harmony with others. Familiarity with these components will enable users to perform diagnostics more efficiently and undertake necessary repairs or replacements when required.

| Component Name | Description | Function |

|---|---|---|

| Engine | The powerhouse of the machine, converting fuel into mechanical energy. | Drives the overall operation of the equipment. |

| Transmission | A system of gears and shafts that transfers power from the engine to the wheels. | Controls the speed and torque delivered to the wheels. |

| Chassis | The base structure that supports various components. | Provides stability and strength to the overall design. |

| Hydraulic System | A network of pumps, hoses, and cylinders that utilizes fluid pressure. | Facilitates movement and operation of lifting and digging mechanisms. |

| Electrical System | Includes wiring, batteries, and control units. | Powers all electronic functions and safety systems. |

By gaining a clear understanding of these fundamental elements, operators can better appreciate the intricacies of the machinery and respond effectively to maintenance challenges.

Common Issues with Kt730 Components

In any complex machinery, various components can encounter problems that affect overall performance. Identifying and understanding these common issues is essential for effective maintenance and troubleshooting. By examining frequent failures and their underlying causes, operators can minimize downtime and ensure optimal functionality.

Worn Out Elements

One of the most prevalent challenges involves the deterioration of critical elements over time. This wear can lead to decreased efficiency and increased energy consumption. Regular inspections and timely replacements are crucial in preventing extensive damage and maintaining operational reliability.

Electrical Malfunctions

Electrical issues often arise, causing erratic behavior or complete failure of certain functions. These malfunctions may stem from faulty wiring, loose connections, or damaged circuitry. It is vital to conduct thorough checks of the electrical system to pinpoint problems early and avoid costly repairs.

