In the realm of firearms, comprehending the intricate workings of a weapon is essential for both enthusiasts and professionals. This section aims to explore the various components that contribute to the functionality and reliability of a specific machine gun model. By gaining insights into its assembly, users can enhance their maintenance and operational skills.

Each element plays a crucial role in ensuring optimal performance, from the trigger assembly to the barrel. By delving into the details of these individual pieces, one can appreciate the engineering behind this robust tool. Understanding these aspects not only aids in proper handling but also fosters a deeper respect for the craftsmanship involved.

Ultimately, a thorough grasp of this machinery empowers users to make informed decisions regarding care and upgrades. This knowledge is vital for anyone looking to enhance their proficiency and safety when utilizing such a powerful instrument.

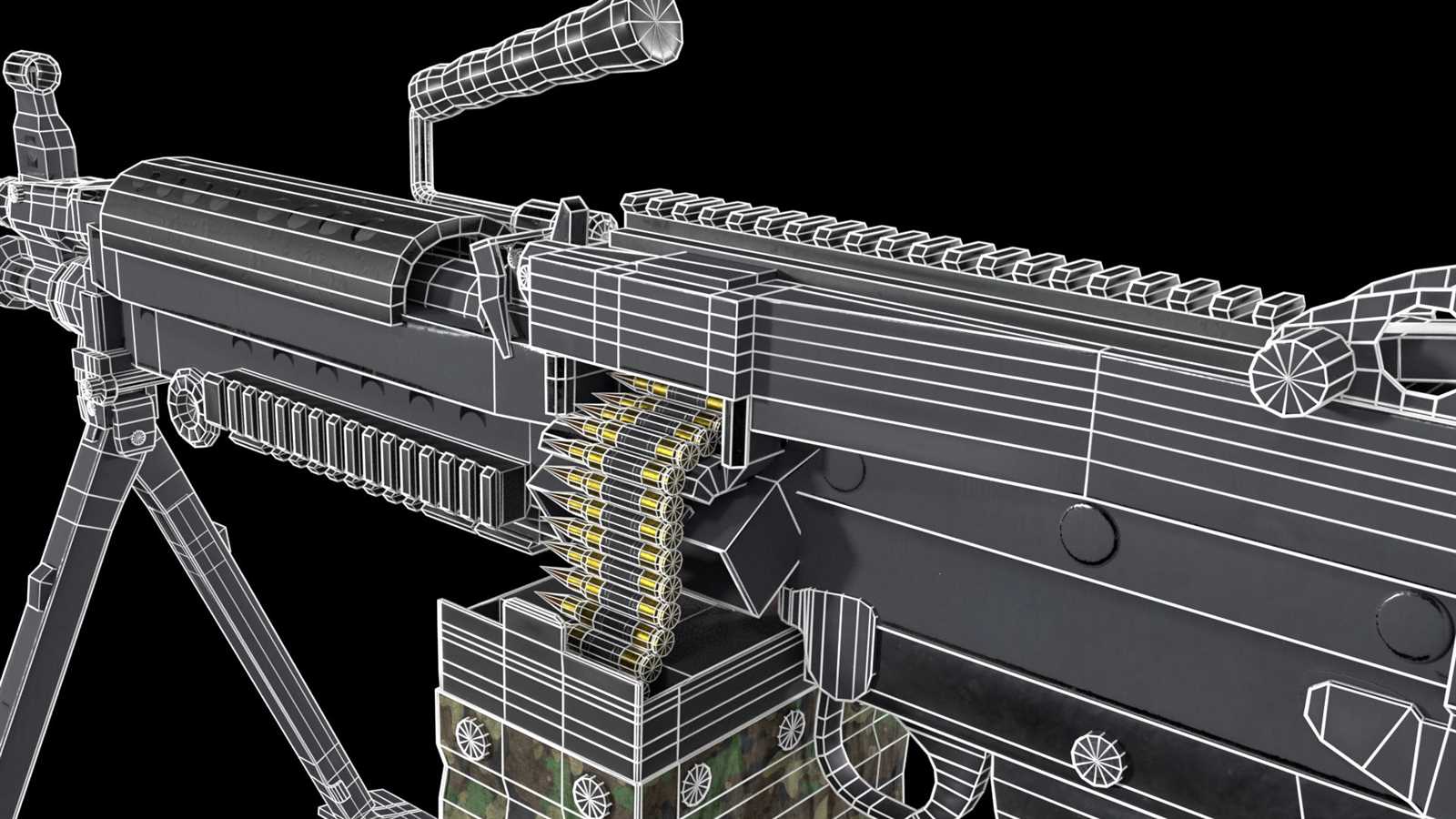

