In the realm of construction and flooring, efficient leveling equipment plays a pivotal role in achieving flawless surfaces. The interplay of various components ensures that the leveling process is not only precise but also streamlined. By grasping the essential elements that contribute to the functionality of this equipment, users can enhance their skills and optimize their workflow.

Every tool comprises specific elements that work in harmony to facilitate its intended purpose. Recognizing how these individual sections interact and contribute to overall performance is crucial for anyone engaged in flooring tasks. This knowledge empowers professionals to make informed decisions and maintain their tools effectively.

In this section, we will delve into the intricate structure of a leveling device, highlighting its significant features. By breaking down the essential components, we aim to provide clarity and understanding, enabling users to utilize their equipment to its fullest potential. Whether you’re a seasoned expert or a newcomer to the field, familiarity with these key aspects will prove invaluable.

Understanding Magic Screed Functionality

The equipment designed for leveling surfaces plays a crucial role in construction and renovation projects. Its innovative approach allows for enhanced efficiency and precision, ensuring that the final results meet the highest standards of quality. This section will explore the key elements that contribute to the effectiveness of this leveling tool.

Core Principles of Operation

This tool operates by utilizing a unique mechanism that streamlines the process of achieving a flat and even surface. By harnessing the power of vibration, it effectively distributes material, minimizing the risk of imperfections. Understanding these principles is essential for maximizing its potential in various applications.

