When dealing with intricate devices designed for smooth operation, it becomes essential to grasp the relationship between their various elements. Each component plays a specific role in ensuring the overall functionality, working together seamlessly to deliver optimal performance. Exploring the structure and connections within these systems can help you appreciate the attention to detail and precision that go into their design.

The arrangement of individual elements in these mechanisms is no accident; every piece is carefully placed to contribute to the overall balance and efficiency. By examining how each part interacts, you gain insight into the inner workings and how these systems maintain their fluid motion. This understanding is crucial whether you’re looking to maintain, repair, or optimize performance.

In the following sections, we

Understanding the Structure of Fishing Reels

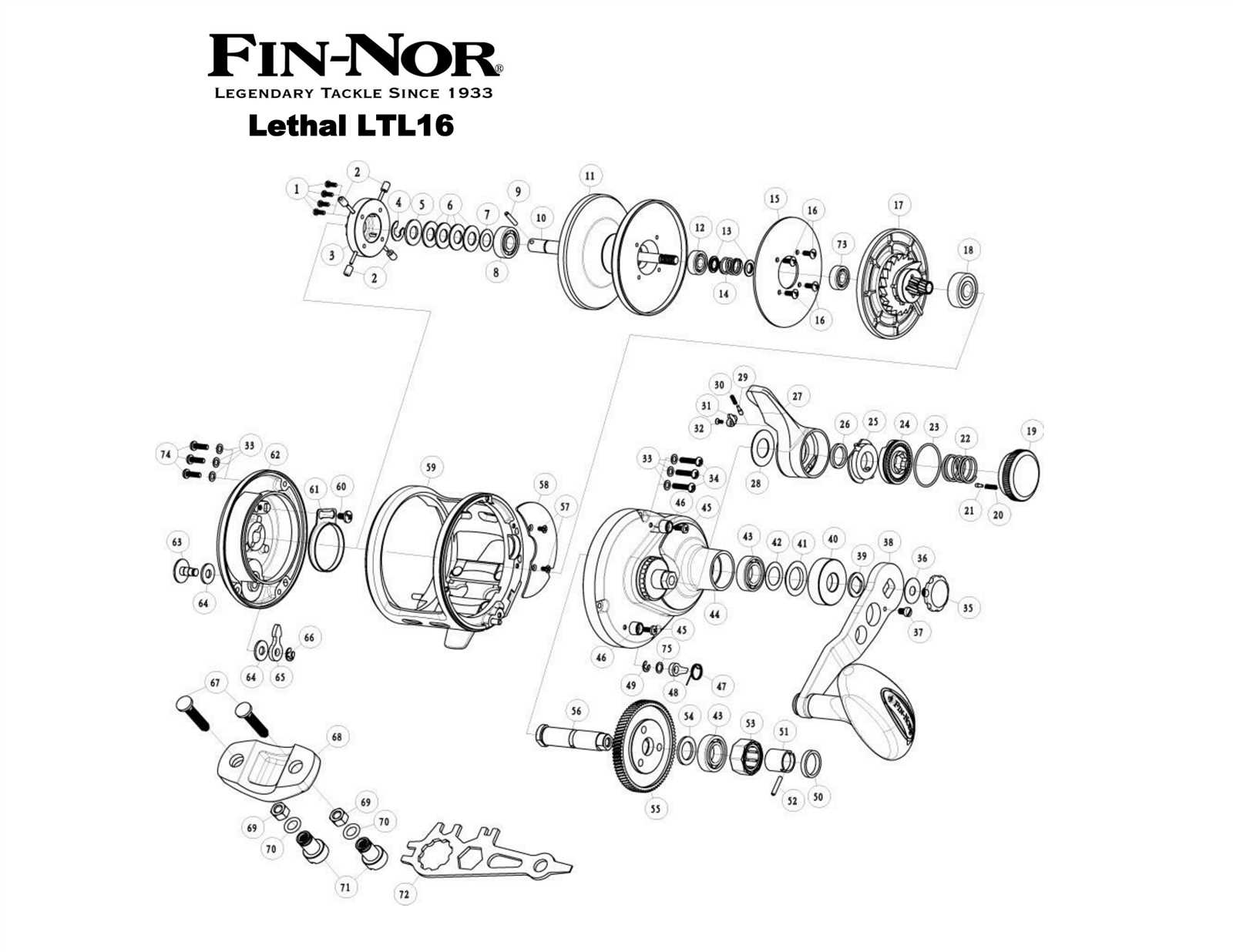

The mechanisms used in angling gear are composed of several interconnected elements, each playing a vital role in ensuring smooth operation during use. These components work in harmony to provide control, flexibility, and strength, essential for a successful fishing experience. By gaining insight into how these parts fit together, one can better understand the overall design and functionality of the system.

- Handle Mechanism: This allows the user to retrieve the line efficiently by rotating the central structure.

- Spool Assembly: Positioned at the core, it holds the

Key Components in Reel Construction

Understanding the fundamental elements in the build of a precision device for line management is essential for effective performance. Each component plays a crucial role in ensuring smooth operation, durability, and control during use. From internal mechanisms to external features, these parts work together to create a balanced and reliable tool for various environments.

Frame and Housing: The foundation of the device, this structure holds all internal mechanisms in place, offering strength and stability. It is designed to endure pressure and protect sensitive components from external damage.

