Understanding the layout and design of various mechanical elements in a high-performance vehicle is essential for both enthusiasts and mechanics. Each section, from the engine to the suspension, plays a critical role in maintaining optimal performance and ensuring the vehicle runs smoothly on diverse terrains.

In this guide, we will delve into the intricacies of a high-powered model’s assembly, focusing on the core elements that contribute to its overall function. By examining these mechanical systems closely, one can gain insights into how each part works together to deliver exceptional power and control.

Key structural components such as the frame, engine, and transmission will be discussed in detail, along with various interconnected systems that enhance durability and speed. This comprehensive look into the vehicle’s design will help both novice and experienced individuals better understand the mechanisms behind high-performance models.

Understanding the LTR450 Components Layout

To maintain and repair your vehicle efficiently, it’s essential to comprehend the structure of its various systems. By familiarizing yourself with the layout of different elements, you can identify potential issues and perform necessary adjustments or replacements with confidence. This section will explore how to interpret technical illustrations related to key assemblies and mechanical functions.

Main Structural Elements

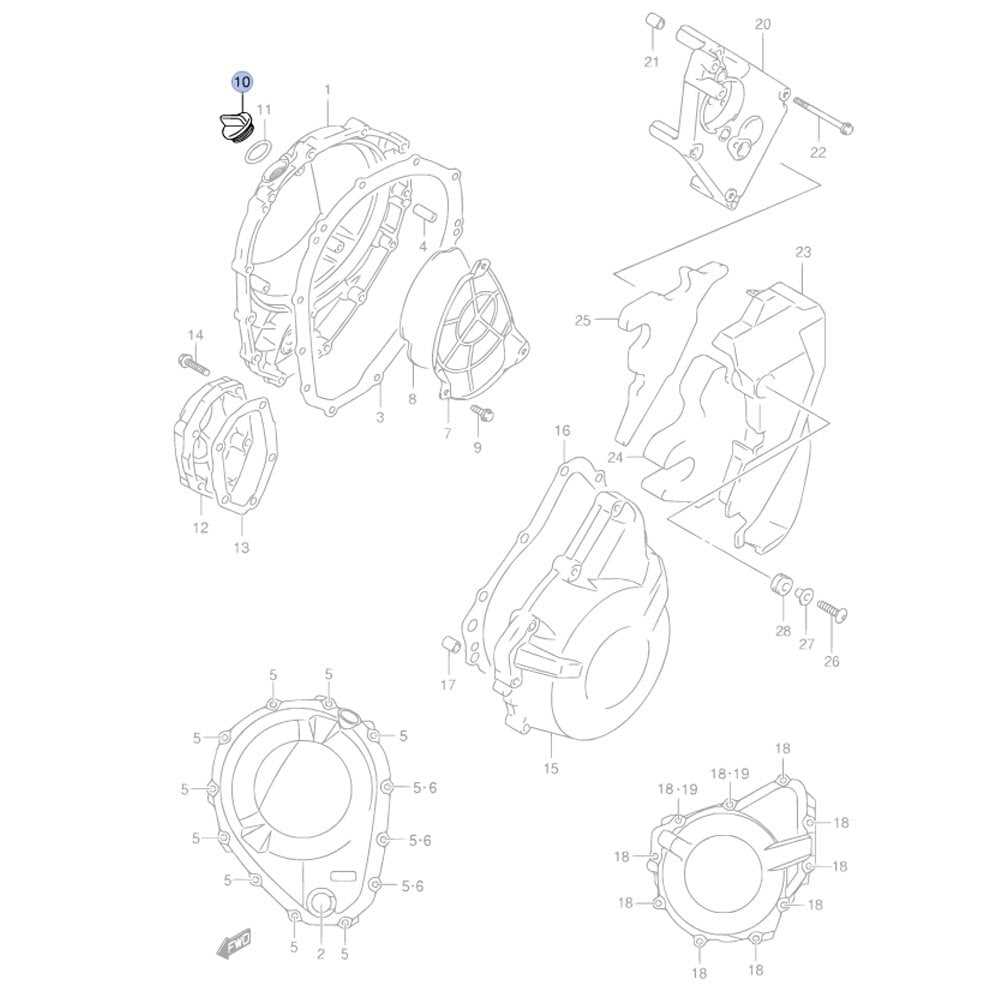

The design of the vehicle consists of several integral sections, each with its own role. From the engine’s internal workings to the frame’s support, knowing how these pieces interact is crucial. Understanding their placement ensures a smoother diagnostic process.