Benefits of Using the Equipment

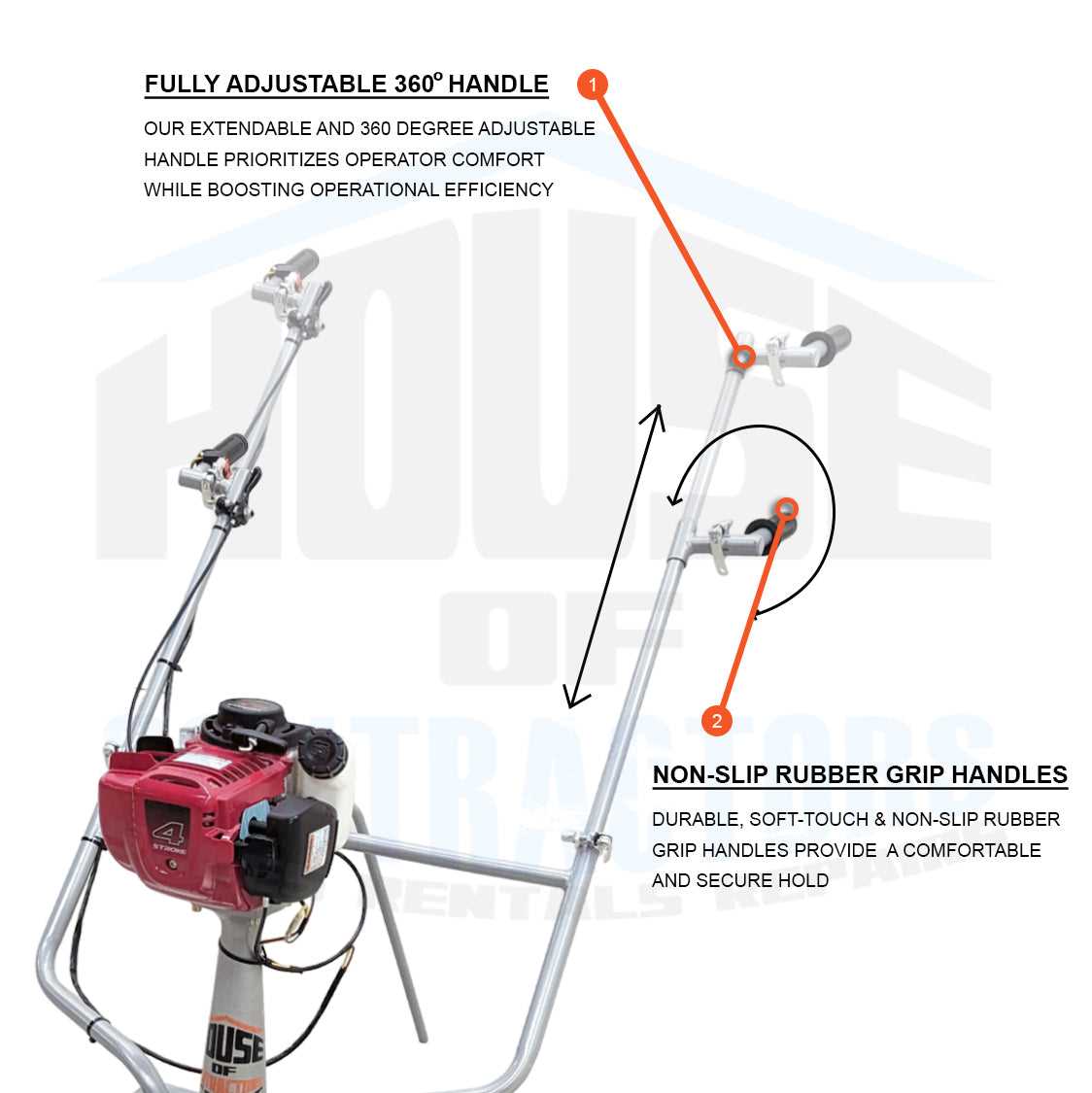

Employing this advanced leveling device offers numerous advantages. Its ability to save time while enhancing accuracy leads to improved workflow and reduced labor costs. Moreover, the ergonomic design ensures ease of use, allowing operators to maintain control and efficiency throughout the leveling process.

