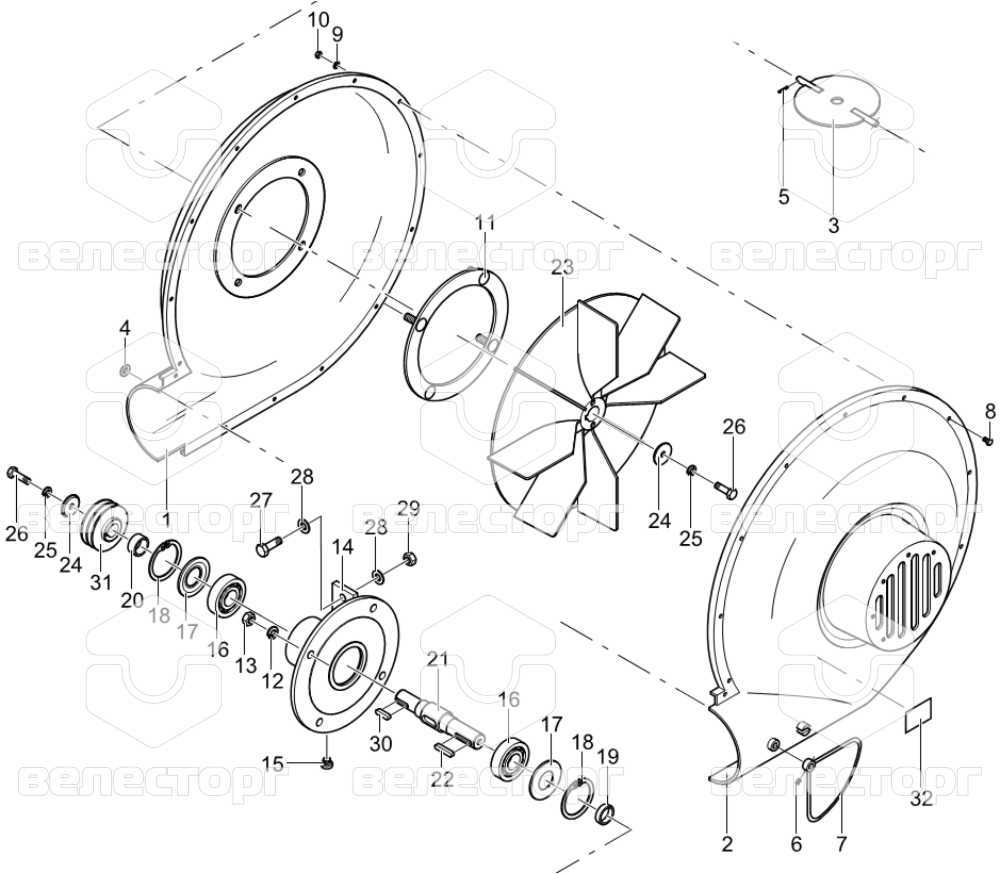

Understanding the intricate arrangement of various elements within a device can greatly enhance its functionality and maintenance. This exploration serves to illuminate the relationships and placements that contribute to the overall performance.

Delving into the specific configurations can reveal crucial insights for users and technicians alike. By examining the different segments and their interactions, one can achieve a more profound appreciation for the mechanics involved.

Ultimately, this knowledge empowers individuals to tackle issues effectively and make informed decisions regarding repairs and enhancements. A clear visualization of these assemblies is essential for anyone looking to optimize their experience with the product.

Understanding Little Wonder Equipment

This section aims to explore the intricacies of a specific brand of outdoor machinery, focusing on its design, functionality, and practical applications. By examining these tools, users can better appreciate their efficiency and versatility in various landscaping tasks.

First and foremost, the equipment is engineered to deliver optimal performance, ensuring that tasks such as aeration, leaf collection, and soil preparation are executed with ease. Each machine integrates advanced technology that enhances usability, making them suitable for both professionals and enthusiasts alike.

Additionally, comprehending the various components and their roles is essential for effective maintenance and operation. This knowledge allows users to maximize the longevity and functionality of their machinery, ensuring it remains a reliable asset in their gardening arsenal.

Key Components of Little Wonder Machines

Understanding the essential elements of these remarkable machines is crucial for optimal performance and maintenance. Each component plays a vital role in ensuring efficiency and reliability, contributing to the overall functionality.

Engine: The heart of the machine, providing the necessary power to drive its operations. A robust engine ensures that tasks are completed swiftly and effectively.

Blade Assembly: This crucial feature is designed for precision and durability. High-quality blades enable effective cutting or shredding, tailored for various applications.