Key System Layouts

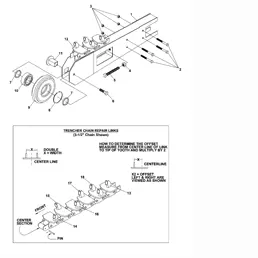

Various systems, such as the drive train, suspension, and electrical connections, are organized in a way that allows efficient operation. Reviewing a schematic representation of these assemblies can help determine where components are located and how they contribute to overall performance.

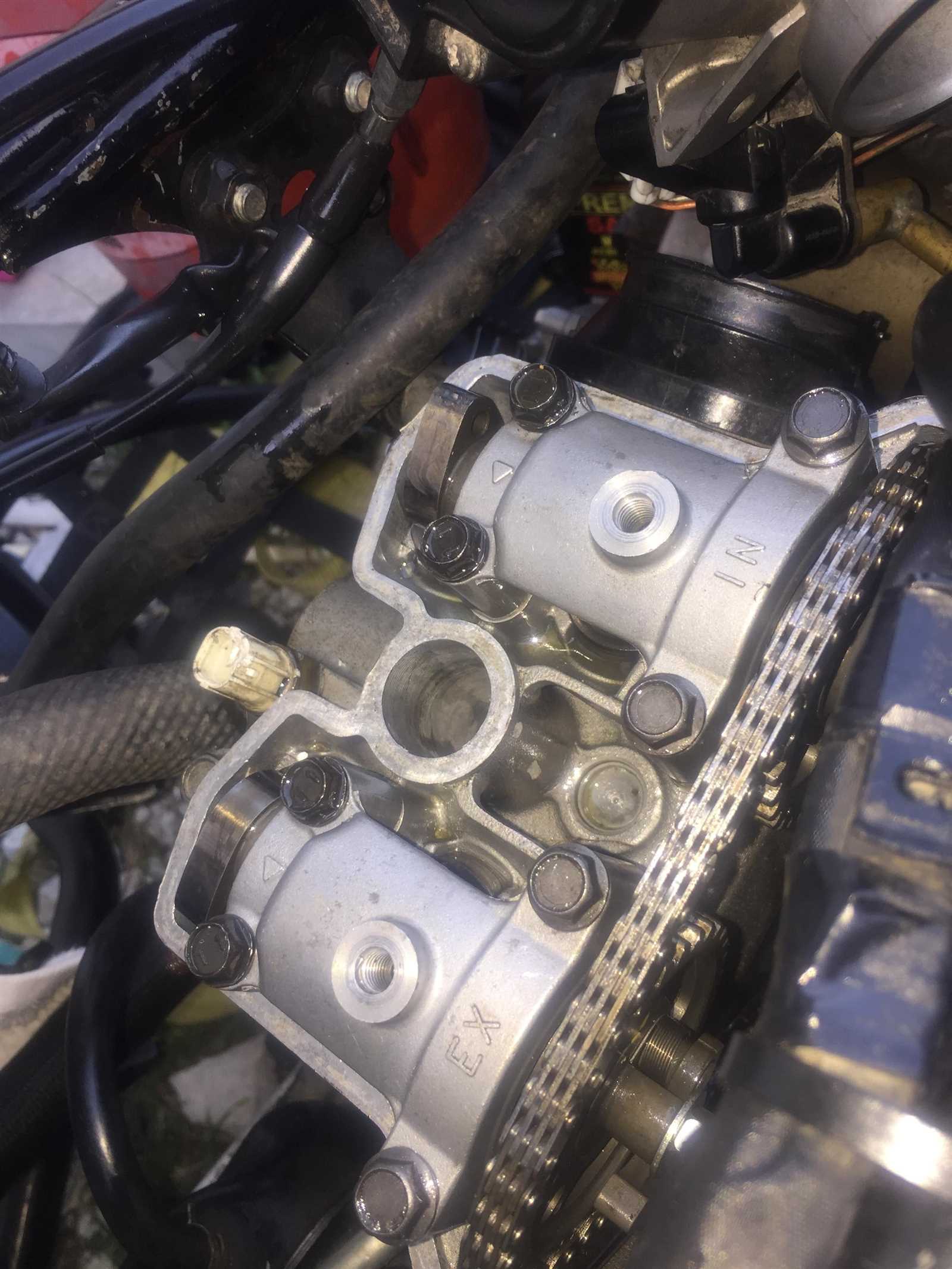

| Key Components of the LTR450 Engine

The heart of a high-performance off-road machine relies on a few critical mechanisms that work together to deliver power and efficiency. Understanding the main structures within the motor assembly provides valuable insights into how this vehicle achieves its dynamic capabilities.