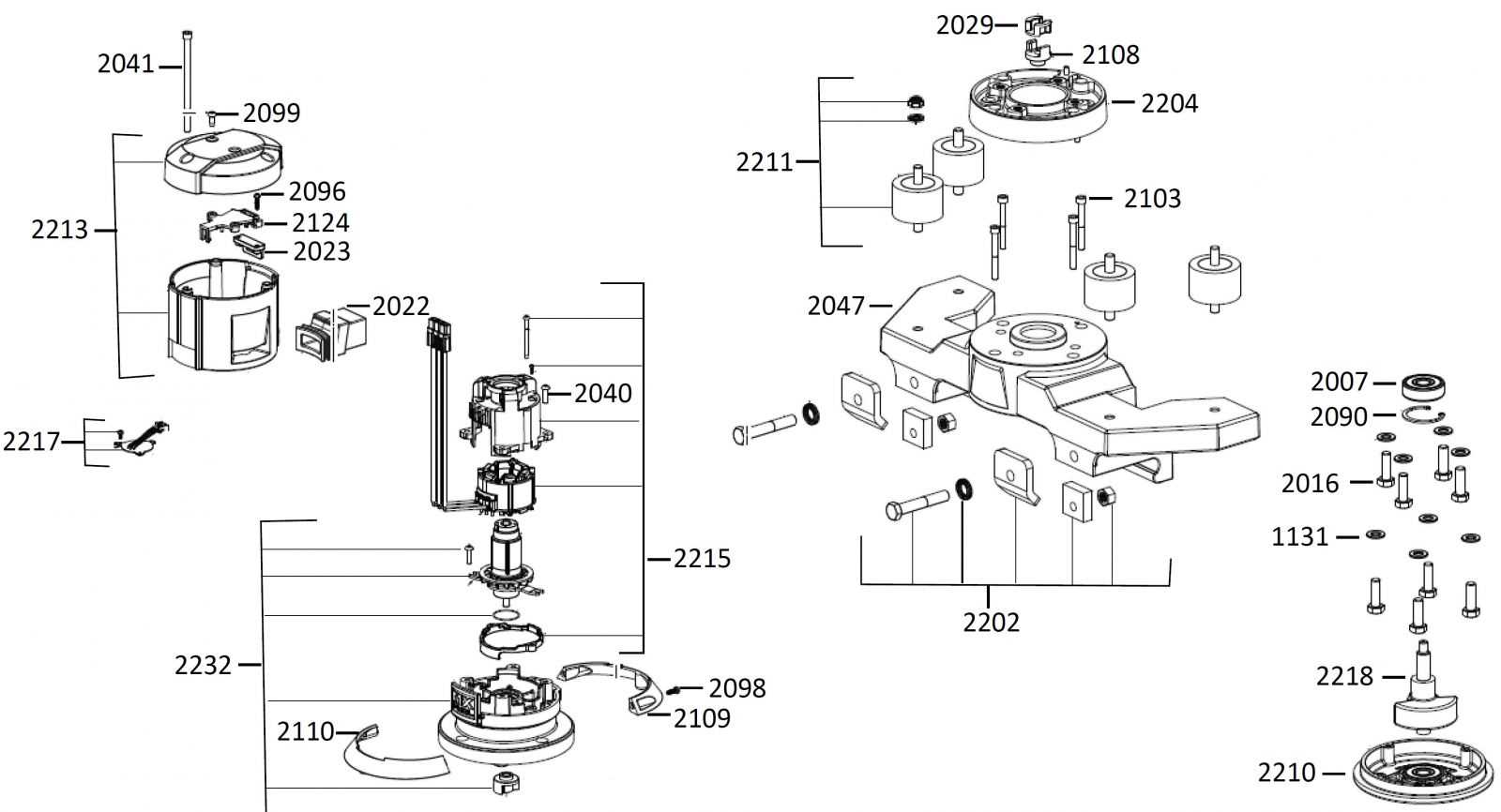

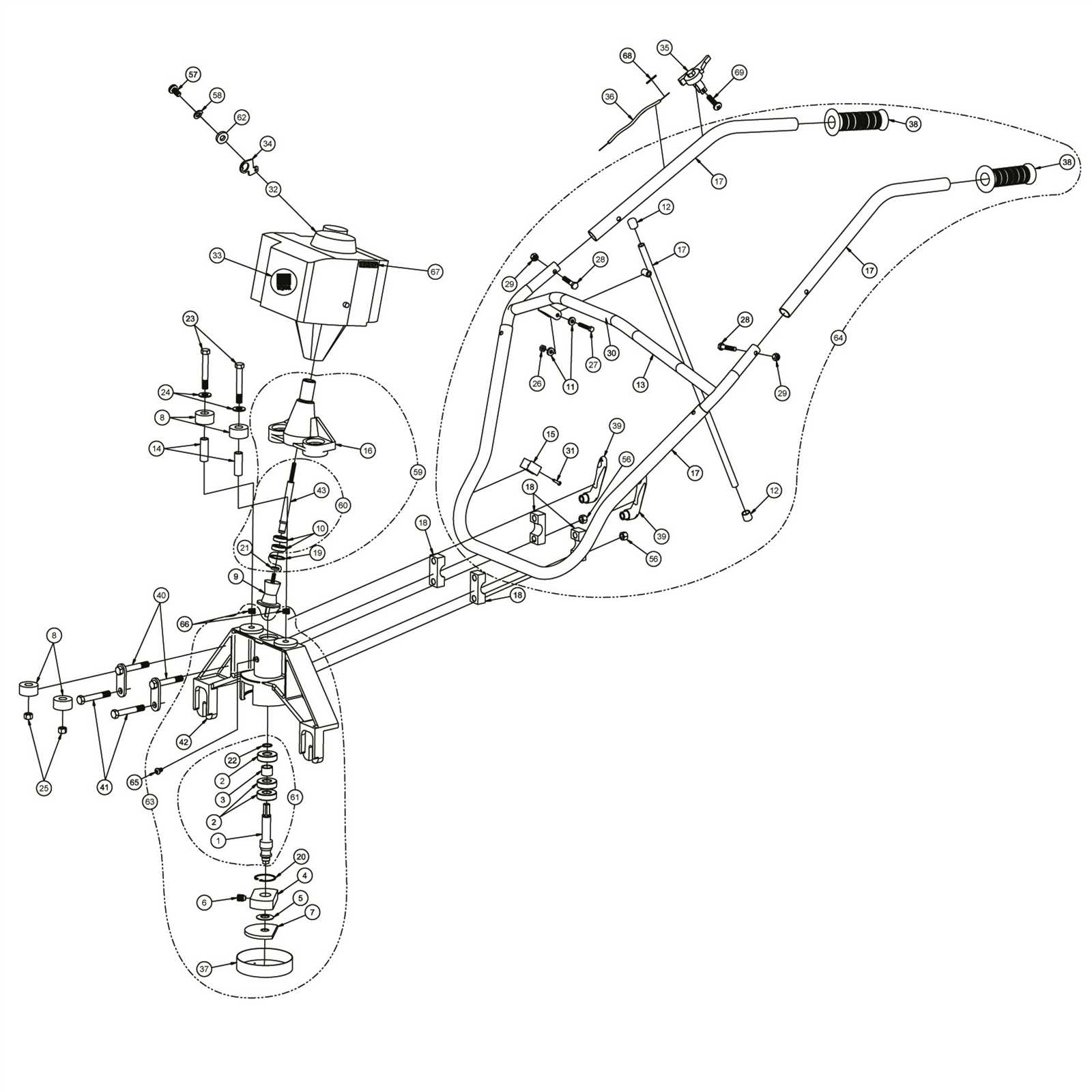

Essential Components of a Magic Screed

Understanding the fundamental elements of this tool is crucial for achieving optimal results in flooring projects. Each component plays a vital role in ensuring efficiency and precision during operation.