Handle Mechan

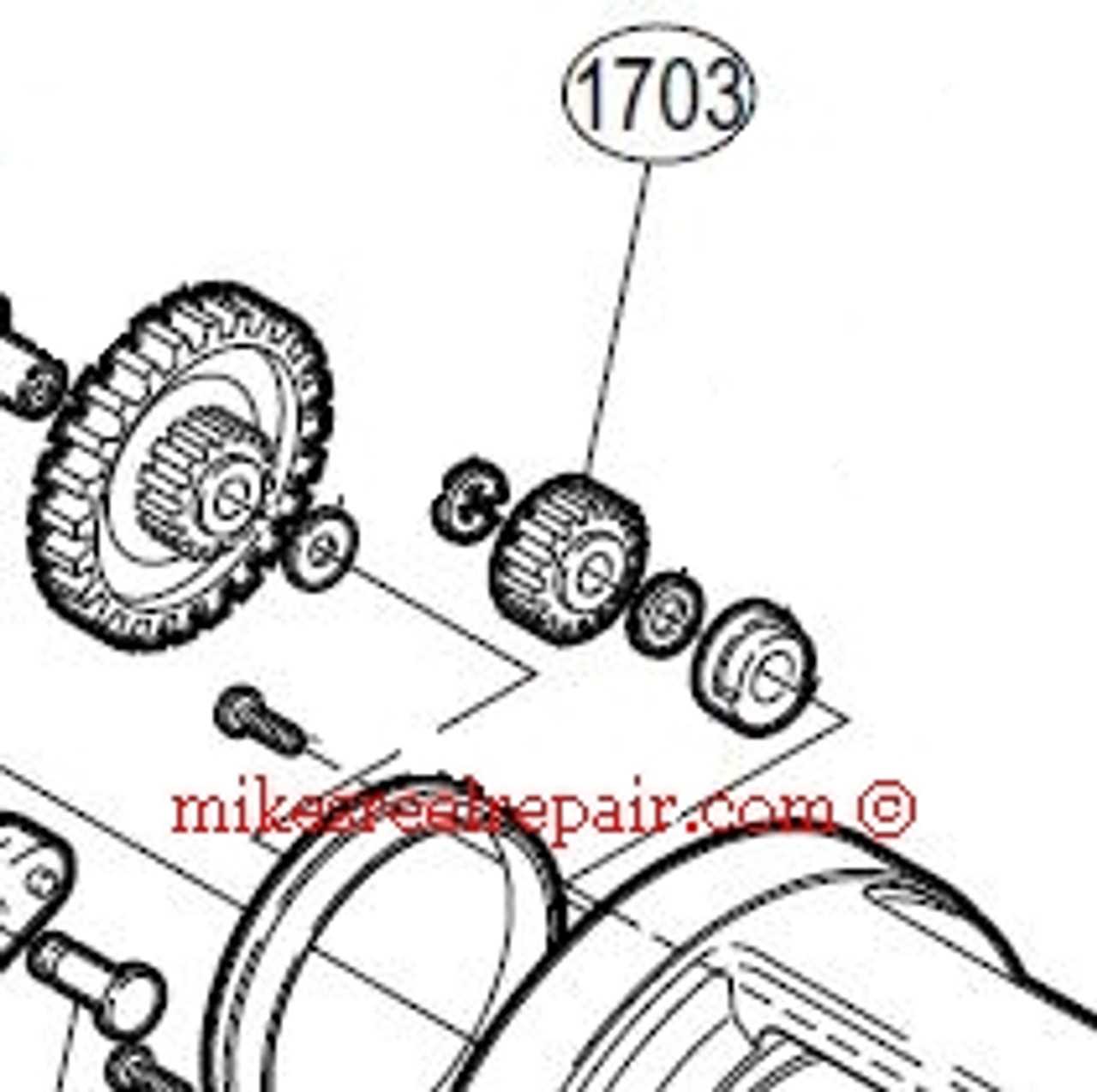

Exploring the Functionality of Internal Gears

Internal gear systems play a pivotal role in the mechanical operation of various devices, transferring rotational force with precision and efficiency. These components, typically placed within a housing, ensure smooth interaction between moving parts, facilitating the transfer of torque from one element to another. Understanding how these gears interact is key to optimizing performance in many mechanical applications.

- Internal gears operate by meshing with external gears, allowing rotational motion to be converted into useful mechanical work.

- They are often designed to handle significant torque while maintaining stability within compact spaces.

- The alignment and design of the teeth ensure minimal

How the Drag System Works in Reels

The mechanism responsible for applying resistance during retrieval plays a crucial role in maintaining control over the tension. This feature ensures that when force is applied, a balance is struck between allowing smooth movement and preventing excessive pressure. Understanding its function helps enhance the efficiency of the overall equipment, making it an essential component for performance.

Here’s a closer look at how this mechanism operates:

- The system uses friction plates to apply resistance.

- These plates are designed to create varying levels of tension based on user adjustments.

- As the user adjusts the control, the pressure on the plates increases or decreases.

- Consistent pressure

Role of Bearings in Smooth Operation

Bearings play a critical role in ensuring efficient and seamless movement in mechanical systems. Their primary function is to minimize friction between moving components, allowing for smoother motion and reduced wear over time. Properly functioning bearings contribute significantly to the durability and performance of various equipment.

Key Functions of Bearings

- Reducing friction to enable fluid movement

- Supporting rotating components for balanced performance

- Enhancing overall efficiency by minimizing energy loss

Impact of Bearing Quality

The quality of the bearings directly affects the lifespan and reliability of a mechanical system. High-grade materials and precise engineering ensure long-term operation, while lower-quality bearings may lead to increased wear, higher maintenance needs, and potential system failures.