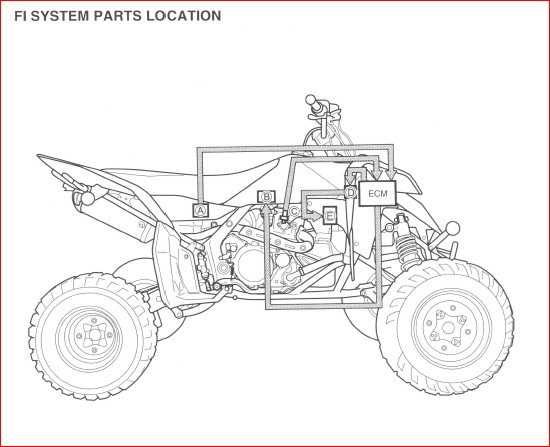

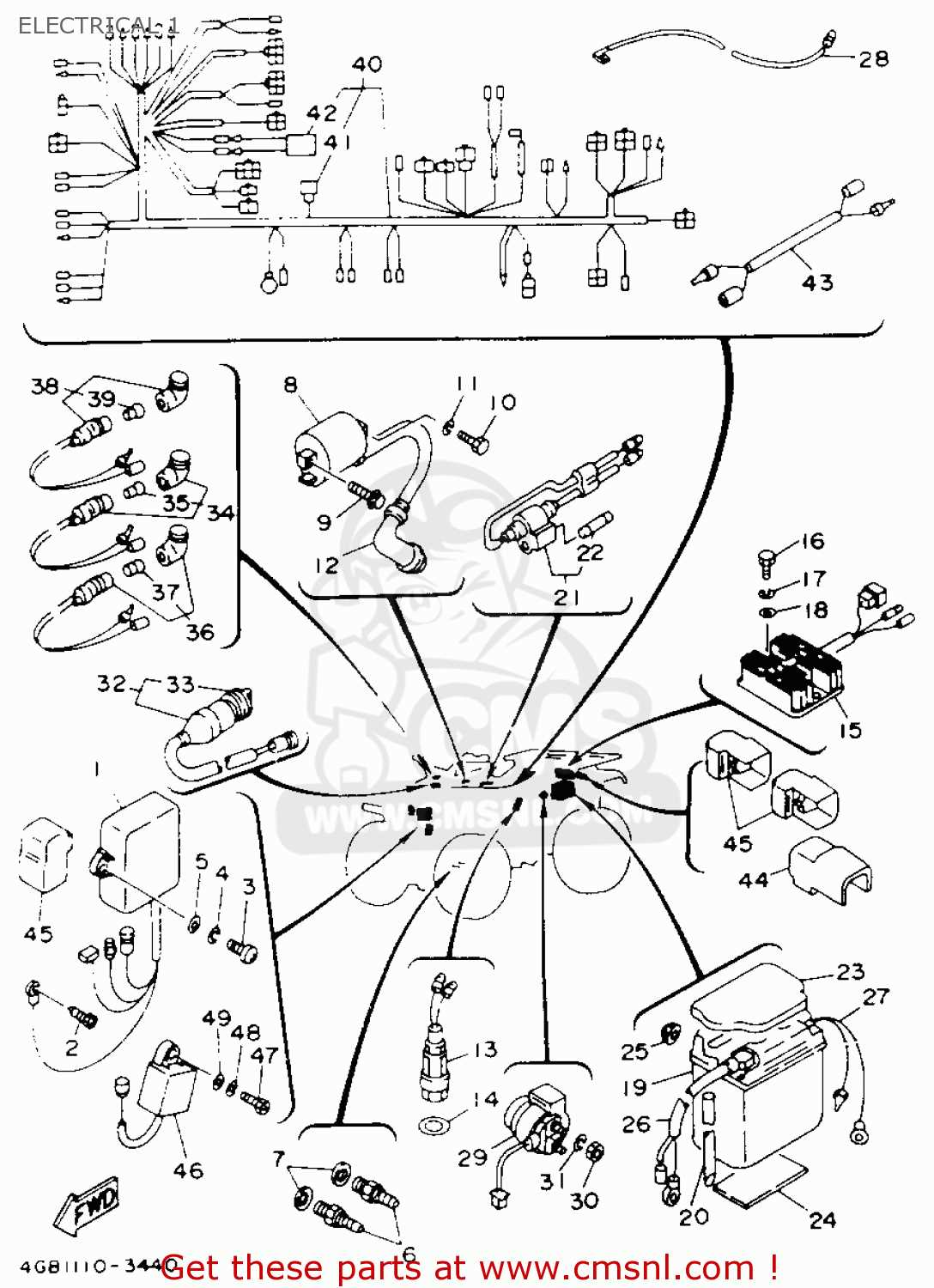

Suspension System Overview for LTR450The suspension mechanism plays a crucial role in ensuring the smooth handling and stability of the vehicle across various terrains. It is designed to absorb shocks and maintain optimal traction, making the riding experience safer and more comfortable. Properly tuned, it enhances performance, especially during off-road and racing conditions, where stability is vital. Key Components of the Suspension SystemAt the heart of the system are the shock absorbers, which compress and rebound to minimize the impact from uneven surfaces. These components are paired with springs that help maintain the ride height and control the vehicle’s movement. Additionally, control arms and linkages work together to allow the wheels to move independently, providing a balanced and responsive ride. Maintenance and AdjustmentsRegular inspection and adjustment of the system can significantly extend its lifespan and ensure peak performance. This includes checking the condition of the shocks, adjusting spring tension, and ensuring that all linkages and bushings are free of wear. Correctly maintaining these elements ensures consistent Electrical System Breakdown in the LTR450The electrical network plays a critical role in ensuring optimal performance and reliability in this high-performance machine. Each component, from ignition to lighting, is connected through a complex system of wiring and controls. Proper functioning of these elements is crucial for maintaining overall functionality, especially during demanding use. Power Generation: The power for the entire system originates from the generator, which supplies electricity to the battery and other components. A well-maintained generator is essential to keep the system charged and operational during both idle and active states. Ignition Circuit: The ignition system relies on precise signals and timing to start and keep the engine running. This circuit includes components such as the stator and CDI unit, both of which ensure smooth power delivery during acceleration and operation. Control and Distribution: A series of relays and fuses helps control the distribution of power across various circuits. These protective elements prevent overload and ensure that only Exploring the Exhaust System LayoutThe exhaust system plays a crucial role in optimizing engine performance and reducing emissions. Understanding its layout is essential for anyone looking to maintain or upgrade their vehicle. This section delves into the components and configuration of the exhaust system, highlighting how each part contributes to the overall functionality. Key Components of the Exhaust Assembly

At the heart of the exhaust assembly is the manifold, which collects exhaust gases from the engine’s cylinders and directs them into the piping system. Following the manifold, the catalytic converter serves to reduce harmful emissions by facilitating chemical reactions that convert pollutants into less harmful substances. The exhaust pipes then carry these gases towards the rear of the vehicle, culminating in the muffler, which dampens sound and further minimizes emissions. Configuration and Flow Dynamics