- Engine: The power source that drives the equipment, typically a gasoline or electric motor.

- Blade: A key element that levels the surface, usually made from durable materials for longevity.

- Handle: Provides control and maneuverability, allowing the operator to guide the device smoothly.

- Frame: The structural support that houses other components, designed for stability and strength.

- Vibration System: Enhances the leveling process by reducing air pockets and ensuring even distribution of the material.

By delving into each of these elements, users can better appreciate how they contribute to the ultimate effectiveness of the tool.

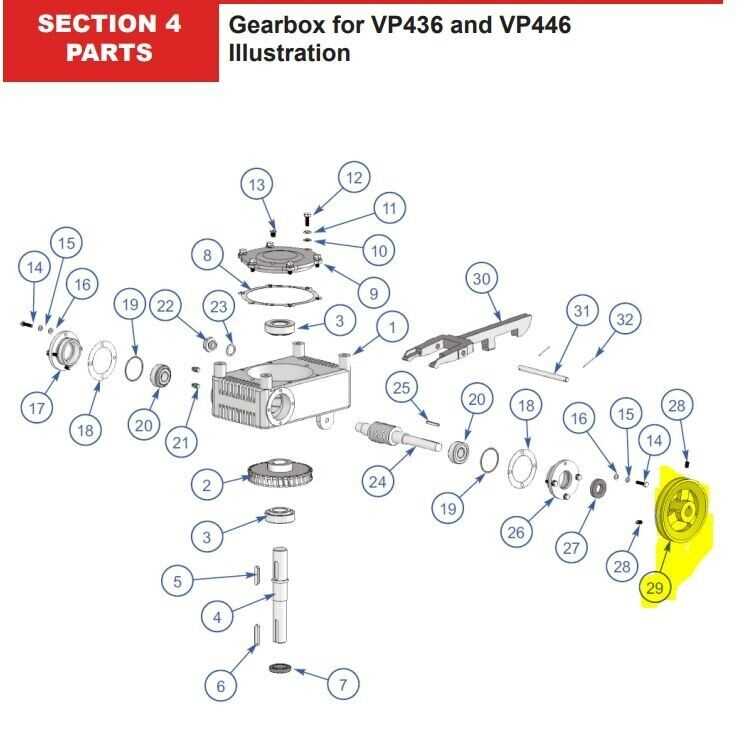

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective assembly and maintenance. Familiarizing yourself with these illustrations can significantly enhance your ability to identify, locate, and utilize each element efficiently.

Key Elements of the Illustration

- Labels: Each item typically has a corresponding label that indicates its name or part number.

- Connections: Arrows or lines may show how various elements interact or are linked.

- Scale: Ensure you are aware of the scale used, as it affects the actual size of the components.

- Legend: A legend may provide additional context, explaining symbols or colors used in the image.

Steps to Interpret the Illustration

- Start by reviewing the entire illustration to get an overview of all elements.

- Identify the labels to match each component with its respective designation.

- Follow the connections to understand how parts fit together.

- Refer to the legend for clarification on any unfamiliar symbols or annotations.

- Take notes on any critical components that require special attention during assembly or maintenance.

Importance of Proper Calibration

Achieving optimal performance in any specialized equipment is essential for ensuring efficiency and quality in outcomes. Calibration plays a pivotal role in aligning the functionality of these tools with the desired standards, leading to improved precision and consistency in results.

Accurate calibration not only enhances the reliability of measurements but also minimizes the risk of errors during operation. When instruments are calibrated correctly, the likelihood of discrepancies is significantly reduced, enabling operators to achieve uniform results across various projects.

The process of calibration also contributes to the longevity of the equipment. Regular adjustments and checks can prevent wear and tear, ensuring that devices function effectively for an extended period. This proactive maintenance approach can lead to substantial cost savings over time.

Furthermore, adherence to proper calibration protocols fosters safety within the working environment. By ensuring that tools operate within their designated parameters, operators can avoid potential hazards that may arise from malfunctioning equipment. Therefore, investing time and resources into meticulous calibration processes is not just beneficial, but necessary for maintaining high standards of operation.

Common Issues with Magic Screeds

In the realm of floor preparation tools, various challenges can arise that affect performance and efficiency. Understanding these frequent complications is essential for optimal usage and maintenance, ensuring that surfaces are leveled and finished properly.

