The intricate world of heavy-duty vehicles encompasses a wide array of essential elements, each playing a crucial role in the overall functionality and efficiency of these massive machines. Delving into the structure reveals a complex interplay of mechanical and electronic systems that work harmoniously to deliver power and performance.

By exploring the various sections and functionalities, one can gain insights into how these colossal vehicles operate. Each segment contributes uniquely, forming an intricate network of mechanisms designed to withstand the demands of rigorous operations.

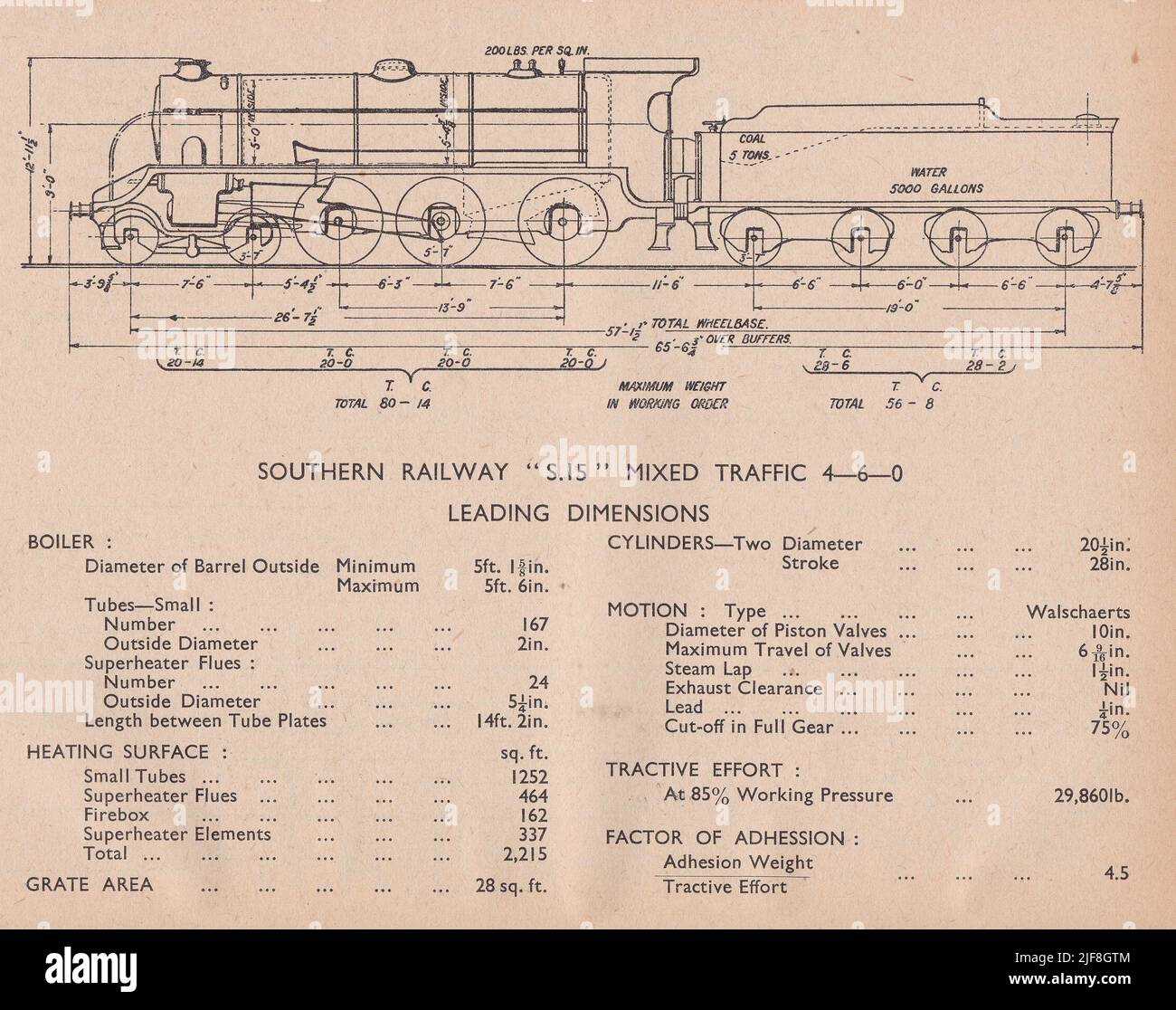

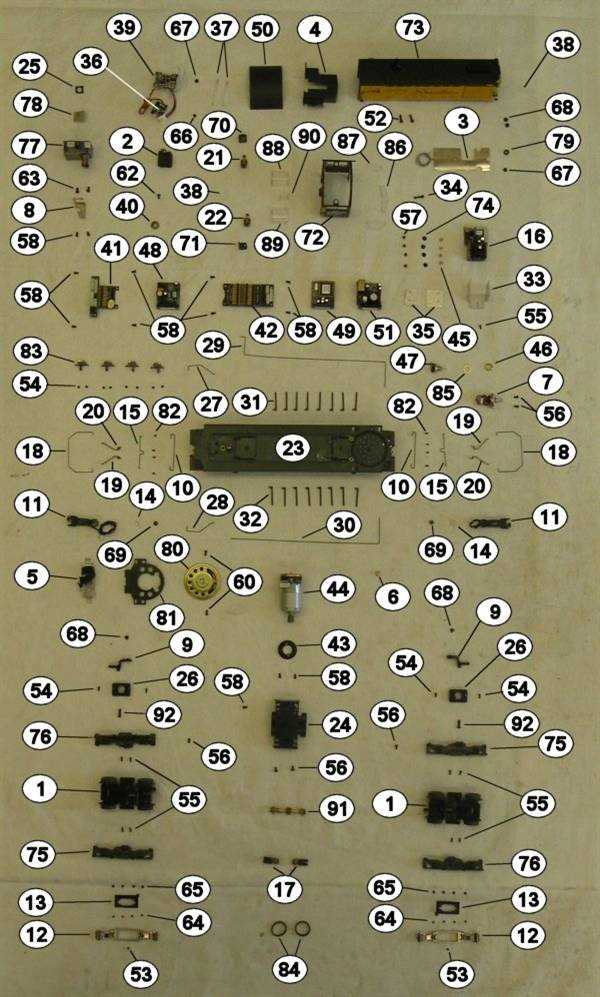

Visual representations provide clarity, allowing enthusiasts and professionals alike to grasp the relationship between different elements. These illustrations serve as valuable tools for understanding how the diverse components interact, enabling effective maintenance and innovative advancements in engineering.

Understanding Locomotive Components

Exploring the various elements that contribute to the functionality of a railway engine provides insight into the intricate workings of these powerful machines. Each component plays a crucial role in ensuring efficiency and reliability on the tracks.

Key Elements of the Engine

- Power Source: The engine’s heart, responsible for generating the necessary energy.

- Transmission System: Transfers power to the wheels, enabling movement.

- Chassis: The framework that supports the entire structure, providing stability.

Supportive Mechanisms

- Braking System: Essential for safety, allowing for effective stopping.

- Cooling System: Maintains optimal temperature, preventing overheating.

- Control Systems: Ensure smooth operation and responsiveness to driver commands.