The configuration of the exhaust system is designed to enhance flow dynamics, ensuring that gases exit efficiently. A well-designed layout minimizes back pressure, allowing the engine to breathe more freely and perform optimally. Additionally, the positioning of each component is strategically planned to facilitate easy access for maintenance and replacement, contributing to the longevity and reliability of the vehicle. Fuel System Parts and ConfigurationThe fuel system is a crucial component in ensuring optimal performance and efficiency in any engine. This system is responsible for delivering the right amount of fuel to the combustion chamber, enabling the engine to function smoothly and effectively. A well-designed fuel delivery setup contributes significantly to the overall reliability and power output of the machine. Typically, the system consists of several key elements, including a fuel tank, fuel pump, fuel lines, and injectors. Each of these components plays a vital role in maintaining the correct fuel pressure and flow. The fuel tank stores the fuel, while the pump transfers it to the engine. The lines are responsible for directing the fuel, and the injectors atomize the fuel for efficient combustion. Configuration of this system can vary based on the design and specifications of the engine. Proper alignment and condition of all components are essential for preventing leaks and ensuring that the fuel is delivered at the right pressure. Regular maintenance and inspection of the fuel system can help identify potential issues before they lead to significant performance problems. In summary, understanding the intricacies of the fuel system and its configuration is vital for anyone looking to optimize engine performance and reliability. Keeping these components in top shape not only enhances efficiency but also prolongs the life of the engine. Cooling System Components in the LTR450The cooling system is essential for maintaining optimal engine performance by regulating temperatures and preventing overheating. Understanding the key elements of this system allows for better maintenance and troubleshooting, ensuring that the engine runs efficiently under various conditions. Several critical components work together to achieve effective cooling:

Regular inspection and maintenance of these components are crucial to ensure the longevity and reliability of the engine. Proper care can help prevent issues such as overheating and coolant leaks, promoting optimal performance. Chassis and Frame Structure Overview