- Improved rotational balance reduces strain on parts

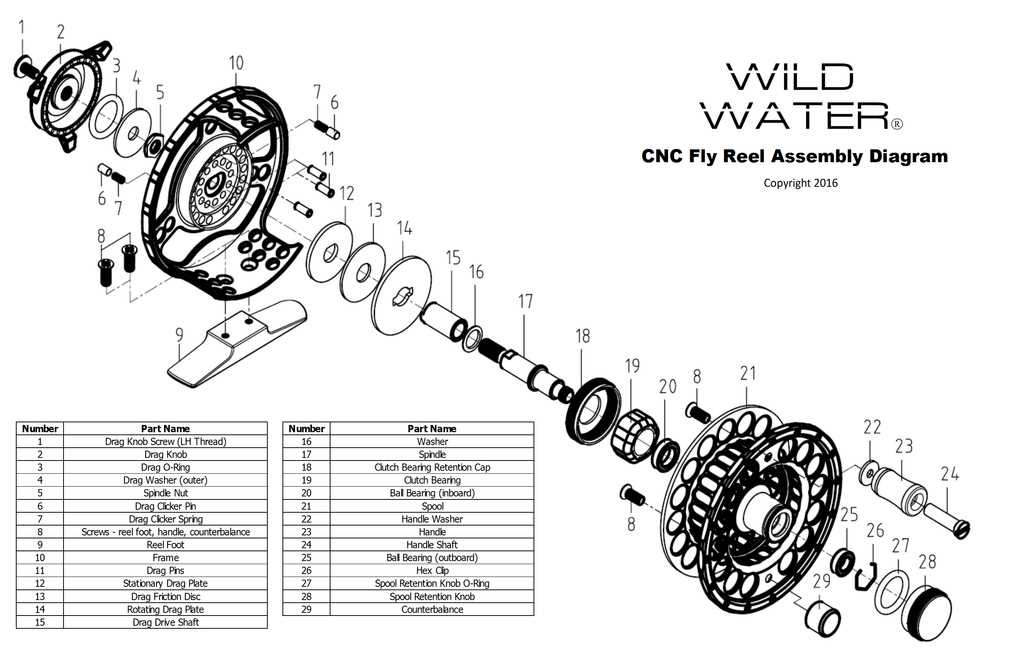

- Examining the Spool Mechanism and Its Function

The spool mechanism plays a crucial role in the efficiency and effectiveness of fishing apparatus. It is designed to manage the line, ensuring smooth deployment and retrieval during use. This component must operate seamlessly to provide anglers with an optimal experience, contributing to both performance and control.

Components of the Spool Mechanism

Understanding the various components that comprise the spool mechanism is essential for appreciating its function. Key elements include the housing, which encases the internal parts, and the spindle, responsible for supporting the line. Additionally, the braking system regulates line tension, preventing tangles and ensuring precise casting.

Functionality and Performance

The performance of the spool mechanism is significantly influenced by its design and materials. A well-crafted spool facilitates effortless casting and reeling, enhancing the overall fishing experience. Regular maintenance is vital for preserving its functionality, as wear and tear can impact efficiency. Understanding the mechanics behind this essential component enables users to maximize their equipment’s potential.

Importance of the Handle in Reel Control

The handle is a critical component that influences the efficiency and precision of fishing operations. Its design and functionality play a significant role in how smoothly and effectively one can operate the device. A well-engineered handle enhances grip, allowing for better maneuverability and control during casting and retrieving.

Ergonomics and User Comfort

An ergonomic handle not only provides comfort during prolonged use but also reduces fatigue. When the user can maintain a secure grip, it leads to improved accuracy and response time. A thoughtfully designed handle can make the difference between a successful fishing trip and a frustrating experience.

Impact on Performance

The responsiveness of the handle directly affects the overall performance of the equipment. A handle that is too rigid may hinder quick adjustments, while one that is too loose could compromise control. Striking the right balance is essential for achieving optimal functionality and ensuring that each movement translates effectively into performance.

Differences Between Frame Materials

The choice of materials used in the construction of frameworks plays a crucial role in determining the overall performance and durability of the equipment. Understanding the variations in material properties can significantly impact the user experience, influencing factors such as weight, strength, and resistance to environmental conditions. This section delves into the primary materials employed in the manufacturing of frameworks, highlighting their unique characteristics and applications.

Common Materials Used

Different materials provide distinct advantages and disadvantages. The following table summarizes the key features of the most commonly utilized materials:

Material Weight Strength Corrosion Resistance Cost Aluminum Lightweight Moderate High Moderate Carbon Fiber Very Lightweight High Moderate High Stainless Steel Heavy Very High Excellent High Plastic Composites Lightweight Low to Moderate Good Low Impact on Performance

Each material affects the overall functionality and handling of the equipment differently. For example, lightweight materials enhance portability, making them ideal for long-duration activities. Conversely, more robust materials offer increased durability, suitable for challenging environments. The choice ultimately hinges on the specific needs of the user and the intended applications.

How Anti-Reverse Systems Affect Fishing

The incorporation of mechanisms that prevent backward motion in fishing equipment significantly influences the angling experience. These systems ensure that the line remains taut during the retrieval process, providing anglers with better control over their catch. Understanding how these features operate can enhance one’s approach to various fishing techniques.