M249 SAW Overview

This section provides an insight into a widely recognized light machine gun, known for its versatility and effectiveness in various combat scenarios. Designed to support infantry units, it combines reliability with a high rate of fire, making it a critical asset on the battlefield.

Key Features

- Chambered for a standard rifle cartridge

- Utilizes a belt-fed ammunition system

- Lightweight construction for ease of mobility

- Adjustable firing modes for tactical flexibility

Operational Role

- Provides suppressive fire to protect advancing troops

- Can be deployed in various environments, from urban to open fields

- Acts as a critical component in team-based combat strategies

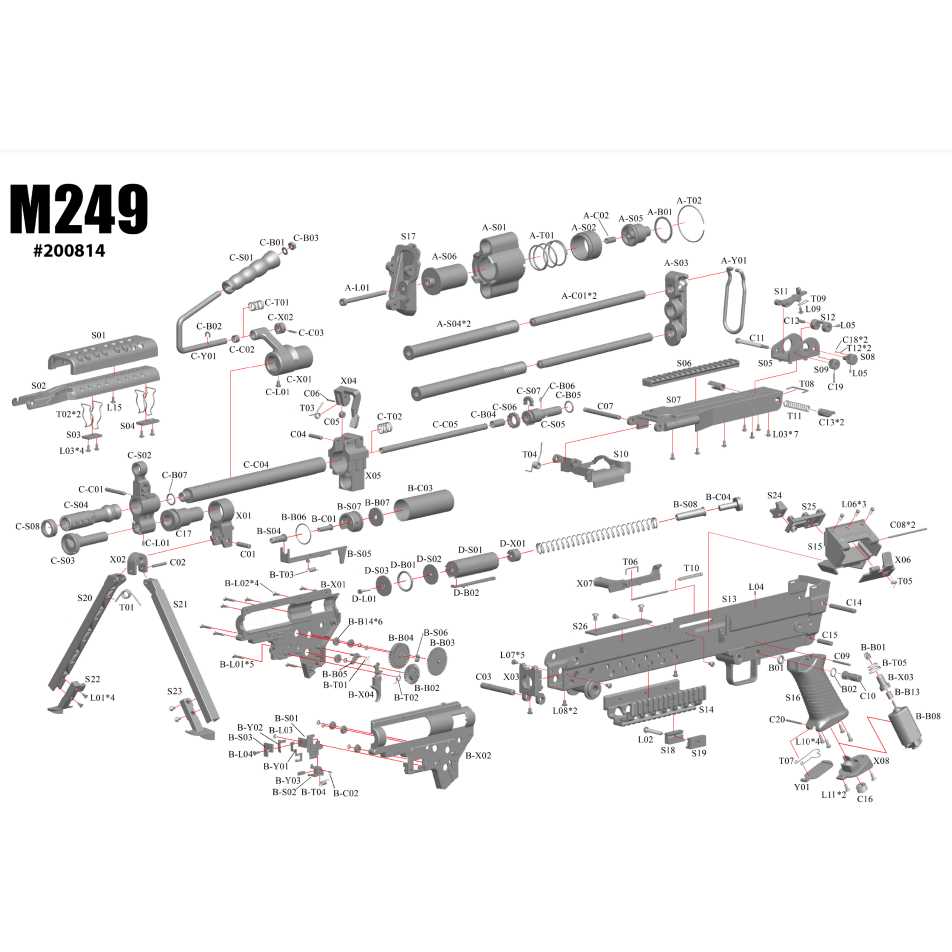

Key Components of the M249

This section explores the essential elements that contribute to the functionality and reliability of the automatic firearm. Understanding these components is crucial for anyone interested in the design and operation of this weapon system.