Overview of Locomotive Systems

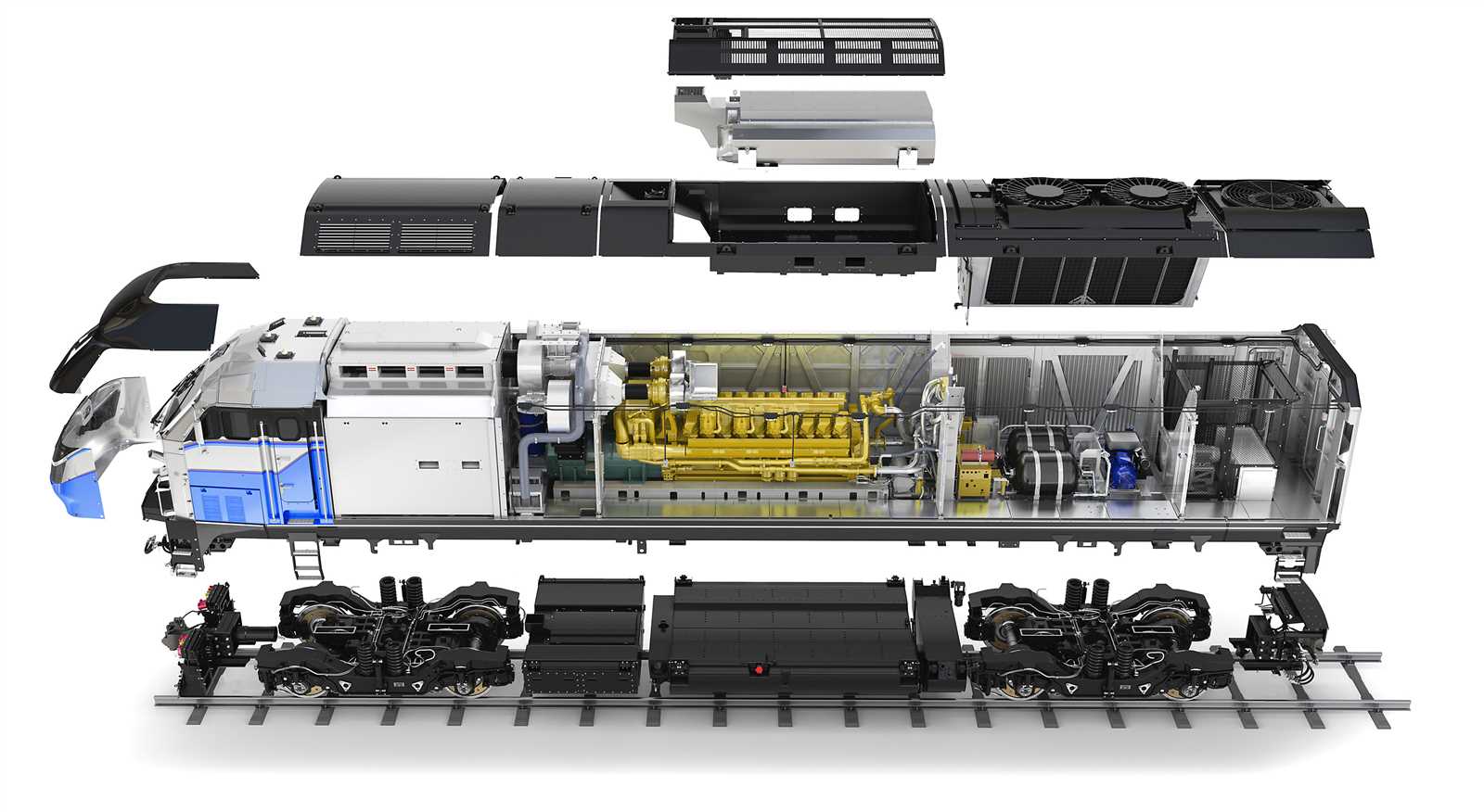

This section explores the intricate components and mechanisms that drive heavy-duty rail vehicles. Understanding these systems is essential for grasping how they function efficiently and reliably in transportation networks.

Core Components

The primary elements of these vehicles include propulsion units, braking mechanisms, and energy sources. Each system plays a crucial role in ensuring optimal performance and safety, with innovative technologies enhancing their effectiveness over time.

System Interconnections

Moreover, the interaction between various systems is vital for seamless operation. For instance, the integration of power distribution and control systems ensures that energy is utilized efficiently, while advanced monitoring systems help maintain operational integrity.

