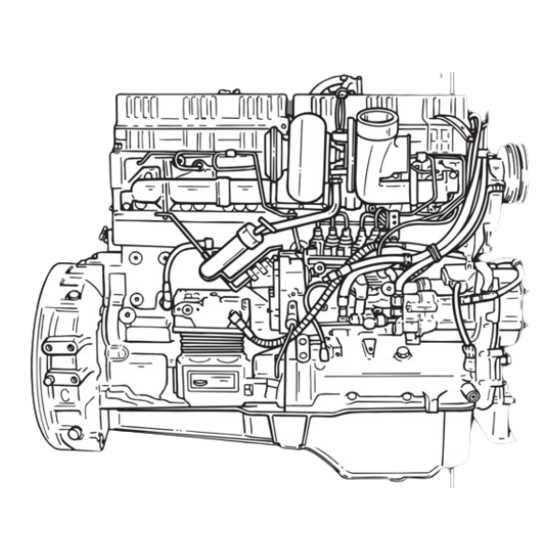

When it comes to the complex machinery that powers heavy-duty vehicles, having a clear visual representation of its inner workings can be invaluable. Such illustrations serve as essential tools for technicians and enthusiasts alike, enabling them to navigate the intricate systems that contribute to optimal performance.

These schematics not only highlight the various elements that make up the engine but also provide insights into their functions and interconnections. By examining these detailed visuals, one can better appreciate the engineering that goes into creating reliable and efficient transportation solutions.

Furthermore, these graphical representations facilitate maintenance and repair processes. With a comprehensive understanding of each component’s placement and role, professionals can diagnose issues more effectively and ensure that vehicles remain in peak condition.

Mack MP8 Parts Diagram

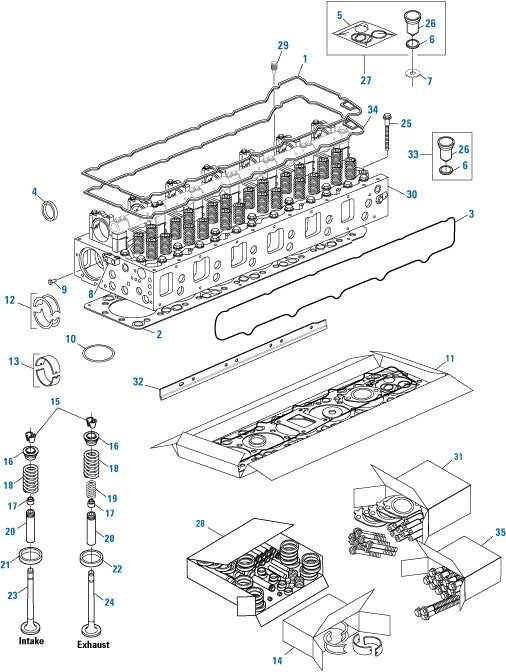

This section delves into the intricate components of a specific heavy-duty engine model, highlighting the essential elements that contribute to its functionality and performance. Understanding these elements is crucial for effective maintenance and repairs, ensuring optimal operation over time.

A comprehensive overview of the various parts and their respective functions is provided below:

| Component Name | Description |

|---|---|

| Cylinder Head | Houses the valves and fuel injectors, playing a critical role in the combustion process. |

| Piston | Moves up and down within the cylinder, converting fuel energy into mechanical work. |

| Crankshaft | Transforms the linear motion of the pistons into rotational motion, powering the drivetrain. |

| Turbocharger | Enhances engine efficiency by forcing more air into the combustion chamber. |

| Fuel Injector | Delivers the precise amount of fuel into the combustion chamber for optimal performance. |

Understanding Engine Components

Engines are complex machines that consist of various elements working in harmony to convert fuel into motion. Each component plays a crucial role in ensuring optimal performance and efficiency. A comprehensive understanding of these parts is essential for diagnosing issues and enhancing the longevity of the engine.

Key components of an engine include the block, which houses the cylinders, and the cylinder head, responsible for sealing the combustion chamber. The pistons move up and down within the cylinders, transferring force to the crankshaft, which then converts linear motion into rotational power. Additionally, the camshaft controls the timing of the valves, allowing air and fuel to enter and exhaust gases to exit the combustion chamber.

Furthermore, the fuel delivery system ensures that the engine receives the proper amount of fuel for combustion, while the cooling system prevents overheating by regulating the engine temperature. Understanding these components and their interactions is vital for maintaining engine efficiency and performance.

Key Features of the Mack MP8

This section highlights the essential characteristics of a well-regarded heavy-duty engine model. Renowned for its robust performance and efficiency, this power unit has become a preferred choice in the trucking industry. Its advanced engineering and design contribute to superior functionality and reliability, making it suitable for various demanding applications.