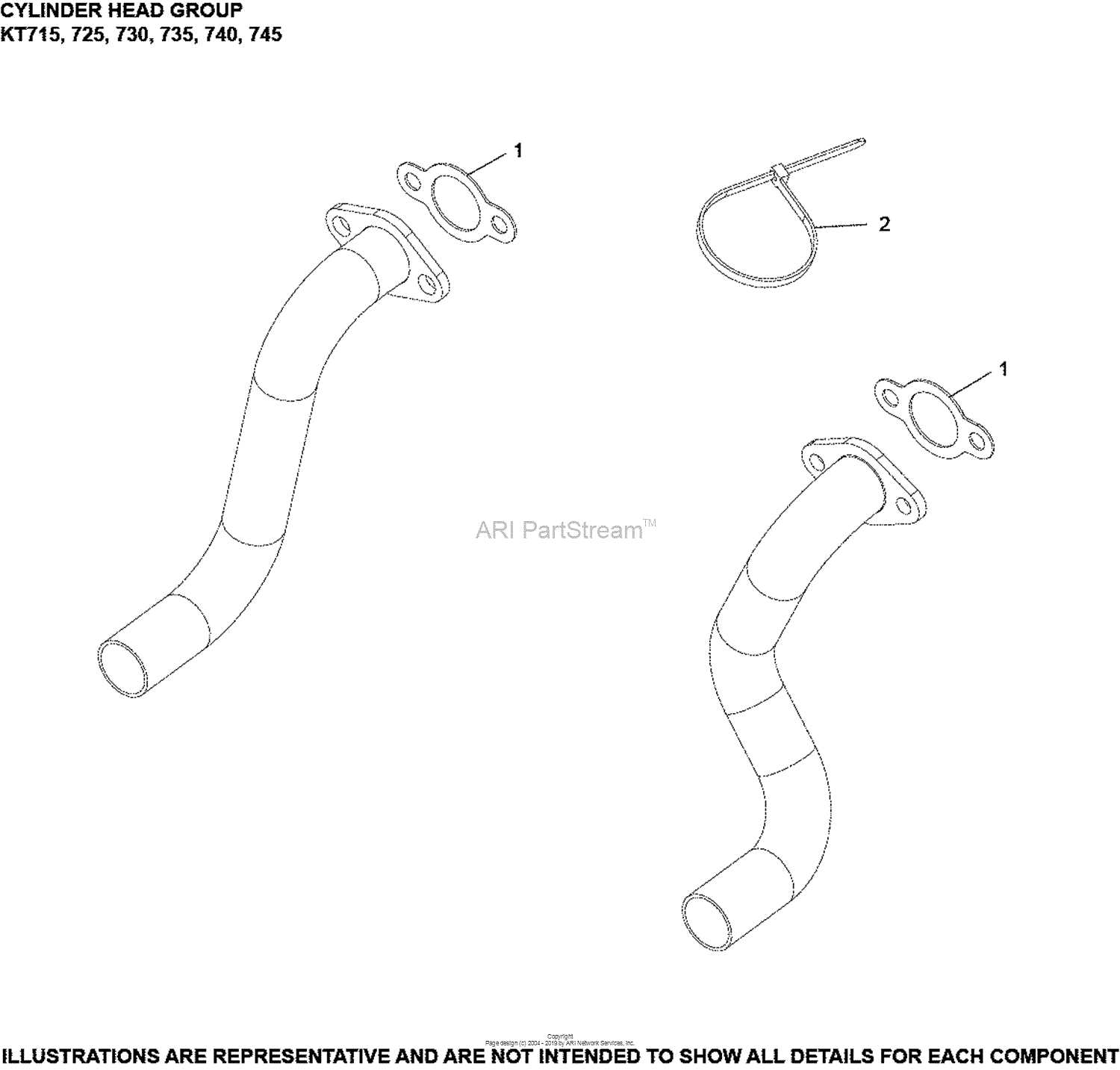

How to Read the Diagram

Understanding a schematic representation is essential for efficient maintenance and troubleshooting of machinery. This section aims to guide you through the critical elements of interpreting these visual aids, enabling you to quickly identify components and their interconnections.

Key Elements to Focus On

- Labels and Annotations: Each symbol or representation is typically accompanied by labels that provide essential information about the component’s function and specifications.

- Connections: Look for lines or arrows that indicate how various parts are connected or interact with one another. These connections often highlight the flow of power or signals.

- Legends: Most visual representations include a legend that explains the symbols used. Familiarizing yourself with this will greatly enhance your understanding.

Steps for Effective Interpretation

- Begin by reviewing the legend to understand the symbols and what they represent.

- Identify the main components by their labels and locate them on the schematic.

- Trace the connections between different elements to comprehend their relationships and functions.

- Take note of any special notations or instructions that may provide further insights into the system’s operation.

By following these steps and focusing on the key elements, you will develop a strong ability to interpret visual representations effectively, facilitating better maintenance and understanding of the equipment.

Maintenance Tips for Kt730

Regular upkeep of your equipment is essential for optimal performance and longevity. By adhering to specific maintenance practices, you can ensure smooth operation and prevent costly repairs. This section outlines effective strategies to maintain your machinery, enhancing reliability and efficiency over time.

Routine Inspections

Conducting frequent checks is crucial. Examine all components for wear and tear, ensuring that each part is functioning as intended. Look for any signs of damage or unusual sounds during operation. Keeping a maintenance log can help track any issues that arise, allowing for timely interventions.

Lubrication and Cleaning

Proper lubrication is vital for moving parts, reducing friction and wear. Use the recommended lubricants and apply them according to the manufacturer’s guidelines. Additionally, regular cleaning of your equipment helps remove debris and contaminants, which can lead to malfunctions if left unchecked.

Where to Find Parts

Locating the necessary components for your machinery can often be a challenging task. Whether you are performing maintenance or looking to replace worn-out elements, understanding where to seek reliable sources is crucial. The right resources can significantly enhance the efficiency and longevity of your equipment.

Online Retailers: Numerous e-commerce platforms specialize in industrial supplies. Websites like Amazon, eBay, and dedicated machinery retailers offer a wide selection of components. Make sure to read reviews and check seller ratings to ensure you are purchasing high-quality items.

Manufacturer’s Website: Visiting the official site of your equipment’s manufacturer is often one of the best options. They usually provide a comprehensive catalog of available components along with specifications and compatibility information. This can save time and prevent errors in ordering.

Local Distributors: Connecting with local distributors or dealers can be beneficial. They often stock various elements and can provide personalized assistance in finding what you need. Building a relationship with these suppliers can also lead to better pricing and support.

Forums and Community Groups: Engaging with online forums and community groups dedicated to your equipment type can yield valuable insights. Members frequently share information about where they source their components, including tips on cost-effective solutions.

Recycling and Salvage Yards: For those looking for economical options, exploring salvage yards or recycling centers can be worthwhile. These places may have used components in good condition at a fraction of the cost, making them a viable alternative for budget-conscious users.