Inconsistent Surface Finish

One prevalent issue is achieving an uneven surface. This can result from improper handling or lack of experience with the tool, leading to inconsistencies in the final layer. Regular calibration and technique improvement can help mitigate this problem.

Mechanical Failures

Another concern involves mechanical breakdowns. Overuse or neglect can cause components to wear out, affecting functionality. Regular inspections and timely replacements of worn parts are crucial to maintaining peak performance.

Choosing the Right Magic Screed

Selecting the ideal leveling tool can greatly influence the efficiency and quality of your flooring projects. Various models come with distinct features designed to meet specific needs, making it essential to understand your requirements before making a choice.

Consider the size of the area you will be working on. Larger spaces may benefit from wider tools that cover more ground quickly, while smaller areas might require more compact options for precision. Additionally, weight and maneuverability play crucial roles; a lighter tool can ease fatigue and improve control during operation.

Evaluate power sources as well. Battery-operated units offer portability, while electric models provide consistent power. Assess your working environment to determine which option is most practical.

Finally, durability and maintenance should not be overlooked. Investing in a robust tool can save time and money in the long run, ensuring reliable performance across multiple projects.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires regular care and attention. Implementing effective maintenance practices not only enhances performance but also prolongs the lifespan of the machinery. By following a few essential guidelines, you can keep your tools in optimal condition and ready for use whenever needed.

Regular Inspections

Conduct routine checks to identify any signs of wear or damage. Look for loose components, unusual noises, or any other irregularities. Early detection can prevent more significant issues and costly repairs down the line.

Proper Cleaning

Keeping your equipment clean is crucial. Remove debris, dust, and residues after each use to prevent buildup that could hinder functionality. Use appropriate cleaning agents to maintain surfaces without causing harm.

Safety Precautions During Use

Ensuring a safe working environment is crucial when operating equipment designed for leveling surfaces. Adhering to specific guidelines can prevent accidents and enhance overall efficiency.

Essential Guidelines

- Always wear appropriate personal protective equipment, including gloves, goggles, and hearing protection.

- Check all equipment for damage or wear before each use.

- Ensure a clear workspace free of obstacles and debris.

Operational Safety Tips

- Maintain a stable footing and balance while operating the machinery.

- Keep hands and body parts away from moving components.

- Follow the manufacturer’s instructions for operation and maintenance.

Comparing Different Models Available

When exploring various tools designed for efficient flooring applications, it’s essential to evaluate their unique features, performance, and suitability for different tasks. Each model offers distinct advantages that cater to specific project requirements, making informed comparisons vital for users aiming to achieve optimal results.

Performance and Efficiency

One of the primary aspects to consider is the performance efficiency of each variant. Some models are engineered for high-speed operation, allowing for quicker completion of tasks, while others focus on precision, providing a smoother finish. The choice between speed and accuracy largely depends on the nature of the project and the materials being utilized.

Durability and Maintenance

Durability is another critical factor. Certain designs are built with robust materials that withstand rigorous use, reducing the frequency of replacements. Additionally, maintenance requirements can vary significantly. Some tools demand regular upkeep to maintain optimal functionality, while others are designed to be more user-friendly and require less intervention, making them appealing for both professionals and DIY enthusiasts.

FAQs About Magic Screed Operations

This section addresses common inquiries regarding the operation of specialized leveling equipment used in construction. Understanding how to effectively use and maintain this tool can significantly enhance productivity and ensure optimal results during floor preparation tasks.

What is the optimal way to operate the device?

To achieve the best results, maintain a steady pace while guiding the tool over the material. Ensure even distribution by adjusting the height settings according to the thickness of the layer being leveled.

How often should maintenance be performed?

Regular maintenance is crucial for efficient performance. Inspect the equipment after each use for any wear or damage and conduct a thorough check every few weeks to keep it in top condition.

Can this tool be used in all weather conditions?

While it can be used in various environments, extreme temperatures or heavy rain can affect the curing process of the material. It’s best to operate in dry and moderate weather for optimal results.

What safety precautions should be taken?

Always wear appropriate protective gear, including gloves and goggles. Ensure that the work area is clear of obstacles and that electrical components are properly secured to prevent accidents.

Is training required to use this equipment?

While basic operation can be learned quickly, formal training is recommended to understand advanced techniques and safety protocols, which can enhance both efficiency and safety on the job.