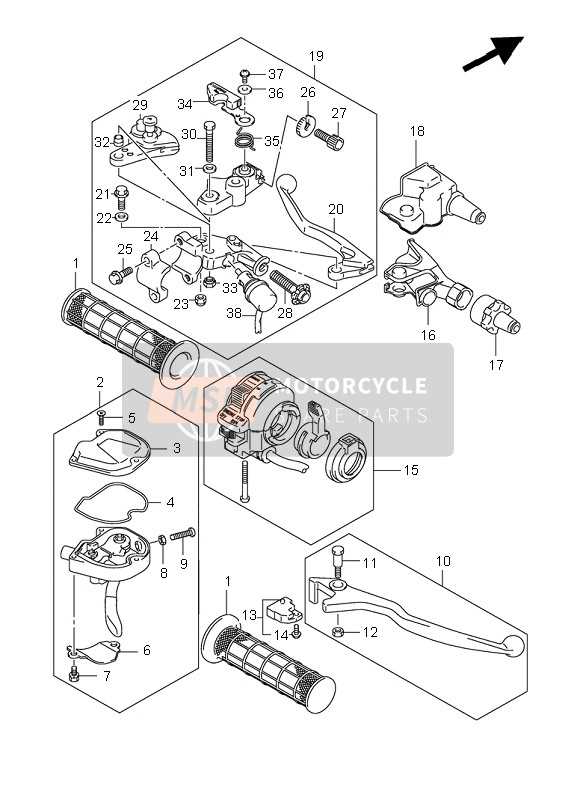

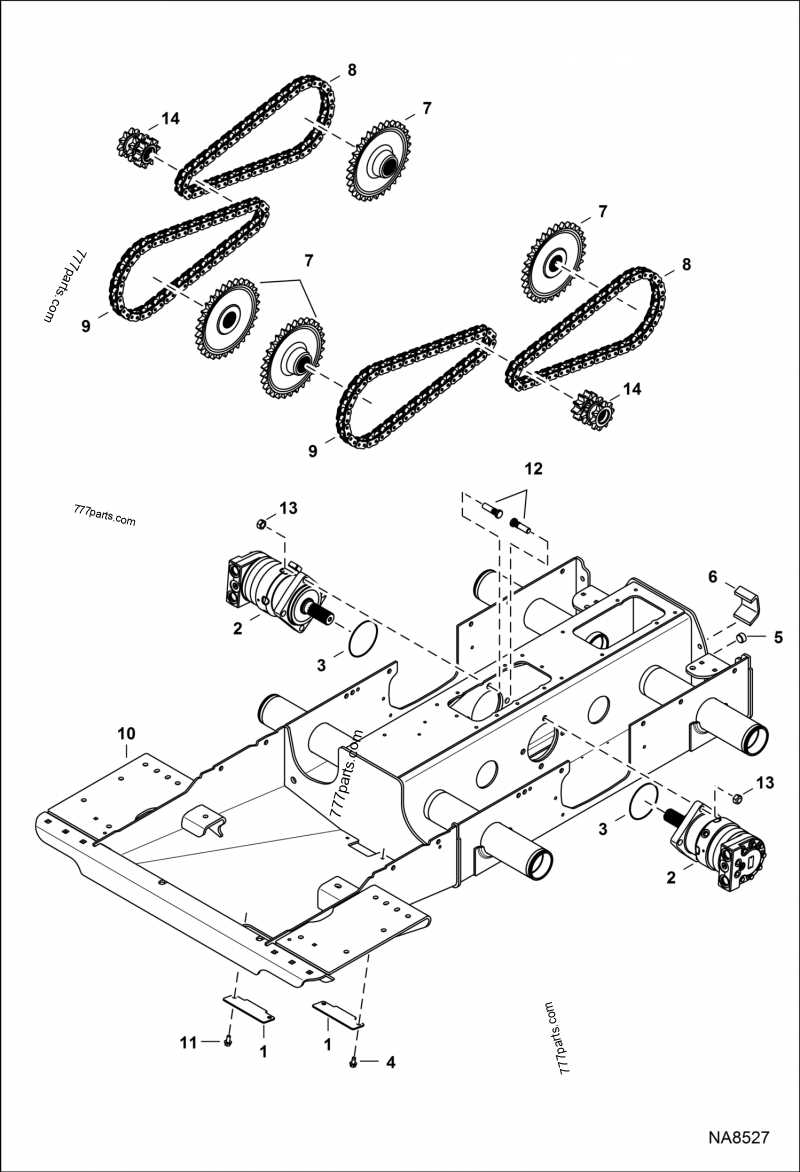

The chassis and frame play a critical role in the overall performance and durability of any vehicle. These components are designed to provide structural integrity while supporting various systems and parts of the machine. A well-engineered frame ensures stability and safety, enhancing the rider’s experience and handling capabilities. Importance of Frame DesignA robust frame design is essential for maintaining the vehicle’s shape and alignment under stress. It serves as the backbone, distributing weight evenly and absorbing shocks from the terrain. The choice of materials, such as steel or aluminum, significantly impacts the overall weight, strength, and resilience of the structure. Key Features of Chassis ConstructionThe construction of the chassis involves various elements, including cross members, support brackets, and mounting points. These features work together to create a balanced and efficient structure. Attention to detail in design allows for better handling, improved aerodynamics, and increased longevity of the machine. Brake System Parts and FunctionalityThe braking mechanism of any vehicle is a crucial component that ensures safety and control. Understanding its individual components and their roles is essential for effective maintenance and operation. Each part works in harmony to deliver the necessary stopping power when needed. Each component plays a vital role in the overall effectiveness of the braking system. Regular inspection and maintenance of these elements help ensure optimal performance and enhance safety on the road. Transmission Assembly and Parts DiagramThe transmission system plays a crucial role in the overall performance of any vehicle, ensuring that power from the engine is effectively transferred to the wheels. Understanding the various components involved in this assembly