Main Features

- Breech mechanism

- Barrel assembly

- Feeding system

- Stock and grip

- Trigger assembly

Operational Parts

- Gas system

- Recoil spring

- Safety mechanism

- Handguard

- Chamber

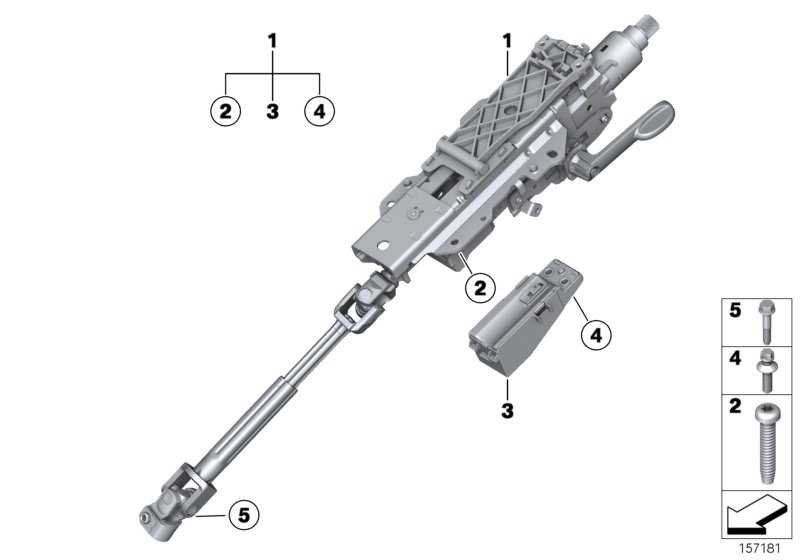

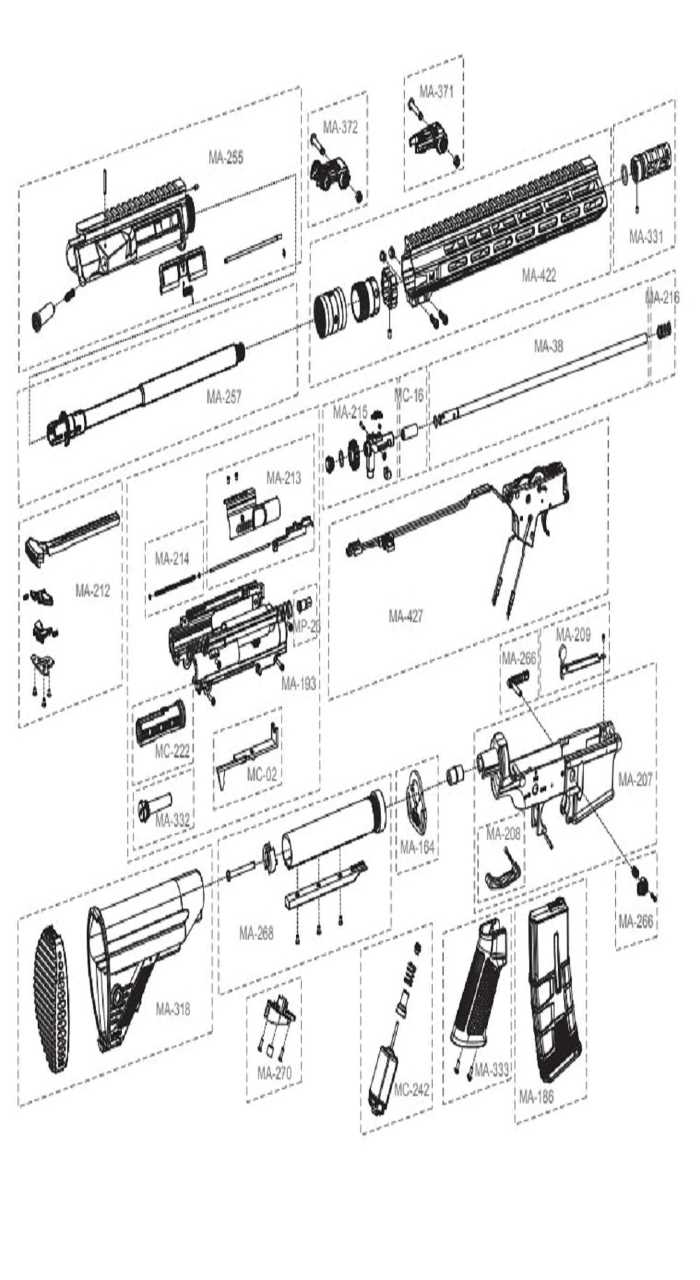

Understanding the Parts Diagram

Grasping the layout of a mechanical assembly is crucial for effective maintenance and repair. Such visual representations serve as essential guides, offering insights into the relationships and functions of individual components within a complex system. By familiarizing oneself with this schematic, one can enhance troubleshooting skills and streamline the assembly process.

Key Components and Their Functions

Each segment within the illustration plays a distinct role, contributing to the overall functionality. Recognizing these roles aids in identifying potential issues. For instance, some elements are pivotal for operation, while others may be integral to safety. Understanding these distinctions fosters a deeper appreciation for the entire structure.

Interconnections and Assembly Flow

The layout also highlights how various elements interact. This interconnection is vital for maintaining efficiency and reliability. By following the flow depicted in the schematic, users can better anticipate the effects of replacing or servicing any particular section, ensuring a comprehensive approach to upkeep.

Functionality of Each Component

This section delves into the essential roles played by various elements of a firearm system. Each part is intricately designed to contribute to the overall performance, reliability, and efficiency of the mechanism, ensuring effective operation in various scenarios.

Primary Components

- Receiver: The central housing that contains key mechanisms, facilitating the interaction between various parts.

- Barrel: Responsible for directing the projectile, its length and design impact accuracy and range.

- Stock: Provides stability and support for the user, enhancing comfort during operation.

Operational Mechanisms

- Feeding System: This component ensures a continuous supply of ammunition, crucial for sustained fire.

- Trigger Assembly: The interface through which the user initiates firing, translating user action into mechanical movement.