Chassis: The structural framework that houses all components. A sturdy chassis contributes to stability and ease of maneuverability, making the device user-friendly.

Fuel System: This system ensures a consistent supply of energy to the engine. Proper maintenance of the fuel system is essential for peak performance.

Control Mechanisms: These allow operators to manage the machine’s functions seamlessly. Intuitive controls enhance user experience and operational efficiency.

Safety Features: Designed to protect users during operation, these elements include emergency shut-off switches and protective guards. Prioritizing safety ensures a secure working environment.

By comprehending these fundamental elements, users can better appreciate the capabilities and maintenance needs of their machinery, leading to improved performance and longevity.

Importance of Accurate Parts Diagrams

Precise visual representations are essential for understanding complex assemblies and ensuring effective maintenance and repairs. They serve as a crucial tool for technicians and engineers, enabling them to identify components and their relationships within a system. When these illustrations are accurate, they enhance communication and streamline the workflow, reducing the potential for errors.

In various industries, the significance of these representations cannot be overstated. They facilitate training, support troubleshooting efforts, and contribute to the overall efficiency of operations. An accurate portrayal not only saves time but also minimizes the risk of costly mistakes during assembly or disassembly processes.

| Benefits | Description |

|---|---|

| Clarity | Helps users understand component arrangements and functions. |

| Efficiency | Reduces time spent on identifying and locating elements. |

| Training | Serves as an educational resource for new technicians. |

| Error Reduction | Minimizes the likelihood of incorrect assembly or repairs. |

Overall, the role of precise visual guides is indispensable in maintaining the integrity and functionality of complex systems. Their accuracy directly impacts performance and reliability, making them a vital resource in any technical field.

Common Issues with Little Wonder Models

Many users encounter various challenges when operating these compact outdoor machines. Understanding these common difficulties can lead to more effective troubleshooting and maintenance, ensuring optimal performance and longevity.

| Issue | Description |

|---|---|

| Engine Starting Problems | Difficulty in starting can stem from fuel issues, ignition failure, or clogged air filters. |

| Overheating | Excessive heat may occur due to low oil levels, blocked cooling vents, or prolonged operation without breaks. |

| Reduced Cutting Efficiency | A decrease in performance can be linked to dull blades, improper height settings, or debris buildup. |

| Vibration Issues | Unusual vibrations can indicate loose components, unbalanced blades, or worn-out engine mounts. |

How to Read Parts Diagrams Effectively

Understanding technical illustrations is crucial for anyone looking to work with mechanical components or systems. These visuals serve as a map, guiding users through the intricate details of assemblies and their individual elements. By mastering the ability to interpret these graphics, one can streamline the repair process, ensure accurate replacements, and enhance overall efficiency.

To effectively decode these representations, follow these key strategies:

| Tip | Description |

|---|---|

| Familiarize Yourself with Symbols | Recognize common icons and notations used in the illustration to understand their meanings quickly. |

| Follow the Flow | Trace the assembly sequence or connections to grasp how each component interacts with others. |

| Reference the Legend | Consult the accompanying legend or key for clarification on colors and markings that indicate specific features. |

| Cross-Check with Manuals | Use manufacturer manuals or online resources to verify details and ensure accurate interpretation. |

| Practice Regularly | Engage with various illustrations to build familiarity and improve speed in identifying components. |

By employing these techniques, users can gain confidence and precision in navigating technical graphics, leading to more successful maintenance and repair outcomes.

Identifying Parts for Repairs

Understanding the components of your device is crucial for effective maintenance and restoration. Recognizing each element not only facilitates smoother repair processes but also enhances overall efficiency and longevity. This section delves into techniques for pinpointing specific elements within your equipment.

Key Strategies for Identification

To accurately identify components, follow these essential strategies:

- Consult manuals and guides that provide detailed information on the assembly.

- Utilize online resources, such as forums and instructional videos, for visual references.

- Take note of any labels or markings that might indicate the part number or specifications.

Common Component Types

Below is a table summarizing some frequently encountered types of elements in various devices:

| Component Type | Description | Common Issues |

|---|---|---|

| Motors | Drives mechanical functions. | Overheating, noise, failure to start. |

| Connectors | Facilitates electrical connections. | Corrosion, loose connections, breakage. |

| Circuit Boards | Houses electronic components and circuitry. | Burnt traces, component failure, shorts. |

Maintenance Tips for Little Wonder Devices

Proper upkeep of your equipment is essential for optimal performance and longevity. Regular attention not only enhances efficiency but also prevents potential breakdowns that could disrupt your work. Implementing a few simple practices can significantly extend the lifespan of your tools and ensure they operate at their best.