Key Parts of a Locomotive

This section explores the essential components that drive the powerful machinery of train engines, highlighting their roles and functions in achieving optimal performance and efficiency. Understanding these elements is crucial for grasping how they work together to ensure smooth operation and reliability on the tracks.

Engine and Power Source

The core of any train engine lies in its engine and power source, which generate the necessary force to propel the entire system. This component typically harnesses energy from various sources, converting it into mechanical power through intricate mechanisms.

Chassis and Suspension

The chassis provides structural integrity and stability, supporting various systems while enabling smooth movement. Coupled with the suspension system, these elements absorb shocks and vibrations, ensuring a comfortable ride and maintaining alignment with the tracks.

Function of the Engine Block

The engine block serves as the core structure within which various components of a power unit are housed and function together. It provides essential support and housing for crucial elements, ensuring that they operate efficiently and harmoniously. This central unit is pivotal in maintaining the overall integrity and performance of the engine.

One of the primary roles of the engine block is to contain the combustion process. It acts as the foundation for the cylinders, where fuel and air mixture ignites, generating the necessary power. Additionally, the block facilitates the distribution of heat generated during this process, helping to maintain optimal operating temperatures.

| Function | Description |

|---|---|

| Structural Support | Holds and secures various engine components, providing stability. |

| Heat Distribution | Disperses heat generated from combustion, preventing overheating. |

| Combustion Chamber | Houses cylinders where the fuel-air mixture is ignited. |

| Fluid Passageways | Contains channels for oil and coolant circulation, ensuring lubrication and temperature regulation. |

In summary, the engine block is indispensable in the functionality of any engine, playing a vital role in both structural integrity and operational efficiency.

Role of the Transmission Assembly

The transmission assembly serves a pivotal function in the overall performance of a vehicle, facilitating the efficient transfer of power from the engine to the wheels. This mechanism ensures that the vehicle operates smoothly across various speeds and terrains, optimizing energy use and enhancing driving experience.

Key Functions

- Power Distribution: Transmits engine power to the drive wheels.

- Speed Regulation: Adjusts the vehicle’s speed based on driving conditions.

- Torque Management: Modulates torque for improved acceleration and handling.

Components Involved

- Gear Set: Determines the gear ratios for speed adjustments.

- Clutch: Engages and disengages power transmission.

- Shifting Mechanism: Allows the driver to change gears smoothly.

Importance of the Cooling System

The cooling mechanism plays a crucial role in maintaining optimal operating conditions for engines. Its primary function is to regulate temperatures, preventing overheating and ensuring efficient performance. Proper thermal management enhances reliability and extends the lifespan of the machinery.

Functionality and Efficiency

A well-designed cooling system enables engines to operate at peak efficiency by removing excess heat generated during combustion. This process not only protects vital components but also contributes to overall fuel efficiency and reduced emissions.

Impact on Performance

When the temperature is properly controlled, it allows for better combustion, resulting in increased power output. Conversely, inadequate cooling can lead to severe damage, compromising performance and safety.

| Key Benefits | Consequences of Poor Cooling |

|---|---|

| Optimal temperature regulation | Overheating risks |

| Enhanced efficiency | Increased wear and tear |

| Longer lifespan of components | Potential engine failure |

Wheels and Track Interaction

The relationship between the rolling elements and the guiding surface is crucial for ensuring smooth operation and stability in transportation systems. This interaction affects performance, safety, and maintenance needs, making it an essential aspect of engineering design.

Fundamental Mechanics

Understanding the mechanics at play involves recognizing how weight distribution and friction influence movement. The curvature and alignment of the guiding surface play a significant role in minimizing wear and tear on the rolling elements while enhancing overall efficiency. Precision in these components is vital for achieving optimal performance.

Impact on Performance

Variations in the surface quality and structural integrity can lead to increased resistance and potential derailments. Regular assessments of the interaction between these elements are necessary to mitigate risks and ensure a reliable transportation experience. Innovations in materials and designs continually aim to improve this vital connection, enhancing durability and efficiency.