- Gas System: Utilizes gases generated from firing to cycle the action, promoting efficient reloading.

Maintenance Tips for M249 Parts

Proper upkeep of your firearm components is crucial for optimal performance and longevity. Regular inspection and maintenance not only enhance functionality but also ensure safety during operation. Here are some essential guidelines to keep in mind.

Regular Cleaning

Ensure that all mechanisms are free from dirt and debris. Use appropriate cleaning solutions and tools to remove residues, which can impede smooth operation. A clean unit operates more efficiently and reduces wear over time.

Lubrication and Inspection

Apply the correct lubricant to moving parts to minimize friction and prevent overheating. Additionally, perform routine checks for signs of wear or damage, replacing any worn-out components to maintain reliability.

Common Issues with M249 Components

In the realm of automatic firearms, various elements can experience malfunctions or wear over time, affecting overall performance and reliability. Understanding these potential problems is crucial for maintenance and operational efficiency.

One frequent concern is the failure of the feeding mechanism, which can lead to jams and misfires. This often stems from inadequate cleaning or improper alignment of components, resulting in inconsistent ammunition delivery.

Another common issue involves the gas system, where blockages or leaks may hinder the cycling of the action. Regular inspection and proper lubrication are essential to mitigate these risks and ensure smooth operation.

Wear and tear on the barrel can also pose significant challenges, impacting accuracy and reliability. Regular checks for erosion or obstructions are necessary to maintain optimal performance during use.

Finally, issues with the trigger assembly can lead to unpredictable firing behavior. Ensuring that all parts are functioning correctly and are free from debris is vital for safety and control.

Replacement Parts Availability

Access to essential components is crucial for maintaining the functionality and longevity of any equipment. Ensuring that users can easily find and procure these elements is vital for optimal performance and reliability.