Begin with routine cleaning after each use to remove debris and prevent corrosion. Check for loose components and tighten them as needed. Lubricating moving parts regularly can minimize wear and tear, while also reducing noise during operation. Additionally, always refer to the manufacturer’s guidelines for any specific maintenance requirements.

It’s advisable to conduct seasonal inspections, focusing on wear indicators and essential systems. Replace any worn or damaged elements promptly to maintain safety and efficiency. Keeping an organized maintenance schedule helps track the condition of your equipment, ensuring you never overlook necessary care.

Lastly, consider storing your tools in a dry, climate-controlled environment to avoid rust and degradation. By dedicating time to these maintenance practices, you can ensure reliable performance and enhance the overall lifespan of your machinery.

Where to Find Parts Diagrams Online

Locating detailed schematics for various devices and equipment is essential for effective maintenance and repairs. Fortunately, numerous resources are available online, providing users with access to comprehensive visuals and information. This section will explore various platforms where you can find these valuable resources.

| Source | Description |

|---|---|

| Manufacturer Websites | Most manufacturers offer official sites with downloadable resources, including schematics for their products. |

| Online Retailers | Many e-commerce platforms include diagrams in their product listings to assist customers in understanding components. |

| Forums and Community Sites | Dedicated communities often share resources, including visuals, which can be helpful for troubleshooting and repairs. |

| Technical Support Sites | Websites focused on technical support frequently provide diagrams alongside troubleshooting guides. |

| Library Archives | Some libraries maintain online archives where historical and contemporary schematics can be accessed. |

Comparison of Little Wonder Models

In the realm of compact outdoor equipment, a variety of models cater to different user needs and preferences. Each variant offers distinct features and capabilities, making it essential to evaluate them based on performance, durability, and ease of use. Understanding these differences helps consumers make informed decisions tailored to their specific tasks.

Model A is known for its exceptional maneuverability and lightweight design. Ideal for residential use, it excels in small to medium-sized areas, allowing users to navigate tight spaces with ease. Additionally, its efficient motor ensures reliable operation without excessive noise.

Model B, on the other hand, focuses on power and versatility. Equipped with a robust engine, this option is well-suited for larger properties and demanding tasks. Its durability is enhanced by high-quality materials, making it a favored choice for professionals who require dependable equipment.

Finally, Model C strikes a balance between performance and user-friendliness. With intuitive controls and a range of adjustable settings, it accommodates both novice users and experienced operators. Its design promotes comfort during extended use, making it a practical choice for diverse landscaping projects.

In conclusion, evaluating these models based on individual needs can lead to a more satisfying user experience. Each version brings unique strengths to the table, ensuring that there is a suitable option for every outdoor challenge.

Replacing Components: A Step-by-Step Guide

Maintaining and upgrading your equipment can significantly enhance its performance and longevity. This section provides a straightforward approach to substituting various elements within your device, ensuring you can tackle repairs or enhancements with confidence.

Understanding the Basics

Before diving into the replacement process, familiarize yourself with the essential tools and components. Gathering the right instruments is crucial for a seamless experience. Additionally, having a clear understanding of each element’s function will help you make informed decisions throughout the procedure.

Step-by-Step Process

Begin by disconnecting your device from any power source to ensure safety. Carefully remove the outer casing to access the internal components. Identify the part you wish to replace and take note of its connections. After removing it, install the new component by following the reverse steps, ensuring all connections are secure. Finally, reassemble the casing and reconnect the power, testing your device to confirm successful replacement.

Tools Needed for Little Wonder Repairs

When embarking on repairs for your equipment, having the right instruments is crucial for achieving the best results. A well-equipped toolkit not only enhances efficiency but also ensures that every task is performed with precision and care.

Essential tools typically include a variety of wrenches, screwdrivers, and pliers. Additionally, a good socket set can make disassembly and reassembly much smoother. Maintenance equipment such as lubricant and cleaning supplies is also vital for keeping components in optimal condition.

For more intricate repairs, specialized instruments like a multimeter may be necessary to diagnose electrical issues. Always ensure your toolkit is comprehensive and suited to the specific needs of your machinery.

Customer Support for Little Wonder Products

Providing exceptional assistance is crucial for ensuring customer satisfaction with our offerings. A dedicated support system helps users navigate challenges and enhances their overall experience.

Our support services include:

- Expert guidance on product usage

- Timely troubleshooting assistance

- Access to comprehensive resources and documentation

For optimal support, customers can:

- Visit our website for FAQs and guides

- Contact our support team via email or phone

- Engage with community forums for shared experiences

We are committed to delivering the ultimate customer experience and resolving any inquiries swiftly.