Performance and Efficiency

The performance and efficiency of this engine are among its standout attributes. Key aspects include:

- High power output, allowing for excellent hauling capabilities.

- Enhanced fuel efficiency, contributing to reduced operational costs.

- Low emissions, meeting stringent environmental standards.

Durability and Maintenance

Another significant aspect is the durability and ease of maintenance associated with this model. Notable features include:

- Robust construction, designed to withstand harsh conditions.

- Accessible components for simpler maintenance and servicing.

- Long-lasting performance, reducing the need for frequent repairs.

Common Replacement Parts Overview

In the realm of heavy-duty machinery, maintaining optimal performance often necessitates the replacement of specific components. Understanding which elements are most commonly replaced can significantly enhance the longevity and efficiency of the equipment. This section delves into frequently needed components, highlighting their roles and the importance of timely replacements.

Essential Components

Various parts play crucial roles in ensuring smooth operation. These components not only contribute to functionality but also affect overall performance. Regular inspections can help identify which elements require replacement, allowing for proactive maintenance and minimizing downtime.

Replacement Component Table

| Component Name | Description | Common Issues |

|---|---|---|

| Fuel Injector | Delivers fuel to the combustion chamber for efficient burning. | Clogging, poor fuel spray pattern. |

| Turbocharger | Increases engine efficiency by forcing more air into the combustion chamber. | Loss of power, excessive noise. |

| Oil Pump | Circulates oil throughout the engine to lubricate and cool moving parts. | Oil pressure issues, engine wear. |

| Air Filter | Prevents dirt and debris from entering the engine. | Restricted airflow, reduced performance. |

| Cooling Fan | Helps regulate engine temperature by directing airflow. | Overheating, fan motor failure. |

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring the long-lasting functionality and efficiency of any machinery. By implementing a systematic approach to maintenance, operators can enhance performance, minimize downtime, and extend the lifespan of their equipment. This section offers valuable strategies for maintaining peak operational efficiency.

Routine Inspections

Conducting frequent checks on critical components can help identify potential issues before they escalate. Focus on the following areas:

- Fluid levels: Regularly monitor engine oil, coolant, and fuel.

- Belts and hoses: Inspect for wear, cracks, or leaks.

- Electrical systems: Ensure all connections are secure and free from corrosion.

- Filters: Replace air, fuel, and oil filters as per manufacturer recommendations.

Scheduled Servicing

Establish a maintenance schedule that aligns with the manufacturer’s guidelines. Key activities include:

- Engine tuning: Regular adjustments improve efficiency and reduce emissions.

- Lubrication: Apply appropriate lubricants to moving parts to minimize friction.

- Cleaning: Keep the exterior and internal components free from dirt and debris.

- Software updates: Ensure that any onboard diagnostic systems are current.

Identifying Common Issues and Solutions

In any mechanical system, recognizing frequent problems and their corresponding fixes is crucial for maintaining optimal performance. Understanding these challenges not only aids in efficient troubleshooting but also prolongs the lifespan of the machinery. Various components may exhibit signs of wear or malfunction, requiring immediate attention to prevent further complications.

Typical Challenges Encountered

Common difficulties often arise from improper maintenance, leading to reduced efficiency or unexpected failures. Components may experience wear and tear due to heavy usage, causing leaks or irregular functioning. Additionally, environmental factors can contribute to the deterioration of various elements, affecting overall performance.

Effective Solutions and Preventive Measures

Addressing these issues typically involves routine inspections and timely repairs. Regular maintenance schedules can help identify potential problems before they escalate. Utilizing high-quality replacement components ensures reliability and longevity. Furthermore, implementing proper storage and handling procedures can minimize damage and extend the operational life of the system.