Supply Sources play a significant role in this process. Various manufacturers and distributors offer a range of components, making it easier for operators to source what they need. Some suppliers specialize in original equipment, while others provide aftermarket alternatives that may offer comparable quality at a lower cost.

It’s also important to consider lead times and stock levels. Availability can fluctuate based on demand and supply chain dynamics, so staying informed about current market conditions is beneficial for timely procurement.

For those seeking to delve deeper into sourcing options, online marketplaces and specialized retailers can provide extensive inventories and detailed descriptions to assist in making informed choices.

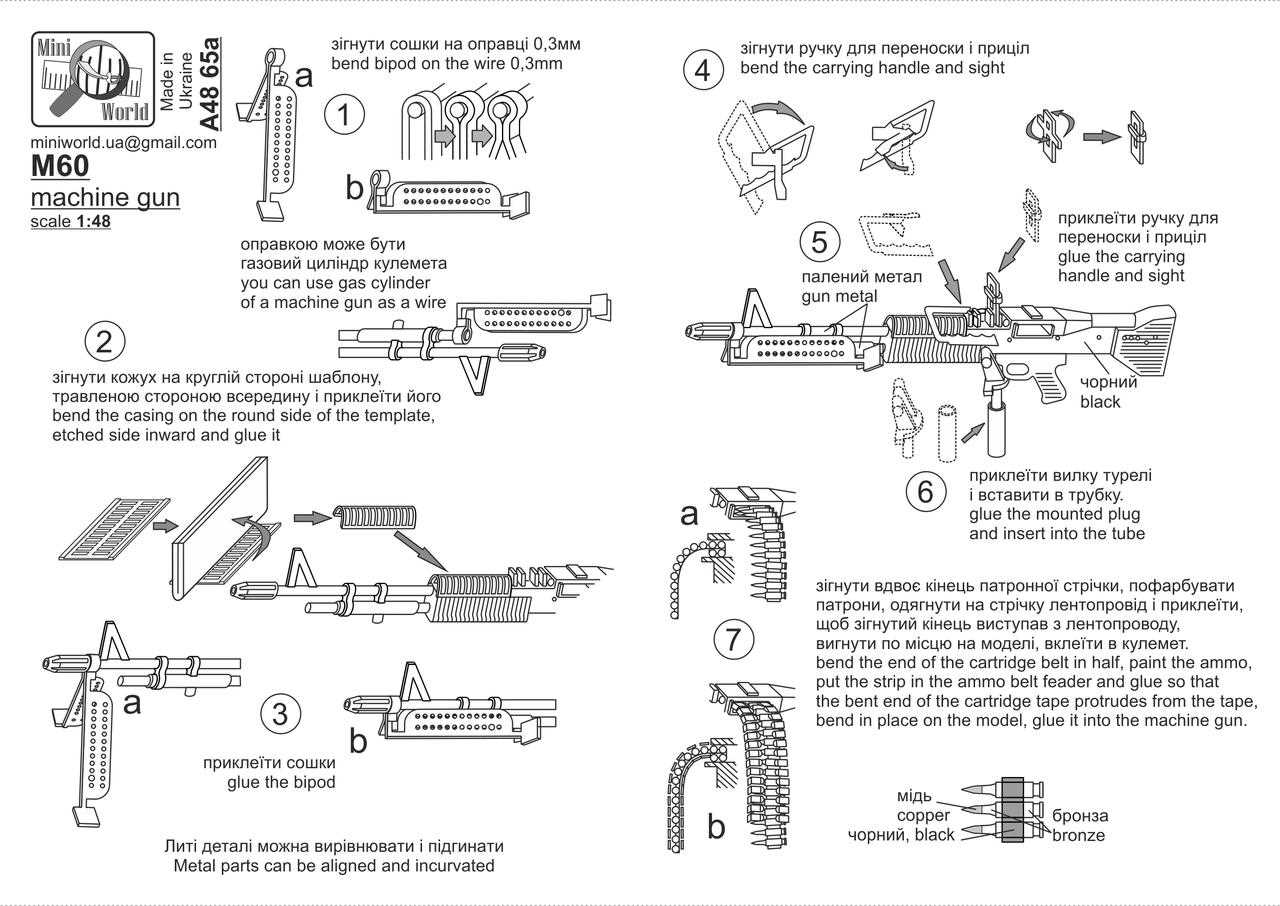

Assembly Process Explained

The assembly of a complex mechanical system involves a series of coordinated steps that ensure all components fit together correctly and function as intended. Understanding this procedure is essential for maintenance, repair, and efficient operation.