can significantly aid in maintenance and troubleshooting efforts. This section delves into the essential elements of the transmission, highlighting their functions and interrelationships. Key Components of the Transmission SystemThe assembly includes several vital components, each contributing to its overall functionality. The gears, for instance, enable the vehicle to change speeds, while the clutch mechanism allows for smooth engagement and disengagement of power. Additionally, the torque converter plays a pivotal role in converting engine output into usable power, enhancing the driving experience. Assembly Overview

In examining the assembly, it’s important to recognize how these components fit together. The intricate design ensures that each part operates in harmony with others, promoting efficiency and performance. Regular inspections and an understanding of this assembly can help prevent common issues, ultimately prolonging the lifespan of the vehicle’s drivetrain. Steering System Overview for LTR450

The steering mechanism plays a vital role in ensuring optimal maneuverability and control in off-road vehicles. Understanding its components and functionality is essential for maintaining performance and safety. This section explores the key elements that make up the steering system, highlighting their importance in enhancing driving precision and responsiveness. At the core of the steering assembly lies the steering column, which connects the driver’s input to the steering linkage. This system often incorporates various parts that work together to provide smooth handling, allowing the vehicle to navigate through diverse terrains effortlessly.

Regular inspection and maintenance of the steering assembly are crucial for ensuring reliable operation. Identifying wear or damage in any components can prevent more significant issues, enhancing overall vehicle safety and performance. |

|---|