One of the primary advantages of these mechanisms is the enhancement of hook-setting efficiency. When the line is held steady, it allows for a more decisive hook penetration into the fish’s mouth. This precision can be crucial, especially when targeting species known for their vigorous fighting ability.

Additionally, the stability provided by these systems contributes to reduced line slippage, which can lead to lost opportunities. By eliminating the possibility of unwinding during critical moments, anglers can focus on their technique rather than worrying about their gear’s reliability.

Furthermore, mechanisms that prevent reverse motion can help mitigate fatigue during extended fishing sessions. By maintaining consistent pressure on the line, anglers can more effectively manage their energy while reeling in larger catches. This advantage becomes evident during competitive fishing scenarios, where every second counts.

In summary, the integration of anti-reverse mechanisms enhances overall performance, allowing for a more efficient and enjoyable fishing experience. Anglers who recognize and leverage these benefits can improve their success rate on the water.

Line Guide Placement and Its Impact

The positioning of the line directing component plays a crucial role in the overall performance and functionality of fishing equipment. Proper alignment can significantly influence casting distance, accuracy, and the handling of various fishing lines. Understanding how this element affects the fishing experience is essential for both amateur and experienced anglers.

Importance of Accurate Positioning

When the directing element is strategically placed, it helps maintain an even tension across the line during casts and retrieves. This balanced distribution reduces the risk of tangles and enhances the smooth flow of the line, ultimately leading to improved casting efficiency. An optimal setup also minimizes wear and tear on the line, extending its lifespan and ensuring reliable performance.

Effects on Casting and Retrieval

Inadequate positioning of the line directing component can lead to various challenges, such as increased friction and erratic line movement. These issues may result in decreased accuracy and reduced casting distances. Moreover, a misaligned setup can negatively impact the retrieval process, causing the line to snag or become entangled, which can frustrate anglers and disrupt their fishing experience. Ensuring correct placement is therefore vital for maximizing both performance and enjoyment.

Maintenance Tips for Prolonging Reel Life

Regular upkeep is essential to ensure the longevity of your fishing gear. By implementing effective maintenance strategies, you can significantly enhance the performance and durability of your equipment, allowing for more enjoyable fishing experiences.

1. Clean After Each Use: After each fishing trip, it’s crucial to rinse your gear with fresh water to remove any salt, dirt, or debris. This simple step prevents corrosion and buildup that can damage internal components.

2. Lubricate Moving Parts: Periodically apply a suitable lubricant to moving mechanisms. This practice reduces friction and wear, ensuring smooth operation during use. Be careful not to over-lubricate, as excess oil can attract dirt.

3. Store Properly: When not in use, store your equipment in a cool, dry place away from direct sunlight. A protective case can shield it from dust and moisture, further extending its lifespan.

4. Inspect Regularly: Regularly check for any signs of wear or damage. Early detection of issues allows for timely repairs, preventing more significant problems down the line.

5. Use the Right Accessories: Ensure that all attached components are compatible and suited for your specific type of fishing. Mismatched accessories can lead to premature wear or failure during use.

By following these maintenance tips, you can significantly enhance the lifespan of your fishing apparatus, ensuring it remains a reliable companion on your fishing adventures.

Common Issues and Fixes in Reel Parts

In the world of angling, various components may encounter problems that affect functionality and performance. Understanding these common challenges is essential for maintaining equipment in optimal condition. This section highlights prevalent concerns along with effective solutions to ensure longevity and reliability.

Wear and Tear

Frequent use can lead to deterioration of components over time, affecting smooth operation. Signs of wear might include unusual noises or difficulty in engagement. Regularly inspecting and replacing damaged elements is crucial. Utilizing high-quality replacements can enhance overall performance.

Improper Assembly

Incorrect assembly can result in malfunctions and hinder effectiveness. It is vital to follow manufacturer guidelines carefully during setup. If issues arise, disassembling and reassembling the unit while ensuring that all components are correctly aligned can rectify problems, restoring functionality.