Step-by-Step Procedure

The following steps outline the typical process for assembling the system:

- Preparation of Components

- Gather all necessary elements

- Inspect for any damage or defects

- Initial Assembly

- Attach the base and main structure

- Secure all fasteners tightly

- Integration of Moving Parts

- Install the mechanical linkages

- Ensure proper alignment for optimal movement

- Final Assembly

- Connect auxiliary components

- Perform a comprehensive inspection of the assembly

Important Considerations

When carrying out the assembly, keep the following points in mind:

- Use the correct tools to avoid damage.

- Follow manufacturer guidelines closely.

- Maintain a clean workspace to prevent contamination.

By adhering to these practices, the assembly will be completed successfully, ensuring reliability and longevity of the equipment.

Safety Considerations with M249

Ensuring the well-being of users and those around them is paramount when handling any firearm. Awareness and adherence to safety protocols can significantly mitigate risks associated with improper use. Understanding the operational mechanics and potential hazards is essential for fostering a secure environment.

Proper Handling Techniques

Always approach the weapon with caution. Keep the muzzle pointed in a safe direction and your finger off the trigger until ready to fire. Regularly inspect the firearm to identify any wear or damage, ensuring that it functions correctly. Training is crucial; familiarize yourself with operational procedures to enhance safety.

Storage and Maintenance

Secure storage is vital for preventing unauthorized access. Utilize a locked cabinet or safe specifically designed for firearms. Routine maintenance, including cleaning and lubrication, not only extends the lifespan of the equipment but also prevents malfunctions that could lead to accidents. Always follow the manufacturer’s guidelines for maintenance practices. Safety first ensures a responsible approach to firearm ownership.

Upgrades and Modifications

Enhancing the functionality and performance of a firearm is a common practice among enthusiasts and professionals. These improvements can significantly impact accuracy, reliability, and overall user experience.

- Barrel upgrades for increased precision

- Stock modifications for improved ergonomics

- Enhanced sighting systems for better target acquisition

- Trigger upgrades to reduce pull weight

Each modification serves a specific purpose and can be tailored to meet individual needs, making the weapon more versatile in various scenarios.