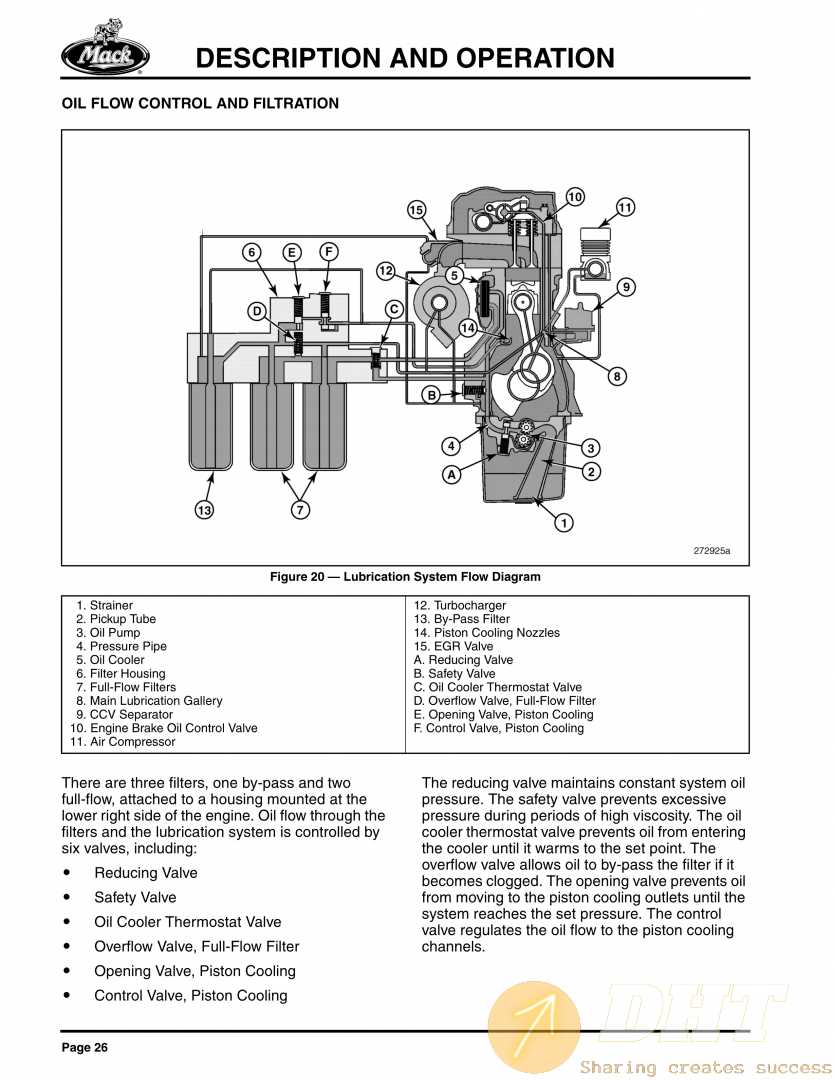

Using the Parts Diagram Effectively

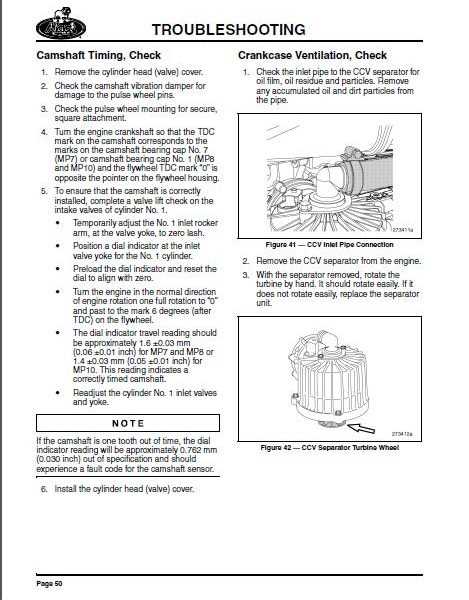

Understanding a visual representation of components is essential for efficient maintenance and repair. This graphical tool allows users to identify various elements quickly, ensuring that necessary replacements or adjustments can be made promptly. By utilizing this resource, technicians can streamline their workflow and enhance their productivity.

To make the most of this visual guide, it is crucial to familiarize yourself with the layout and coding used. Each section typically corresponds to specific components, providing clarity on their relationships and functions. Paying close attention to these details will aid in diagnosing issues accurately and prevent potential oversights during repairs.

Additionally, referencing this illustration while working on machinery can significantly improve accuracy. Having a clear image of the necessary components nearby allows for quick cross-checking against the actual equipment. By doing so, you can ensure that every part is in its proper place, reducing the likelihood of errors. Overall, leveraging this visual aid effectively contributes to successful maintenance practices.

Where to Find Genuine Parts

When seeking authentic components for heavy-duty vehicles, it’s crucial to know the right places to look. Genuine parts ensure reliability and compatibility, which is essential for the optimal performance of your equipment. Here are some effective ways to source original items:

Authorized Dealerships

Visiting authorized dealerships is one of the most reliable methods to obtain genuine components. These locations provide:

- Access to a comprehensive inventory of authentic items.

- Expert advice from trained professionals who understand the specifics of your vehicle.

- Manufacturer warranties that guarantee quality and performance.

Online Retailers

Many reputable online platforms offer a wide selection of genuine components. When using these resources, consider the following:

- Look for vendors with positive reviews and a solid reputation.

- Verify the authenticity of items through product descriptions and certifications.

- Check for return policies in case the component does not meet your expectations.

Comparing MP8 to Other Models

The evaluation of one engine series against others in the same category reveals significant distinctions in design, performance, and efficiency. These differences can influence decisions for various applications, depending on user needs and preferences.