By leveraging these resources, you can effectively find the necessary elements to keep your machinery running smoothly and efficiently.

Replacing Faulty Components

Ensuring optimal performance in machinery often requires the timely replacement of malfunctioning elements. Identifying these defective components is crucial to maintaining the overall functionality and longevity of the equipment. Regular inspections can help spot wear and tear, enabling users to take corrective actions before issues escalate.

Identifying Malfunctions

Before undertaking any replacements, it is essential to accurately diagnose the problems at hand. Look for signs such as unusual noises, decreased efficiency, or visible damage. Conducting a thorough assessment can provide insights into which parts may need to be replaced. Utilizing user manuals and technical references can aid in pinpointing the exact nature of the faults.

Steps for Replacement

Once the faulty elements have been identified, the next step involves acquiring the appropriate replacements. Ensure that the new components match the specifications required for the machinery. Begin the replacement process by disconnecting power sources and following safety protocols. Carefully remove the defective parts and install the new ones, ensuring a secure fit. After installation, conduct a thorough test to confirm that the machinery operates correctly and efficiently.

Upgrades and Modifications

Enhancing performance and functionality is a common pursuit among machinery enthusiasts. This section explores various improvements and alterations that can elevate operational efficiency and adaptability. By focusing on strategic upgrades, users can tailor their equipment to better meet specific tasks and challenges.

Performance Enhancements

One effective way to boost efficiency is by upgrading the engine components. Enhanced fuel injectors and improved air intake systems can significantly increase power output and responsiveness. Additionally, implementing advanced electronic controls can optimize performance by adjusting various parameters in real-time, leading to smoother operation and better fuel efficiency.

Functional Modifications

Beyond performance, functional modifications can greatly enhance usability. Installing aftermarket attachments, such as specialized buckets or tools, allows for greater versatility in handling different materials. Upgrading the hydraulic system can also improve lifting capacity and speed, making it easier to tackle demanding jobs. These changes can transform standard machinery into customized solutions for a wide range of applications.

Cost Considerations for Repairs

When undertaking maintenance or restoration of machinery, understanding the financial implications is crucial. The costs associated with fixing equipment can vary widely depending on several factors. A careful assessment of these elements can help prevent unexpected expenses and ensure a well-planned budget.

Key Factors Influencing Repair Costs

- Labor Expenses: Skilled technicians often charge varying rates based on their expertise and the complexity of the task. Assessing local labor rates and the anticipated time required for repairs is essential.

- Material Prices: The cost of components can fluctuate due to availability, brand reputation, and quality. Sourcing from reliable suppliers can mitigate costs in the long run.

- Age of Equipment: Older machinery may require more frequent repairs, potentially increasing overall expenditure. It’s essential to evaluate whether it is more economical to repair or replace.

- Frequency of Repairs: If a particular machine frequently requires maintenance, this might indicate a need for a more thorough examination of its condition and potential upgrades.

- Warranty Considerations: If the equipment is under warranty, certain repairs may be covered, significantly reducing out-of-pocket expenses.

Strategies for Managing Repair Costs

- Conduct regular maintenance to identify issues early, preventing costly breakdowns.

- Establish a budget for repairs and allocate funds accordingly to avoid financial strain.

- Seek multiple quotes from service providers to ensure competitive pricing.

- Invest in quality parts and services to reduce the likelihood of recurring issues.

- Consider training staff to handle minor repairs internally, thereby saving on labor costs.

By carefully considering these factors, one can develop a strategic approach to managing repair expenses, ensuring that financial resources are used efficiently and effectively.

Comparing Kt730 with Similar Models

This section explores the similarities and differences between the Kt730 and its comparable models in the market. By analyzing various features, specifications, and performance metrics, we aim to provide insights that assist in making informed decisions for potential buyers or users.

Key Features Comparison

- Engine Performance:

- Power output and torque levels

- Fuel efficiency ratings

- Emission standards compliance

- Durability and Build Quality:

- Materials used in construction

- Resistance to wear and tear

- Warranty and service options

- Technology Integration:

- Control systems and user interfaces

- Safety features and assistance systems

- Upgrade options and modularity

Market Positioning

- Price Range: Comparison of the pricing strategies across similar models.

- Target Audience: Analysis of the demographics targeted by each model.

- Brand Reputation: Overview of customer reviews and brand loyalty.

By considering these aspects, potential users can better understand how this model stacks up against its peers and what advantages or disadvantages may influence their choice.