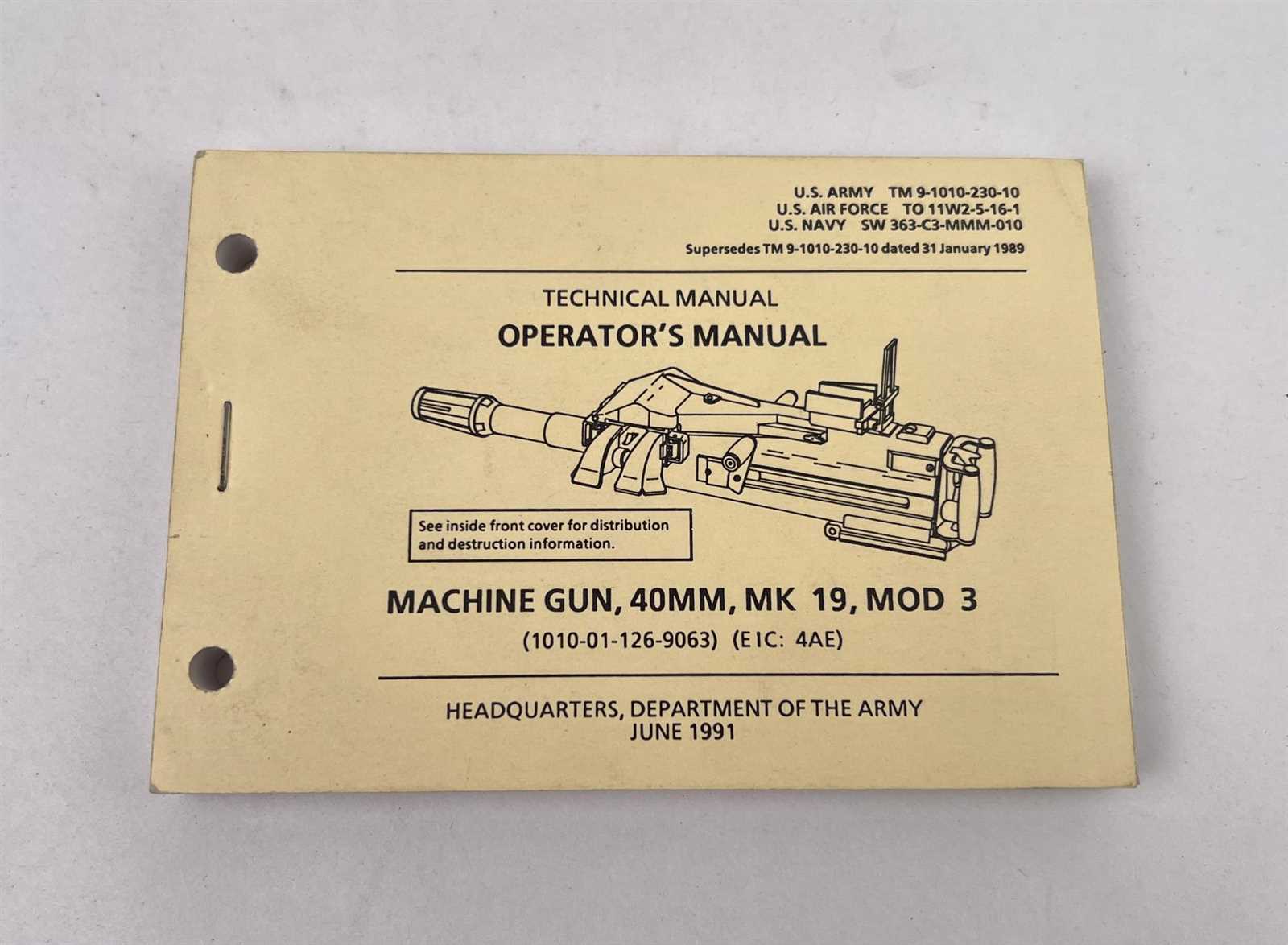

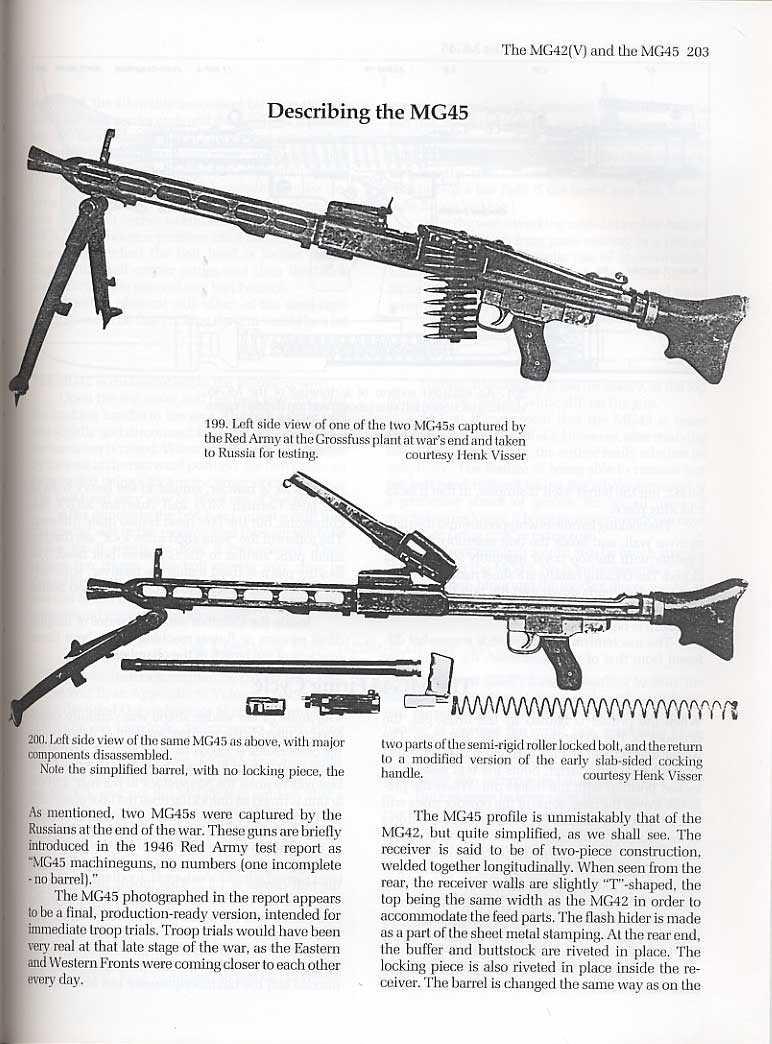

Historical Context of the M249

The development of this automatic firearm reflects the evolving needs of military forces throughout the late 20th century. Designed to provide sustained fire support, it emerged from the desire for enhanced firepower in various combat scenarios. The introduction of this weapon system marked a significant shift in infantry tactics, prioritizing versatility and reliability on the battlefield.

Its design roots can be traced back to earlier models, incorporating lessons learned from previous conflicts. As militaries sought to improve their operational effectiveness, this weapon became a critical component in various engagements, demonstrating its adaptability in diverse environments. Over the years, its role in troop deployments underscored the importance of lightweight and efficient systems in modern warfare.

Furthermore, its incorporation into military arsenals around the world showcased a broader trend toward mechanization and specialization within infantry units. As technology advanced, modifications and updates continued to enhance its performance, ensuring its relevance in changing combat landscapes. The historical significance of this firearm lies not only in its technical achievements but also in its impact on military strategy and soldier effectiveness.

Comparison with Other Machine Guns

When evaluating various automatic firearms, it is essential to consider their design, functionality, and operational efficiency. Each model offers unique characteristics that cater to specific military and tactical needs. By analyzing these distinctions, one can gain insights into the advantages and limitations of different systems, enhancing the understanding of their roles in combat scenarios.

Ergonomics and Handling