Brake Mechanisms Explained

Understanding the intricacies of braking systems is essential for ensuring safety and efficiency in heavy machinery. These mechanisms play a pivotal role in controlling motion and halting movement effectively, making them crucial components in any transportation system.

Types of Brake Mechanisms

- Air Brakes: Utilizes compressed air to create pressure that activates the braking system.

- Hydraulic Brakes: Relies on fluid pressure to transfer force, allowing for smooth and powerful stops.

- Electromagnetic Brakes: Employs electric current to generate a magnetic field, providing immediate stopping power.

Key Components of Braking Systems

- Brake Pads: Friction material that presses against the rotor to create stopping power.

- Rotors: Disc-like structures that rotate with the wheels, interacting with brake pads.

- Actuators: Mechanisms that initiate the braking process, whether pneumatic or hydraulic.

Electrics and Control Systems

This section explores the intricate systems that govern the electrical and control functionalities essential for efficient operation. Understanding these systems is crucial for ensuring optimal performance and reliability in heavy machinery.

Key Components

- Power Supply Units

- Control Panels

- Wiring Harnesses

- Sensors and Actuators

Control Mechanisms

- Monitoring Systems

- Feedback Loops

- Signal Processing Units

These elements work together to facilitate seamless communication between different systems, ultimately enhancing operational efficiency.

Fuel Delivery and Injection Systems

This section explores the vital mechanisms responsible for transporting and introducing fuel into the combustion chamber, ensuring optimal performance and efficiency.

- Fuel Supply: The initial stage involves transferring fuel from the tank to the injection system.

- Filtration: Contaminants are removed to protect sensitive components from damage.

- Pressure Regulation: Maintaining the correct pressure is crucial for effective injection.

Effective fuel injection enhances engine performance and reduces emissions.

- Types of Injection Systems:

- Direct Injection

- Port Fuel Injection

- Common Rail Injection

- Components Involved:

- Fuel Pump

- Injectors

- Fuel Rails

Understanding these systems allows for deeper insight into enhancing overall efficiency and reliability.

Maintenance of Locomotive Parts

Regular upkeep of essential components is crucial for ensuring optimal performance and longevity in any heavy machinery. Implementing a structured maintenance routine not only enhances efficiency but also minimizes the risk of unexpected failures, which can lead to costly downtimes. By focusing on key elements of care, operators can safeguard their equipment and maintain operational excellence.

Inspection and Cleaning

Routine inspection is vital for identifying wear and tear before it escalates into serious issues. Each component should be carefully examined for signs of damage or malfunction. Additionally, cleaning helps prevent the buildup of debris that can impede functionality. Regularly scheduled cleaning sessions can significantly improve the overall performance and reliability of the system.

Lubrication and Replacement

Proper lubrication of moving components reduces friction and prevents premature wear. It’s essential to use the recommended types of lubricants and adhere to specified intervals for application. Moreover, timely replacement of worn-out elements ensures that the machinery operates smoothly and efficiently, reducing the likelihood of breakdowns and enhancing safety.

Future Innovations in Locomotive Design

As we move into an era of advanced transportation technologies, the evolution of rail systems promises to redefine efficiency and sustainability. The focus on integrating cutting-edge materials and smart technologies aims to enhance performance while minimizing environmental impact.

Smart Technologies Integration

The incorporation of artificial intelligence and real-time data analytics will allow for predictive maintenance and optimized routes, ensuring smoother operations and reduced downtime. Sensors and connectivity will play crucial roles in this transformation, enabling seamless communication between vehicles and control centers.

Sustainable Materials and Energy Sources

Innovations in materials science are set to revolutionize design, with lightweight and durable composites reducing energy consumption. Additionally, the shift towards alternative energy sources, such as hydrogen fuel cells and battery-electric systems, will further promote eco-friendly transit options, paving the way for greener travel solutions.