When analyzing engine configurations, it’s crucial to note variations in fuel efficiency, power output, and emissions standards. Some models might prioritize higher torque at lower RPMs, making them ideal for heavy-duty tasks, while others excel in maintaining efficiency over longer distances.

In addition, the technological advancements integrated into newer variants often enhance functionality. These innovations can include improved turbocharging systems, refined fuel injection technologies, and advanced engine management systems, which collectively contribute to better overall performance.

Lastly, it is essential to consider maintenance requirements and the availability of support for each engine type. Some engines might have a more extensive network of service options, making them more accessible for repairs and replacements, ultimately influencing the long-term ownership experience.

Aftermarket Components: Pros and Cons

When considering alternatives for vehicle components, many individuals weigh the benefits and drawbacks of choosing secondary market options. These components often provide a cost-effective solution, yet their quality and compatibility can vary significantly. Understanding the advantages and disadvantages can assist in making an informed decision regarding the best choices for maintenance and repair needs.

| Advantages | Disadvantages |

|---|---|

| Typically lower cost compared to original equipment. | Quality may not always match that of original parts. |

| Wider selection available, allowing for customization. | Compatibility issues can arise with some vehicles. |

| Often readily available from multiple suppliers. | Potential for limited warranty or support compared to OEM. |

| Can enhance performance with specialized options. | May not meet manufacturer specifications, affecting safety. |

Assembly and Disassembly Guidelines

Proper techniques for the assembly and disassembly of complex mechanical systems are crucial for maintaining functionality and ensuring safety. Following systematic procedures can help prevent damage and enhance efficiency during these processes.

Before starting, it is essential to gather all necessary tools and components. Here are some key steps to consider:

- Preparation: Ensure the workspace is clean and organized. Lay out all tools and parts for easy access.

- Documentation: Refer to relevant manuals or schematics for guidance on the correct assembly sequence and specifications.

- Inspection: Examine all components for wear and damage before reassembly. Replace any faulty parts as needed.

During assembly, follow these practices:

- Sequential Assembly: Follow the specified order to assemble components, ensuring that each part fits correctly before moving on to the next.

- Torque Specifications: Use a torque wrench to tighten fasteners to the manufacturer’s recommended settings to avoid over-tightening or loosening.

- Alignment: Verify that all parts are aligned properly to prevent issues during operation.

When disassembling, adhere to these guidelines:

- Reverse Order: Take apart components in the reverse order of assembly to ensure nothing is missed.

- Labeling: Mark parts as they are removed to simplify the reassembly process.

- Handle with Care: Be cautious with sensitive components to prevent damage during removal.

By following these assembly and disassembly guidelines, you can maintain the integrity of the mechanical system and ensure its long-term performance.

Significance of Regular Inspections

Regular examinations of heavy machinery play a crucial role in ensuring optimal performance and longevity. Consistent checks not only help in identifying potential issues before they escalate but also contribute to the overall safety of operations. This proactive approach can lead to significant cost savings and reduce downtime.

Enhanced Safety

Conducting frequent assessments is essential for maintaining a safe working environment. By identifying wear and tear, operators can prevent accidents that may arise from equipment failure. This diligence safeguards both personnel and assets, fostering a culture of responsibility and care.

Cost Efficiency

Investing time in regular evaluations can yield substantial financial benefits. Early detection of problems can mitigate expensive repairs and prolong the lifespan of the machinery. This practice ultimately translates to reduced operational costs and maximized productivity.

| Inspection Type | Frequency | Benefits |

|---|---|---|

| Visual Inspection | Daily | Identifies visible issues early |

| Functional Testing | Weekly | Ensures equipment operates correctly |

| Comprehensive Assessment | Monthly | In-depth analysis for potential problems |

Upgrading Components for Enhanced Efficiency

Improving the various elements of a heavy-duty vehicle can significantly boost its overall performance and fuel efficiency. By focusing on enhancements that reduce wear and tear, optimize power delivery, and increase operational reliability, owners can experience notable gains in productivity and cost-effectiveness.

One of the most impactful upgrades involves enhancing the engine’s airflow system. Implementing high-performance air filters and exhaust systems allows for better air intake and exhaust flow, resulting in increased power and efficiency. Moreover, using advanced fuel injectors can improve combustion efficiency, leading to better fuel consumption rates.

In addition, upgrading the cooling system is essential for maintaining optimal operating temperatures, which helps in preventing overheating and prolonging engine life. Utilizing high-capacity radiators and efficient coolant solutions can enhance heat dissipation and overall system reliability.

Finally, incorporating lightweight materials for various components can reduce the overall weight of the vehicle, leading to improved handling and increased fuel efficiency. Each of these upgrades contributes to a more powerful, efficient, and reliable vehicle, ensuring that it meets the demands of modern transportation.