The ease of use and maneuverability are critical factors that set different automatic firearms apart. Some models feature lightweight construction and well-placed controls, allowing for swift handling in dynamic environments. In contrast, others may prioritize firepower and durability, leading to increased weight and complexity. This trade-off can significantly affect a soldier’s performance in the field, making ergonomics a vital consideration during selection.

Fire Rate and Caliber

Another aspect of comparison lies in the rate of fire and caliber options. Certain systems are designed for high rates of fire, providing overwhelming suppressive capability, while others might focus on accuracy and long-range effectiveness. The choice of caliber can also impact recoil management and ammunition versatility, further influencing operational tactics. Understanding these differences is crucial for determining the best fit for specific missions and environments.

Field Testing and Performance Analysis

This section delves into the practical assessment and evaluation of a specific firearm during operational conditions. Through rigorous testing, various performance metrics are measured to ensure reliability, accuracy, and overall effectiveness in real-world scenarios.

Testing Methodology

The assessment process involves a series of controlled and field-based trials. These trials focus on examining factors such as firing rate, recoil management, and accuracy at varying distances. Each test is meticulously documented to capture essential data that influences operational decision-making.

Results and Observations

Initial findings indicate a strong correlation between the weapon’s design features and its performance under duress. For instance, the weight distribution plays a crucial role in mitigating fatigue during prolonged use. Additionally, feedback from operators highlights the importance of maintenance routines in sustaining functionality and enhancing overall effectiveness. Continuous improvements based on these insights can lead to more reliable equipment in the field.